Method for recovering flue gas waste heat of coke oven

A technology for waste heat and waste heat recovery of flue gas, which is applied in steam generation methods, furnaces, waste heat treatment and other directions using heat carriers, which can solve the problems of poor installation, difficult later maintenance, and poor practicability, and achieves reduced impact, reliable and continuous operation. The effect of efficient waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

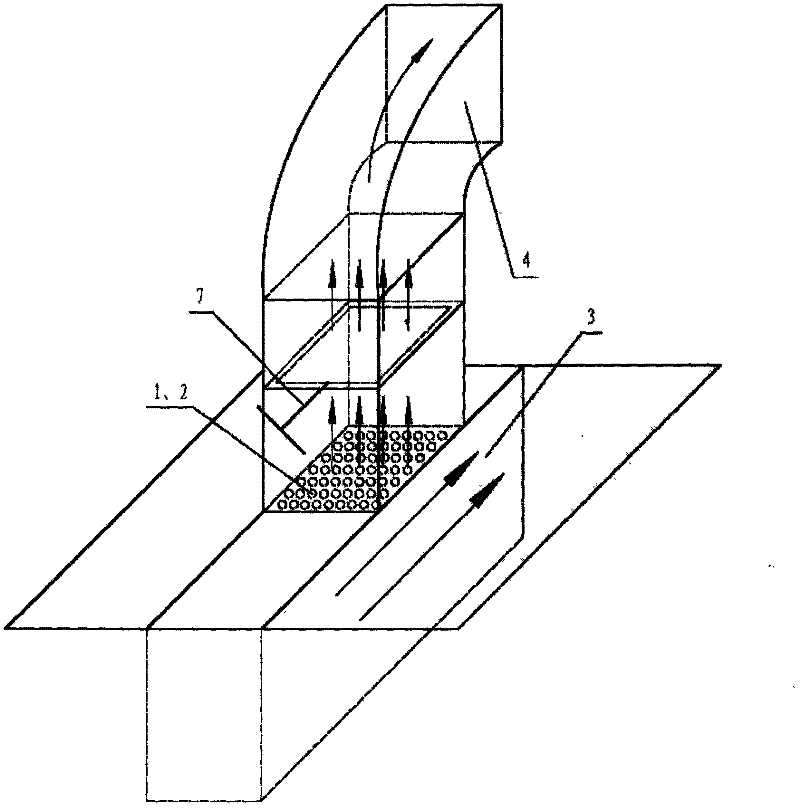

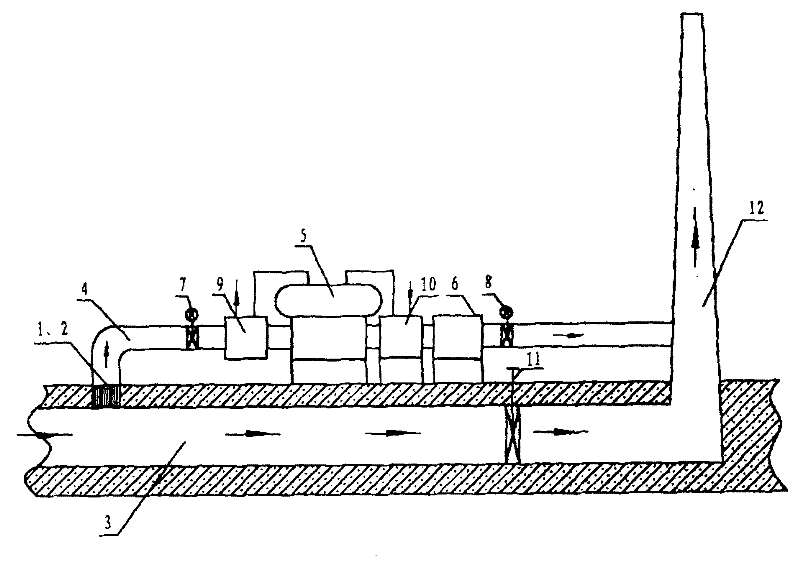

[0020] Below with accompanying drawing as embodiment the present invention is further described: as figure 1 As shown, the coke oven flue gas waste heat recovery method first processes the conveying path for flue gas collection on the coke oven output flue; At the same time, a waste heat recovery system is installed in the waste heat recovery pipeline to adjust the pressure in the waste heat recovery pipeline. The waste heat recovery system converts heat energy and outputs heat energy. emission.

[0021] There are mainly two types of methods for processing flue gas collection, transportation and output channels. One is to build a new coke oven system. A flue gas collection and delivery channel and an output channel with a cross-sectional area of 0.5-1.5 times the cross-sectional area of the coke oven output flue are reserved on the duct. The shape of the flue gas collection and delivery channel and the output channel can be circular, square or rectangular, etc. similar s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com