Energy saving system for adopting absorption heat pump to deeply recover smoke waste heat for central heating

An absorption heat pump and flue gas waste heat technology, applied in hot water central heating systems, heating systems, household heating, etc., can solve problems such as temperature drop, underutilization, and flue gas loss, and achieve enhanced heat transfer capacity, considerable economic and environmental benefits, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

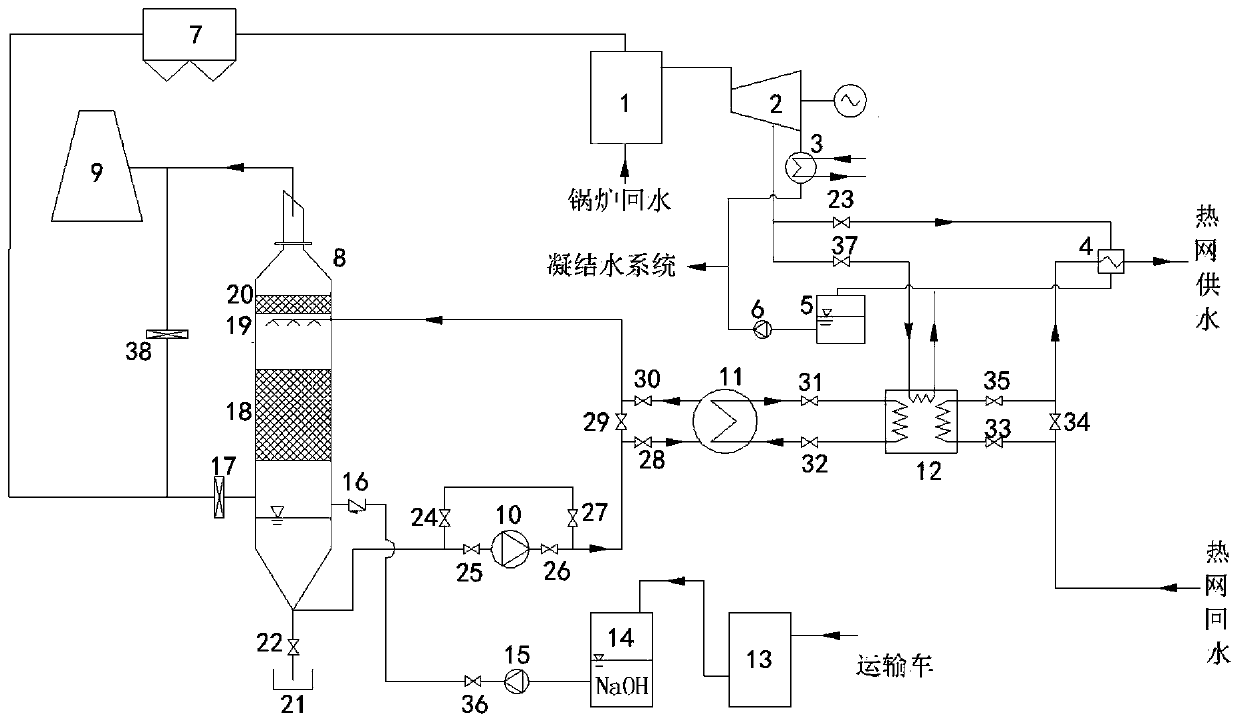

[0021] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0022] During the heating period, the return water temperature of the heating network is T h , The outlet water temperature of flue gas waste heat recovery tower 8 is T tc , use the anti-corrosion high-efficiency water-water plate heat exchanger 11 and the absorption heat pump 12 in series to recover the waste heat of the flue gas: the return water from the heat network enters the absorption heat pump 12, and recovers the waste heat of the flue gas through the anti-corrosion high-efficiency water-water plate heat exchanger 11 The circulating water from tower 8 undergoes indirect heat exchange, and the temperature rises by ΔT 1 , corresponding to the opening of the valve 37, the absorption heat pump 12 uses the air drawn by the steam turbine as the driving heat source; if at this time (T h +ΔT 1 )≥T g , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com