Metallurgical slag granulation-catalyst preparation and modification integrated device system and method

A metallurgical slag and catalyst technology, applied in the field of metallurgical slag granulation and oxygen carrier preparation and modification integrated device system, can solve the problem of low added value of metallurgical slag recycling products, achieve high mechanical strength, increase economic value, and high-efficiency waste heat The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the metallurgical slag is a blast furnace slag, and the decorative agent is iron powder.

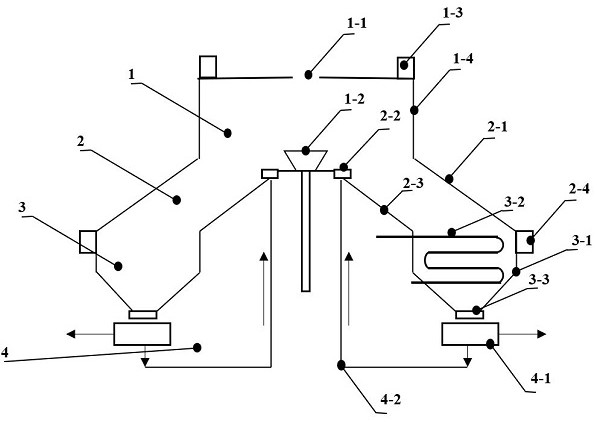

[0026] Metallurgical slag granulation - catalyst preparation and modification of the integrated device system mainly consistently connected by the particleification system 1, the catalyst modification system 2, the remaining heat recovery system 3, the separation, and the circulation system 4. Among them, the granulation system 1 consists of a liquid residue inlet 1-1, a particleification device 1-2, a blower 1-3, and an outer cover 1-4; catalyst modification system 2 by a drain cover 2-1, a modifier inlet 2-2 , The modified agent carrier 2-3 and the blower 2-4 are composed of the remainder heat recovery system 3, composed of the remaining heat boiler 3-1, the heat transfer pipe bundle 3-2, and the particle outlet 3-3; separation and circulation system 4 by screening device 4 -1 and circulating feed unit 4-2.

[0027] Metallurgical slag granulation - catalyst prepa...

Embodiment 2

[0038] In this embodiment, metallurgical slag is copper slag, and the modification agent is a CaO powder.

[0039] Metallurgical slag granulation - catalyst preparation and modified integrated device system and method mainly include the following steps:

[0040] (1) Metallurgical slag particle

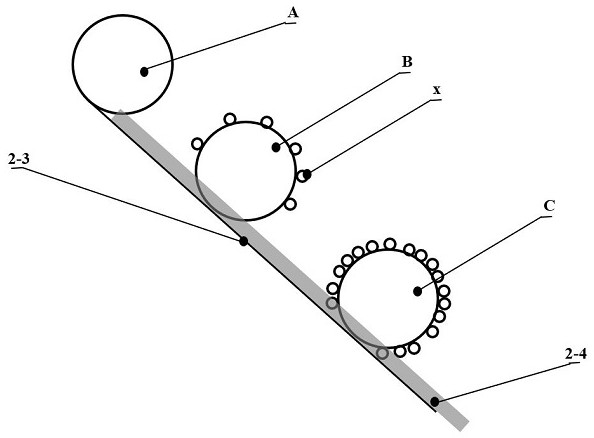

[0041] 1250 ~ 1350 ° C Molten state copper residue enters the particleification system 1 by liquid residue inlet 1-1, in the particleification system 1, liquid residue transitions into a metallurgical slag initial particle A of 0.5 mm to 3 mm by granulation apparatus 1-2. The initial particles of metallurgical slag were 1100 ° C (± 50 ° C). The outer surface of metallurgical slag initial particles A reached an initial solidification state, and the center is still molten liquid state. In the granulation system 1, the introducer blower 1-3 leads the heated air in the particleification system 1 to the outer cover 1-4. The initial particles A of metallurgical slag entered the catalyst modifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com