Blast furnace slag recycling device

A blast furnace slag storage technology, which is applied in the field of waste heat recovery system, can solve the problems of insignificant effect and little use of the partition 33, and achieve the effects of assembly line operation, reduction of safety hazards, and efficient installation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

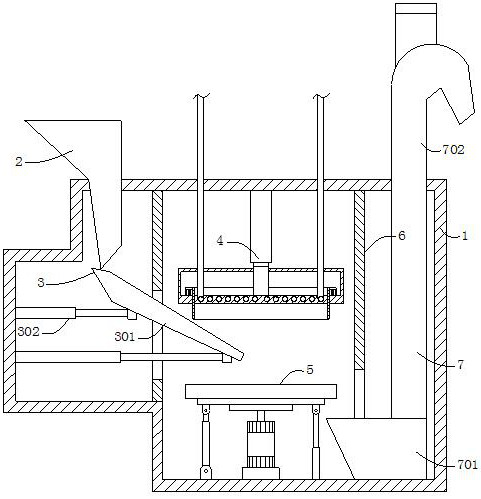

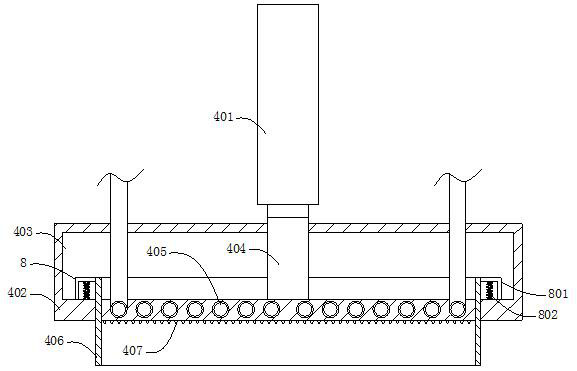

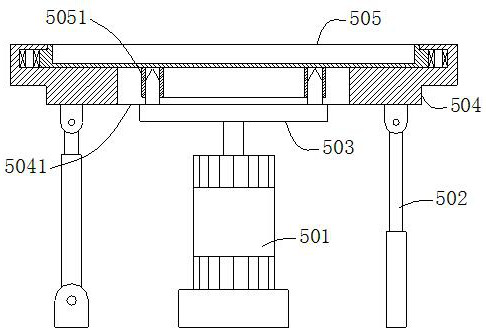

[0032] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a blast furnace slag recycling device of the present invention includes a box body 1, and the inner cavity of the box body 1 is divided into a first zone, a second zone and a third zone in turn by two vertical partitions 6, The top of the first zone is fixedly embedded with a feed hopper 2, the middle of the first zone is equipped with a material guide mechanism 3 for conducting slag, and the top and bottom of the second zone are respectively equipped with a waste heat recovery mechanism 4 and a storage and dumping mechanism 5. The waste heat recovery mechanism 4 is arranged opposite to the accommodating and dumping mechanism 5. The waste heat recovery mechanism 4 includes a base block 402. The bottom of the base block 402 is interspersed with a limiting cylinder 406. The sides of the limiting cylinder 406 are equidistantly arranged with four Force mechanism 8, and a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com