Liquid slag waste heat recovery device and method for recovering slag waste heat by utilizing same

A waste heat recovery device and slag technology, applied in recycling technology, furnace, waste heat treatment, etc., can solve the problems of time and geographical limitations, low waste heat recovery rate, etc., and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

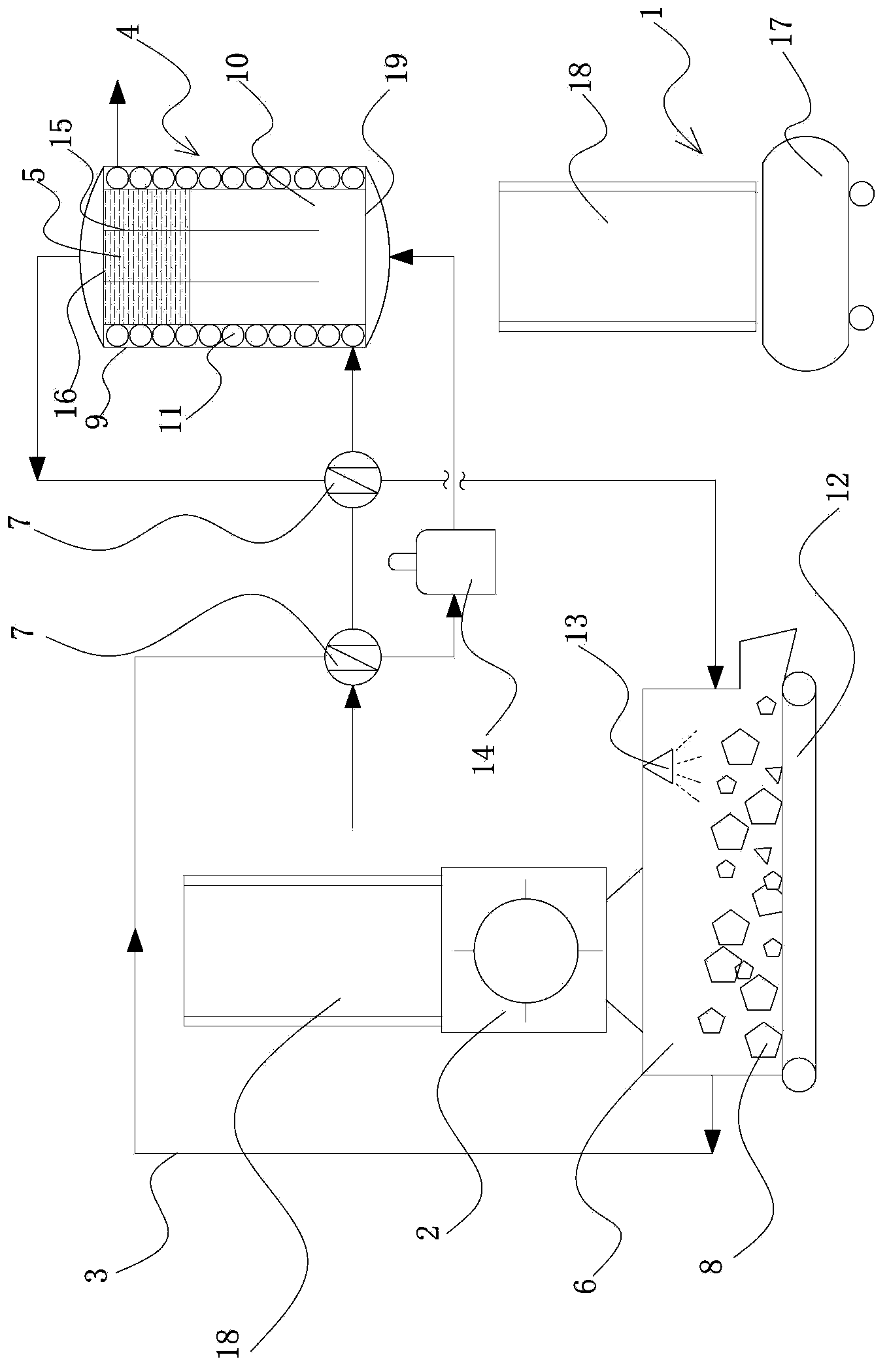

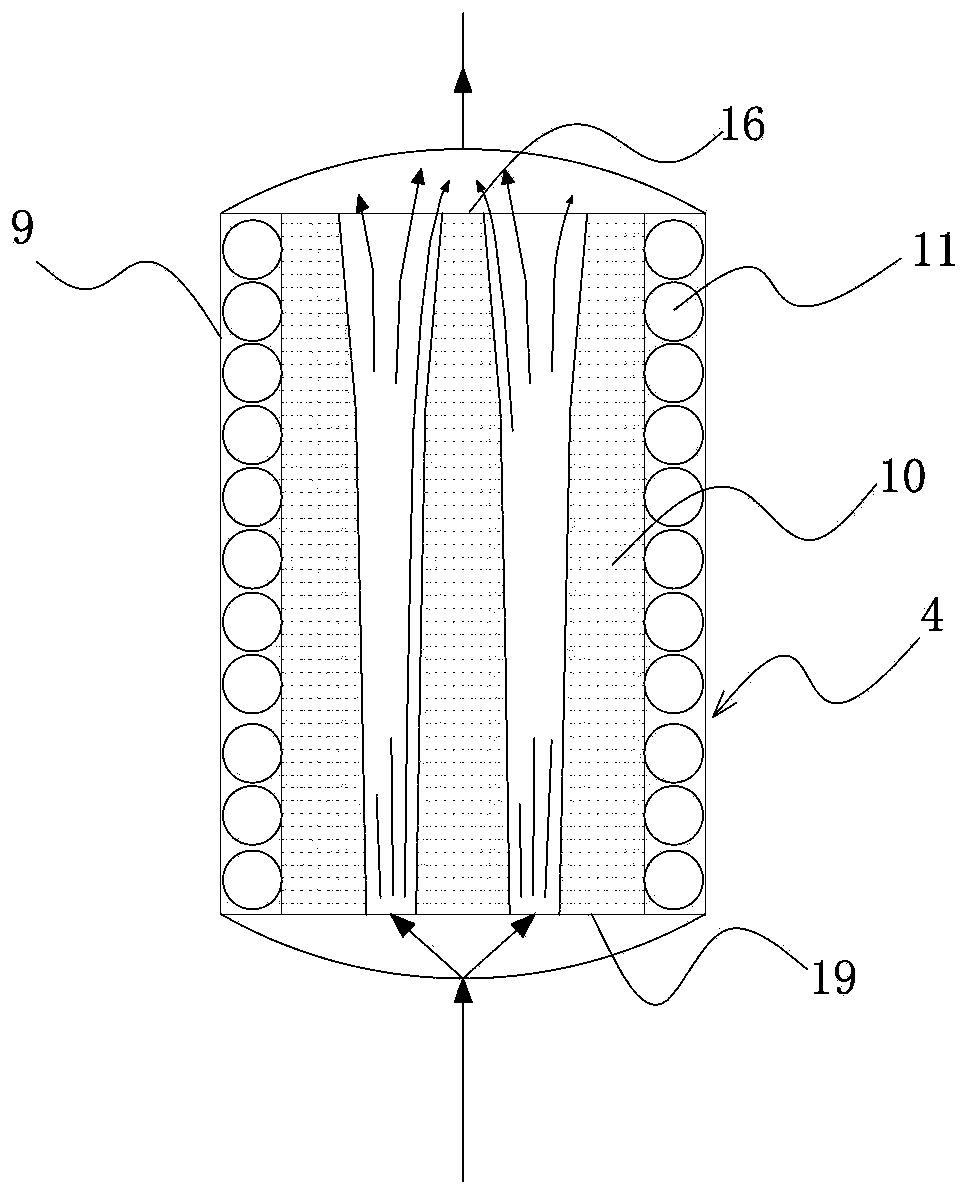

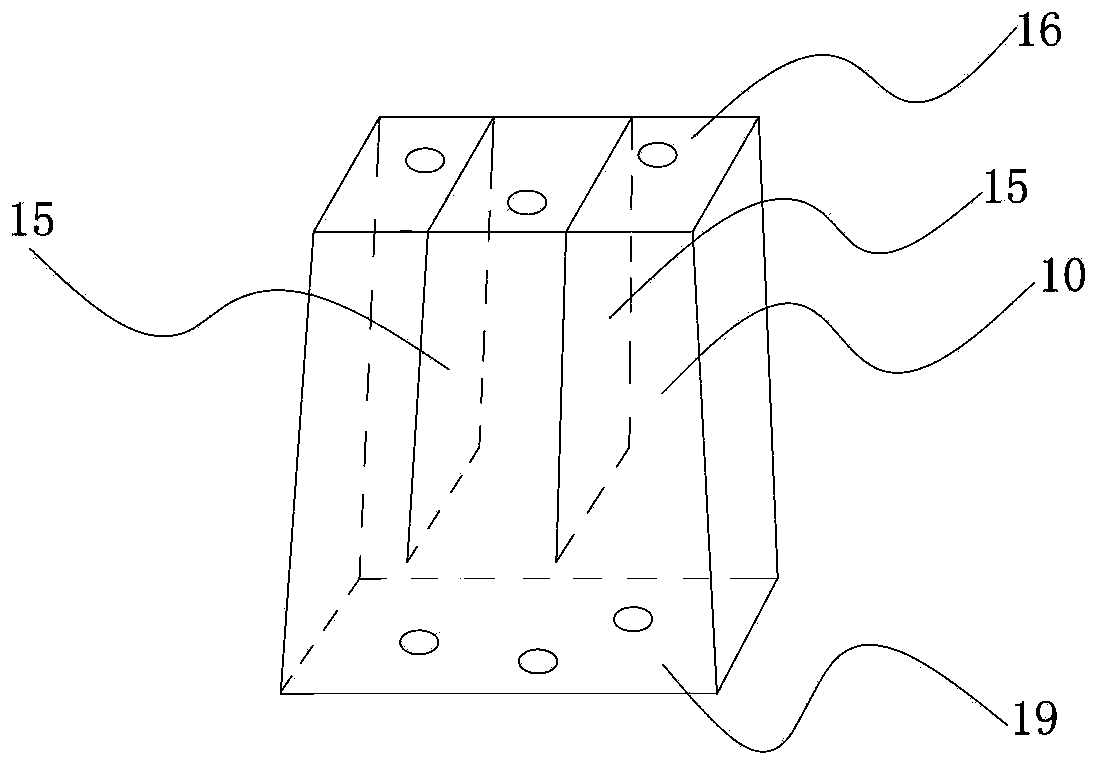

[0039] The following with attached Figure 1 to Figure 3 The liquid slag waste heat recovery device of the present invention and the method for recovering slag waste heat by using the liquid slag waste heat recovery device are further described in detail.

[0040] For the liquid slag waste heat recovery device of the present invention, please refer to Figure 1 to Figure 3, comprising a superheated steam generator 4, an evaporator 6, a breaker 2, an insulated slag transporter 2 and a slag delivery device 12, the breaker 2 is located above the evaporator 6 and communicated with the two, and the evaporator 6 is connected to the A circulating steam circulation loop is formed between the superheated steam generators 4 through a steam channel 3, and the upstream of the superheated steam generator 4 is provided with a steam pressurizing device 14 and a heat exchanger 7 for heat exchange with deionized water, so The downstream of the superheated steam generator 4 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com