Patents

Literature

38results about How to "Realize countercurrent heat exchange" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

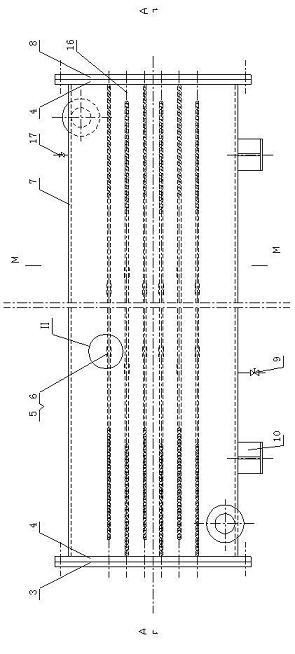

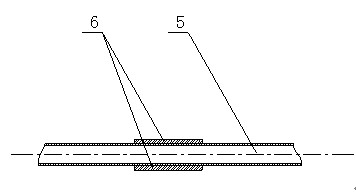

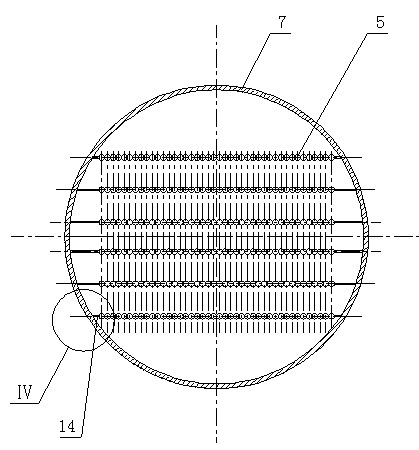

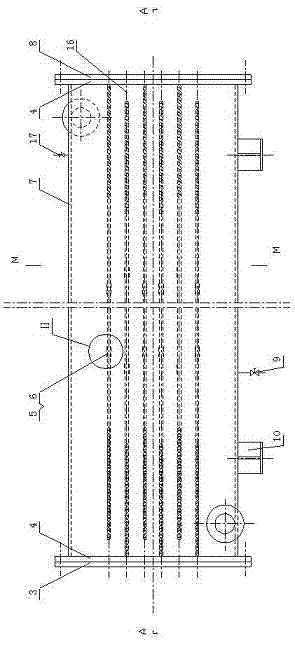

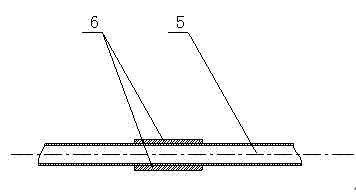

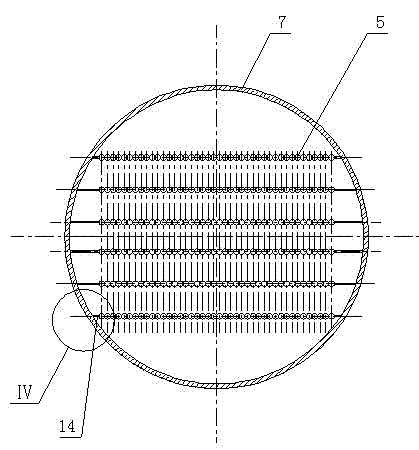

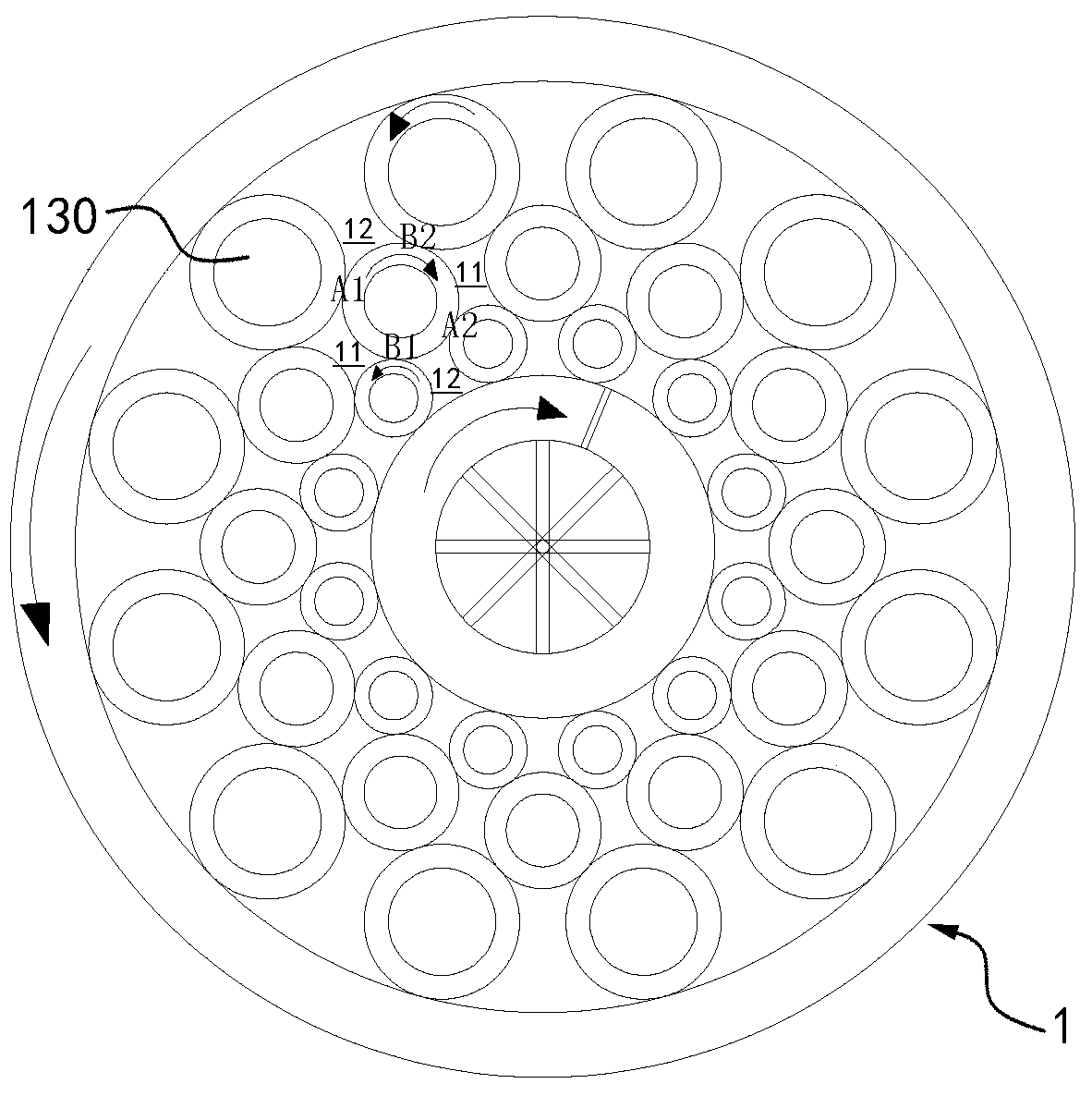

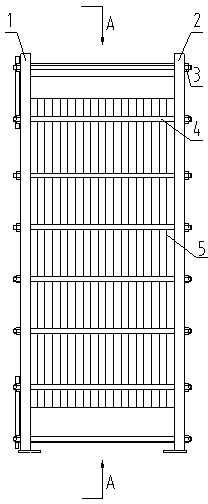

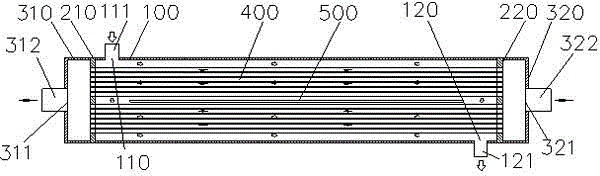

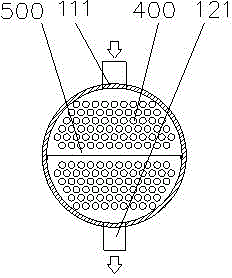

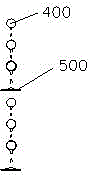

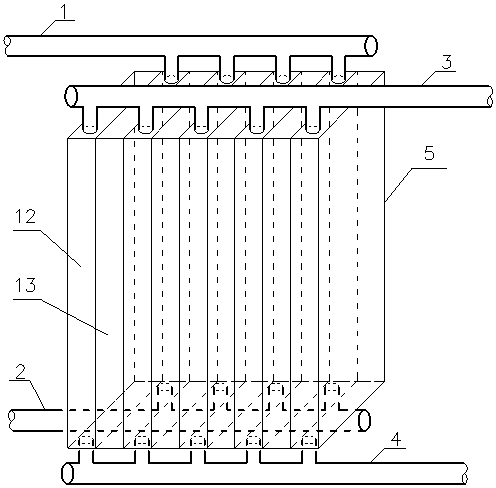

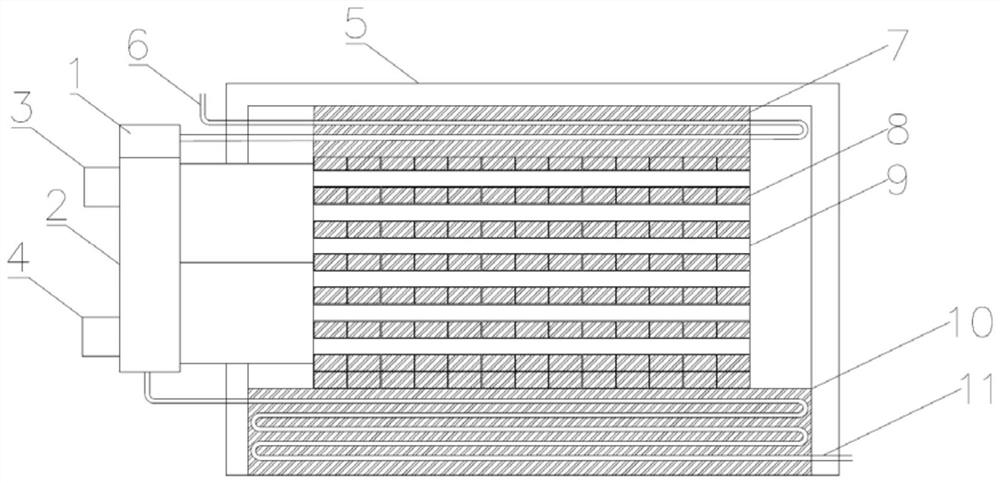

A shell and tube sewage heat exchanger

InactiveCN102288053ASignificant progressSignificantly substantialStationary tubular conduit assembliesHeat exchange apparatusFilter systemEngineering

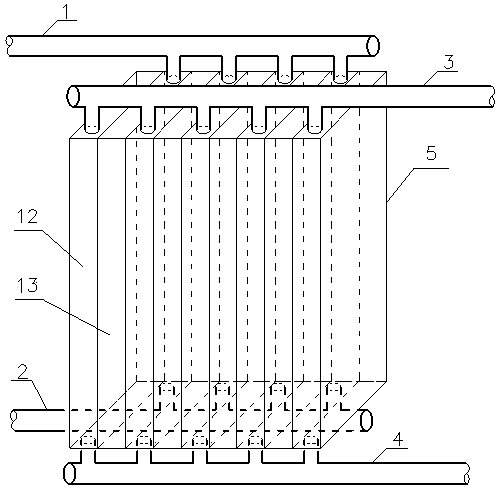

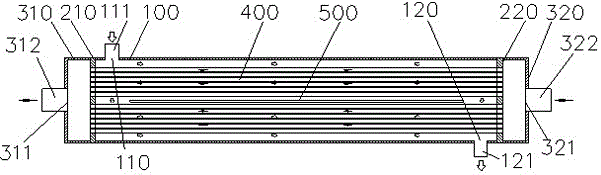

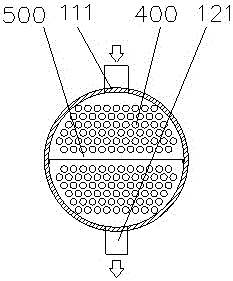

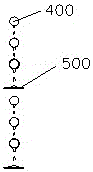

The invention discloses a shell and tube sewage heat exchanger. The heat exchanger comprises an external shell and internal heat exchange tubes, wherein the shell is provided with a sewage inlet pipe and a sewage outlet pipe. The heat exchanger is characterized in that: a plurality of parallelly arranged heat exchange tube rows are arranged in the shell; each heat exchange tube row is formed by arranging N heat exchange tubes and is supported and fixed through a supporting and fixing plate connected to the shell; and seal heads are arranged at the two ends of the shell and are connected with the shell through fixed flanges. Compared with the prior art, the invention has the advantages that: sewage can directly enter the heat exchanger without blocking the heat exchanger and can be directly subjected to heat exchange with intermediary water, a secondary refrigerant or a refrigerant without being subjected to any treatment, so that a filtering system is eliminated, higher efficiency andsimplicity are achieved, and manufacturing cost is lower; and the heat exchanger has a detachable structure, can be conveniently maintained, and can meet various engineering requirements.

Owner:王英慧

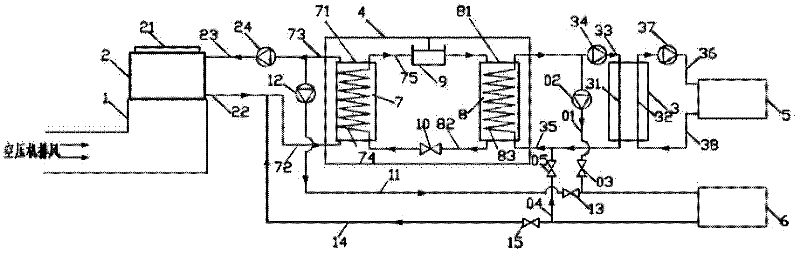

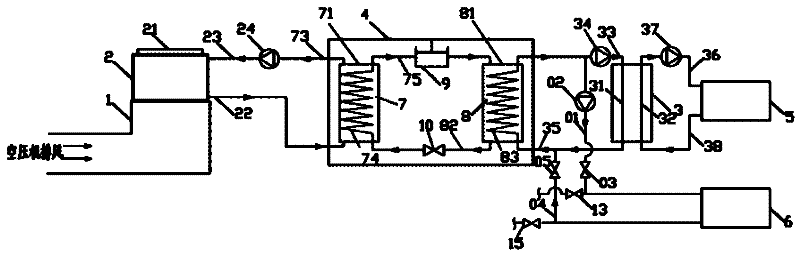

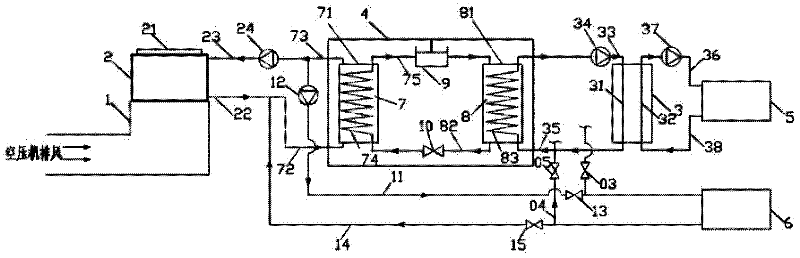

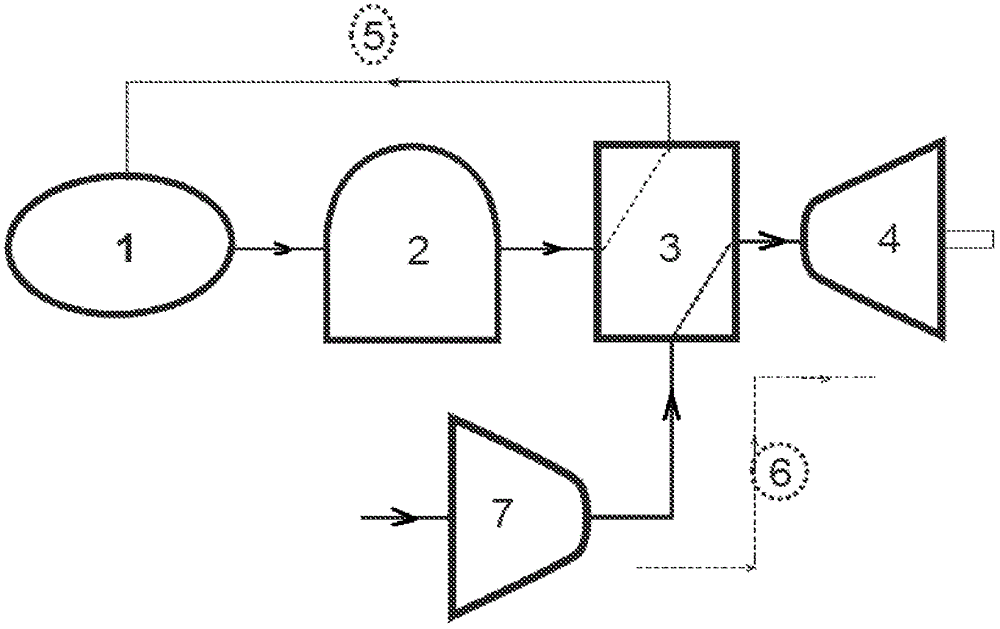

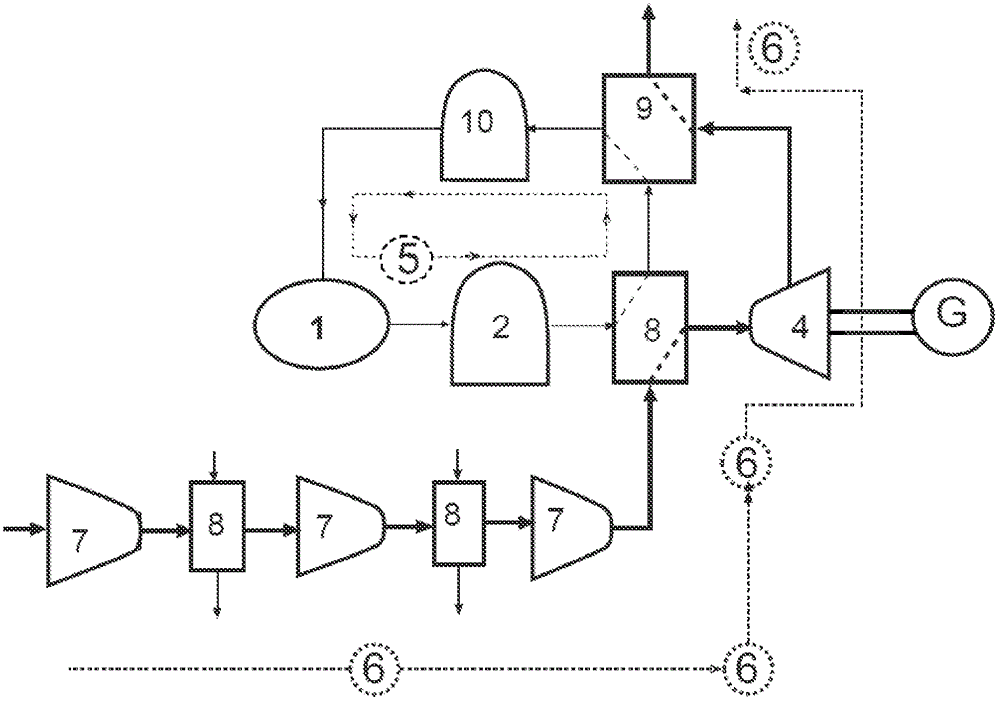

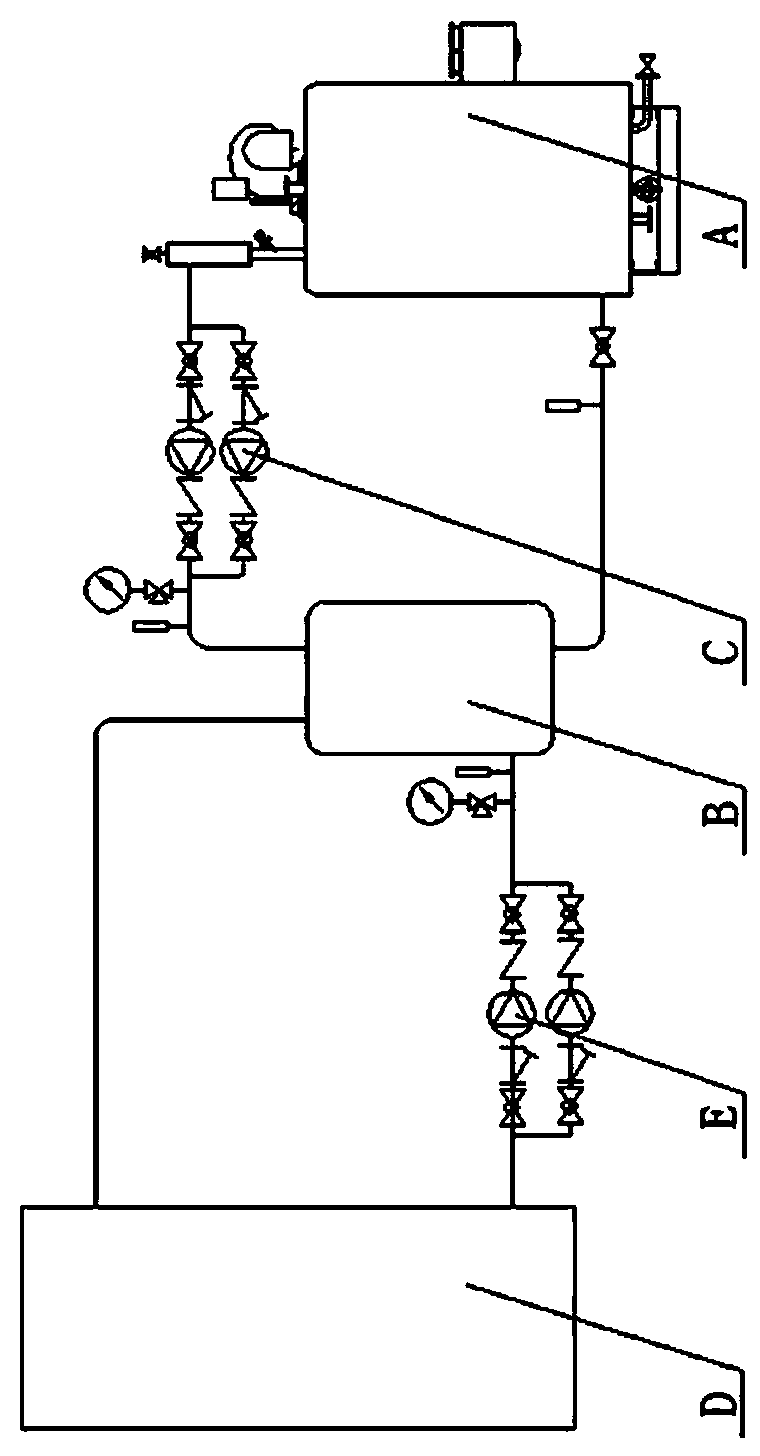

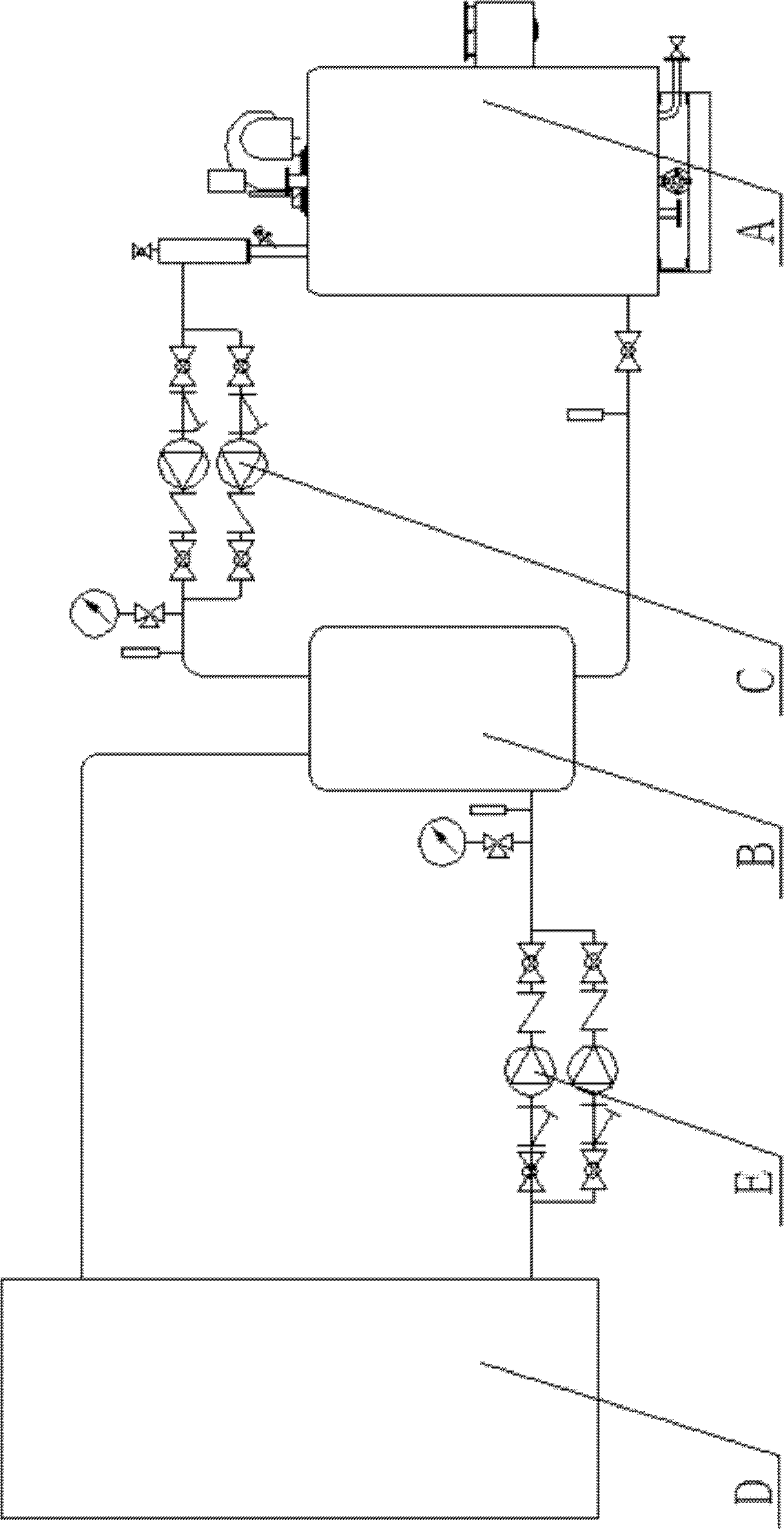

Waste heat recovery and utilization system for coal mine air compressor

ActiveCN102410665AIncrease profitMeet the protection requirementsClimate change adaptationHeating and refrigeration combinationsGas compressorEvaporation

The invention relates to a waste heat recovery and utilization system for a coal mine air compressor. The system comprises a heat pipe heat exchanger arranged at the top of the air discharge duct of the air compressor; a heat exchange circulation pipeline is formed between the heat pipe heat exchanger and the casing of a shell-and-tube evaporator through a heat exchange circulating water outlet pipeline and a heat exchange circulating water return pipeline; a refrigerant circulation pipeline is formed between the evaporation heat exchange pipeline of the shell-and-tube evaporator and the casing of a shell-and-tube condenser through a compressor and an expansion valve; a domestic hot water primary circulation pipeline is formed between the condensation heat exchange pipeline of the shell-and-tube condenser and the hot water pipeline of a plate heat exchanger; a domestic hot water secondary circulation pipeline is formed between the cold water pipeline of the plate heat exchanger and a domestic hot water tank; a winter user heating circulation water supply pipeline is formed between user equipment and the condensation heat exchange pipeline of the shell-and-tube condenser; and a summer user refrigerating circulation water supply pipeline is formed between the user equipment and the casing of the shell-and-tube evaporator. By adopting the invention, winter heating, summer refrigerating, and domestic hot water providing all year round for coal mine buildings are realized.

Owner:北京矿大节能科技有限公司

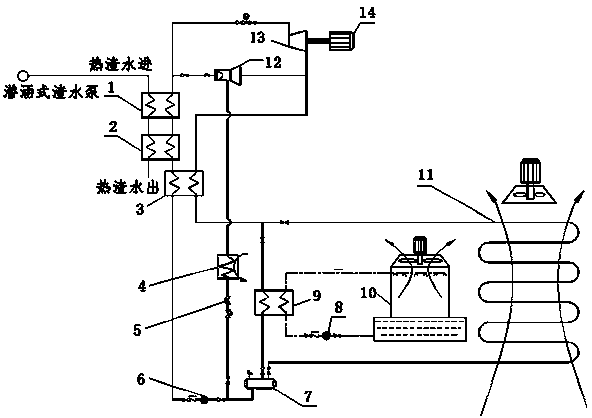

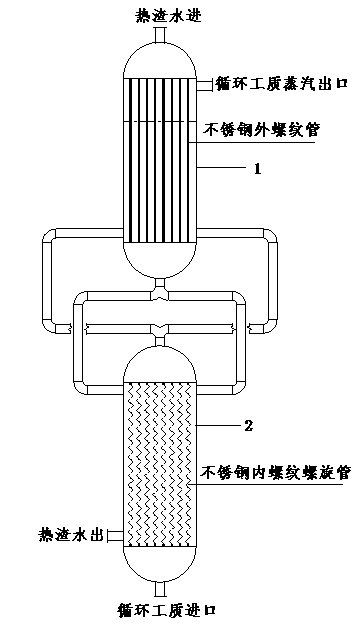

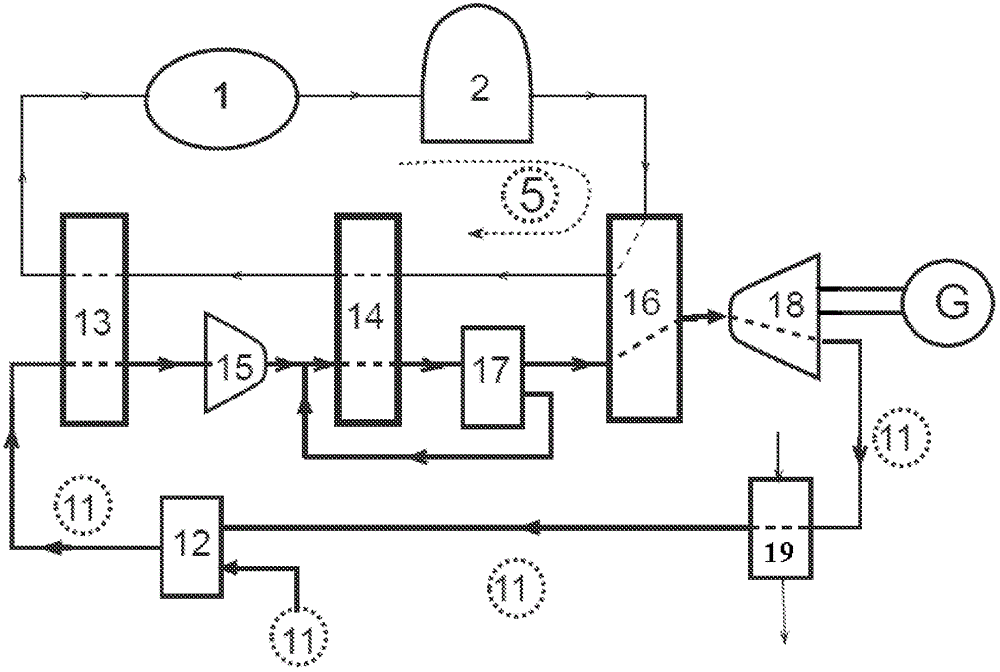

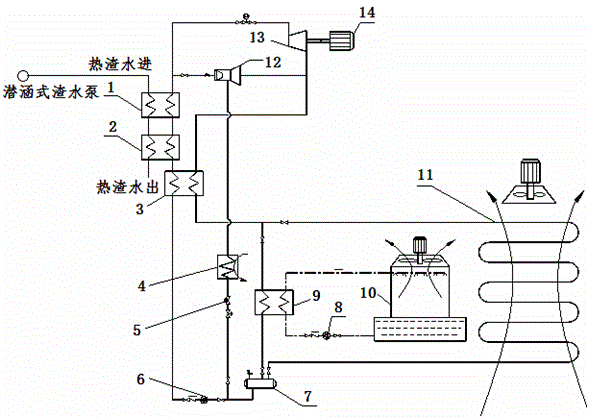

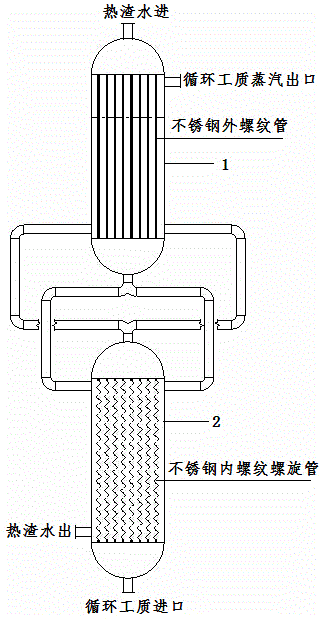

System capable of conducting power recovering and cooling by using waste heat of blast furnace slag flushing water

ActiveCN104196584AEnhanced boiling heat transferAvoid pollutionClimate change adaptationEnergy industryElectricityVapor–liquid separator

The invention relates to a system capable of conducting power recovering and cooling by using waste heat of blast furnace slag flushing water, and belongs to the technical field of energy and environment. The system comprises a slag flushing water heat recovery and heat exchange system, an organic Rankine cycle, a steam injection type cooling system and a cooling water circulation system. An internal-thread stainless steel spiral tube shell-and-tube heat exchanger is used as a pre-heater, an external-thread stainless steel tube shell-and-tube heat exchanger is used as a steam generator, and the steam generator is also used as a gas-liquid separator. The system has the advantages of being simple in structure, easy to machine and manufacture, low in manufacturing cost, capable of preventing blockage, capable of realizing countercurrent flow heat exchange, high in heat exchange efficiency, capable of effectively utilizing waste heat of the slag flushing water and the like; the system can be independently used for generating electricity or providing prime power, can also be independently used for cooling and can further provide electric power and chilled water required by a cooling air conditioner at the same time.

Owner:KUNMING UNIV OF SCI & TECH

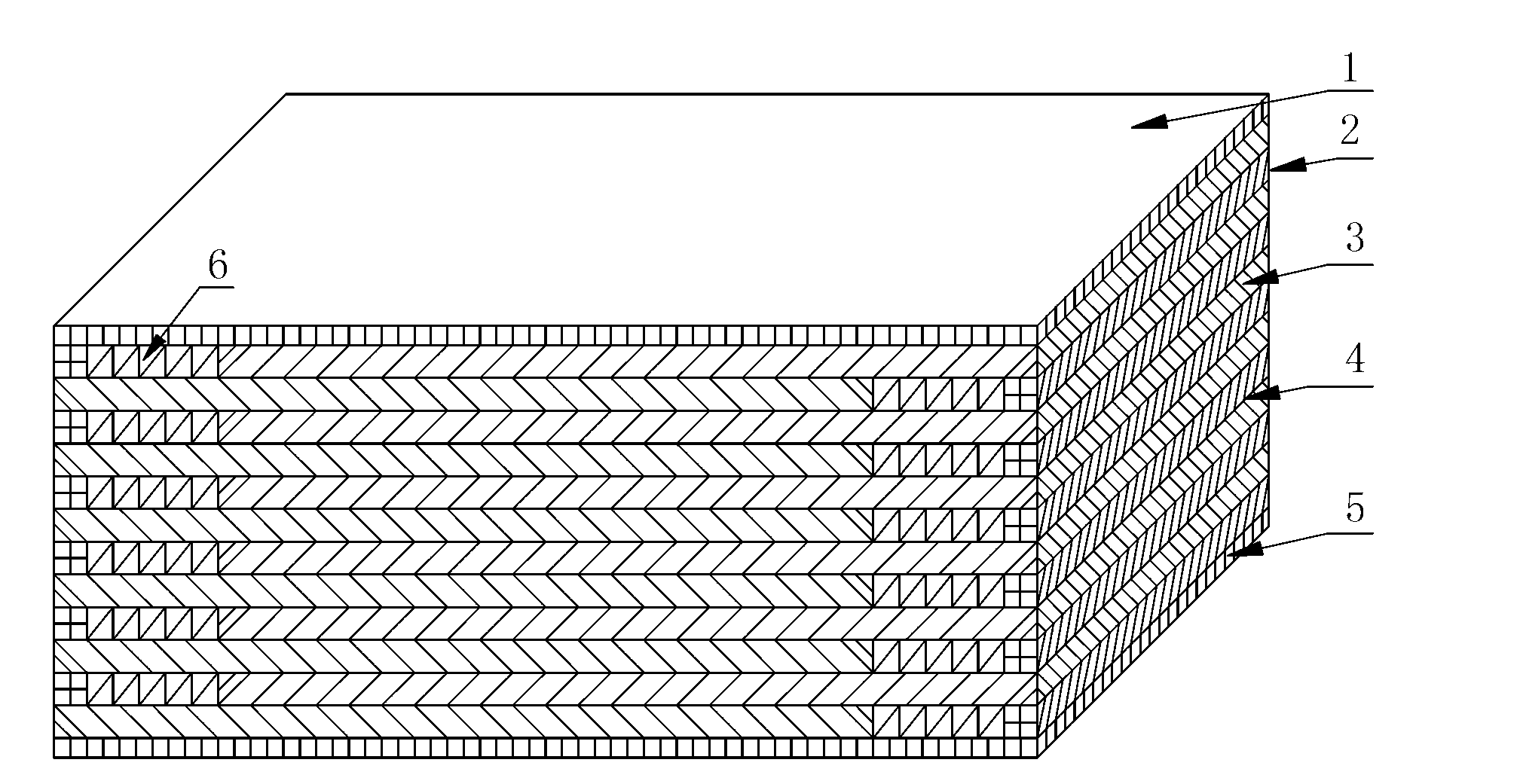

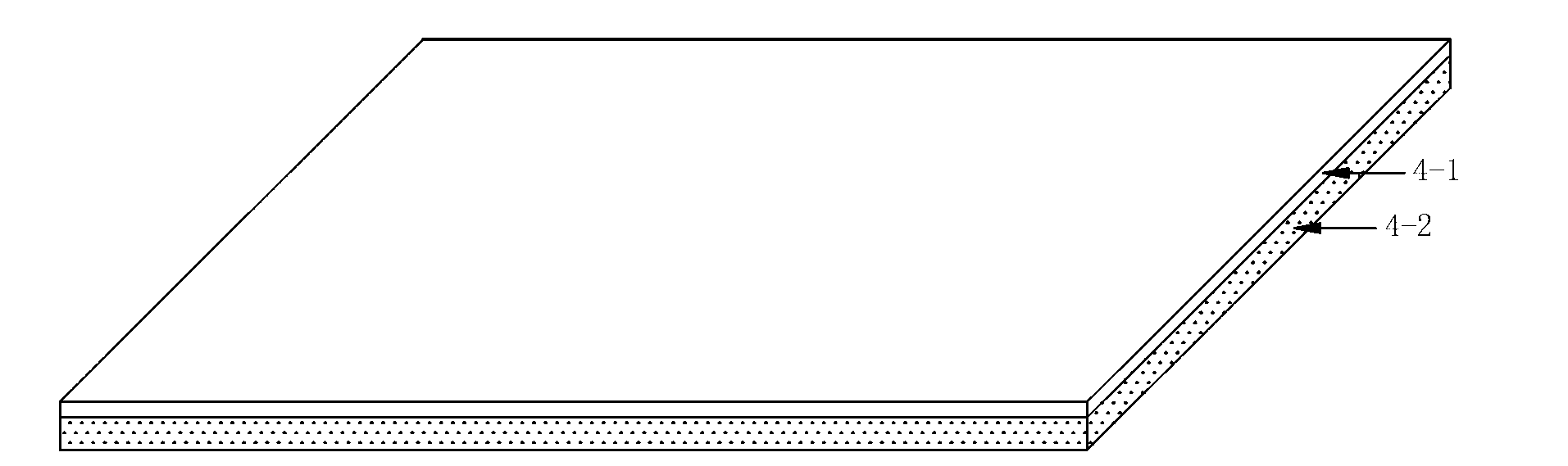

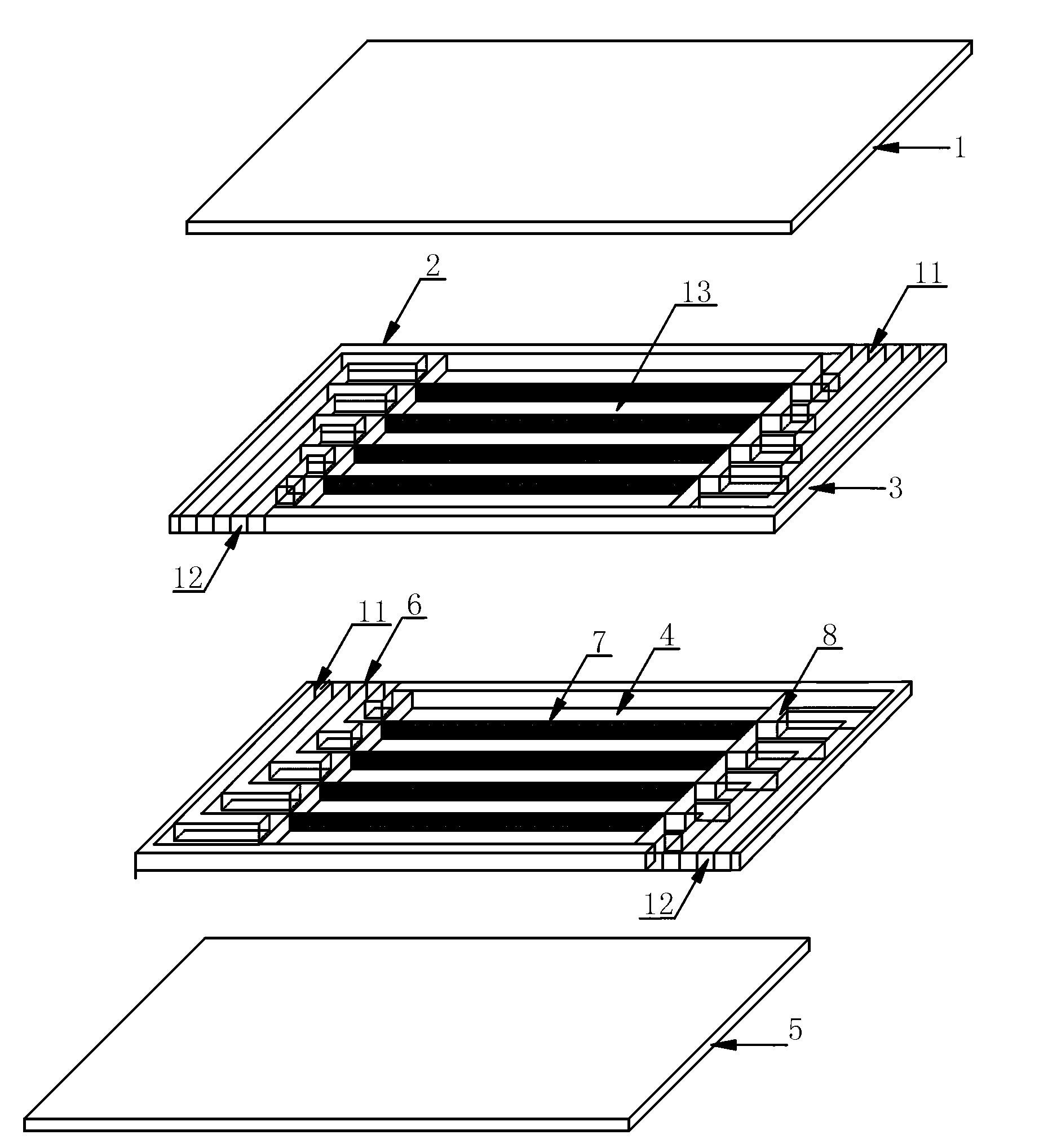

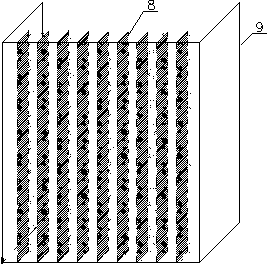

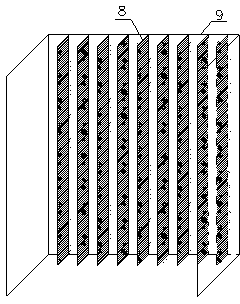

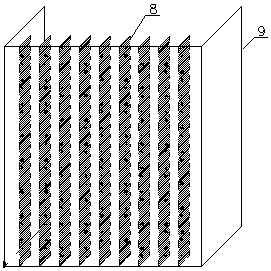

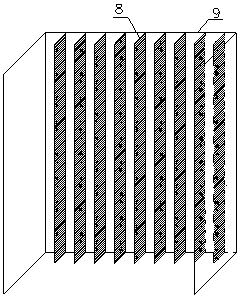

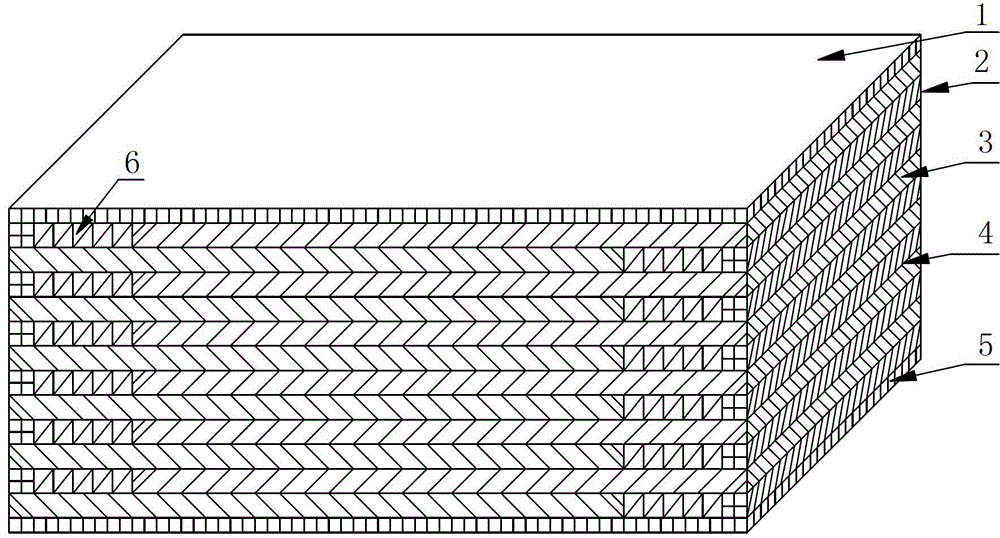

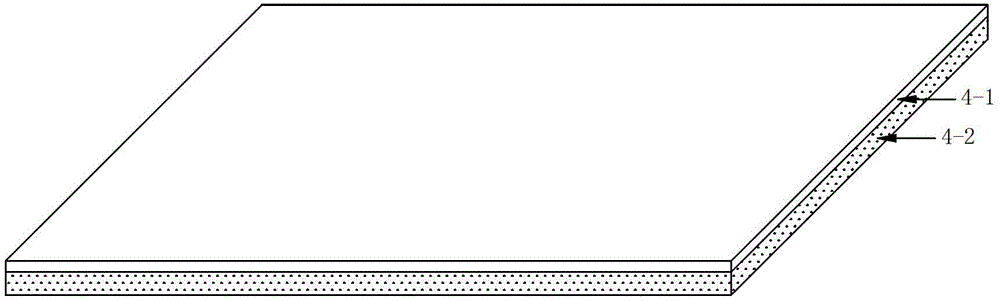

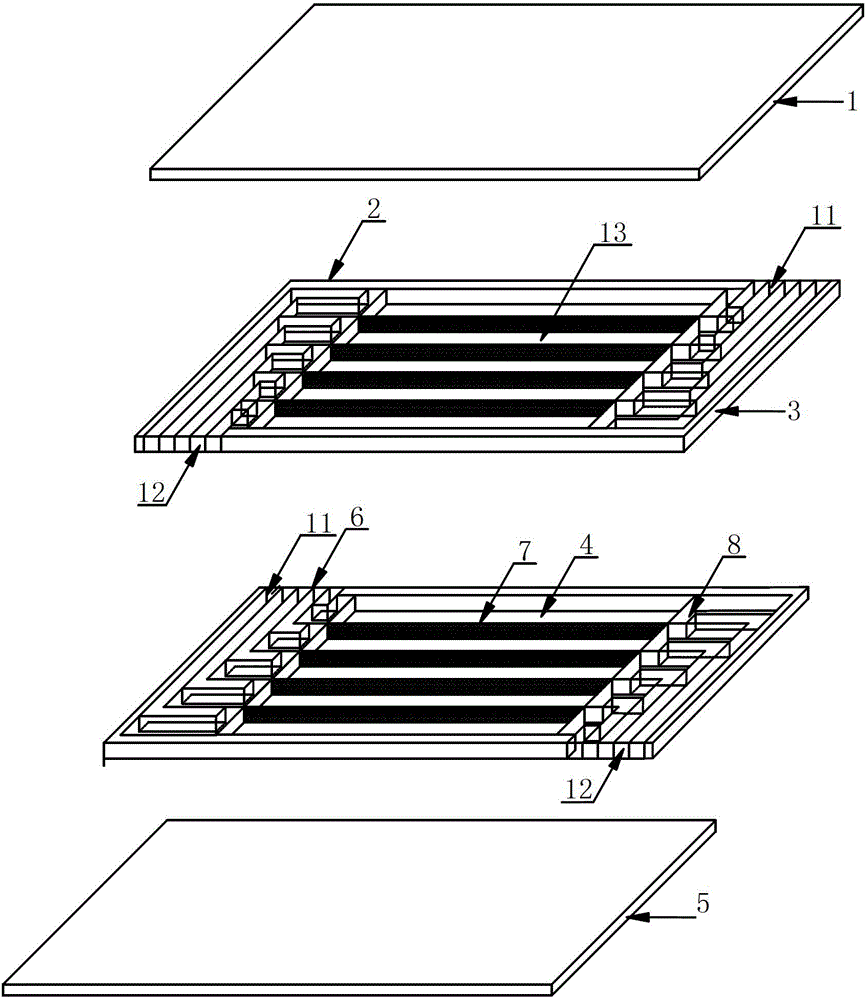

Guide plate film type total-heat heat exchange core body for fresh air ventilator

InactiveCN103175292AImprove cleanlinessSimple structureSpace heating and ventilation detailsStationary plate conduit assembliesFriction lossHeat transfer efficiency

The invention provides a guide plate film type total-heat heat exchange core body for a fresh air ventilator. The guide plate film type total-heat heat exchange core body comprises a top plate, a bottom plate, and heat exchange units. Each heat exchange unit is composed of a heat exchange composite film, a supporting frame, an airflow baffle and a guide plate, wherein each heat exchange composite film and each supporting frame are fixedly connected for forming a bottom surface of each supporting frame. Each supporting frame is provided with an air inlet and an air outlet, and each airflow baffle perpendicular to each heat exchange composite film is arranged on each air inlet or each air outlet. Each guide plate is vertically arranged on the surface of the each heat exchange composite film for forming a heat exchange channel, two ends of each heat exchange channel are connected with an air inlet channel or an air outlet channel through a reducing and increasing pipe, and communication between each air inlet and each air outlet can be achieved. At least two heat exchange units are arranged between the top plate and the bottom plate in a stacking mode, air inlets and air outlets of two adjacent heat exchange units are opposite in position, and the air inlets and the air outlets of two alternating heat exchange units are identical in position. The guide plate film type total-heat heat exchange core body is excellent in heat and mass transfer property, high in heat transfer efficiency, small in resistance loss and size, low in cost and convenient to apply.

Owner:CENT SOUTH UNIV

Shell and tube sewage heat exchanger

InactiveCN102288053BImprove heat transfer efficiencyImprove reliabilityStationary tubular conduit assembliesHeat exchange apparatusFilter systemEngineering

Owner:王英慧

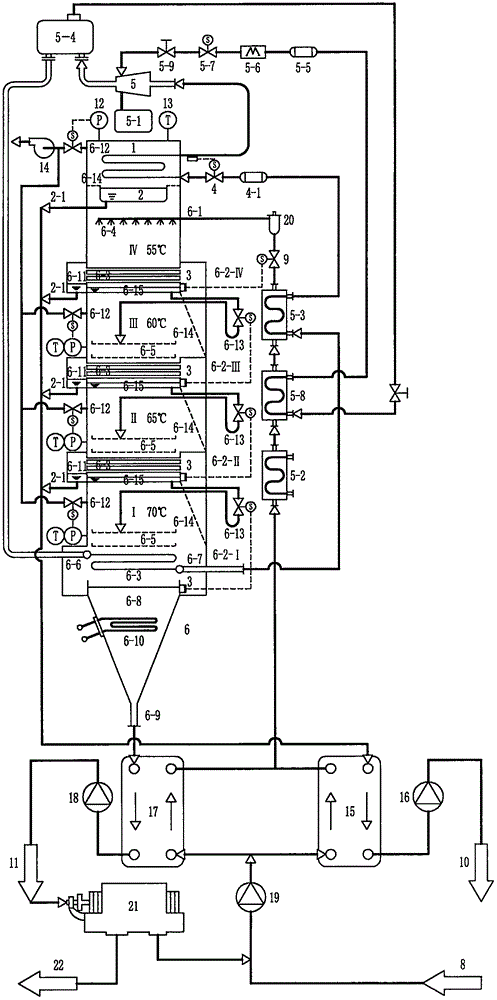

Condensed steam source heat pump driven multi-effect horizontal pipe falling film distillation column

InactiveCN106582054AProvide independentRealize countercurrent heat exchangeEnergy recuperation in distillationFractional distillationMulti effectSteam condensation

The invention provides a condensed steam source heat pump driven multi-effect horizontal pipe falling film distillation column. A condensed steam source heat pump, heat pipe heat exchange, a horizontal pipe falling film and multi-effect distillation are integrated in a system, and the distillation column is a transboundary product of the heat pump industry, the heat exchange industry and the distillation industry. Last-effect secondary steam condensation latent heat is directly recycled through the condensed steam source heat pump, and it is achieved that a condenser independently provides a heat source needed by first-effect distillation. By means of open-type multi-level heat pipe overlaying, the distillation process of countercurrent flow heat exchange, the horizontal pipe falling film and single-column multiple effects is achieved, and the secondary steam condensation latent heat is utilized effect by effect. Integrated design of the condenser, a multi-effect horizontal pipe falling film distillation column and an evaporator is achieved. The multi-effect horizontal pipe falling film distillation process driven by the condensed steam source heat pump is achieved.

Owner:侴雨宏 +1

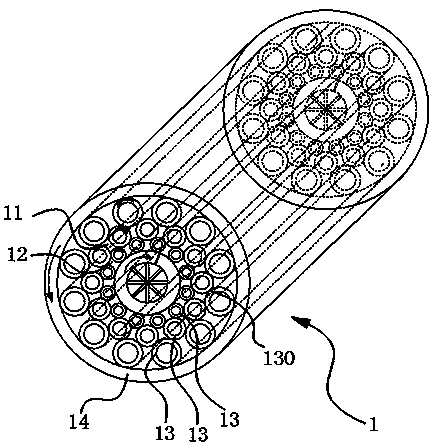

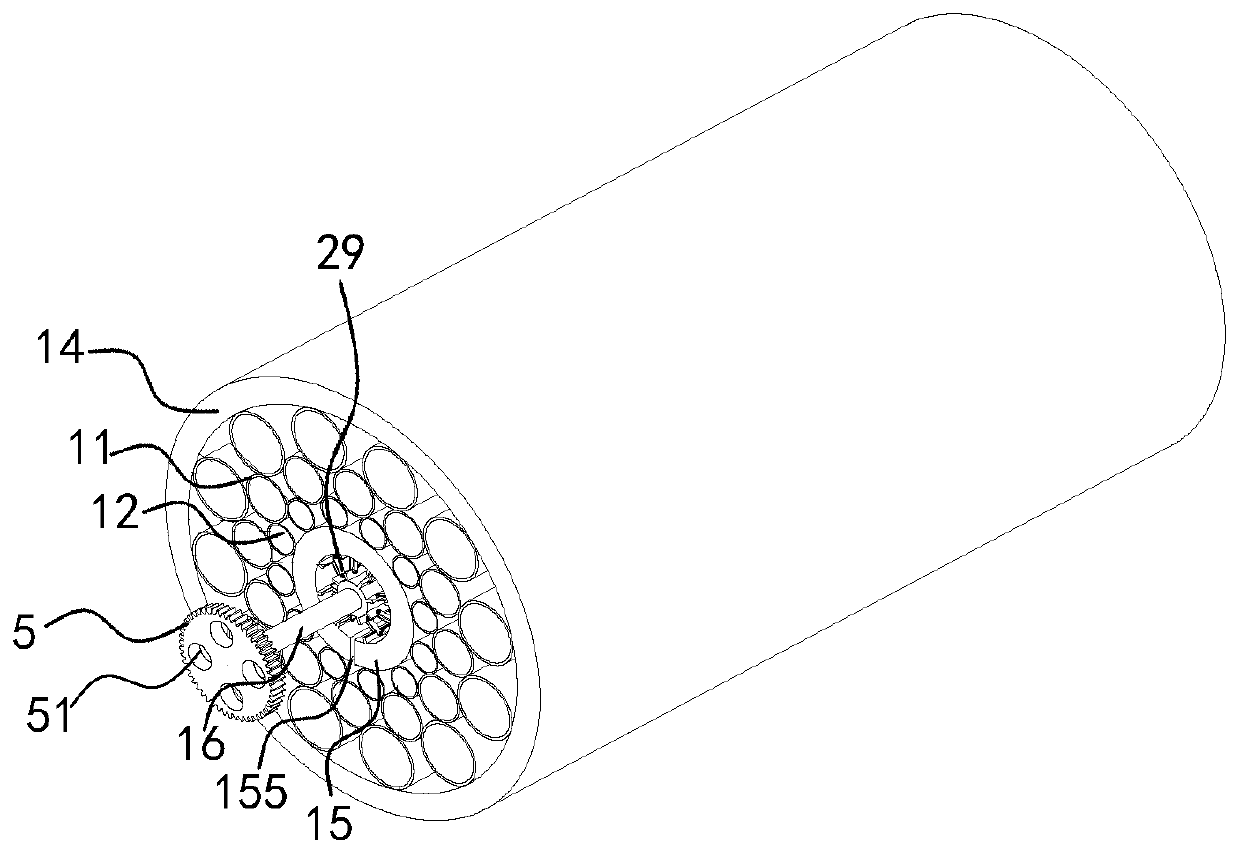

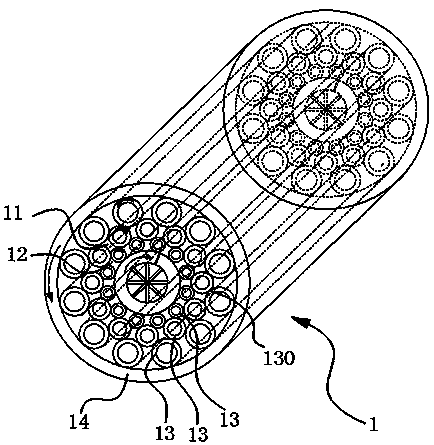

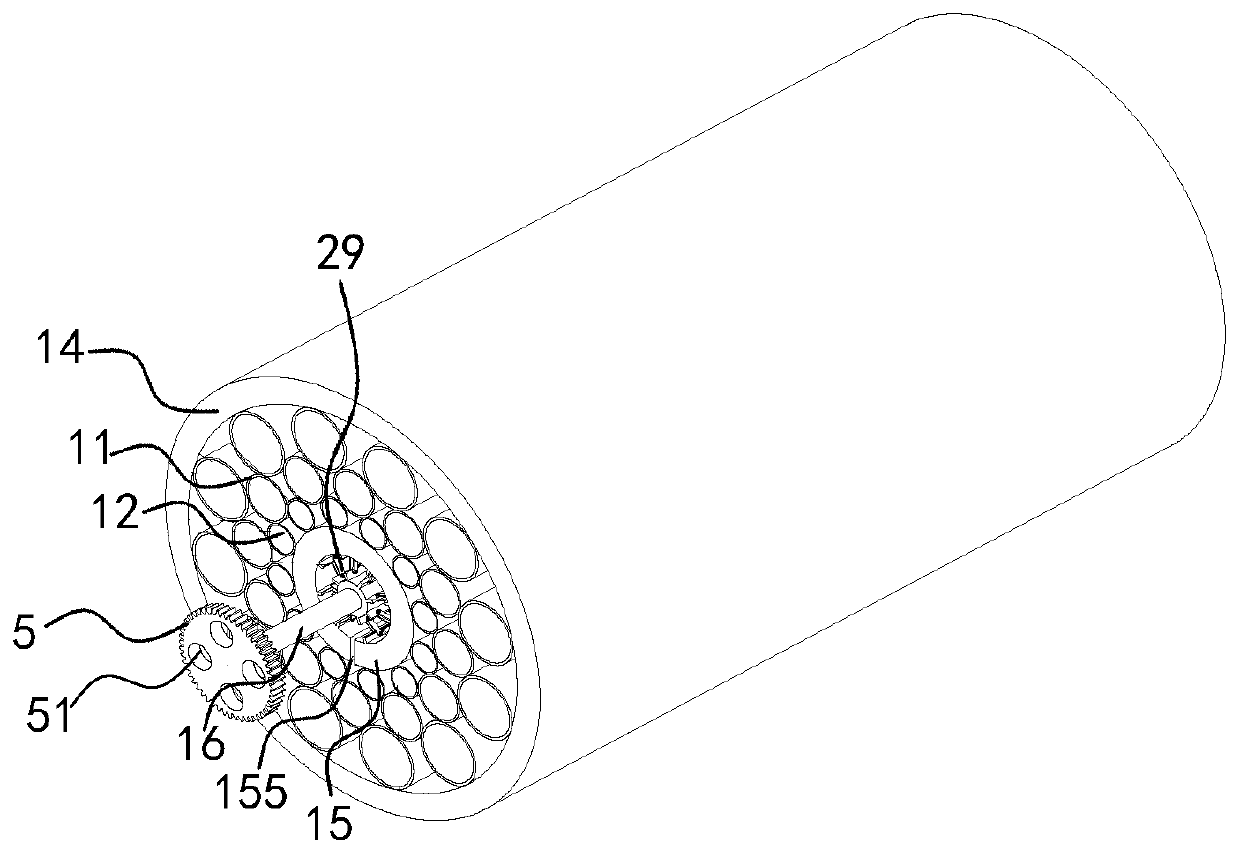

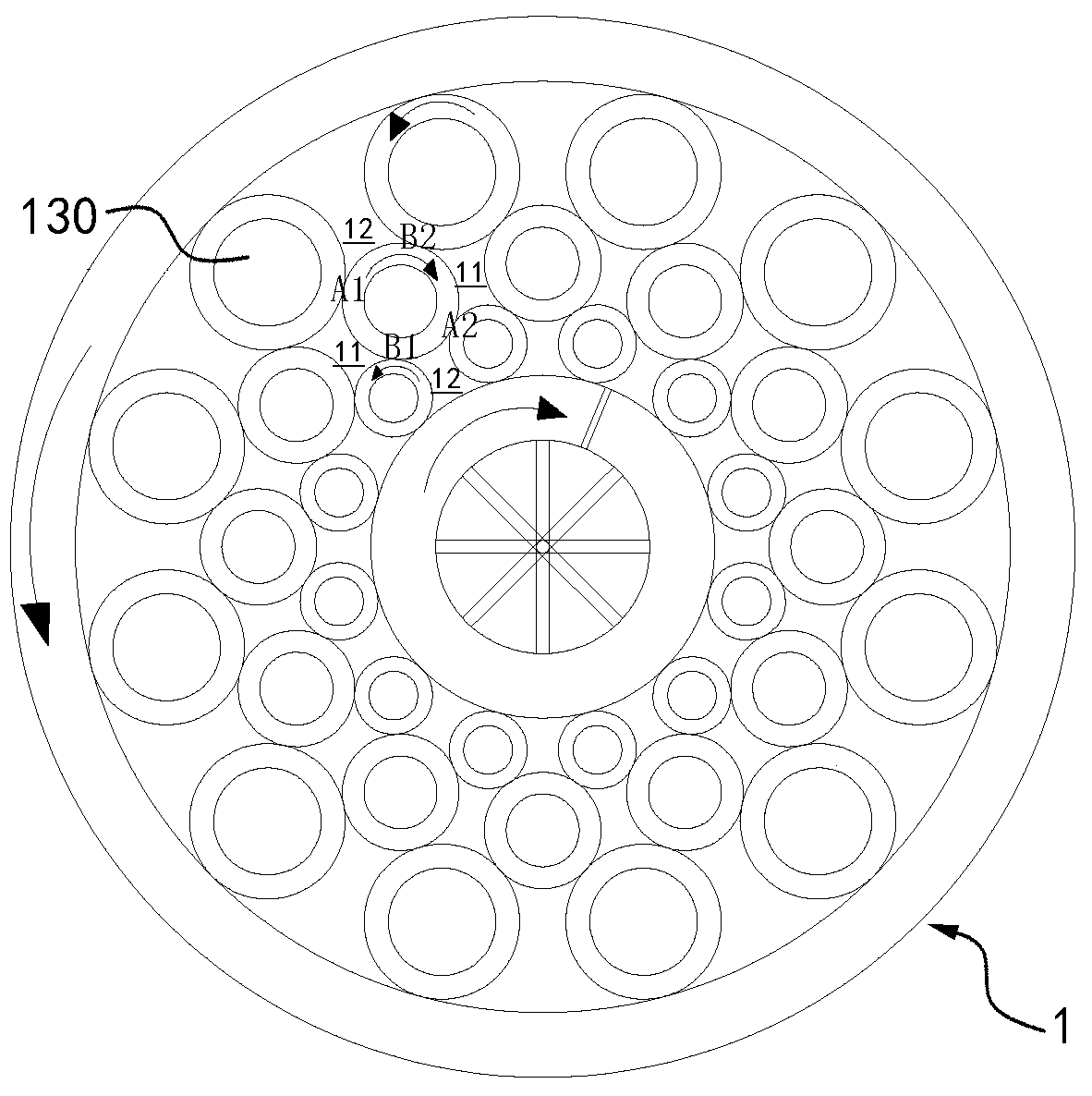

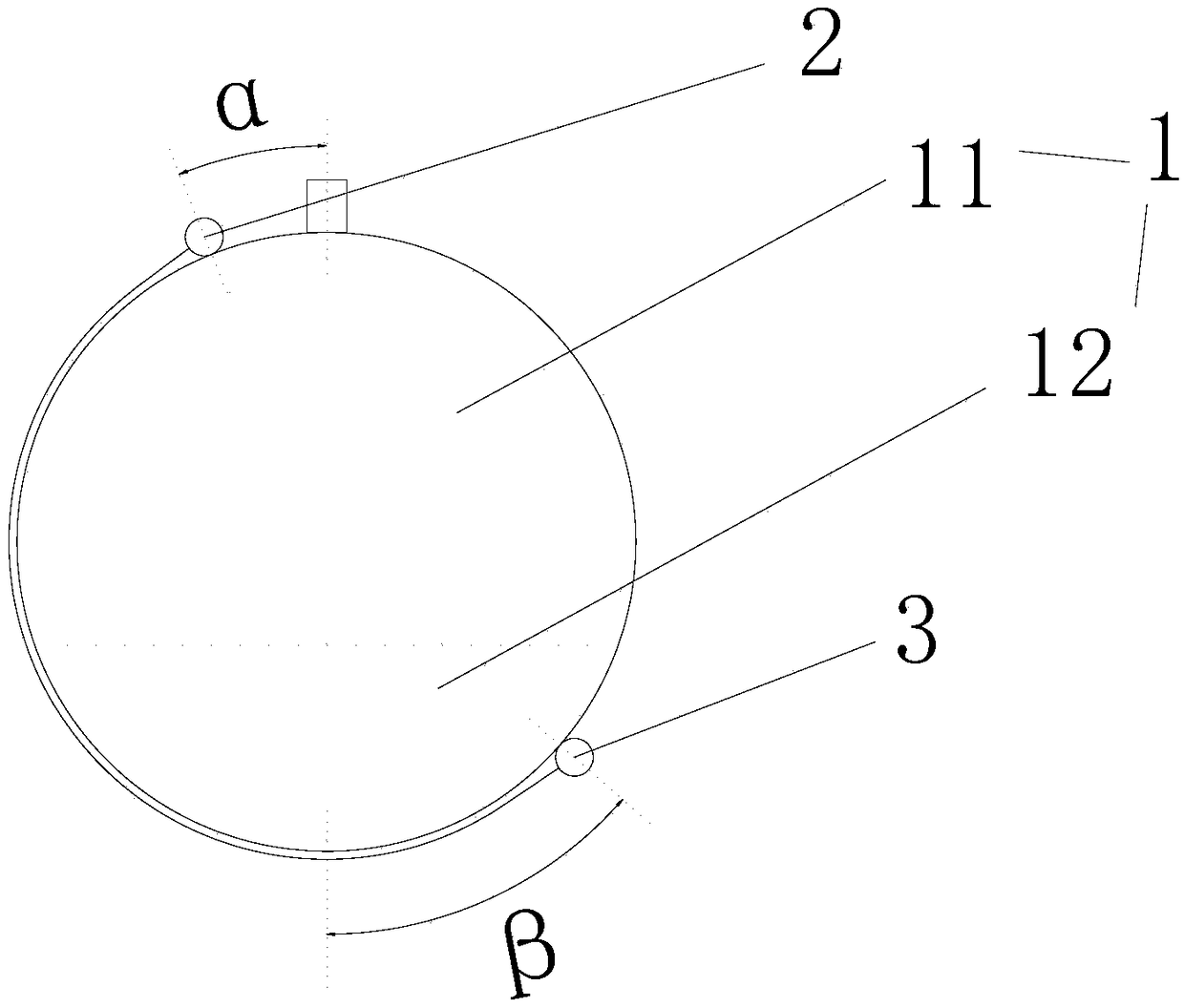

Heat exchanger suitable for high temperature and wide pressure difference as well as heat exchange mechanism

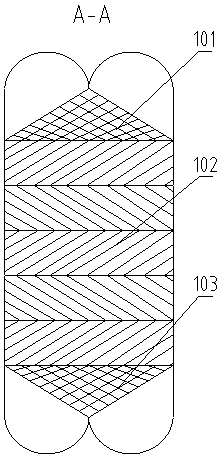

ActiveCN110822953ASolve the heat transfer problem at high temperature (≥1000°C)Realize countercurrent heat exchangeHeat exchanger casingsStationary tubular conduit assembliesEngineeringPressure difference

The invention discloses a heat exchanger suitable for high temperature and wide pressure difference as well as a heat exchange mechanism. The heat exchange mechanism comprises a cylinder body, a corecolumn and a plurality of unit layers, wherein the cylinder body has a cylindrical structure; the core column and the cylinder body are coaxially arranged, and the outline of the core column is cylindrical; each unit layer comprises a plurality of rotary cylinders which surround the core column uniformly and are parallel with the core column; a plurality of unit layers are sequentially arranged onthe core column and are clamped between the core column and the cylinder body; the rotary cylinders positioned on the same layer have the same diameter; and each layer of rotary cylinders have the same number and are arranged uniformly. The heat exchanger and the heat exchange mechanism have high heat exchange efficiency and can be applied to heat exchange scenes with high temperature and wide pressure difference.

Owner:BEIJING FUDIAN ENG TECH CO LTD

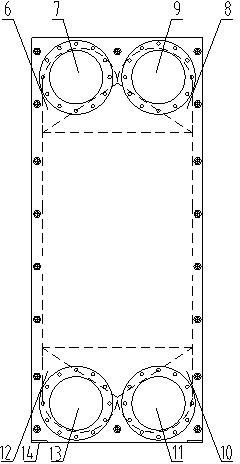

Welded plate frame type heat exchanger

InactiveCN104748591ASolve the problem of expansion crack failureResolve bundle thermal expansion deformationHeat exchanger casingsStationary plate conduit assembliesThermal expansionEngineering

Disclosed is a welded plate frame type heat exchanger. The welding plate frame type heat exchanger comprises a welded heat exchange plate bundle, plate bundle cold and hot end headers and cold and hot medium inlet and outlet connecting tubes; a first pressing plate, a second pressing plate and clamping bolts and nuts form a frame in a space structure; the heat exchange plate bundle is mounted inside the frame; the first pressing plate and the second pressing plate are pressed through the clamping bolts and nuts and fixedly welded with the heat exchange plate bundle; the welded heat exchange plate bundle is connected with the cold and hot medium inlet and outlet connecting tubes through the plate bundle cold and hot end headers to form the welding plate frame type heat exchanger. The welding plate frame type heat exchanger solves the problem of thermal expansion and deformation of plate type heat exchangers during practical work and has the advantages of being capable of changing the plate bundle, heat-resistant, pressure-resistant, high in integral compactness and the like.

Owner:GANSU LANPEC TECH

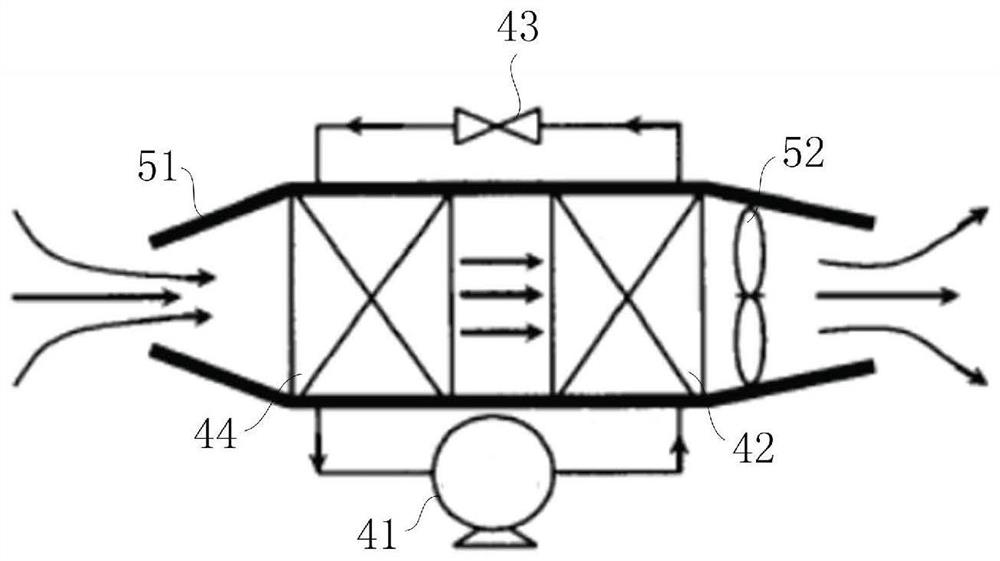

Drying system and clothes treating equipment comprising same

PendingCN112323341AReduce the burden onImprove dehumidification effectWashing machine with receptaclesTextiles and paperEngineeringMechanical engineering

The invention relates to the technical field of clothes treatment, in particular to a drying system and clothes treatment equipment comprising the same. The problems that an existing drying system islong in drying time and large in energy consumption are solved. The drying system comprises a refrigerant circulation loop, an air circulation loop and a cooling circulation loop, wherein the refrigerant circulation loop comprises a compressor, a condenser, a throttling element and an evaporator; the air circulation loop comprises a drying chamber, a gas-liquid heat exchanger, an evaporator and acondenser, an air inlet of the gas-liquid heat exchanger communicates with a wet air outlet of the drying chamber, an air outlet of the gas-liquid heat exchanger communicates with an inlet of the evaporator, an outlet of the evaporator communicates with an inlet of the condenser, and an outlet of the condenser communicates with a dry air inlet of the drying chamber; and the cooling circulation loop comprises a water pan, a water pump and a gas-liquid heat exchanger, a liquid inlet and a liquid outlet of the gas-liquid heat exchanger communicate with a first part and a second part of the waterpan respectively, and a refrigerant pipe part is arranged on the second part in a coiled mode. The dehumidification capacity of the evaporator can be guaranteed, and the drying energy consumption is reduced.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

Double-loop solar heating and heat exchanging combined device

ActiveCN104633748AIncrease profitImprove effective utilizationLighting and heating apparatusSpace heating and ventilation detailsThin metalBuilding integration

The invention relates to a double-loop solar heating and heat exchanging combined device. A plurality of double-flow-channel heat transferring units are arranged in parallel. Each double-flow-channel heat transferring unit is internally provided with two flow channels. Every two flow channels are partitioned through thin metal walls. The upper end and the lower end of one flow channel are connected with an upper collecting pipe and a lower collecting pipe of an auxiliary heat source loop, and the upper end and the lower end of the other flow channel are connected with an upper collecting pipe and a lower collecting pipe of a solar loop. Two working modes are adopted for the device, one mode is a heating mode, and the other mode is a heat exchanging mode. The heating mode is further divided into three operating modes, the operating modes can be selected according to the weather situation, heat dissipation cladding is adopted for the heating season, and the heat provided by the solar energy or an auxiliary heat source is released into a room through the heat dissipation cladding. According to the heat exchanging mode, in the non-heating season, the heat dissipation clapping is changed to be heat preservation cladding, and in the double-flow-channel heat transferring units, the heat in the solar loop is transferred to the auxiliary heat source loop. The double-loop solar heating and heat exchanging combined device can be combined with a conventional concentrated heating system, solar energy is fully utilized, the system is simplified, energy efficiency is improved, and integration of the solar energy and a building is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Solar heat storage and high temperature gas generation system using quicksand as working medium

ActiveCN103392068BStable generationContinuousSolar heating energySolar heat devicesProcess engineeringHigh pressure

Owner:陈裕启

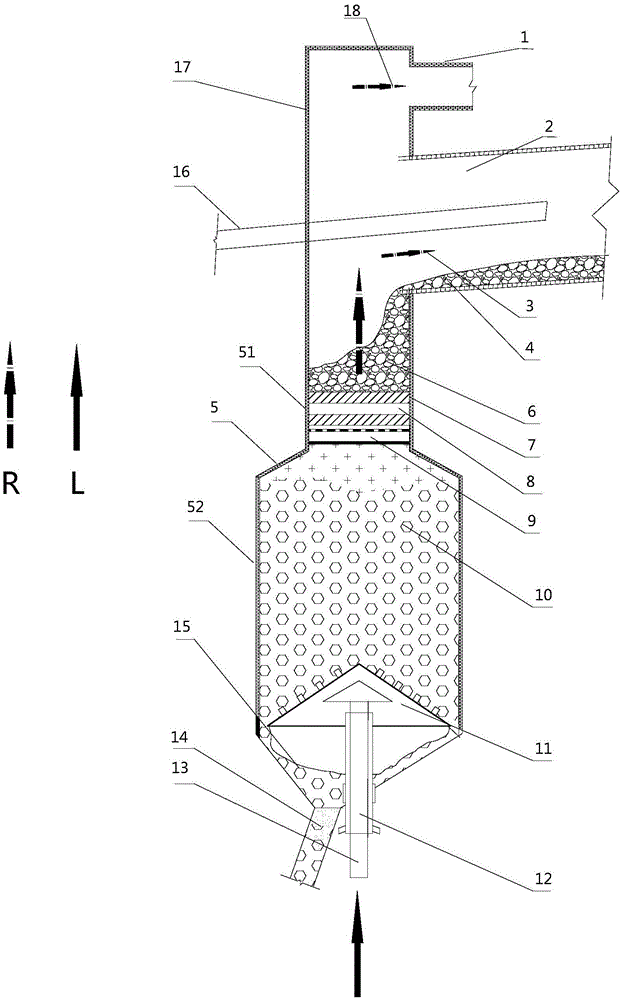

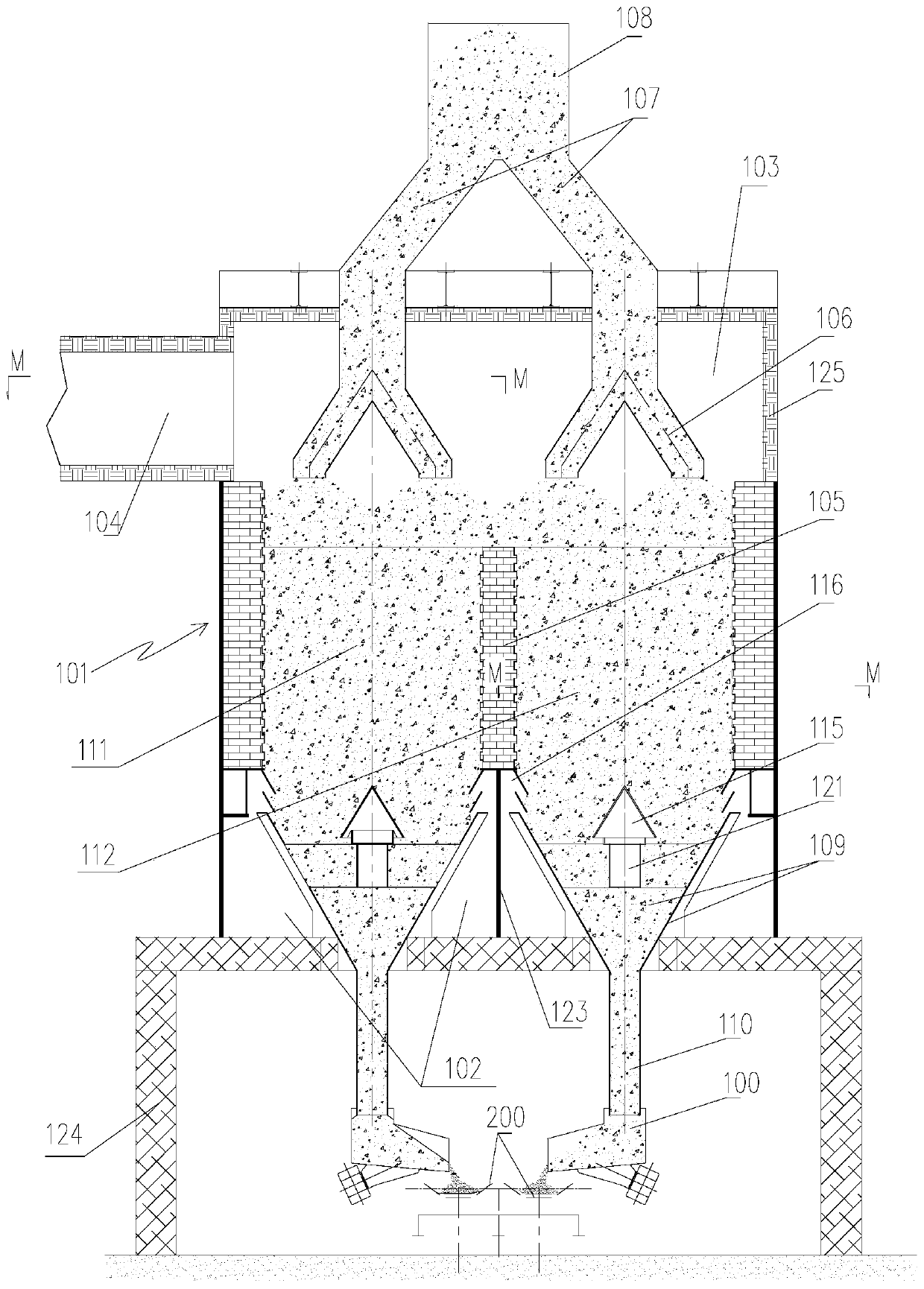

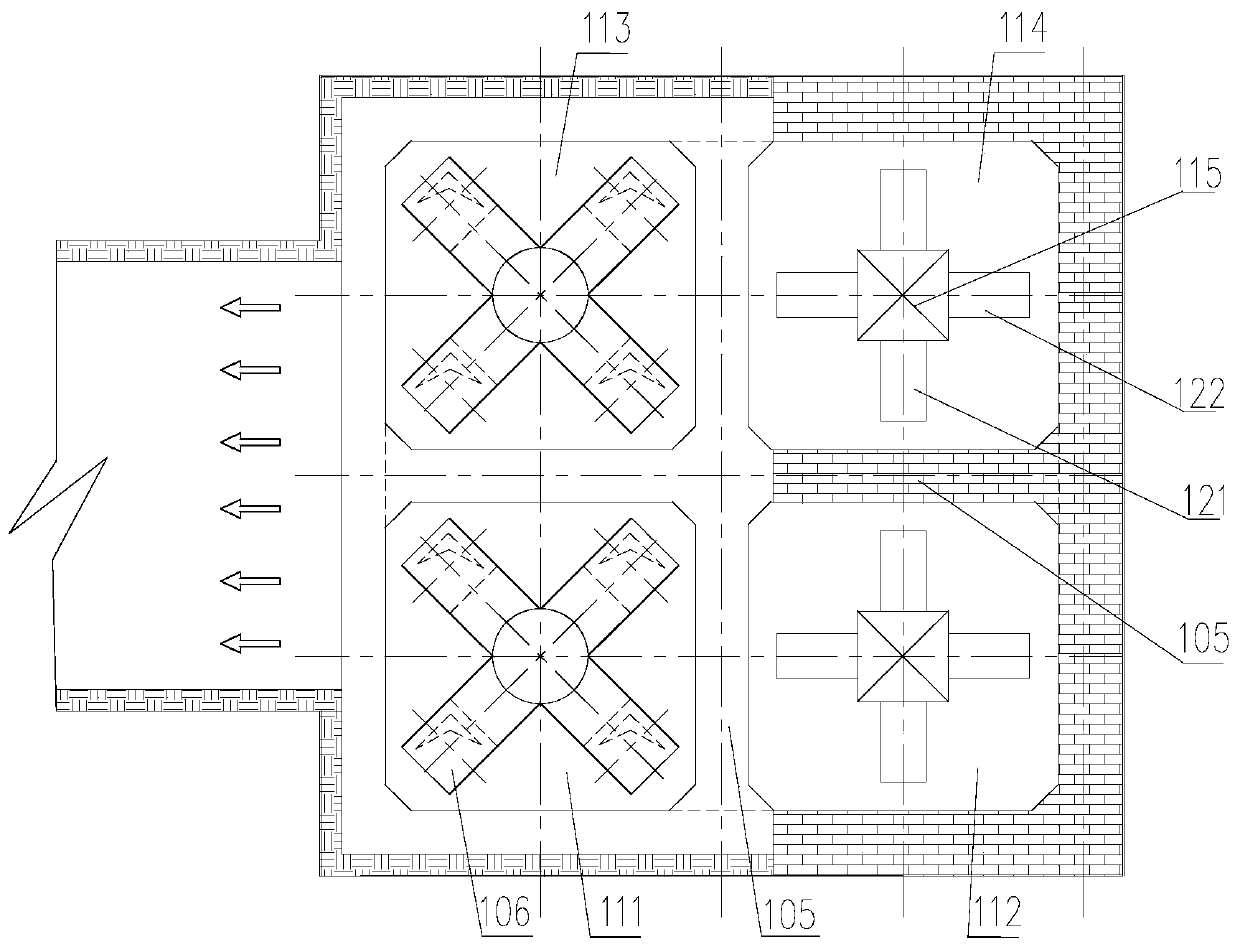

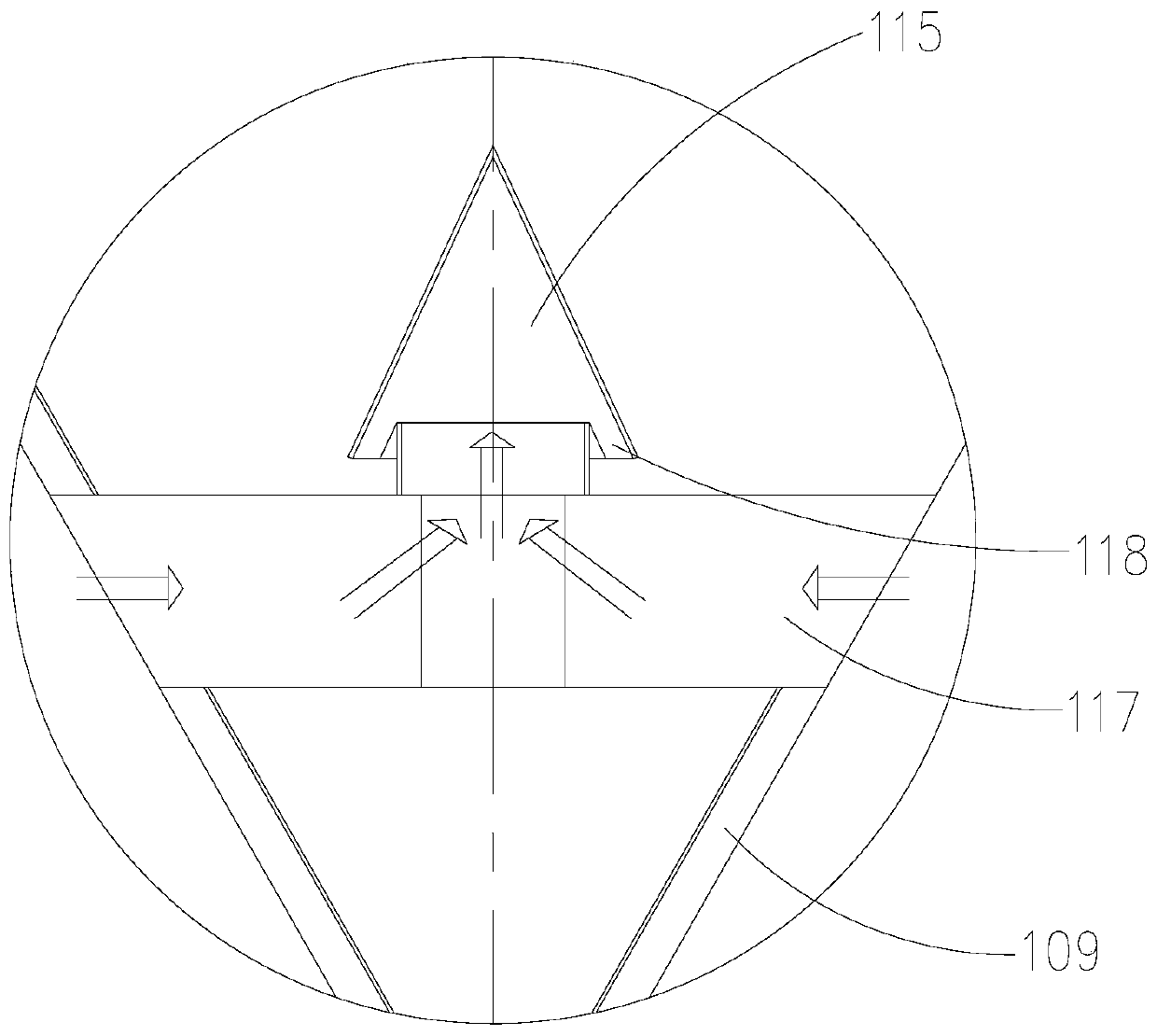

A vertical cement clinker cooler

InactiveCN104359321BRealize countercurrent heat exchangeIncrease profitHandling discharged materialClinker productionCouplingGas exchange

The invention provides a vertical cement clinker cooling machine, and belongs to a solid material cooler. The vertical cement clinker cooling machine comprises a cylinder body, wherein the cylinder body consists of an upper vertical cylinder and a lower vertical cylinder which are in tight coupling, a material inlet is connected with the upper part of the upper vertical cylinder, a crushing machine is arranged in the upper vertical cylinder, a discharging machine is arranged in the lower vertical cylinder and is driven by a transmission mechanism, a discharging tube is arranged at the bottom of the lower vertical cylinder, a fixed shaft of the transmission mechanism is a hollow air inlet tube, and the air inlet tube is communicated with the interior of the lower vertical cylinder. The vertical cement clinker cooling machine has high heat exchange efficiency and heat utilization efficiency so that materials and gas exchange heat in a countercurrent flow manner, and the hot solid materials are quickly cooled down. Therefore, the characteristics that the energy consumption and the cost are low are achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Vertical cooling kiln and mineral aggregate cooling and waste heat recovery method

PendingCN110779323AImprove uniformityRealize countercurrent heat exchangeVertical furnacesWaste heat treatmentThermodynamicsHot blast

The invention relates to the technical field of sinter cooling devices, in particular to a vertical cooling kiln and a mineral aggregate cooling and waste heat recovery method. The vertical cooling kiln comprises a kiln body, an inner ring air supply device, and an outer ring air supply device, wherein a cooling air supply chamber is arranged at the bottom of the kiln body, a hot air concentrationchamber is arranged at the top of the kiln body, and at least one cooling unit chamber is arranged between the cooling air supply chamber and the hot air concentration chamber; the cooling air supplychamber is used for providing cooling air to the cooling unit chambers, and the hot air concentration chamber is used for communicating with a hot air delivery channel; the inner ring air supply device is used for making the cooling air flow to the periphery from the centers of the cooling unit chambers; and an outer ring air inlet of the outer ring air supply device communicates with the coolingair supply chamber, and the outer ring air supply device is used for making the cooling air flow from the periphery of the cooling unit chambers to the centers. According to the vertical cooling kilnand the method, the uniformity of air supply into the cooling unit chambers can be improved, the uniform cooling of a mineral aggregate is realized, and the waste heat recovery efficiency is improved.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

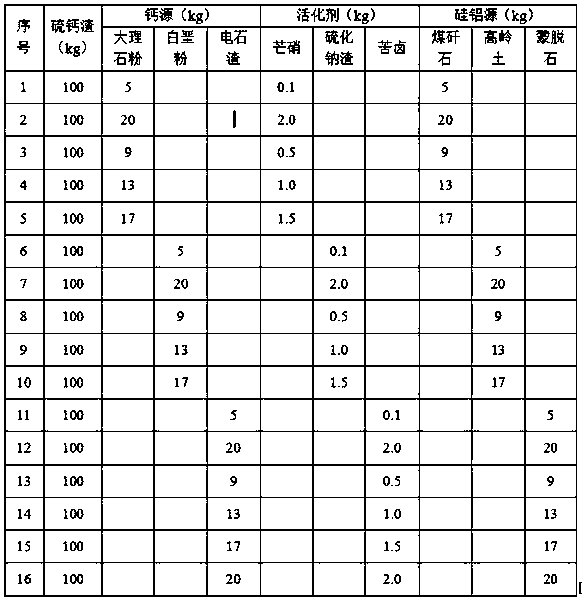

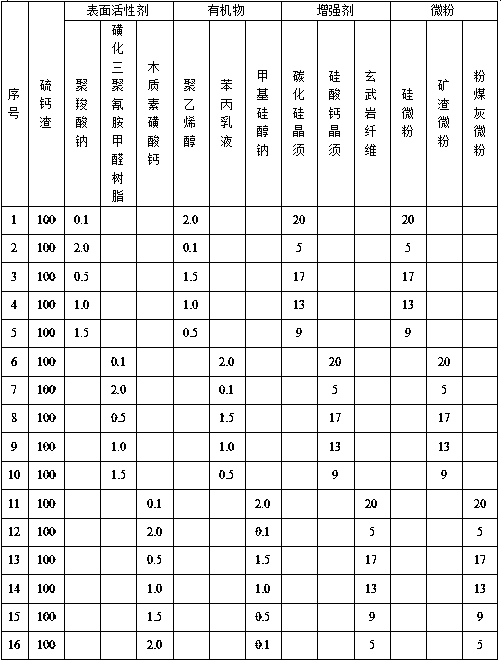

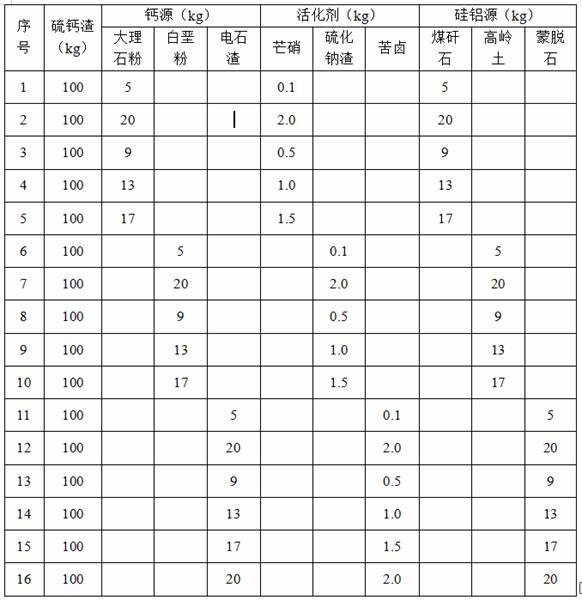

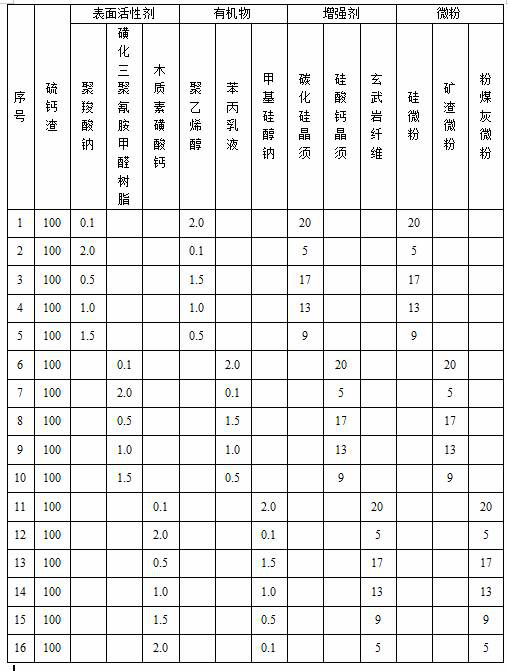

Method for preparing high-strength anhydrous gypsum from sulfur-calcium slag

The invention discloses a method for preparing high-strength anhydrous gypsum from sulfur-calcium slag. The method comprises the following steps: adding the sulfur-calcium slag, a calcium source, an activator and a silicon-aluminum source into a drying scatter to obtain a dry material, adding the dry material into a countercurrent dryer for dehydrating, cooling the material in a fluidized bed to obtain anhydrous gypsum, adding a surfactant, an organic matter, a reinforcing agent and micro powder into the anhydrous gypsum, and carrying out uniform mixing to obtain the high-strength anhydrous gypsum. The method is low in production cost and high in efficiency, and high-quality cyclic utilization of resources is achieved.

Owner:四川地维科技有限公司

Efficient shell tube type heat exchanger and manufacturing method thereof

ActiveCN104819651AImprove heat transfer coefficientPrevent dripping from affecting heat transferEvaporators/condensersHeat exchanger casingsBusiness efficiencyLiquid state

The invention discloses an efficient shell tube type heat exchanger and a manufacturing method of the heat exchanger. Gaseous refrigerants of an upper layer heat exchange tube surface of the heat exchanger are cooled to liquid, and the liquid is dropped and poured to a lower layer heat exchange tube surface level by level from the upper layer heat exchange tube surface, and then dropped and poured to a dropping and pouring prevention partition plate, it is ensured that a lower layer heat exchange tube cannot be dropped and poured by liquid-state refrigerants of an upper layer heat exchange tube, the contact area of the lower layer heat exchange tube and the gaseous refrigerants is increased, heat resistance is reduced, and the heat exchange effect is improved; the refrigerants are located outside a heat exchange tube to flow, cooling water is located in the heat exchange tube to flow, but, the flowing direction of the cooling water is reverse, backward flowing of two strands of fluid of the refrigerants and the cooling water can be achieved, the surface heat exchange coefficient of the heat exchange tube is improved, the heat exchange effect is improved, and the heat exchange performance of the reverse flow shell type heat exchanger is greatly improved. Compared with a traditional shell tube type heat exchanger, the phenomenon that the liquid-state refrigerants of the surface of the heat exchange tube are dropped and poured to the position between tube layers, and heat exchange is affected is avoided, the reverse flow heat exchange of two kinds of heat exchange fluid of a shell side and a tube side is achieved, the heat exchange coefficient is higher, the heat exchange temperature difference is more uniform, materials are saved, and meanwhile, the energy efficiency ratio is improved.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

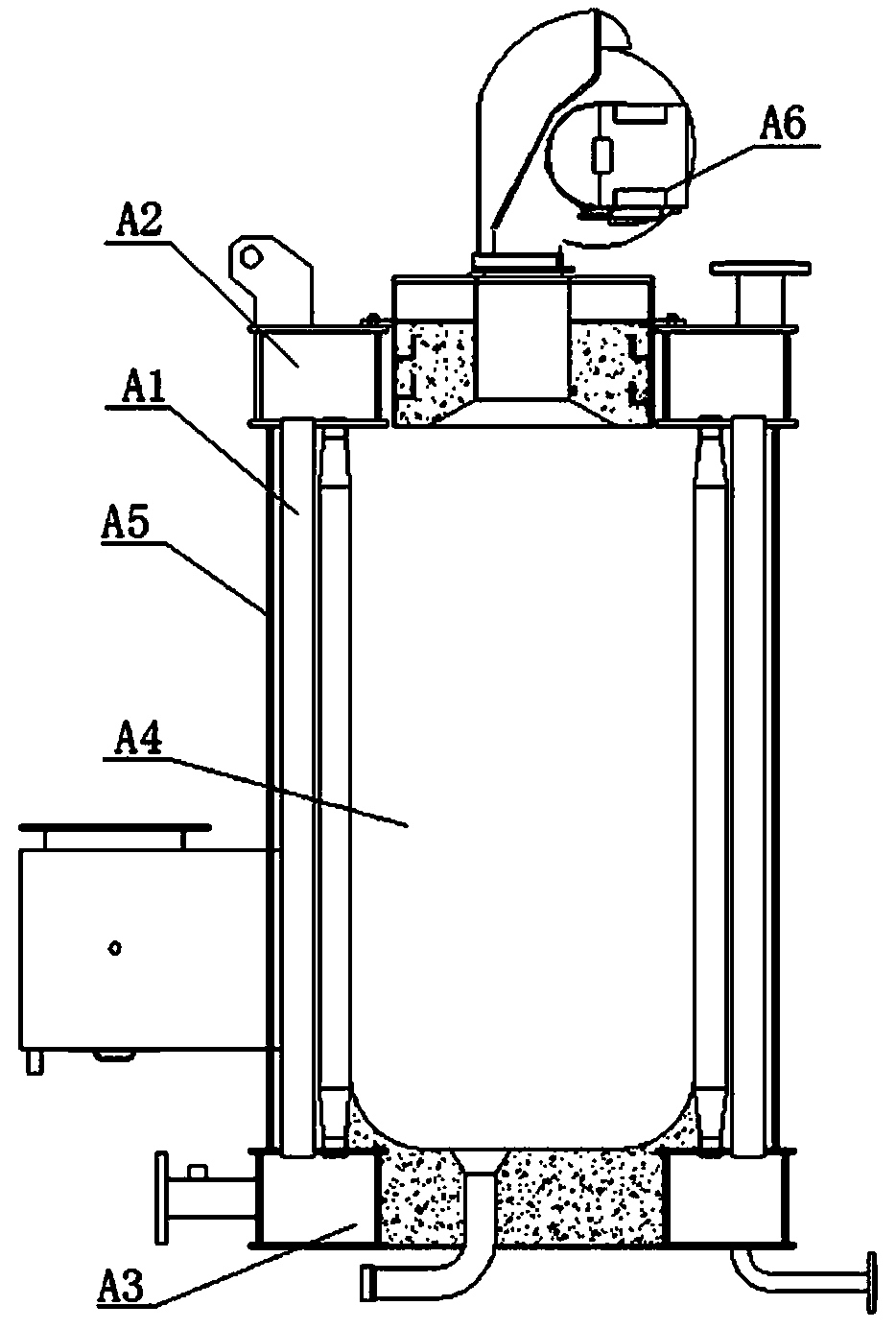

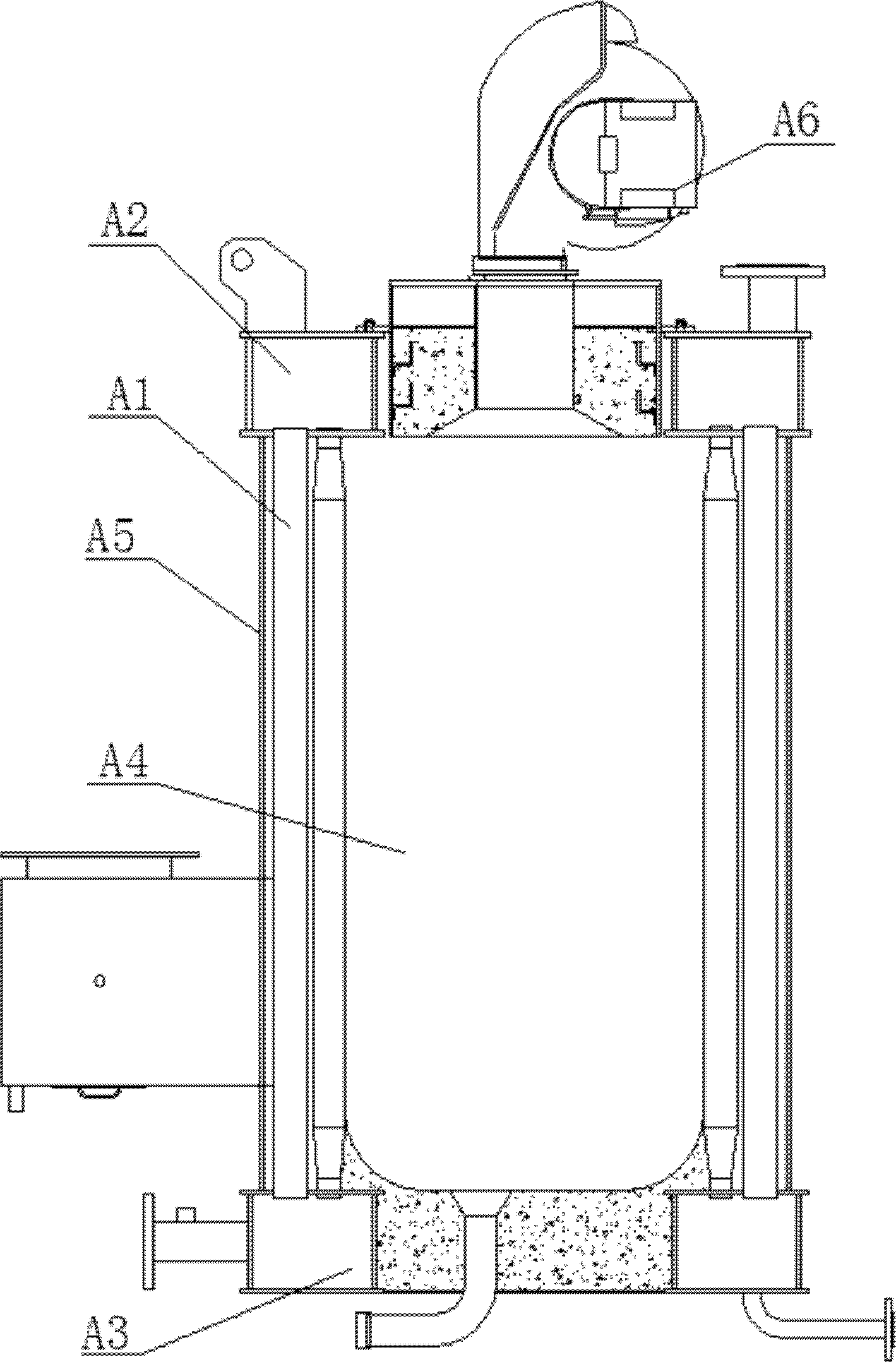

Integrated through-flow normal pressure hot water boiler

InactiveCN103851778AImprove heat transfer effectLow costWater heatersCombustion chamberThermal insulation

The invention discloses an integrated through-flow normal pressure hot water boiler, which comprises a heating surface water pipe, an upper annular collection box, a lower annular collection box, a combustion chamber and a barrel body, wherein the heating surface water pipe is arranged at the internal of the barrel body, the upper and lower ends of the heating surface water pipe are respectively communicated with the upper annular collection box and the lower annular collection box; at least one of the upper annular collection box and the lower annular collection box is provided with at least one heat exchanger; and a thermal insulation downcomer is communicated between the upper annular collection box and the lower annular collection box. According to the invention, the heat exchanger is integrated at the internal of the boiler body, a traditional once circulation water pump and a corresponding matched pipe are cancelled, so that the cost and needed energy consumption of the once circulation water pump are saved and the heat dissipation loss of the once circulation water pump and the matching pipe is also reduced accordingly; by integrating the heat exchanger at the internal of the boiler, the entire system structure of the boiler is more compact.

Owner:TAIJUNE BOILER IND KUSN

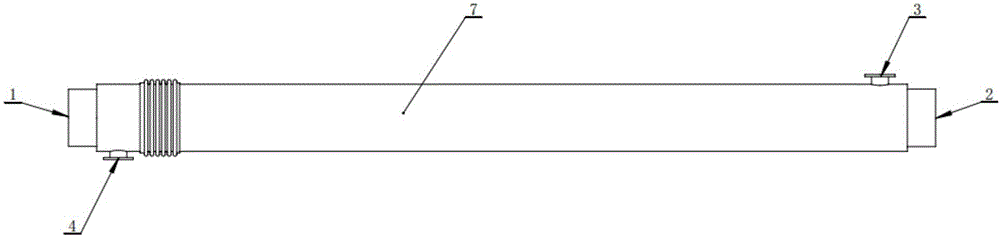

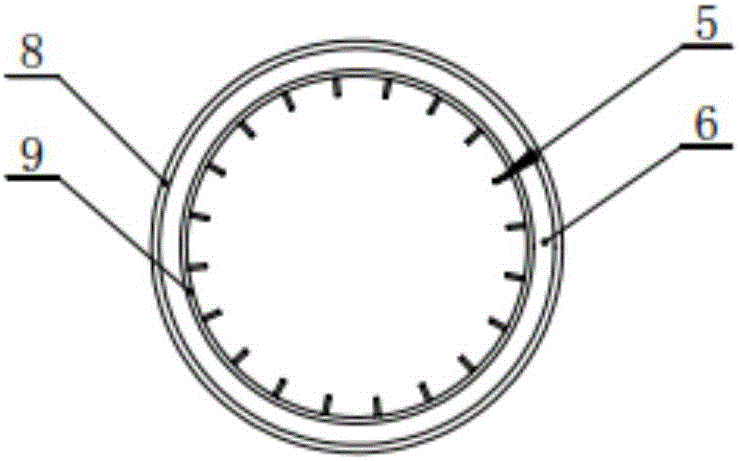

Extension-type gas-solid high-speed two-phase flow efficient heating equipment

InactiveCN106403659AFast heat exchangeSolve the wear lifeStationary tubular conduit assembliesDetonationEngineering

The invention relates to extension-type gas-solid high-speed two-phase flow efficient heating equipment. The extension-type gas-solid high-speed two-phase flow efficient heating equipment comprises a heating pipe, a gas-solid mixture circulation inlet pipe, a gas-solid mixture circulation outlet pipe, a heat source pipe inlet and a dewatering pipe outlet. The gas-solid mixture circulation pipes are arranged in the heating pipe; the heat source pipe inlet is formed in the top end of the outer side of the heating pipe; the dewatering pipe outlet is formed in the tail end of the outer side of the heating pipe; outer sleeves are arranged on the outer sides of the gas-solid mixture circulation pipes; and zones between the outer sleeves and inner pipes serve as heat source circulation pipes, and steam circulates along annular sleeve channels. Rib plates circumferentially arranged at intervals are arranged on the inner side or the outer side of an original gas-solid mixture pipe. A gas-solid mixture passing through the equipment at a high speed can be rapidly heated through the equipment, and the abrasion requirement of the gas(steam)-solid mixture can be met. The problems in friction durability, heat exchange efficiency, circulation resistance, accumulated detonation and the like of the heating equipment are solved.

Owner:北京蓝爱迪电力技术有限公司

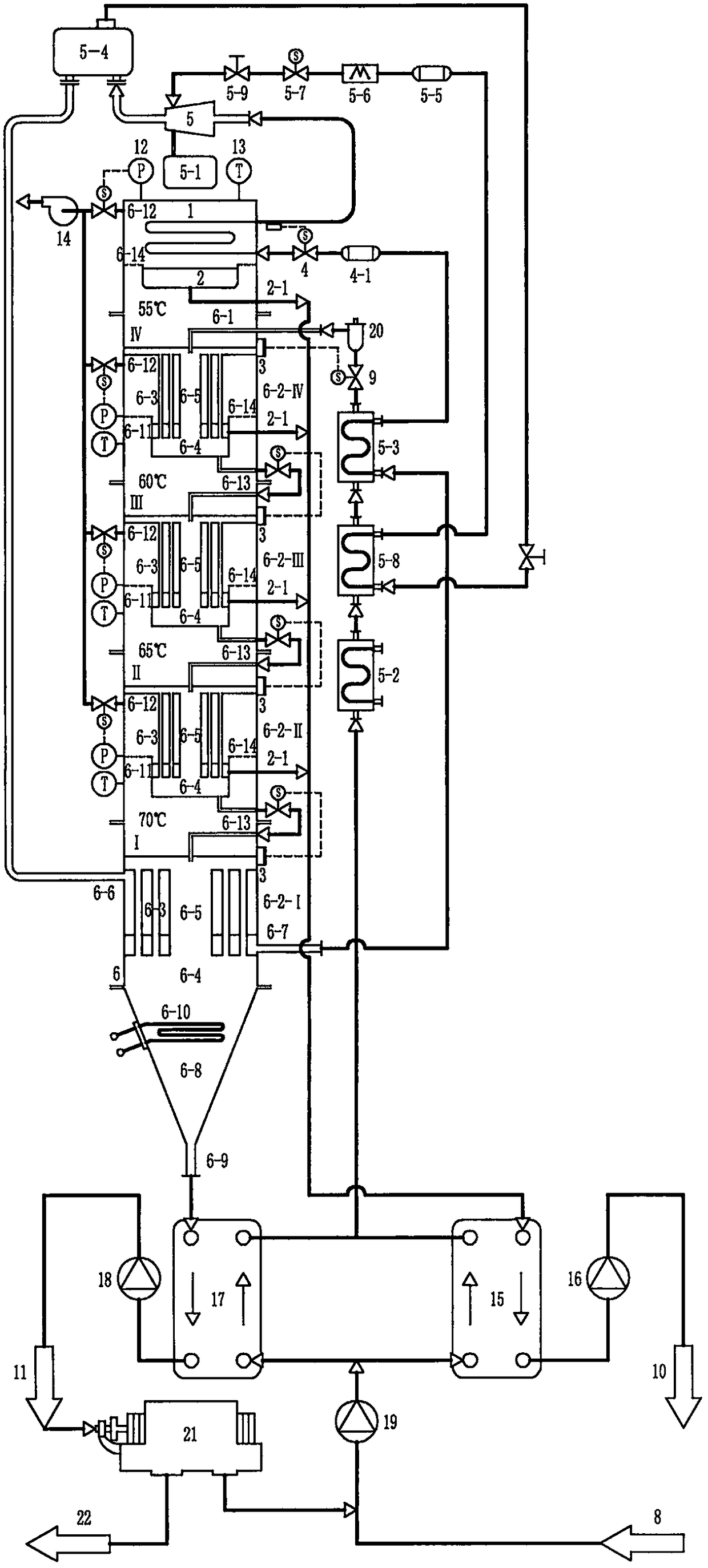

Multiple-effect heat pipe type distillation column driven by condensation steam source heat pump

InactiveCN108379865AProvide independentRealize countercurrent heat exchangeWater/sewage treatment by centrifugal separationHeat recovery systemsEvaporatorMulti effect

The invention provides a multiple-effect heat pipe type distillation column driven by a condensation steam source heat pump. The multiple-effect heat pipe type distillation column driven by a condensation steam source heat pump integrates a condensation steam source heat pump, a heat pipe heat exchanger and multiple-effect distillation technology to form a whole system, and is a cross-boundary product of a heat pump industry, a heat exchange industry and a distillation industry; condensation latent heat of last effect secondary steam is recovered by using the condensation steam source heat pump, and a condenser independently provides the heat source required for first effect distillation; through the superposition of open type multi-stage heat pipes, countercurrent heat change and single-tower and multi-effect distillation technology are realized, and secondary steam condensation latent heat is utilized by effect in order; an integrated design of the condenser, the multiple-effect heattubular type distillation column and an evaporator is realized; and the multiple-effect heat tubular type distillation technology driven by the condensation steam source heat pump is realized.

Owner:侴雨宏 +1

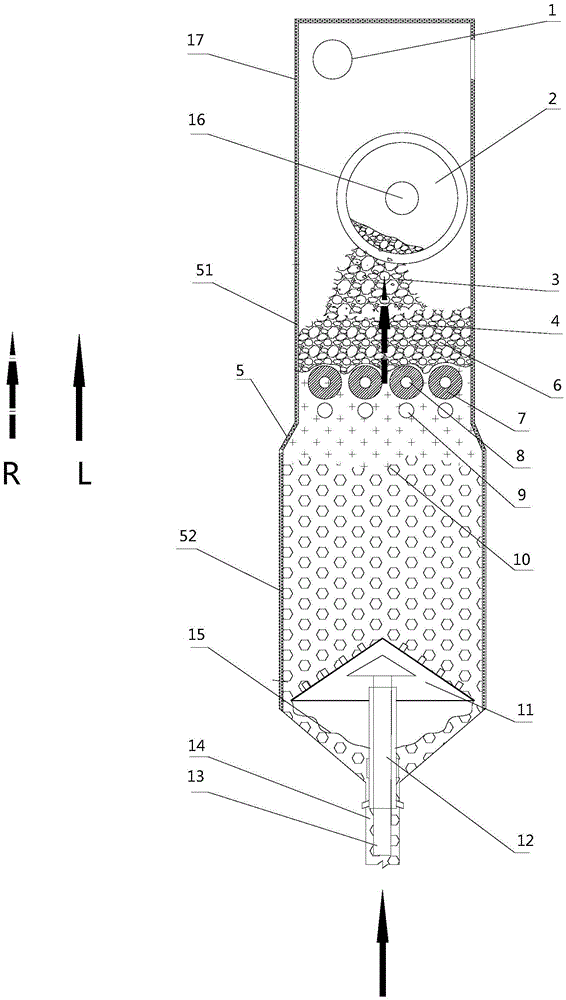

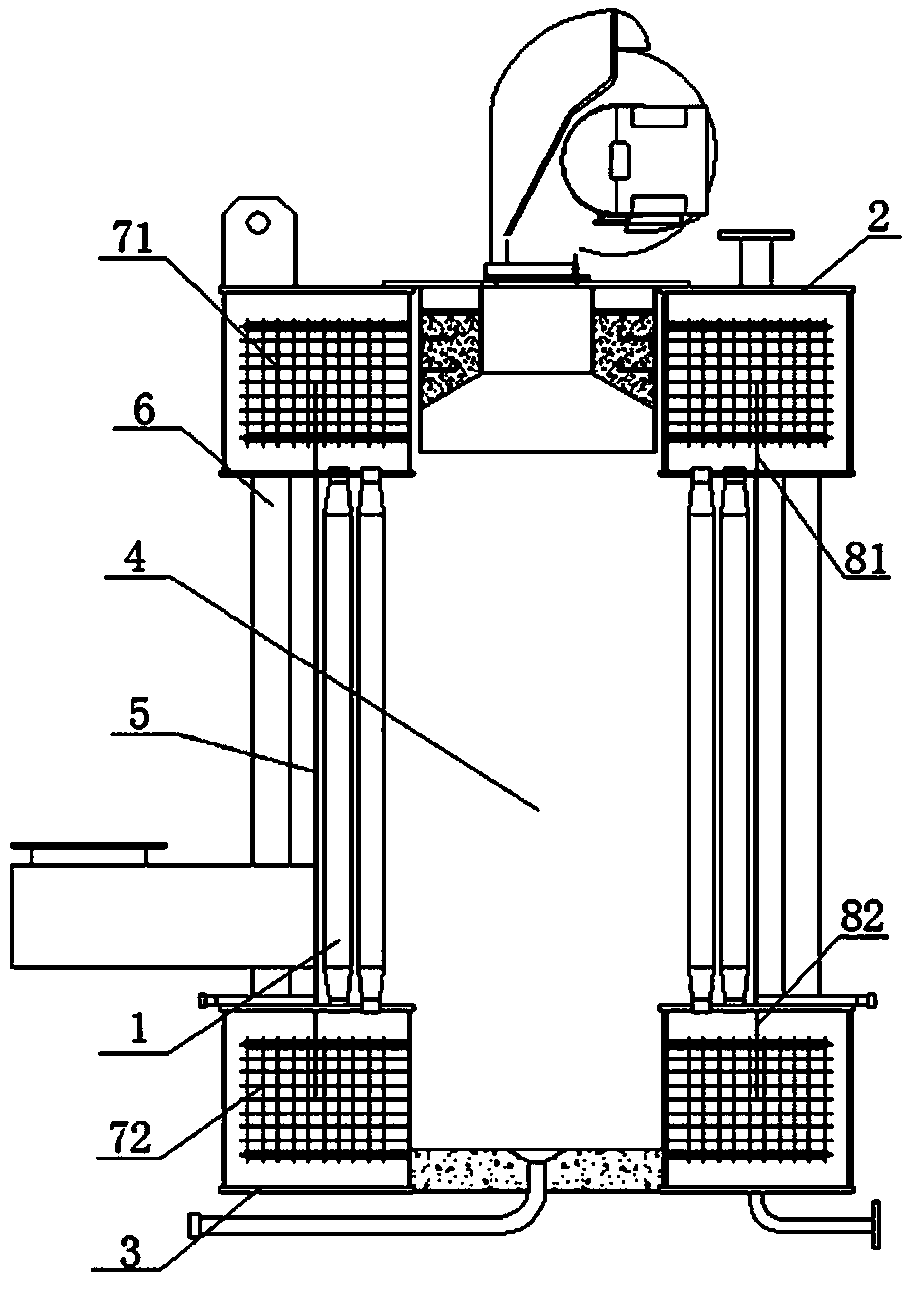

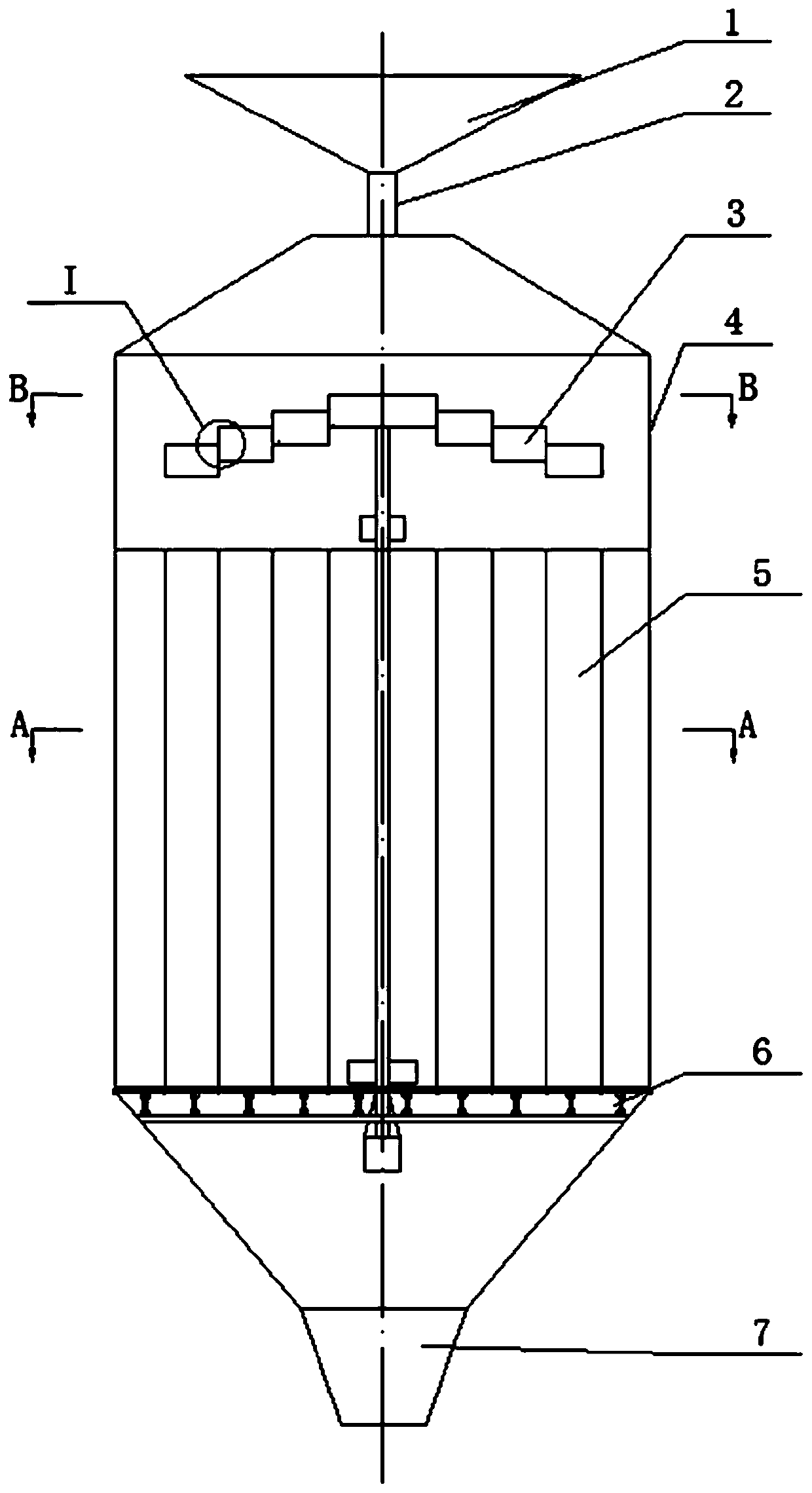

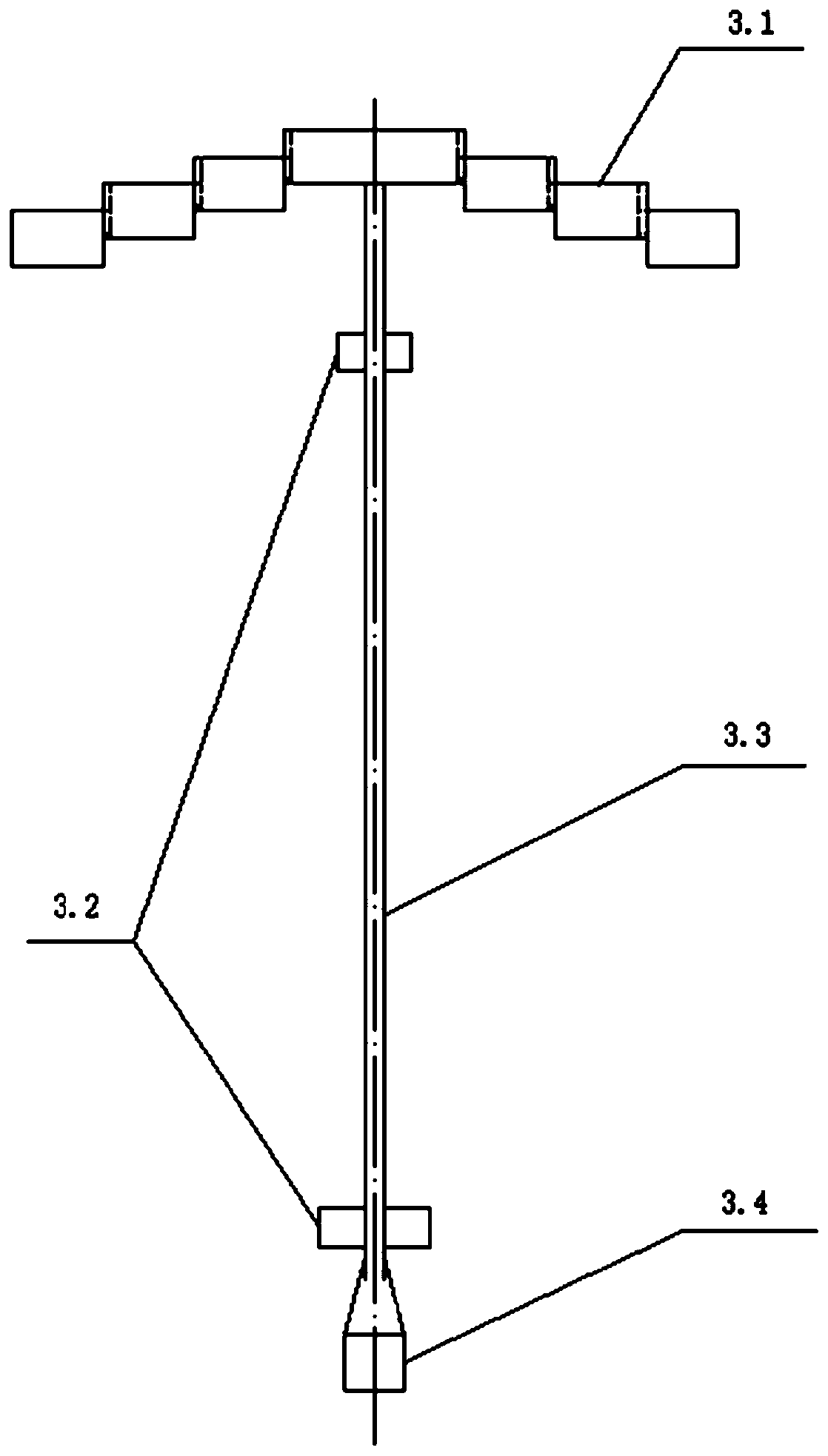

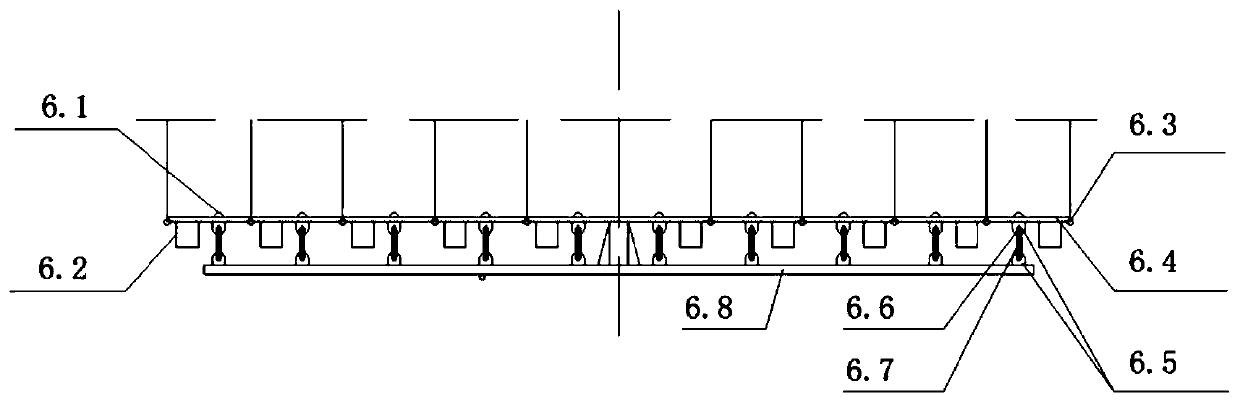

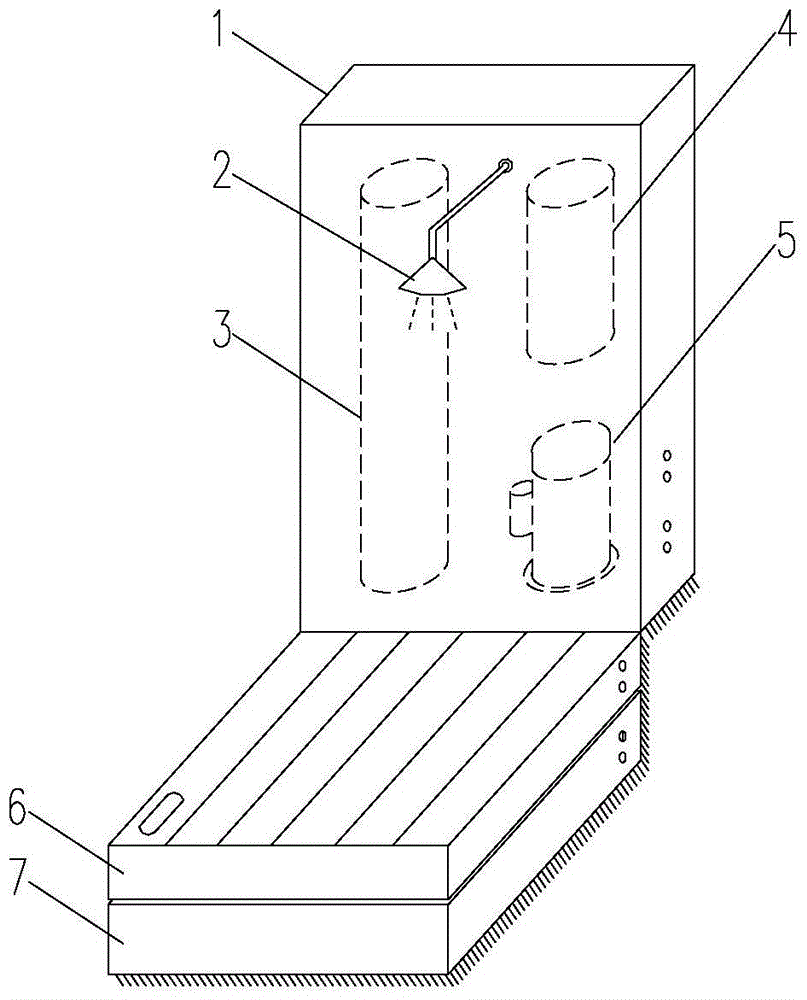

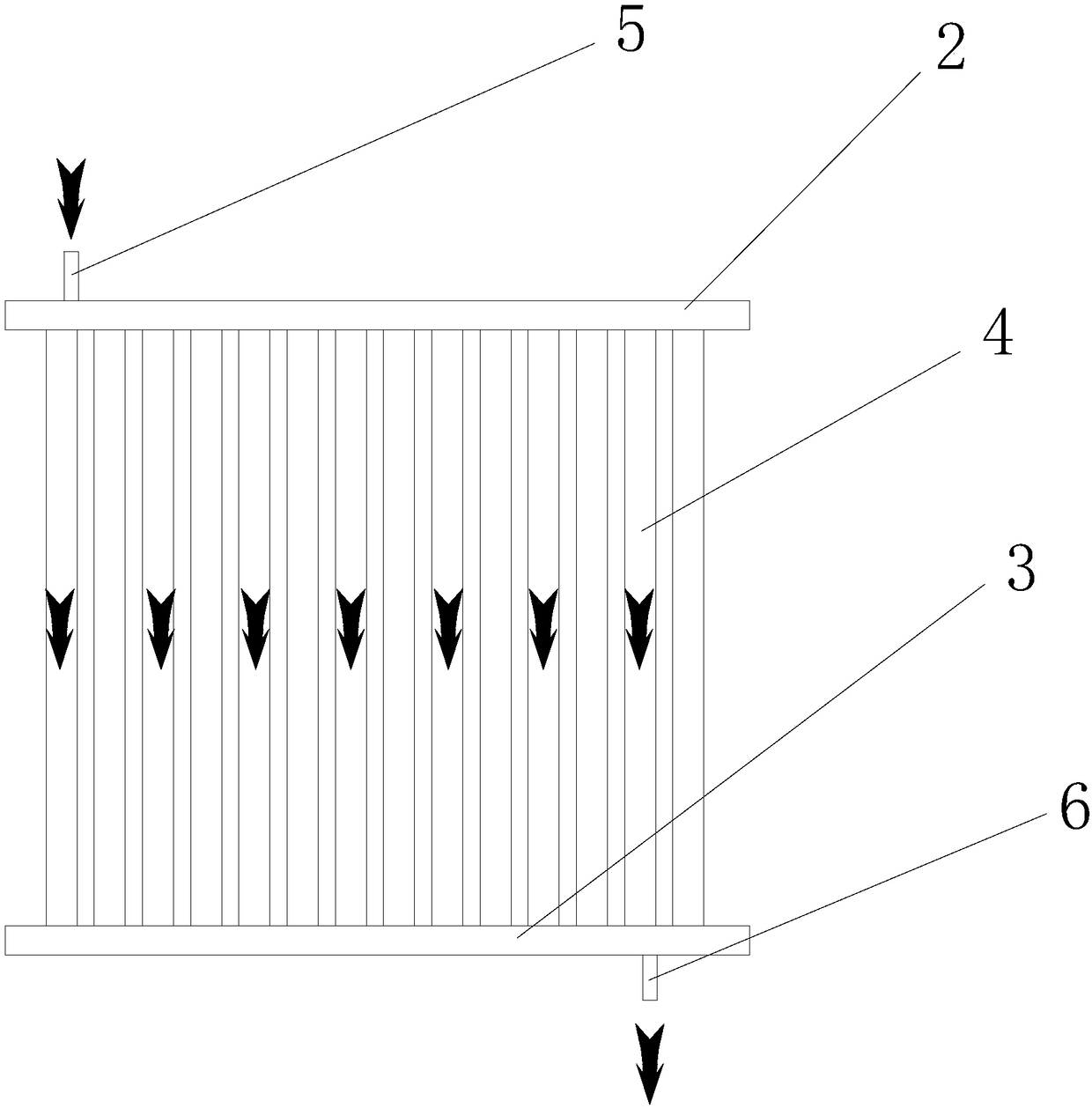

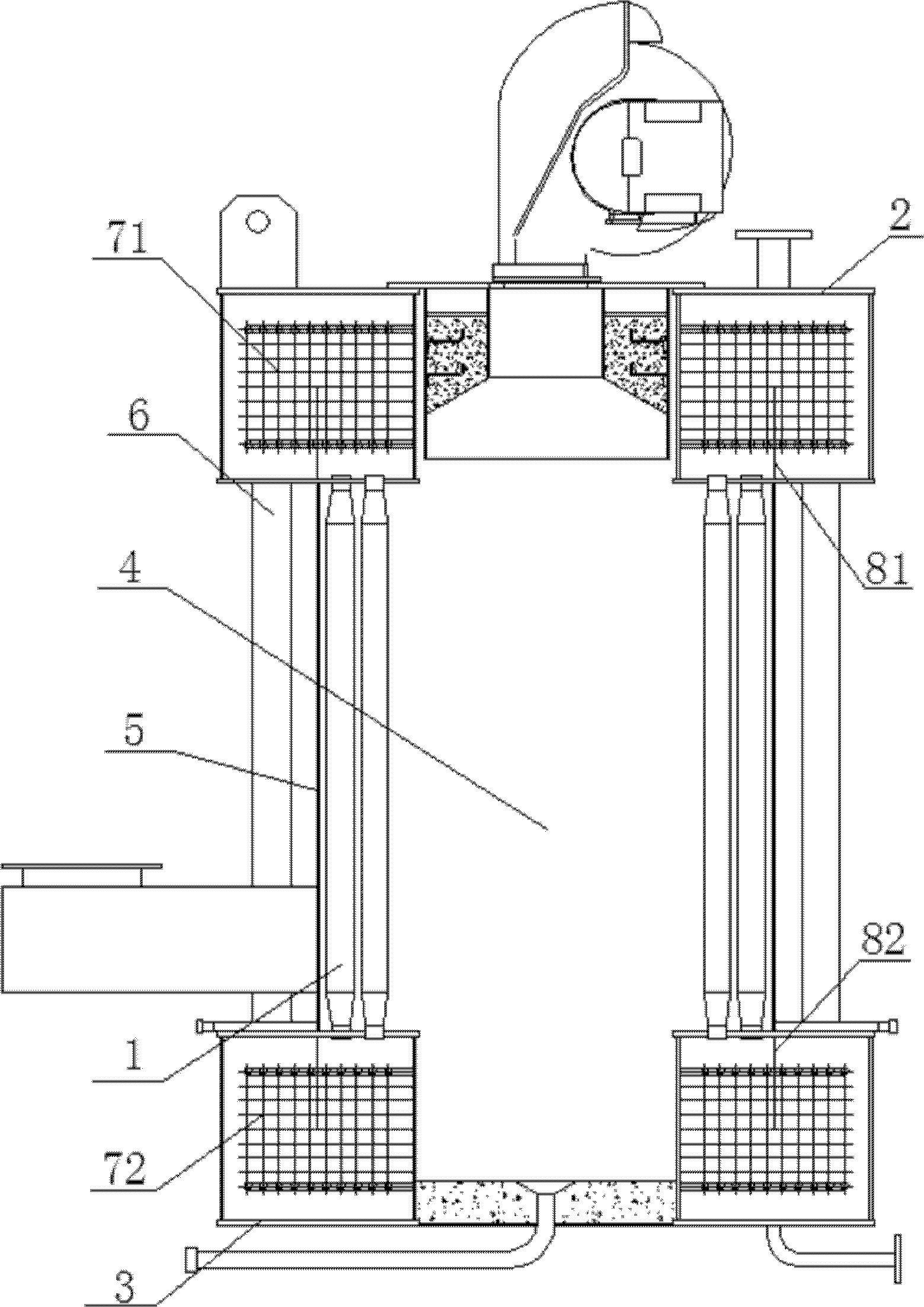

Vertical sinter cooler

ActiveCN111306944AImprove cooling effectCool evenlyHandling discharged materialControl devices for furnacesCooling towerEngineering

The invention relates to a vertical sinter cooler. The cooler comprises a bin (1), a feeding pipe (2), a cooling tower (4), a distributor (3), a separation type barrel (5), fans (6.2), a discharging device (6) and a discharging collection segment (7). The bin (1) is connected with the top end of the cooling tower (4) through the feeding pipe (2). The distributor (3) and the separation type barrel(5) are mounted in the cooling tower (4). The bottom of the cooling tower (4) is connected with the discharging collection segment (7) through the discharging device (6). A hot air outlet (8) is arranged at the upper end of the cooling tower (4). The interior of the cooling tower (4) is divided by the separation type barrel (5) into multiple independent spaces. The corresponding fan (6.2), a temperature detection device (6.1) and a distributed gate (6.4) are mounted at the bottom of each independent space. The discharging collection segment (7) is arranged at the lower ends of the distributedgates (6.4), and cooled sinter is collected. The occupied area of the cooler is small, and cost is reduced.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

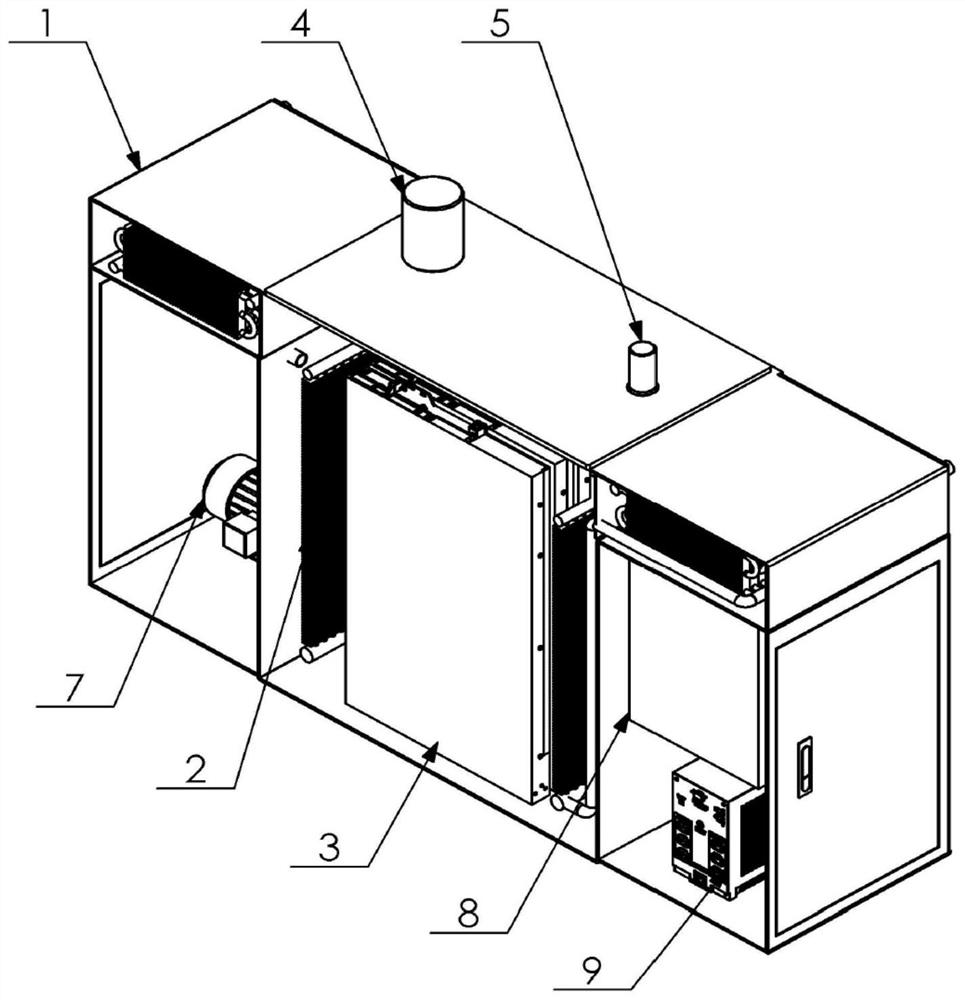

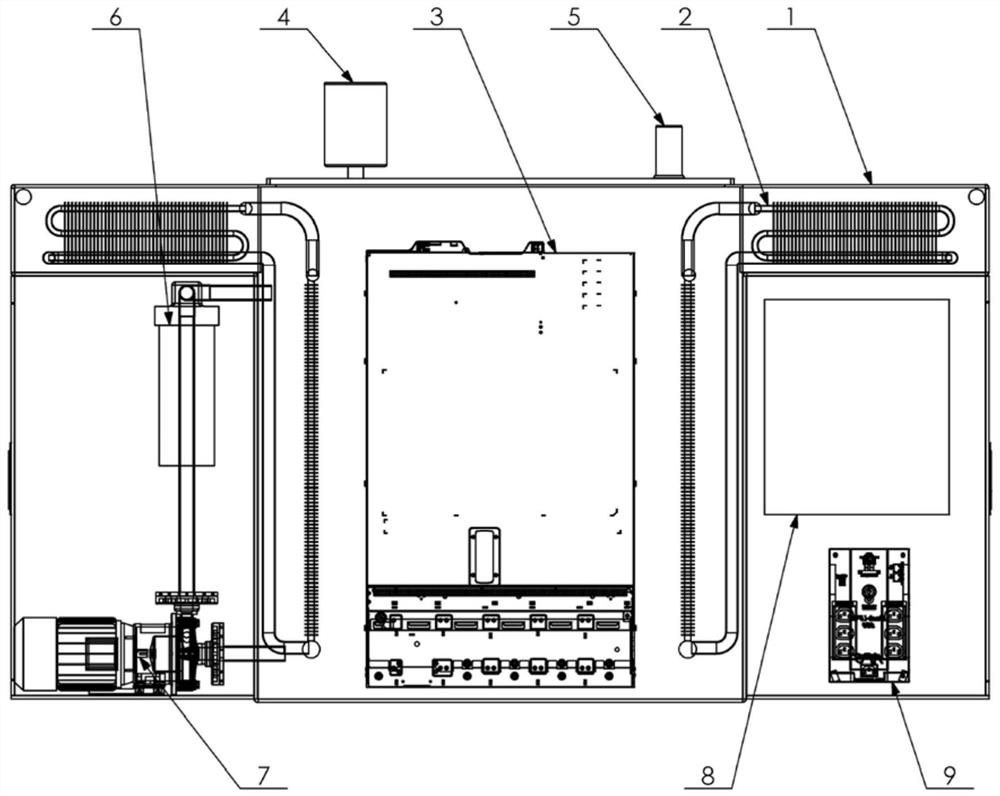

Liquid cooling server heat exchange equipment based on separated heat pipe heat exchanger

PendingCN113056167ARealize countercurrent heat exchangeAvoid exposure to leaksCooling/ventilation/heating modificationsHeat transmissionEngineering

The invention provides liquid cooling server heat exchange equipment based on a separated heat pipe heat exchanger. The liquid cooling server heat exchange equipment comprises a liquid cooling server composed of a server and a fluorinated liquid, the separated heat pipe heat exchanger loaded with refrigerants and a cooling box body loaded with cold water. The server is immersed in the fluorinated liquid, one part of the separated heat pipe heat exchanger is immersed in the fluorinated liquid, the other part of the separated heat pipe heat exchanger is immersed in cold water, heat transfer among the fluorinated liquid, the refrigerants and the cold water is achieved through phase-change heat transfer of the refrigerants in the separated heat pipe heat exchanger, and the temperature of the server is reduced. The separated heat pipe heat exchanger comprises an evaporation section, a condensation section, an air guide pipe and a liquid guide pipe, wherein the air guide pipe and the liquid guide pipe are used for connecting the two. According to the invention, the heat exchange equipment which is efficient, saves energy, saves the occupied area and has improved data stability and safety is provided, meanwhile, the sealing performance and safety of the liquid cooling server are improved, the non-conductivity of the fluorinated liquid is guaranteed to the maximum extent, and the leakage rate of the fluorinated liquid is reduced.

Owner:上海菡威装备有限公司

High-efficiency shell-and-tube heat exchanger and manufacturing method thereof

ActiveCN104819651BImprove heat transfer coefficientPrevent dripping from affecting heat transferEvaporators/condensersHeat exchanger casingsSurface levelEngineering

The invention discloses an efficient shell tube type heat exchanger and a manufacturing method of the heat exchanger. Gaseous refrigerants of an upper layer heat exchange tube surface of the heat exchanger are cooled to liquid, and the liquid is dropped and poured to a lower layer heat exchange tube surface level by level from the upper layer heat exchange tube surface, and then dropped and poured to a dropping and pouring prevention partition plate, it is ensured that a lower layer heat exchange tube cannot be dropped and poured by liquid-state refrigerants of an upper layer heat exchange tube, the contact area of the lower layer heat exchange tube and the gaseous refrigerants is increased, heat resistance is reduced, and the heat exchange effect is improved; the refrigerants are located outside a heat exchange tube to flow, cooling water is located in the heat exchange tube to flow, but, the flowing direction of the cooling water is reverse, backward flowing of two strands of fluid of the refrigerants and the cooling water can be achieved, the surface heat exchange coefficient of the heat exchange tube is improved, the heat exchange effect is improved, and the heat exchange performance of the reverse flow shell type heat exchanger is greatly improved. Compared with a traditional shell tube type heat exchanger, the phenomenon that the liquid-state refrigerants of the surface of the heat exchange tube are dropped and poured to the position between tube layers, and heat exchange is affected is avoided, the reverse flow heat exchange of two kinds of heat exchange fluid of a shell side and a tube side is achieved, the heat exchange coefficient is higher, the heat exchange temperature difference is more uniform, materials are saved, and meanwhile, the energy efficiency ratio is improved.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

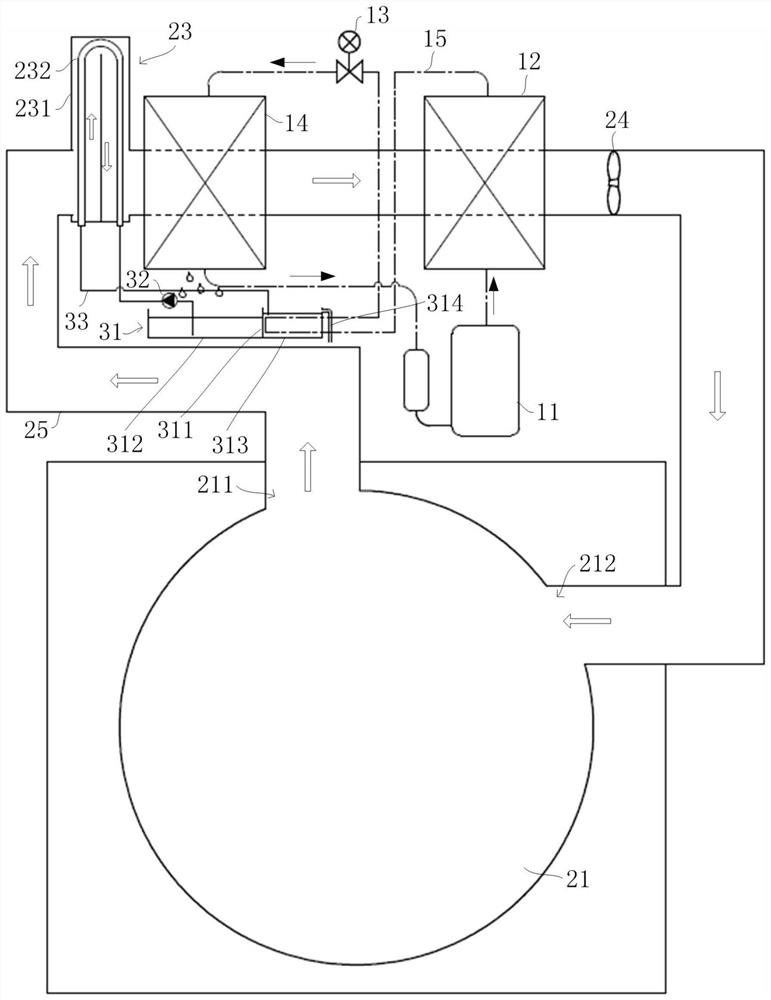

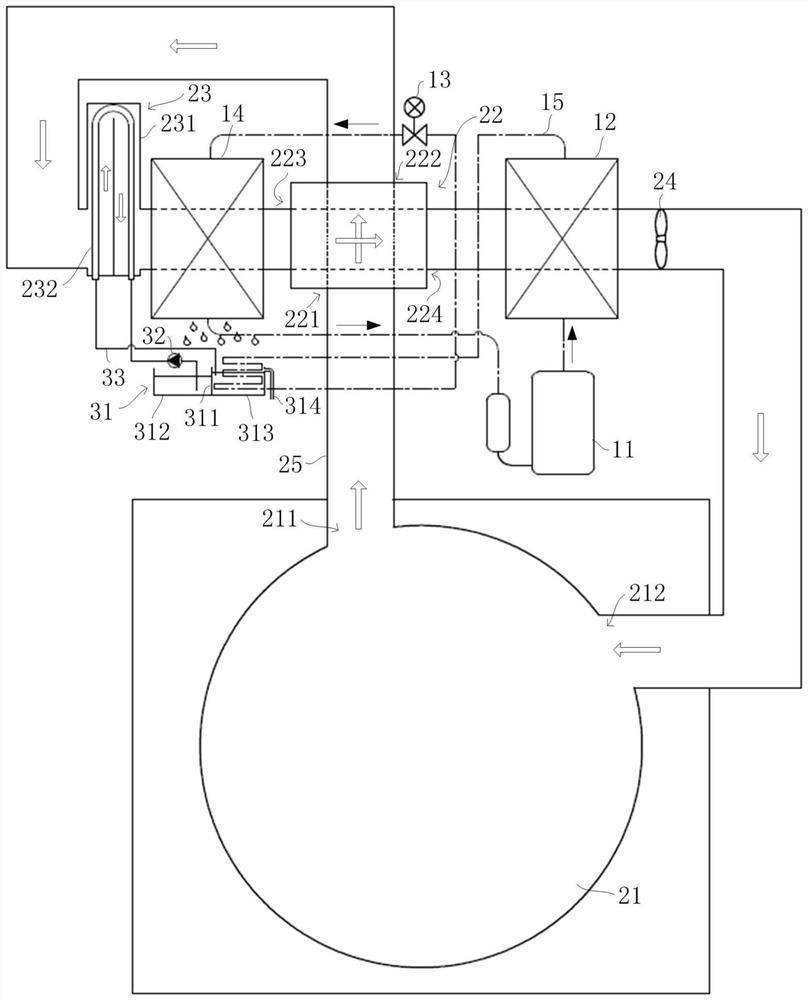

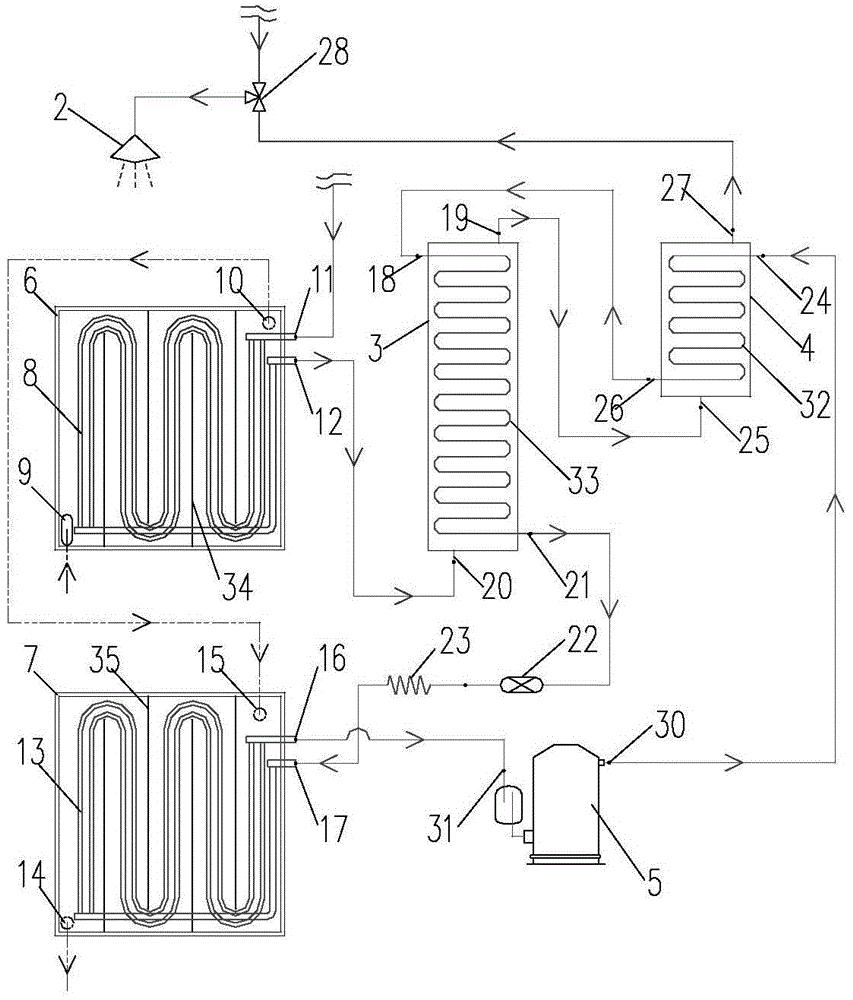

A heat recovery type bath machine

ActiveCN104224004BMeet the needs of bathingRealize comprehensive utilizationFluid heatersBathsWarm waterEngineering

The invention discloses a heat recovery type bathing machine, which comprises a high-temperature water tank, a low-temperature water tank, a compressor, a recovery box for a bathing platform, and an evaporation box; Heat exchange, the hot sewage after heat exchange enters the evaporation tank, and the clean water after heat exchange flows through the medium temperature water tank and high temperature water tank in turn, and then mixes with unheated clean water through the water mixing valve and then sprays out from the nozzle; the water discharged from the compressor The gaseous refrigerant passes through the heat exchange coil three in the high-temperature water tank and the heat exchange coil four in the medium-temperature water tank to exchange heat with the clean water outside the tube. After the heat exchange, the gaseous refrigerant condenses and releases heat to become a liquid state, and the liquid refrigerant enters again The heat exchange coil 2 in the evaporator performs heat exchange with the hot sewage outside the tube, and the liquid refrigerant after the heat exchange becomes gaseous, and the gaseous refrigerant flows into the compressor to be compressed and then discharged. The invention realizes the reuse of waste heat from hot sewage, meets the demand of hot water bathing, and greatly improves energy utilization efficiency.

Owner:深圳渥特思能源有限公司

Double-loop solar heating and heat exchange compound device

ActiveCN104633748BRealize countercurrent heat exchangeImprove heat transfer effectLighting and heating apparatusSpace heating and ventilation detailsThin metalBuilding integration

The invention relates to a double-loop solar heating and heat exchanging combined device. A plurality of double-flow-channel heat transferring units are arranged in parallel. Each double-flow-channel heat transferring unit is internally provided with two flow channels. Every two flow channels are partitioned through thin metal walls. The upper end and the lower end of one flow channel are connected with an upper collecting pipe and a lower collecting pipe of an auxiliary heat source loop, and the upper end and the lower end of the other flow channel are connected with an upper collecting pipe and a lower collecting pipe of a solar loop. Two working modes are adopted for the device, one mode is a heating mode, and the other mode is a heat exchanging mode. The heating mode is further divided into three operating modes, the operating modes can be selected according to the weather situation, heat dissipation cladding is adopted for the heating season, and the heat provided by the solar energy or an auxiliary heat source is released into a room through the heat dissipation cladding. According to the heat exchanging mode, in the non-heating season, the heat dissipation clapping is changed to be heat preservation cladding, and in the double-flow-channel heat transferring units, the heat in the solar loop is transferred to the auxiliary heat source loop. The double-loop solar heating and heat exchanging combined device can be combined with a conventional concentrated heating system, solar energy is fully utilized, the system is simplified, energy efficiency is improved, and integration of the solar energy and a building is achieved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A heat exchanger suitable for high temperature and wide pressure difference and its heat exchange mechanism

ActiveCN110822953BSolve the heat transfer problem at high temperature (≥1000°C)Realize countercurrent heat exchangeHeat exchanger casingsStationary tubular conduit assembliesEngineeringPressure difference

The invention discloses a heat exchanger suitable for high temperature and wide pressure difference as well as a heat exchange mechanism. The heat exchange mechanism comprises a cylinder body, a corecolumn and a plurality of unit layers, wherein the cylinder body has a cylindrical structure; the core column and the cylinder body are coaxially arranged, and the outline of the core column is cylindrical; each unit layer comprises a plurality of rotary cylinders which surround the core column uniformly and are parallel with the core column; a plurality of unit layers are sequentially arranged onthe core column and are clamped between the core column and the cylinder body; the rotary cylinders positioned on the same layer have the same diameter; and each layer of rotary cylinders have the same number and are arranged uniformly. The heat exchanger and the heat exchange mechanism have high heat exchange efficiency and can be applied to heat exchange scenes with high temperature and wide pressure difference.

Owner:BEIJING FUDIAN ENG TECH CO LTD

Guide plate film type total-heat heat exchange core body for fresh air ventilator

InactiveCN103175292BRealize countercurrent heat exchangeImprove heat transfer efficiencySpace heating and ventilation detailsStationary plate conduit assembliesComposite filmInlet channel

The invention provides a guide plate film type total-heat heat exchange core body for a fresh air ventilator. The guide plate film type total-heat heat exchange core body comprises a top plate, a bottom plate, and heat exchange units. Each heat exchange unit is composed of a heat exchange composite film, a supporting frame, an airflow baffle and a guide plate, wherein each heat exchange composite film and each supporting frame are fixedly connected for forming a bottom surface of each supporting frame. Each supporting frame is provided with an air inlet and an air outlet, and each airflow baffle perpendicular to each heat exchange composite film is arranged on each air inlet or each air outlet. Each guide plate is vertically arranged on the surface of the each heat exchange composite film for forming a heat exchange channel, two ends of each heat exchange channel are connected with an air inlet channel or an air outlet channel through a reducing and increasing pipe, and communication between each air inlet and each air outlet can be achieved. At least two heat exchange units are arranged between the top plate and the bottom plate in a stacking mode, air inlets and air outlets of two adjacent heat exchange units are opposite in position, and the air inlets and the air outlets of two alternating heat exchange units are identical in position. The guide plate film type total-heat heat exchange core body is excellent in heat and mass transfer property, high in heat transfer efficiency, small in resistance loss and size, low in cost and convenient to apply.

Owner:CENT SOUTH UNIV

A power recovery and cooling system using the waste heat of blast furnace slag flushing water

ActiveCN104196584BEnhanced boiling heat transferAvoid pollutionClimate change adaptationEnergy industrySlagOrganic Rankine cycle

The invention relates to a system capable of conducting power recovering and cooling by using waste heat of blast furnace slag flushing water, and belongs to the technical field of energy and environment. The system comprises a slag flushing water heat recovery and heat exchange system, an organic Rankine cycle, a steam injection type cooling system and a cooling water circulation system. An internal-thread stainless steel spiral tube shell-and-tube heat exchanger is used as a pre-heater, an external-thread stainless steel tube shell-and-tube heat exchanger is used as a steam generator, and the steam generator is also used as a gas-liquid separator. The system has the advantages of being simple in structure, easy to machine and manufacture, low in manufacturing cost, capable of preventing blockage, capable of realizing countercurrent flow heat exchange, high in heat exchange efficiency, capable of effectively utilizing waste heat of the slag flushing water and the like; the system can be independently used for generating electricity or providing prime power, can also be independently used for cooling and can further provide electric power and chilled water required by a cooling air conditioner at the same time.

Owner:KUNMING UNIV OF SCI & TECH

A method for preparing high-strength anhydrite from sulfur-calcium slag

This patent discloses a method for preparing high-strength anhydrous gypsum from sulfur-calcium slag. Add sulfur-calcium slag, calcium source, activator, and silicon-aluminum source to a drying and dispersing machine to obtain dry material, and then add the dry material to a countercurrent dryer for dehydration. Enter the fluidized bed to cool to obtain anhydrous gypsum, add surfactant, organic matter, reinforcing agent, and micropowder to the anhydrite and mix evenly to obtain high-strength anhydrous gypsum. The method has low production cost and high efficiency, and realizes high-quality recycling of resources.

Owner:四川地维科技有限公司

Heat exchange water tank and water heater

PendingCN108645029AAvoid heat exchangeEnhanced condensation heat transfer capacityFluid heatersEngineeringWater temperature

The invention provides a heat exchange water tank and a water heater. The heat exchange water tank comprises a liner and a heat exchange part, wherein a first heat exchange area is formed at the upperpart in the liner, and a second heat exchange area is formed at the lower part; and the heat exchange part comprises a first current collecting pipe, a second current collecting pipe and multiple heat exchange pipes. In the heat exchange water tank and the water heater, the first current collecting pipe is arranged in the first heat exchange area, and the second current collecting pipe is arranged in the second heat exchange area; when a refrigerant enters the heat exchange part, the refrigerant exchanges heat with the second heat exchange area after heat exchange with the first heat exchangearea, so that the heat exchange of the refrigerant with the first heat exchange area again after heat exchange with the second heat exchange area can be prevented, and the condensation and heat exchange performance in channel heat exchange is effectively improved; and meanwhile, the first current collecting pipe is arranged on the upper side, and the second current collecting pipe is arranged onthe lower side, so that the flowing direction of the refrigerant and the distribution direction of the water temperature in the liner from low to high are opposite, the countercurrent heat exchange isrealized, and the heat exchange performance is further improved.

Owner:GREE ELECTRIC APPLIANCES INC

Integrated through-flow ordinary-pressure hot water boiler

The invention discloses an integrated through-flow ordinary-pressure hot water boiler; which comprises a heating surface water pipe, an upper annular collecting box, a lower annular collecting box, a combustion chamber and a barrel body; the heating surface water pipe is positioned in the barrel body; the upper end and the lower end of the heating surface water pipe are respectively communicated with the upper annular collecting box and the lower annular collecting box; at least one heat exchanger is arranged in at least one of the upper annular collecting box and the lower annular collecting box; and an adiabatic falling pipe is communicated between the upper annular collecting box and the lower annular collecting box. According to the integrated through-flow ordinary-pressure hot water boiler disclosed by the invention, the heat exchanger is integrated in a boiler body; a traditional primary circulating water pump and corresponding supporting pipes are removed, thus, the cost of the primary circulating water pump and the required energy consumption can be saved, and the radiation heat loss of the primary circulating water pump and the supporting pipes is relatively reduced; and because the heat exchanger is integrated into the boiler body, the whole boiler system is more compact in structure.

Owner:TAIJUNE BOILER IND KUSN

Solid heat storage method

PendingCN114754617AIncrease profitAvoid wastingHeat storage plantsProcess engineeringSuperheated steam

The invention discloses a solid heat storage method. The solid heat storage method comprises the following steps: superheated steam enters a steam-water separator through a superheating section coil pipe; the cooled steam is changed into saturated steam, the first driving fan runs, and the second driving fan stops running; steam releasing latent heat in the heat exchanger is changed into saturated water to enter a preheating section coil pipe of the preheating section, and heat is transferred into the preheating section. Low-temperature feed water passes through a preheating section coil pipe, heat in a preheating section is transferred into supercooled water in the preheating section coil pipe, a first driving fan stops running, a second driving fan runs, and heat is transferred into saturated steam of a heat exchanger from an evaporation section; and saturated steam of the heat exchanger enters an overheating section coil pipe of the overheating section. According to the solid heat storage method, the steam heat energy is stored through solid heat storage, the energy utilization rate is increased, the technology of converting high-grade energy into low-grade energy in the prior art is replaced, and energy waste is avoided.

Owner:HUANENG CLEAN ENERGY RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com