Welded plate frame type heat exchanger

A technology of heat exchangers and welded plates, which is applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., to achieve the effects of compact structure, reduced possibility of leakage, and expanded use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

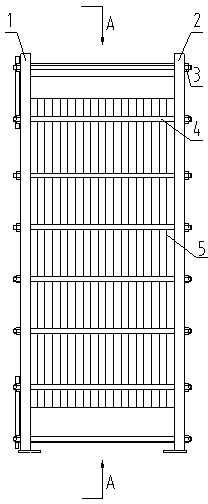

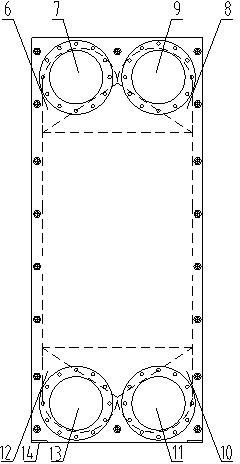

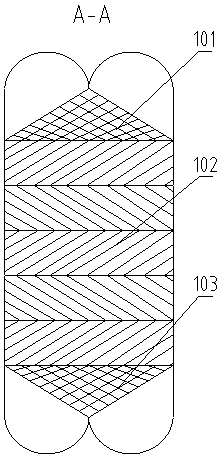

[0030] Embodiment 1, under the condition of single process, refer to the attached Figure 1a , 1b , 1c, cold and hot fluids are arranged in countercurrent, side in and side out, and the flow direction of the fluid in the plate bundle is diagonal flow. A welded plate and frame heat exchanger involved in this embodiment includes welded heat exchange plate bundles 5, the first 1. The second pressing plate 1, 2, the clamping stud nut 4, 3, the inlet and outlet pipe boxes of the cold and hot ends of the plate bundle, the inlet and outlet pipes of the cold and hot medium, and other components.

[0031] The first and second pressing plates 1, 2 and the clamping stud nuts 4, 3 constitute the frame of the heat exchanger. The frame can be made of carbon steel, and its function is to carry the weight of the equipment, carry the bundle of plates, and provide support for it . The hexagonal plate can be made of stainless steel, titanium, nickel-based alloy and other materials, and is welde...

Embodiment 2

[0035] Embodiment 2, under the multi-process working condition, the implementation process of embodiment 2 is basically the same as that of embodiment 1. The difference is that the inlet and outlet ports of the cold and heat medium in embodiment 2 are located on both sides of the first and second compression plates 1 and 2, and the inlet and outlet ports of the cold and heat medium are located on the first and second compression plates 1 and 2. 2 through the via hole 16 is oblong.

Embodiment 3

[0036] Embodiment 3, with reference to attached Figure 2a , 2b , 2c, the implementation process of embodiment 3 is basically the same as the implementation process of embodiment 1. The difference is that the hot and cold fluid inlet and outlet connecting pipes of embodiment 2 are located on the upper and lower sides of the plate bundle, and the opening position of the connecting pipe is located on the upper side of the pipe box round arch, so there is no need to set openings on the first and second pressing plates 1 and 2. The holes allow the hot and cold fluids to enter the tube box straight up and down, which can get better heat exchange effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com