Integrated through-flow normal pressure hot water boiler

A hot water boiler, an integrated technology, applied in the field of boilers, can solve the problems of occupying boiler room area, increasing energy consumption, complex structure, etc., and achieving the effects of reducing heat dissipation loss, compact structure, and favorable heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

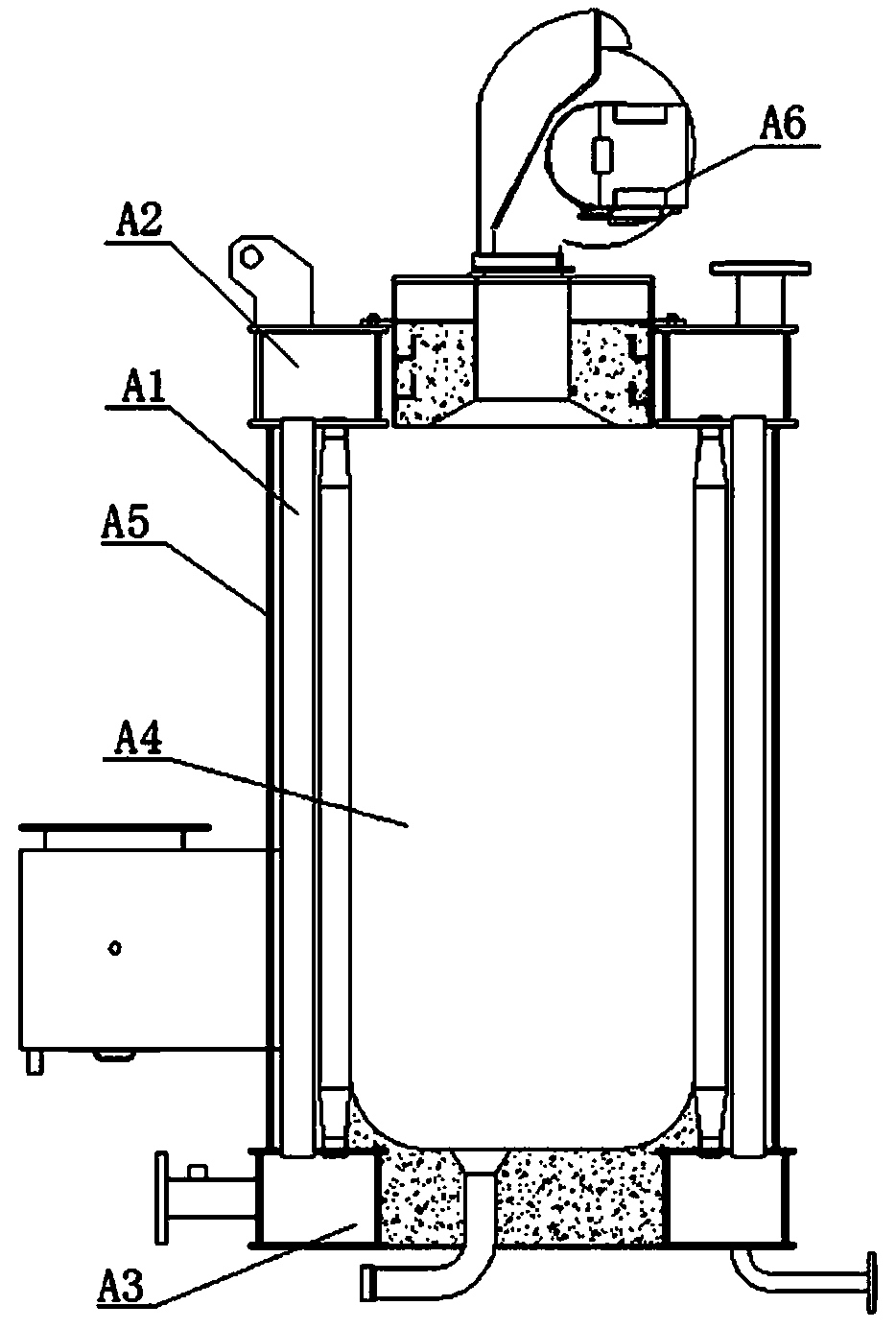

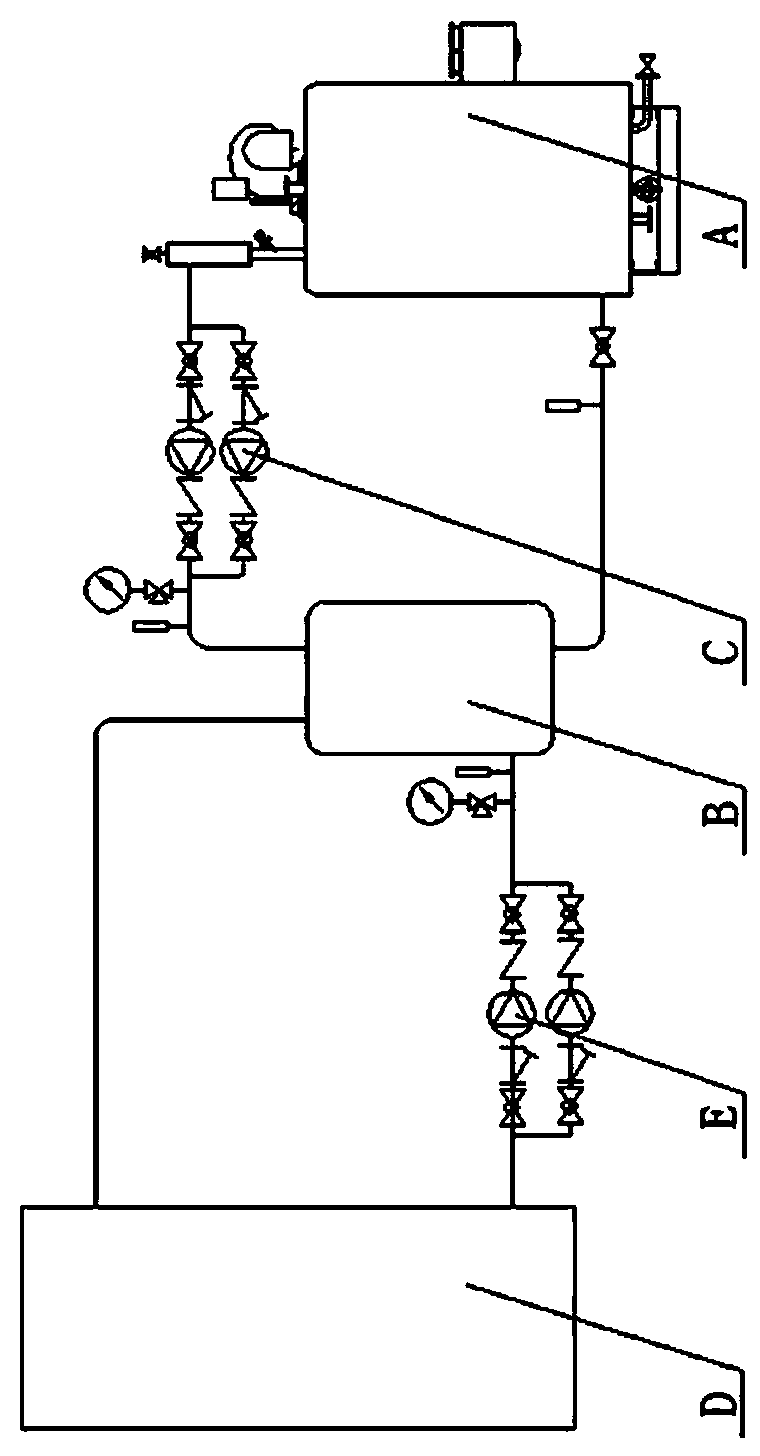

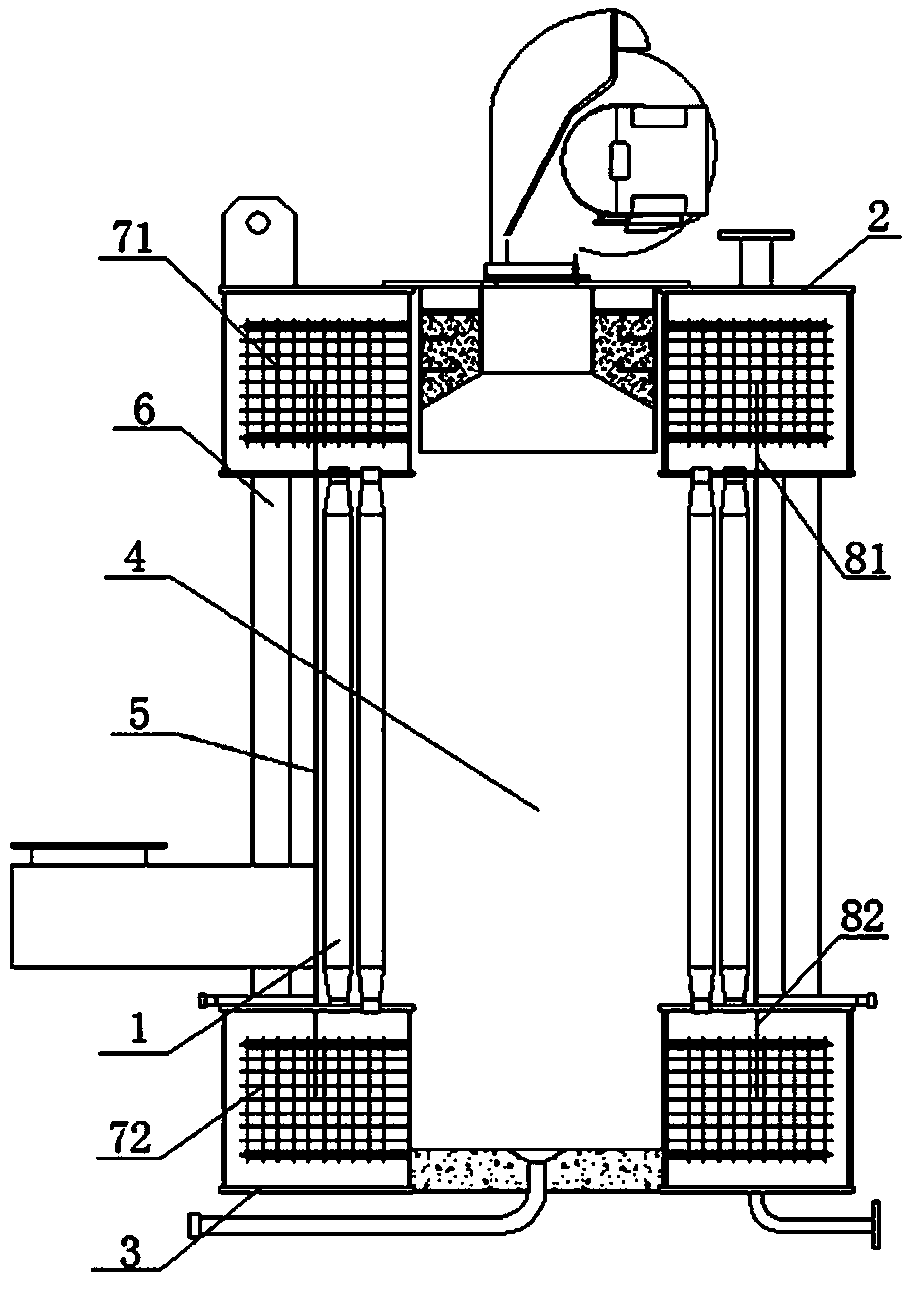

[0026] Embodiment: An integrated cross-flow atmospheric hot water boiler, including a heating surface water pipe 1, an upper annular header 2, a lower annular header 3, a combustion chamber 4 and a cylinder body 5, the heating surface water pipe is located in the cylinder body, The upper and lower ends of the heating surface water pipe 1 communicate with the upper annular header 2 and the lower annular header 3 respectively, and at least one of the upper annular header 2 and the lower annular header 3 is provided with at least one In the heat exchanger, an insulated downcomer 6 communicates between the upper annular header 2 and the lower annular header 3 .

[0027] The water pipe on the heating surface is jointly defined by the furnace head and the furnace bottom to form a combustion chamber. The water pipe on the heating surface can be specifically divided into an inner ring and an outer ring, that is, the convection section has two returns, the first return is the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com