High-temperature flue gas waste heat recovery and advanced purification system

A technology of waste heat recovery and high-temperature flue gas, which is applied in waste heat treatment, energy efficiency improvement, lighting and heating equipment, etc., can solve the problem of low utilization rate of waste heat, achieve the effect of improving utilization rate, reducing damage, and reducing flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

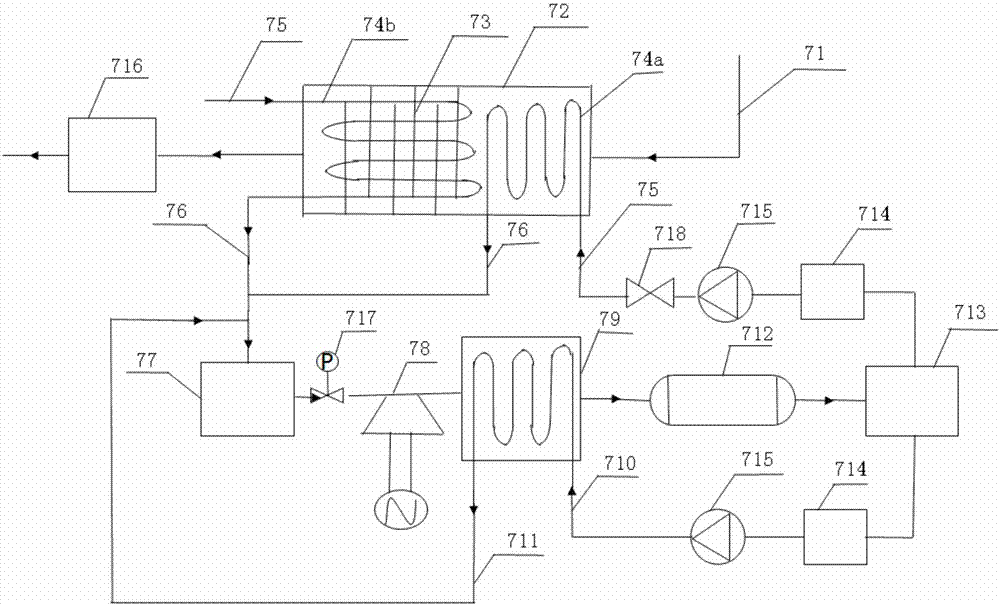

[0025] see figure 1 , a high-temperature flue gas waste heat recovery and deep purification system in the diagram is the preferred solution of the present invention, which consists of a waste heat recovery module 72, a gas collection box 77, a power generation module 78, an organic Rankine cycle heat exchanger 79, Condenser 712, working medium separator 713, liquid storage tank 714, dust removal and purification module 716 and other parts. The inlet end of the waste heat recovery module 72 is connected to the high-temperature flue gas inlet 71, the gas outlet end of the waste heat recovery module 72 is connected to the dust removal and purification module 716, and the heat exchange medium pipe outlet 76 of the waste heat recovery module 72 is connected to the gas collection Box 77, the gas collection box 77 is connected to the power generation module 78 through the regulating valve 717, the gas outlet of the power generation module 78 is connected to the inlet of the organic R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com