Efficient shell tube type heat exchanger and manufacturing method thereof

A shell-and-tube heat exchanger, high-efficiency technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problem of large heat area, waste of heat exchange tubes and heat exchanger materials, heat exchange Poor efficiency and other problems, to achieve high heat transfer coefficient, reduce thermal resistance, improve heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

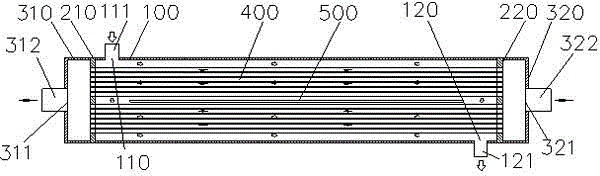

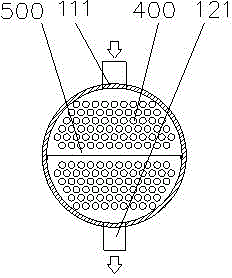

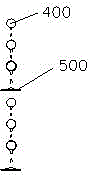

[0031] Such as Figure 1-3 As shown, the high-efficiency shell-and-tube heat exchanger includes a cylinder 100, a first tube sheet 210, a second tube sheet 220, a first end cover 310, a second end cover 320, a heat exchange tube 400 and an anti-drip partition 500, the cylinder 100 is set to open at both ends, the first tube sheet 210 and the second tube sheet 220 are respectively arranged on the two open ends of the cylinder 100, and the first end cover 310 is set on the outside of the first tube sheet 210 , the second end cover 320 is set on the outside of the second tube sheet 220; the first tube sheet 210 and the second tube sheet 220 are provided with heat exchange tube mounting holes 230; the drip-proof partition 500 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com