Liquid cooling server heat exchange equipment based on separated heat pipe heat exchanger

A separate heat pipe and heat exchange equipment technology, applied in the field of liquid-cooled server heat exchange equipment, can solve the problems of easy burning of servers, loss of data, high leakage rate of fluorinated liquid, etc., to reduce the risk of water content, improve stability and safety , the effect of small equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

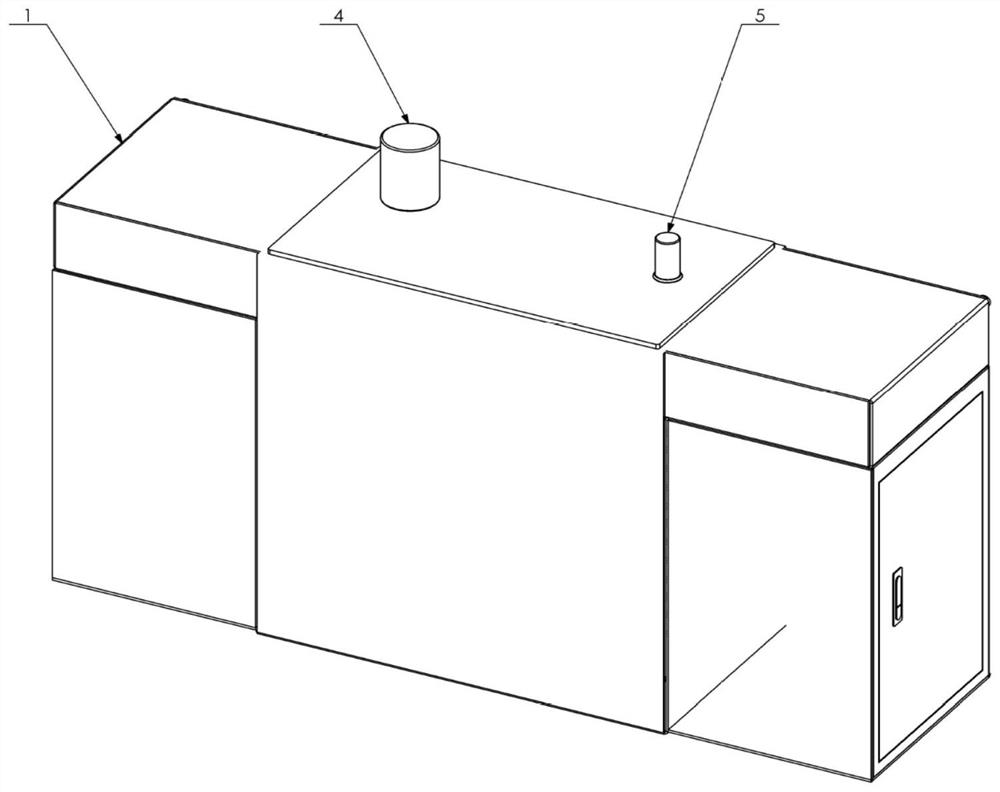

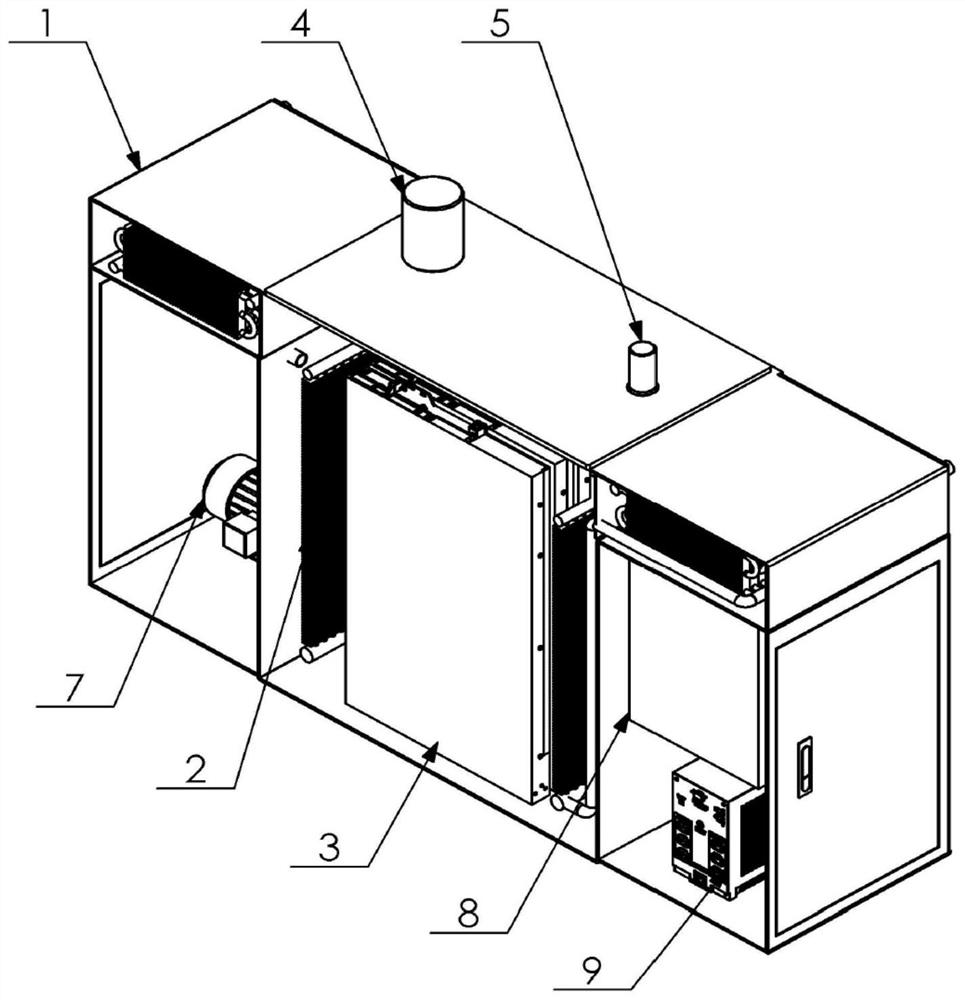

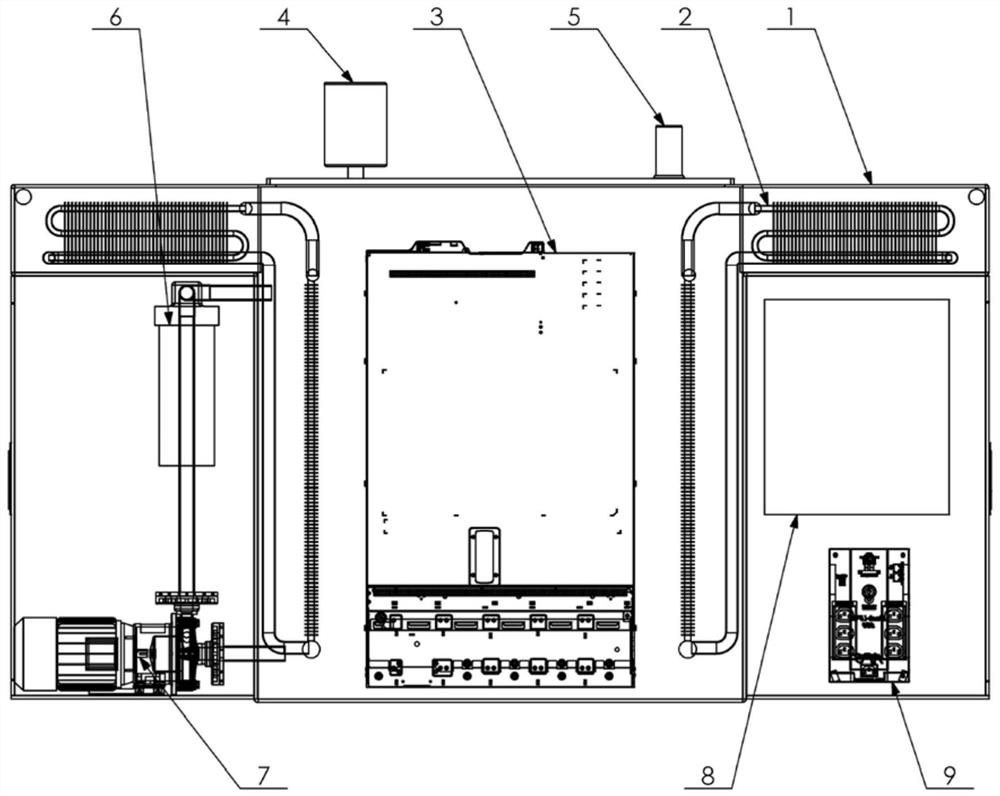

[0040] Such as Figure 1~4 Shown is a liquid-cooled server heat exchange device according to a preferred embodiment of the present invention. The heat exchange device mainly uses three heat exchange liquids: fluorinated liquid A, refrigerant B, and cold water C. Among them, refrigerant B is a A fluid different from fluorinated liquid and cold water. This fluid is easy to absorb heat and become a gas, and it is easy to release heat to become a liquid. Refrigerant B is a liquid customized according to the required liquefaction and vaporization temperature. Through the temperature of these three liquids Passing ultimately achieves cooling of the server. The structure and function of each component are described in detail b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com