Flue gas waste heat recovery device and method with spark capturing function

A flue gas waste heat and recovery device technology, which is applied in the field of high-temperature flue gas treatment in the metal melting process, can solve problems such as easy fires, and achieve the effects of improving resource utilization, improving equipment utilization, and realizing energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

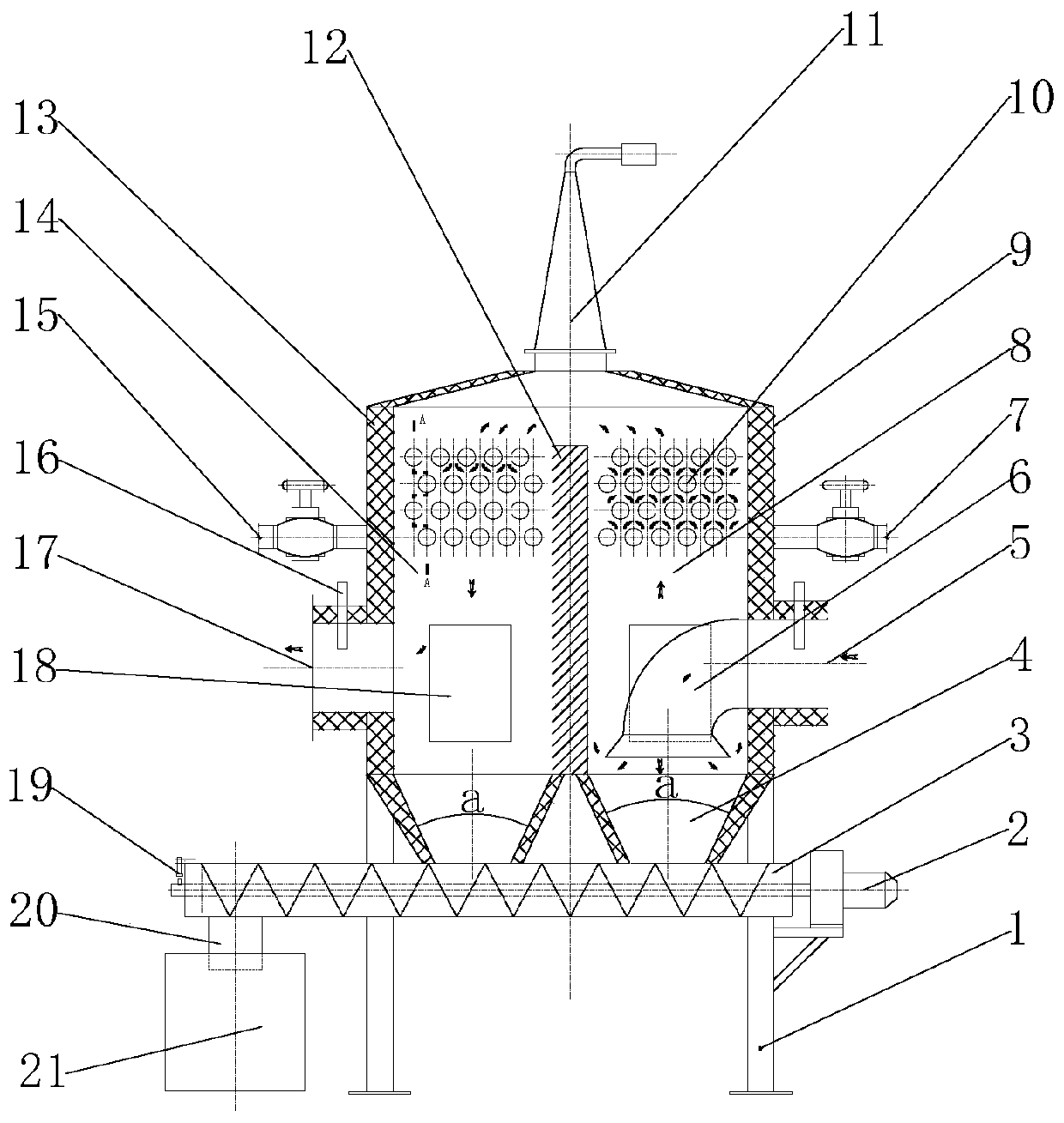

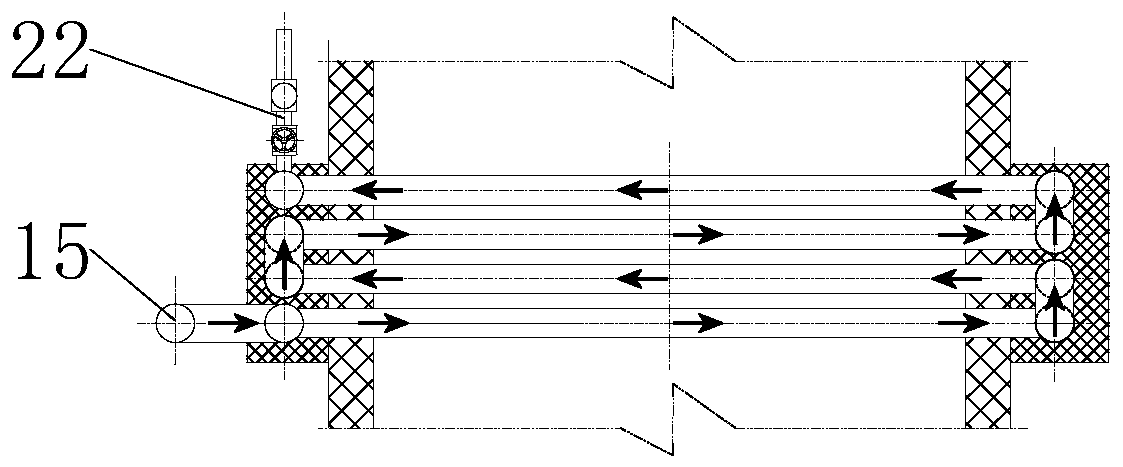

[0031] like Figure 1 to Figure 2 As shown, the flue gas waste heat recovery device with spark capture function of the present invention includes a frame 1 and a box body 9 installed on the frame 1, a soot blower 11 is installed on the top of the box body 9, and a soot blower 11 is installed in the box body 9 The partition 12 divides the box body into a left chamber 14 and a right chamber 8, and the lower ends of the left and right sides of the box body 9 are provided with a smoke outlet 17 and a smoke inlet 5 to communicate with the left chamber 14 and the right chamber 8 respectively. , the box body 9 is provided with an elbow 6 connected to the flue gas inlet 5, and the left and right chambers are provided with a column pipe 10 with a spark capture function connected to the water supply pipe 15 and the drain pipe 7 outside the box body 1, and the bottom of the box body 9 The ash discharge hopper 4 connected with the left and right chambers is symmetrically arranged, the ash...

Embodiment 2

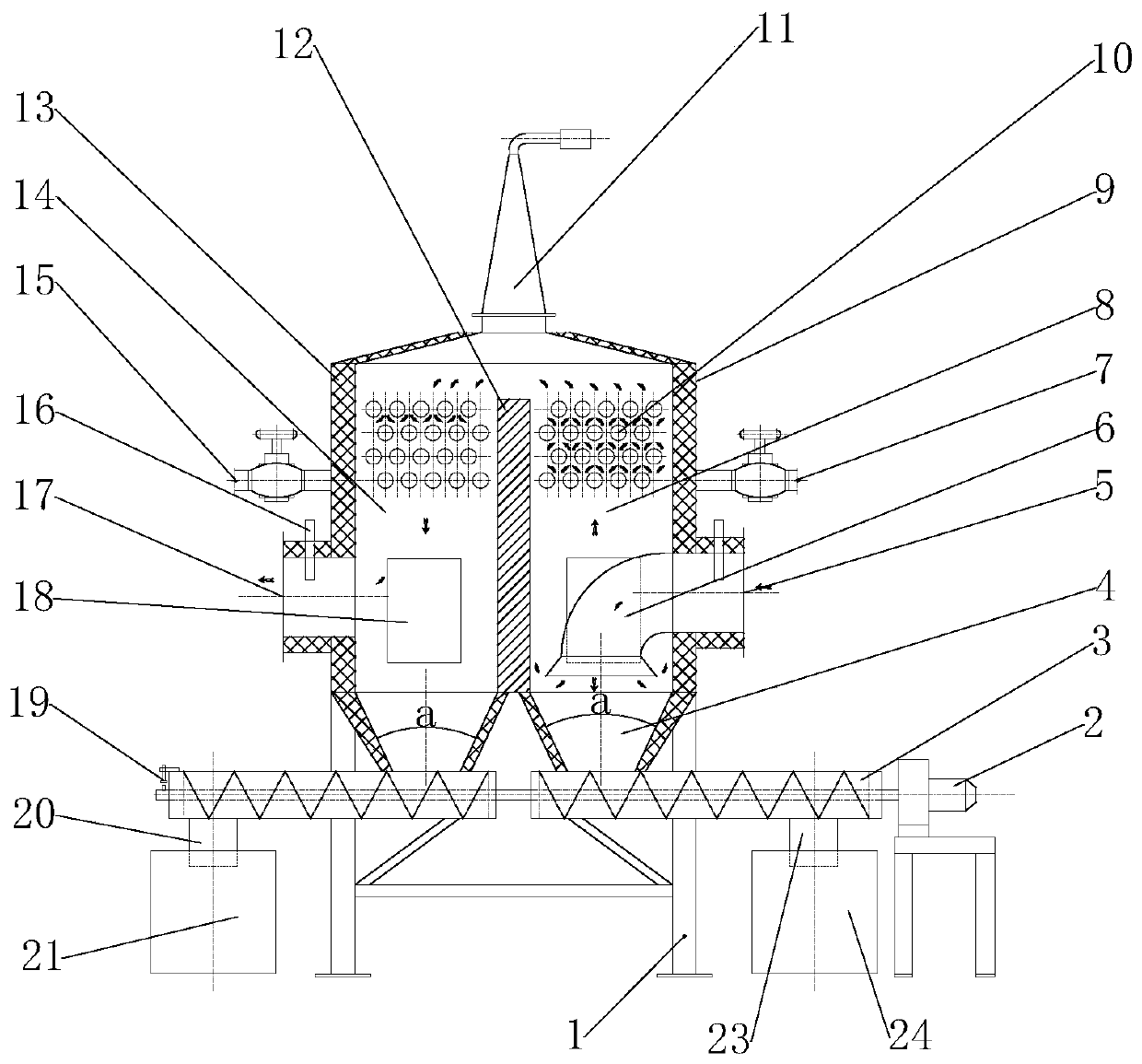

[0042] like image 3 As shown, the difference between the flue gas waste heat recovery device with spark capture function in this embodiment and that in Embodiment 1 is that the conveyor 3 connected to the ash discharge hopper 4 has a coaxial two-stage structure, and the two stages rotate in opposite directions. It is connected with the left and right chamber ash discharge hoppers 4, the lower side of the outer end of one section is connected with the first ash discharge port 20, the first collection box 21 is arranged on the lower side of the first ash discharge port 20, and the outer end of the other section The lower side is connected with the second ash discharge port 23, and the second collection box 24 is arranged on the lower side of the second ash discharge port 23. The conveyor 3 is driven by the motor 2, and the dust particles etc. falling from the left chamber 14 pass through the second collection box 24. A row of ash outlets 20 are discharged to the first collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com