Multi-point gap type high-temperature flue sensible heat recovery power generating equipment

A high-temperature flue and sensible heat recovery technology, applied in the field of energy conservation and environmental protection, can solve the problems affecting the normal operation of the electric furnace system of the cooling device, the large amount of low-pressure saturated steam, and the lack of heat recovery, so as to prevent heat loss and the device from being impacted by the outside world. , Enhance the effect of disturbance and use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is a further description of the multi-point gap type high-temperature flue sensible heat recovery power generation equipment of the present invention.

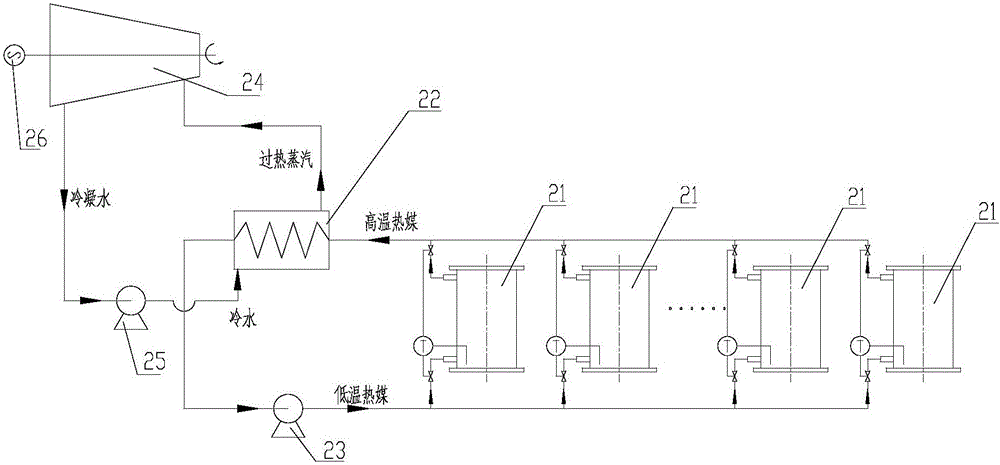

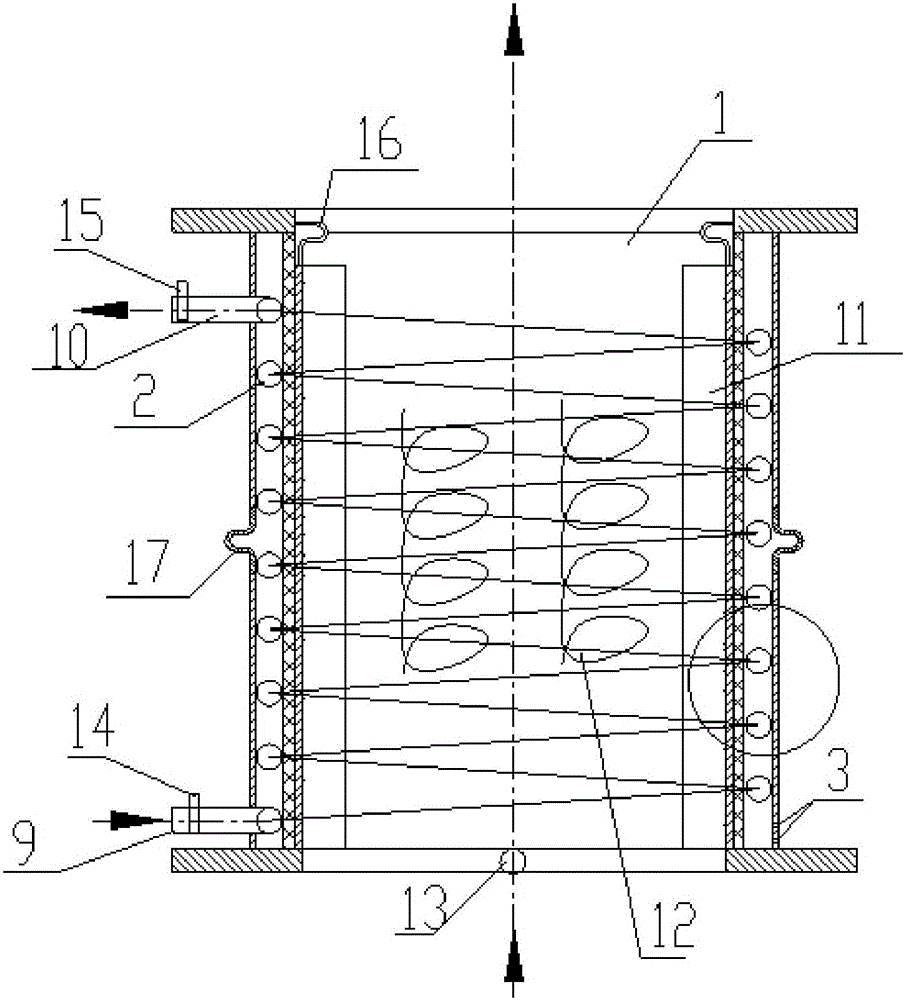

[0030] Multi-point gap type high temperature flue sensible heat recovery power generation equipment, see figure 1 , Including a waste heat boiler 22, a heat medium pump 23, a steam turbine 24, a water pump 25, a generator 26, and a set of gap-type high-temperature flue sensible heat recovery devices 21 arranged in parallel with multiple points; the waste heat boiler 22 includes hot coal pipelines and steam water circulation Pipeline; the heat medium outlet 10 of the gap type high temperature flue sensible heat recovery device 21 arranged in parallel at multiple points is connected to the hot coal pipeline of the waste heat boiler 22 and the heat medium pump 23 in sequence, and the heat medium pump 23 is connected to each gap type high temperature smoke The heat medium inlet 9 of the sensible heat recovery devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com