Condensed steam source heat pump driven multi-effect horizontal pipe falling film distillation column

A horizontal tube falling film and source heat pump technology, which is applied in distillation separation, distillation energy recovery, fractionation, etc., can solve problems such as high maintenance cost, difficulty in miniaturization, home appliances, and slow delivery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

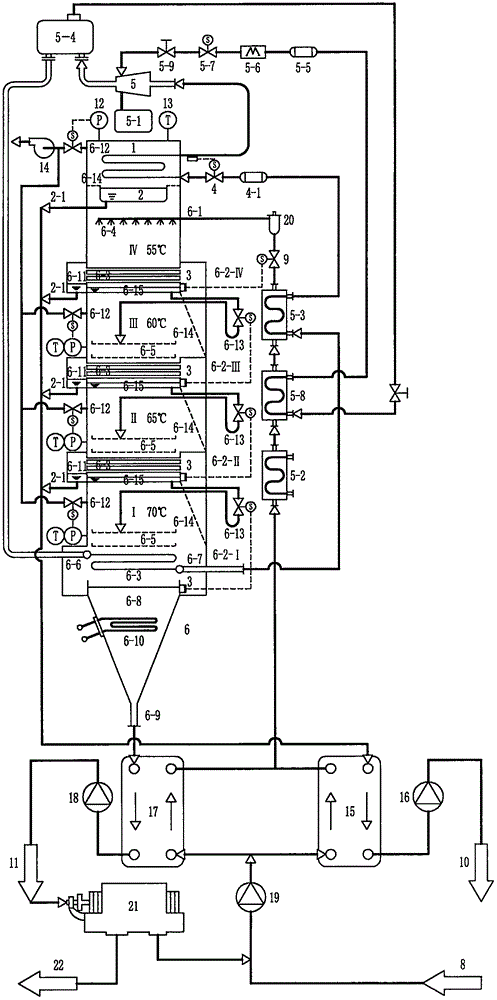

[0070] The embodiment of the multi-effect horizontal tube falling film distillation column driven by the condensing steam source heat pump proposed by the present invention is attached figure 1 As shown, the description is as follows: the evaporator 1 is made of copper tubes with 664kW of evaporative heat, horizontally installed; 0.3m3 fresh water tank 2; the stainless steel fresh water tube 2-1 with a diameter of 10mm / wall thickness of 1mm / total length 1600mm ;Stainless steel liquid level switch 3 with elevation 100mm; copper thermal expansion valve 4 with interface diameter 60mm / wall thickness 1mm; copper dry filter 4-1 with interface diameter 60mm / wall thickness 1mm; compressor 5 with suction capacity 600m3 / h ;Gas internal combustion engine 5-1 with an output shaft power of 109kW; cylinder liner regenerator 5-2 with cylinder liner cooling and flue gas regenerating capacity of 109kW; subcooling regenerator 5-3 with regenerating capacity of 33kW; Separator 5-4; copper oil fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com