Outward-turning type coaxial cylinder viscometer of hollow cylinder type optical fiber Bragg grating

A hollow cylinder and hollow cylinder technology, applied in the directions of cladding fiber, optical waveguide light guide, flow characteristics, etc., can solve the problems of incomplete elimination of wavelength shift, difficult to eliminate measurement errors, and easy damage, so as to eliminate wavelength drift. , Eliminate measurement errors and achieve accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

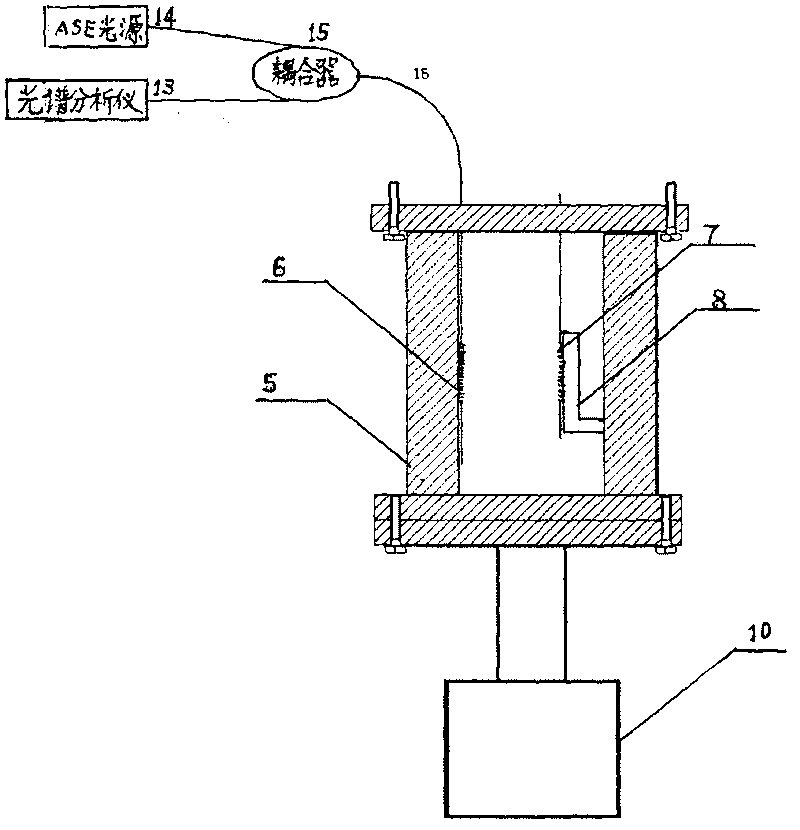

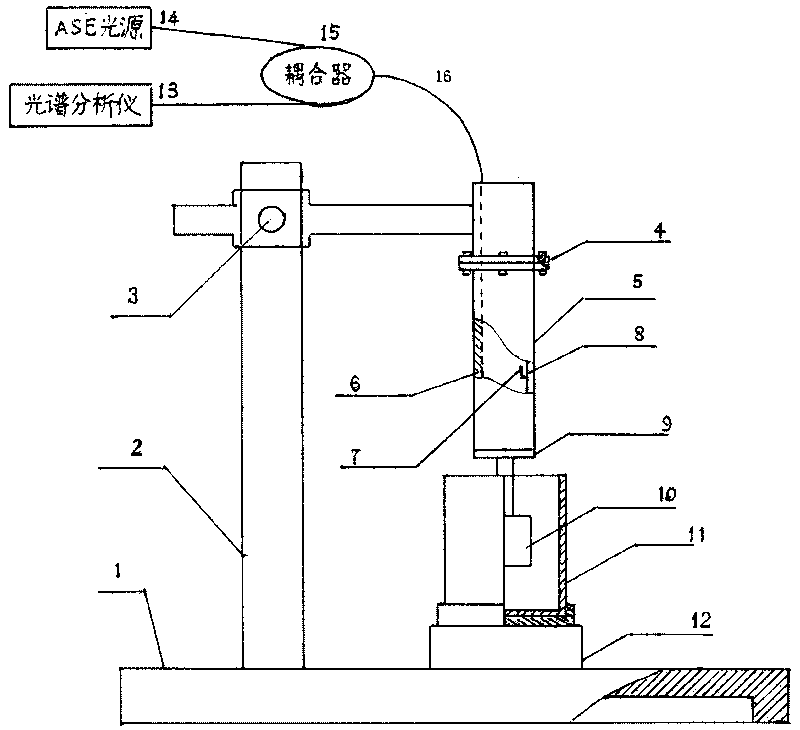

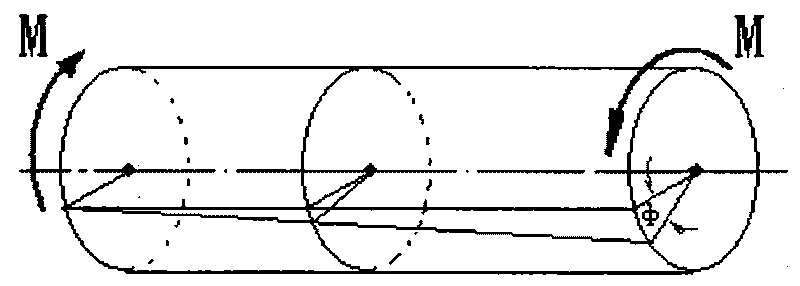

[0031] Take the elastic hollow cylinder made of hard aluminum alloy as an example, according to the attached figure 2 Configure the experiment, in this embodiment, the stator is completely immersed in the liquid to be tested, and the liquid is stirred by the motor. The design parameters are:

[0032] 1. The size parameters of the elastic hollow cylinder are: outer wall diameter D = 8.6mm, inner wall diameter d = 7.8mm;

[0033] 2. Elastic hollow cylinder, the material parameters are: hard aluminum alloy, the shear modulus is G=26GPa;

[0034] 3. The stator, the size parameters are: h=100mm, the outer radius of the stator is r 1 = 10mm;

[0035] 4. For the outer cylinder, the angular velocity Ω=4πr / s is obtained according to the motor, that is, two revolutions per minute, and the inner radius of the outer cylinder is r 2 = 30mm;

[0036] 5. The technical parameters of fiber Bragg grating are: central wavelength B=1542.5nm, fiber Bragg grating relative wavelength shift stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com