Shell and tube sewage heat exchanger

A shell-and-tube heat exchanger technology, applied in heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of limited materials and structures of heat exchangers, low heat exchange efficiency, and inability to disassemble and replace. , to achieve the effects of small heat transfer temperature difference, low cost and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

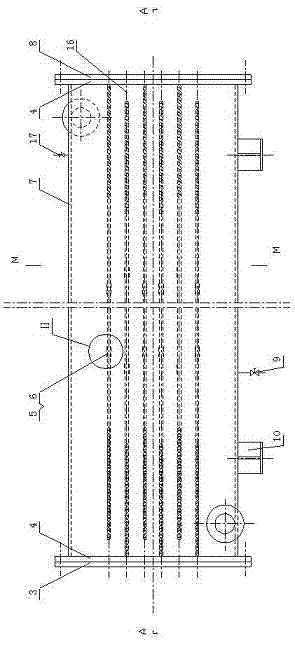

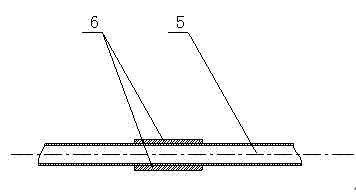

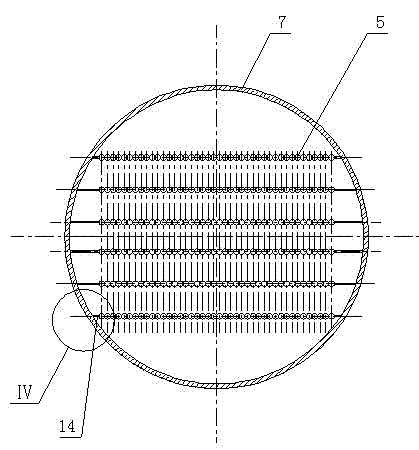

[0034] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , The heat exchanger includes a circular shell 7, the circular shell 7 is provided with a sewage inlet pipe 2, a sewage outlet pipe 12, a sewage outlet 9, and a vent 17, and a plurality of ( Layer) The heat exchange tube rows arranged in parallel, each heat exchange tube row is composed of multiple heat exchange tubes 5 arranged, corresponding to each (layer) heat exchange tube row, in the circular shell 7 A plurality of supporting and fixing plates 6, both ends of the supporting and fixing plates 6 are fixedly connected with the side walls of the circular shell 7, and each (layer) heat exchange tube row is supported and fixed by the supporting and fixing plates 6, in the circular shell 7 The two ends are respectively provided with heads, the left head 3 and the right head 8, the two heads and the circular shell 7 are connected by a fixed flange 4. In order to facilitate cleaning or replacement of parts, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com