An energy-saving and low-dust emission coal-fired thermal power generation system

A coal-fired, low-dust technology, applied in combustion methods, indirect carbon dioxide emission reduction, fixed tubular duct assemblies, etc., can solve the problem of water and electricity consumption, increase flue gas emissions, reduce waste heat recovery economy and safety, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

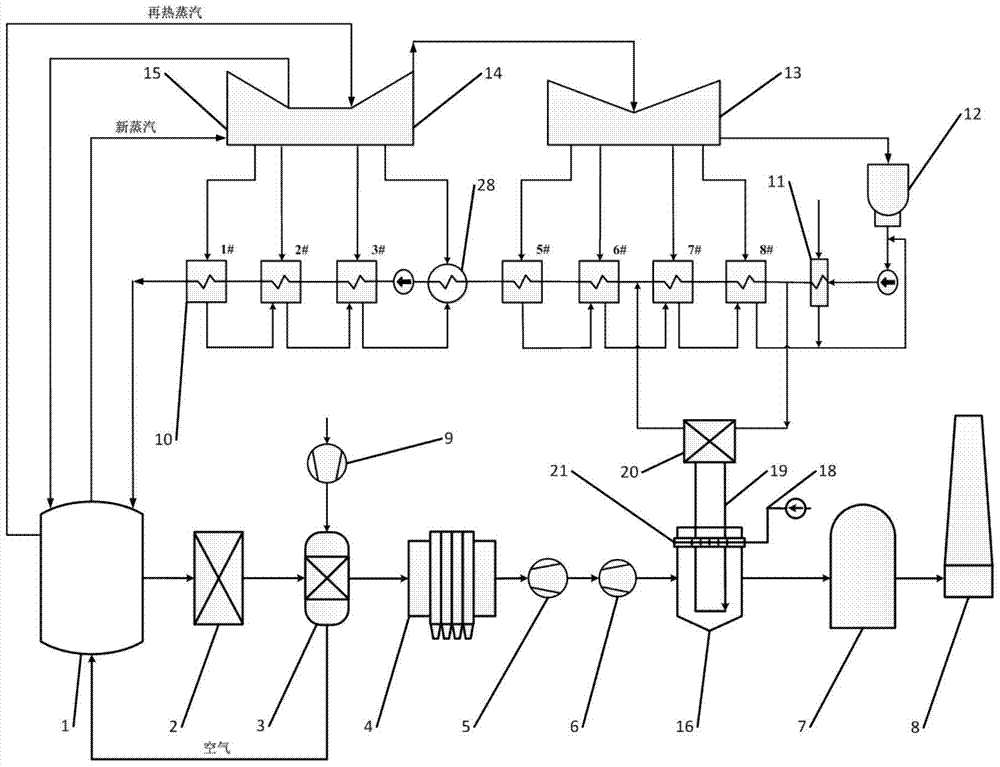

[0077] Such as figure 2 As shown, an energy-saving and low-dust emission coal-fired thermal power generation system includes a boiler 1, an SCR denitrification tower 2, an air preheater 3, an electrostatic precipitator 4, an induced draft fan 5, a booster fan 6, a desulfurization tower 7, and a chimney 8 , a waste heat recovery system is arranged upstream of the desulfurization tower 7 . The waste heat recovery system includes a steam turbine module, a non-metal tube heat exchanger 16 , a waste heat system flushing water pump 17 , a waste heat system circulating water pipeline 18 , a non-contact cooler 19 and a waste heat system flushing water nozzle 20 . The steam turbine module includes a deaerator 28, a shaft seal heater 11, a condenser 12, a steam turbine low-pressure cylinder 13, a steam turbine medium-pressure cylinder 14, a steam turbine high-pressure cylinder 15 and heaters at all levels (1#, 2#, etc. in the figure) ). The non-metallic tubular heat exchanger 16 is a...

Embodiment 2

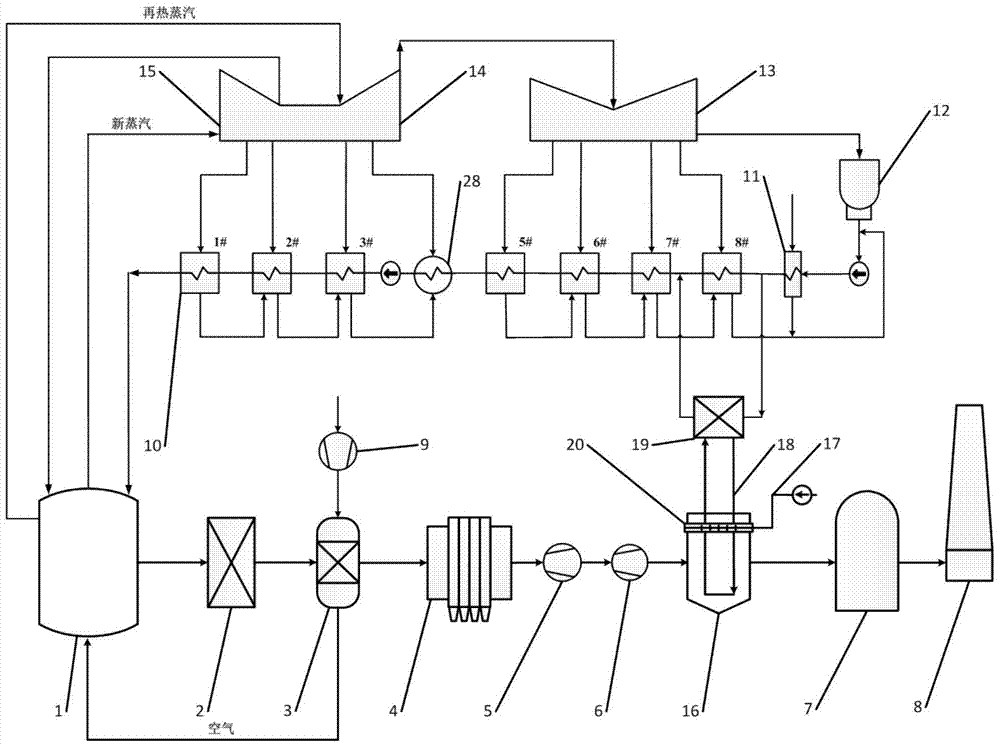

[0089] Such as image 3 As shown, the waste heat recovery system of this embodiment is the same as that of Embodiment 1 in the arrangement of the non-metal tube heat exchanger 16 and the non-contact cooler 19, except that the condensed water is drawn from the 8# low-pressure heater of the steam turbine, and after being heated Send into 7# low-pressure heater, save the steam in 8# heater.

Embodiment 3

[0091] Such as Figure 4 As shown, the waste heat recovery system of this embodiment is the same as that of Embodiment 1 and Embodiment 2 in the arrangement of the non-metallic tubular heat exchanger 16 and the non-contact cooler 19, except that the feed water is drawn from the 7# low-pressure heater of the steam turbine, After being heated, it is sent to the 6# low-pressure heater, which saves the steam in the 7# heater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com