A combined waste heat recovery device and waste heat recovery method for high-temperature solid materials

A waste heat recovery device and waste heat recovery technology, which are applied in the field of waste heat recovery devices for direct heat recovery, can solve the problems that waste heat recovery devices cannot meet the direct recovery of high-temperature solid physical heat, and achieve the effect of smooth flow and high-efficiency waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, and the present invention is not limited to the following examples.

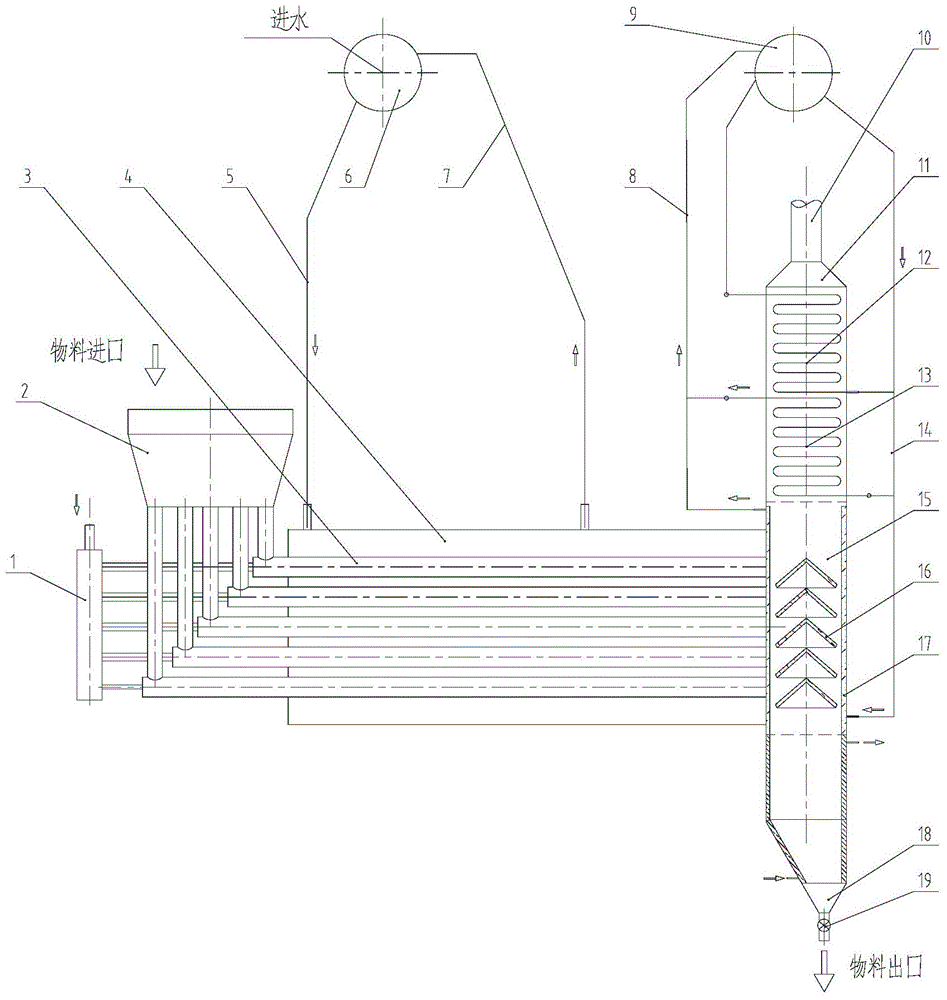

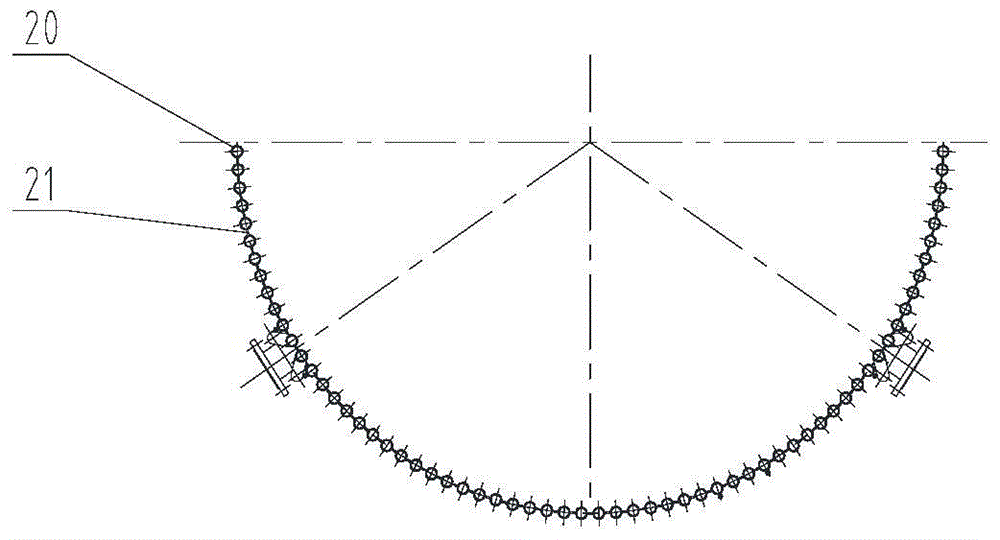

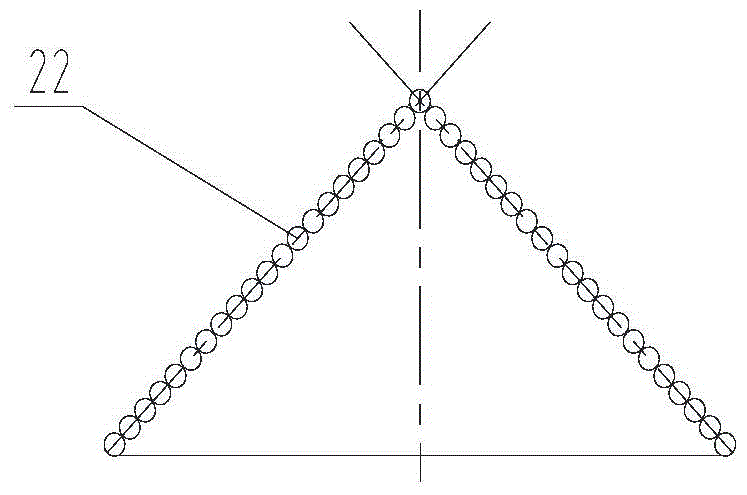

[0046] figure 1 It is a flow chart of the combined high-temperature solid material waste heat recovery device according to the present invention; figure 2 yes figure 1 Schematic diagram of the structure of the evaporative-cooled film wall and water-cooled film wall of the device in ; image 3 yes figure 1 Schematic diagram of the structure of the evaporative cooling deflector in the device.

[0047] The combined waste heat recovery device for high-temperature solid materials (granular or powder) of the present invention fully recovers the heat in the high-temperature solid materials as much as possible to generate steam and utilizes it. It includes two units: the first unit is a horizontal Pneumatic conveying solid-gas-liquid waste heat recovery unit; the second unit is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com