A method for preparing high-strength anhydrite from sulfur-calcium slag

Anhydrous gypsum and calcium slag technology, applied in the application field of sulfur-calcium slag, can solve the problems of environmental pollution, land occupied by titanium gypsum, loss of titanium gypsum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific examples.

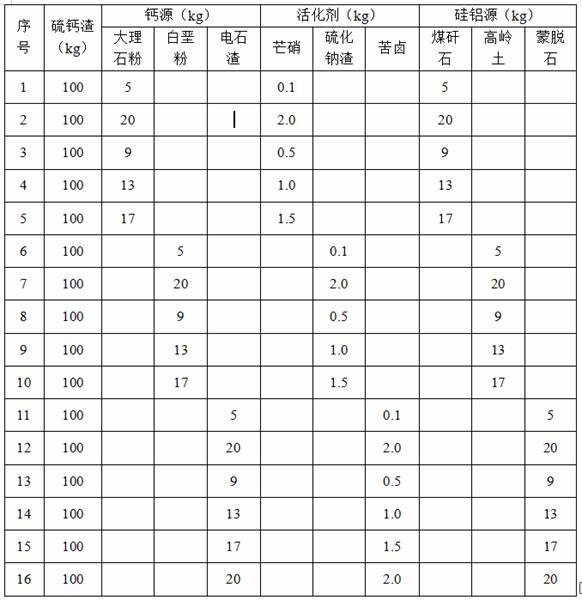

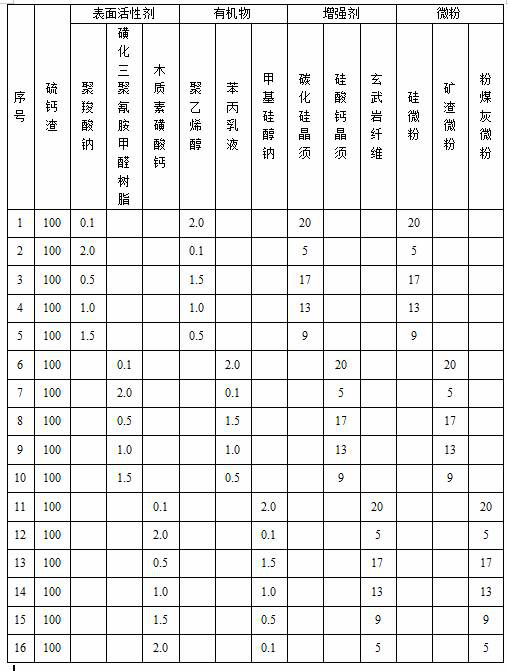

[0031] Add sulfur-calcium slag, calcium source, activator, and silicon-aluminum source to the drying and dispersing machine to obtain dry material, add the dry material to a countercurrent dryer for dehydration, and then enter the fluidized bed to cool to obtain anhydrous gypsum. See Table 1 for the amount of sulfur-calcium slag, calcium source, activator, and silicon-aluminum source. Add surfactant, organic matter, reinforcing agent and fine powder to anhydrite and mix evenly to obtain high-strength anhydrous gypsum. See Table 2 for the amount of surfactant, organic matter, reinforcing agent, and micropowder added.

[0032] Table 1

[0033]

[0034] Table 2

[0035]

[0036] It can be concluded from Example 1-Example 16 that the dry compressive strength of the obtained high-strength anhydrous gypsum is greater than 110 MPa, and the softening coefficient is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com