Multiple-effect heat pipe type distillation column driven by condensation steam source heat pump

A technology of heat pipe type and source heat pump, which is applied in the direction of tubular distiller, heat recovery system, multi-stage water treatment, etc., and can solve problems such as difficult maintenance, high maintenance cost, and expensive water vapor compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

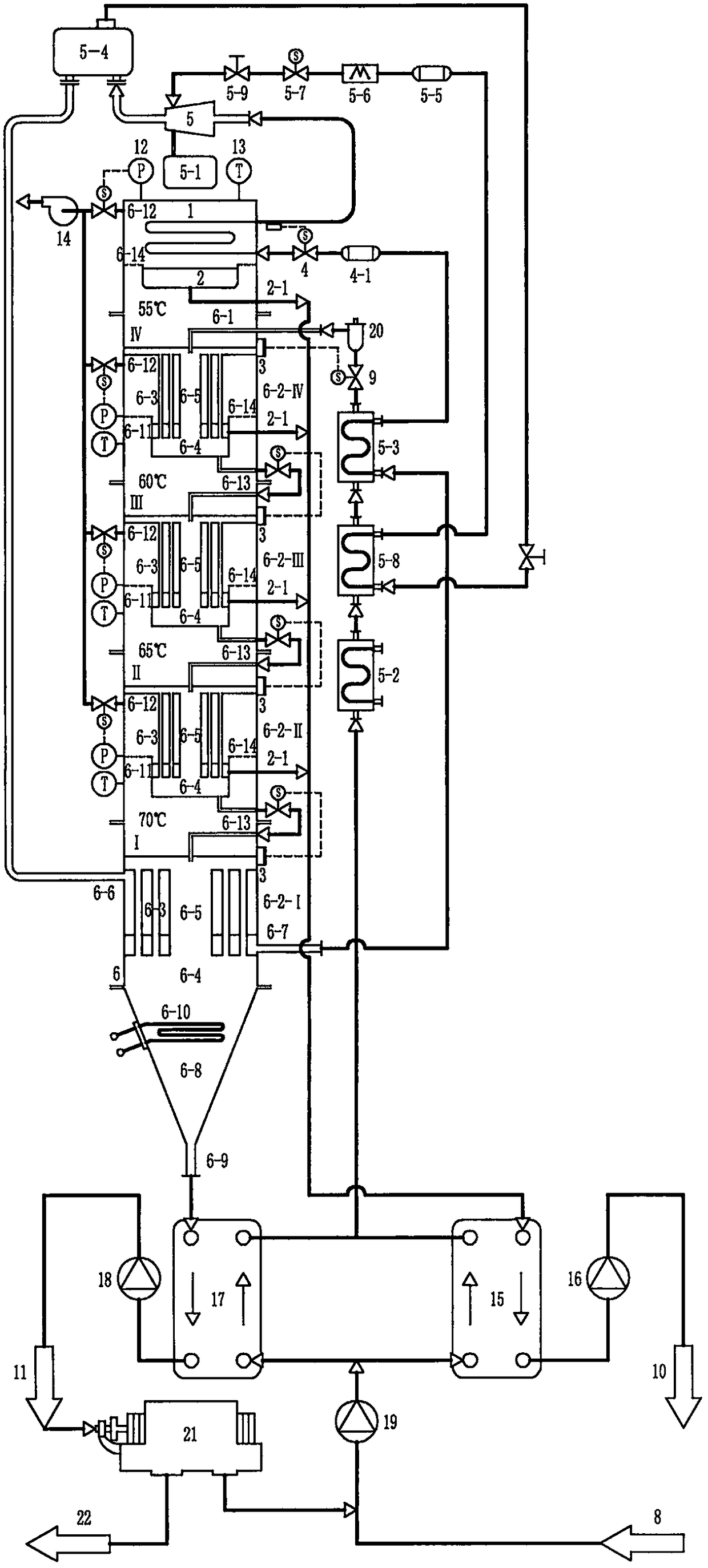

[0065] The embodiment of the multi-effect heat pipe distillation column driven by the condensation source heat pump proposed by the present invention is attached figure 1 As shown, the description is as follows: the evaporator 1 is made of copper tubes with 664kW of evaporative heat, horizontally installed; 0.3m3 fresh water tank 2; the stainless steel fresh water tube 2-1 with a diameter of 10mm / wall thickness of 1mm / total length 1600mm ;Stainless steel liquid level switch 3 with elevation 100mm; copper thermal expansion valve 4 with interface diameter 60mm / wall thickness 1mm; copper dry filter 4-1 with interface diameter 60mm / wall thickness 1mm; compressor 5 with suction capacity 600m3 / h ;Gas internal combustion engine 5-1 with an output shaft power of 109kW; cylinder liner regenerator 5-2 with cylinder liner cooling and flue gas regenerating capacity of 109kW; subcooling regenerator 5-3 with regenerating capacity of 33kW; Separator 5-4; copper oil filter 5-5 with interface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com