Acid Production Process by Coupling Coke Oven Flue Gas Waste Heat and Sulfur Pollutants

A technology for flue gas waste heat and pollutants, which is used in gas treatment, combined devices, and greenhouse gas reduction. It can solve the problems of ineffective recovery of coke oven flue gas waste heat, poor operation stability, frequent system blockage, etc., and achieve increased value. , the effect of improving humidity and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

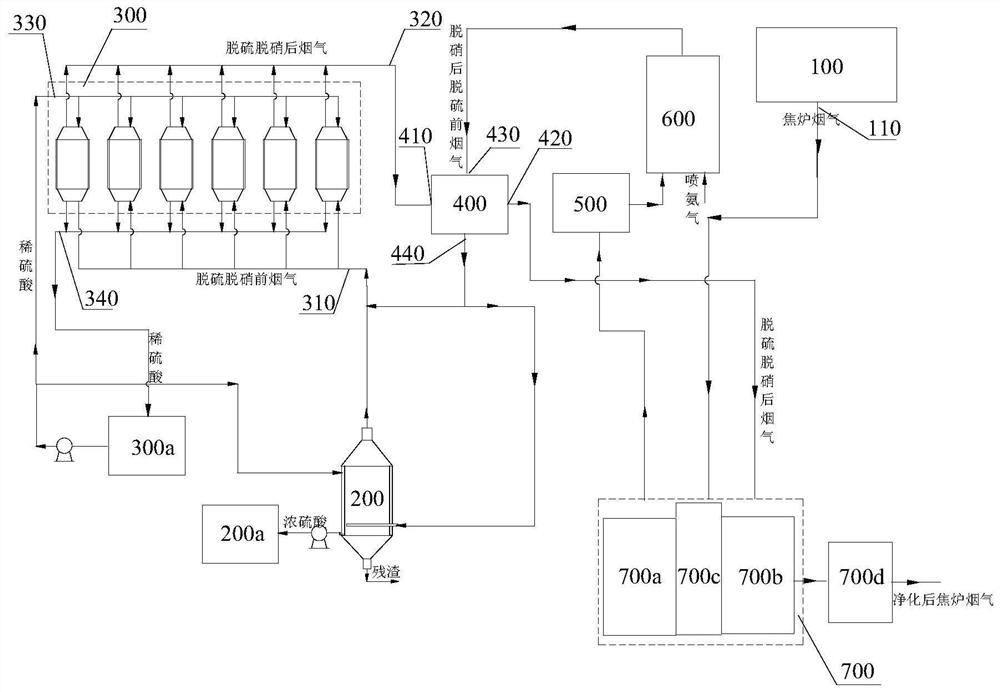

[0052] This embodiment discloses a first denitrification and then desulfurization process, specifically as follows:

[0053] Such as figure 2 As shown, adjust the regulating valve 700c on the coke oven horizontal flue 700 so that the coke oven flue gas discharged along the coke oven flue gas outlet 110 of the coke oven 100 flows out along the horizontal flue 700a at the exit section of the coke oven combustion chamber and passes through the heater 500 After heating up to 380°C, it enters the SCR denitration reactor 600 and mixes with supplementary ammonia and air, and enters the denitration catalyst bed of the denitration reactor 600 together, and NH is generated on the surface of the denitration catalyst. 3 The denitrification reaction of reducing NOx, the flue gas after denitrification also contains sulfur dioxide gas, so it is the flue gas before desulfurization after denitrification, and the flue gas before desulfurization after denitrification enters the heat exchanger 4...

Embodiment 2

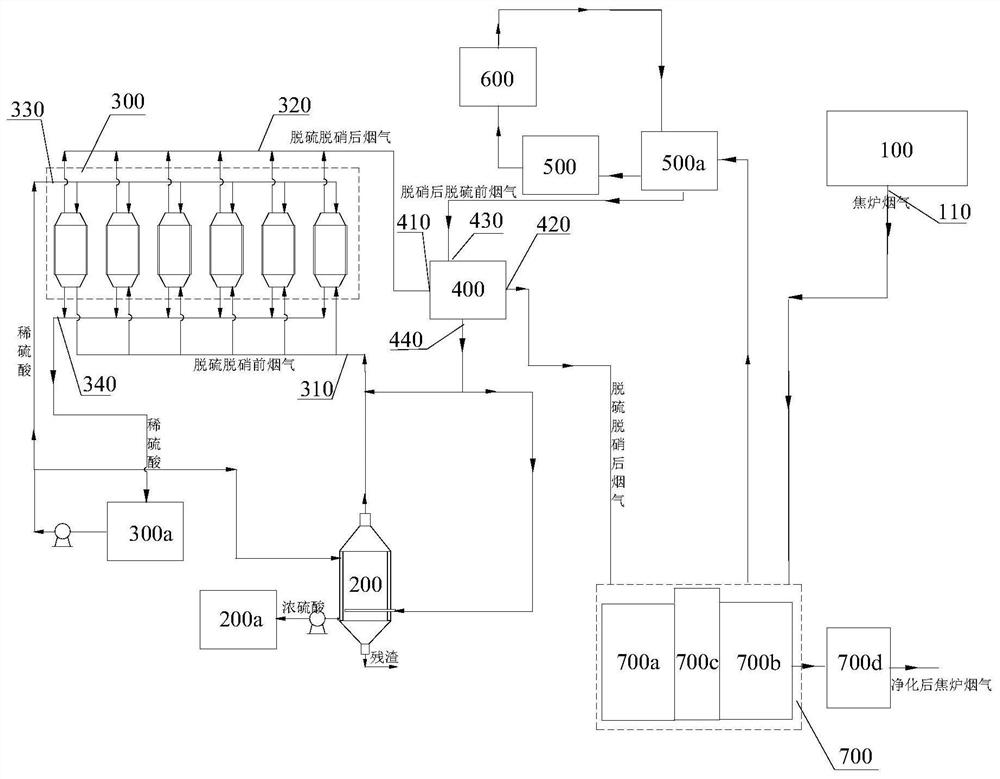

[0055] This embodiment discloses a first denitrification and then desulfurization process, specifically as follows:

[0056] Such as figure 1 As shown, the regulating valve 700c on the coke oven horizontal flue 700 is adjusted so that the coke oven flue gas discharged along the coke oven flue gas outlet 110 of the coke oven 100 flows out along the horizontal flue 700a at the exit section of the coke oven combustion chamber, and then passes through the second changer. Heater 500a exchanges heat with flue gas after denitrification and before desulfurization, then is heated up to 380°C by heater 500 and then sent to SCR denitrification reactor 600, mixed with supplementary ammonia and air, and enters the denitrification catalyst bed of denitrification reactor 600 together layer, NH occurs on the surface of the denitration catalyst 3 The denitrification reaction of reducing NOx, the obtained flue gas after denitrification and before desulfurization circulates into the second heat...

Embodiment 3

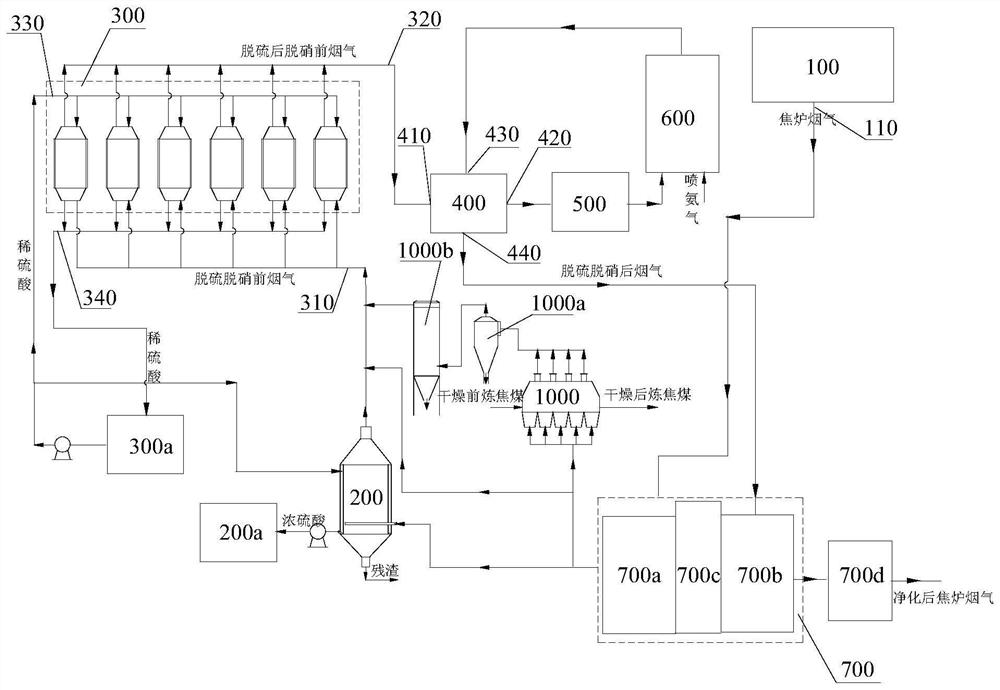

[0058] This embodiment discloses a first desulfurization and then denitrification process, specifically as follows:

[0059] Such as image 3 As shown, the regulating valve 700c on the coke oven horizontal flue 700 is adjusted so that the coke oven flue gas discharged along the coke oven flue gas outlet 110 of the coke oven 100 flows out along the horizontal flue 700a at the exit section of the coke oven combustion chamber and is divided into three gas streams. Pipeline, a gas pipeline is part of the coke oven flue gas bubbling into the dilute acid concentrator 200, which directly contacts with dilute sulfuric acid for heat exchange, humidification, and cooling, and then leaves the dilute acid concentrator 200 and sends it to the carbon-based catalytic desulfurization acid production device 300, one gas pipeline is for part of the coke oven flue gas to be directly sent to the carbon-based catalytic desulfurization acid production device 300, and the other gas pipeline is for p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com