Boiler

A technology for boilers and drums, applied in the field of boilers, which can solve the problems of increased difficulty in boiler processing and use, increased complexity of boiler structure, unfavorable popularization, etc., and achieves the effects of increasing utilization efficiency, increasing area, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

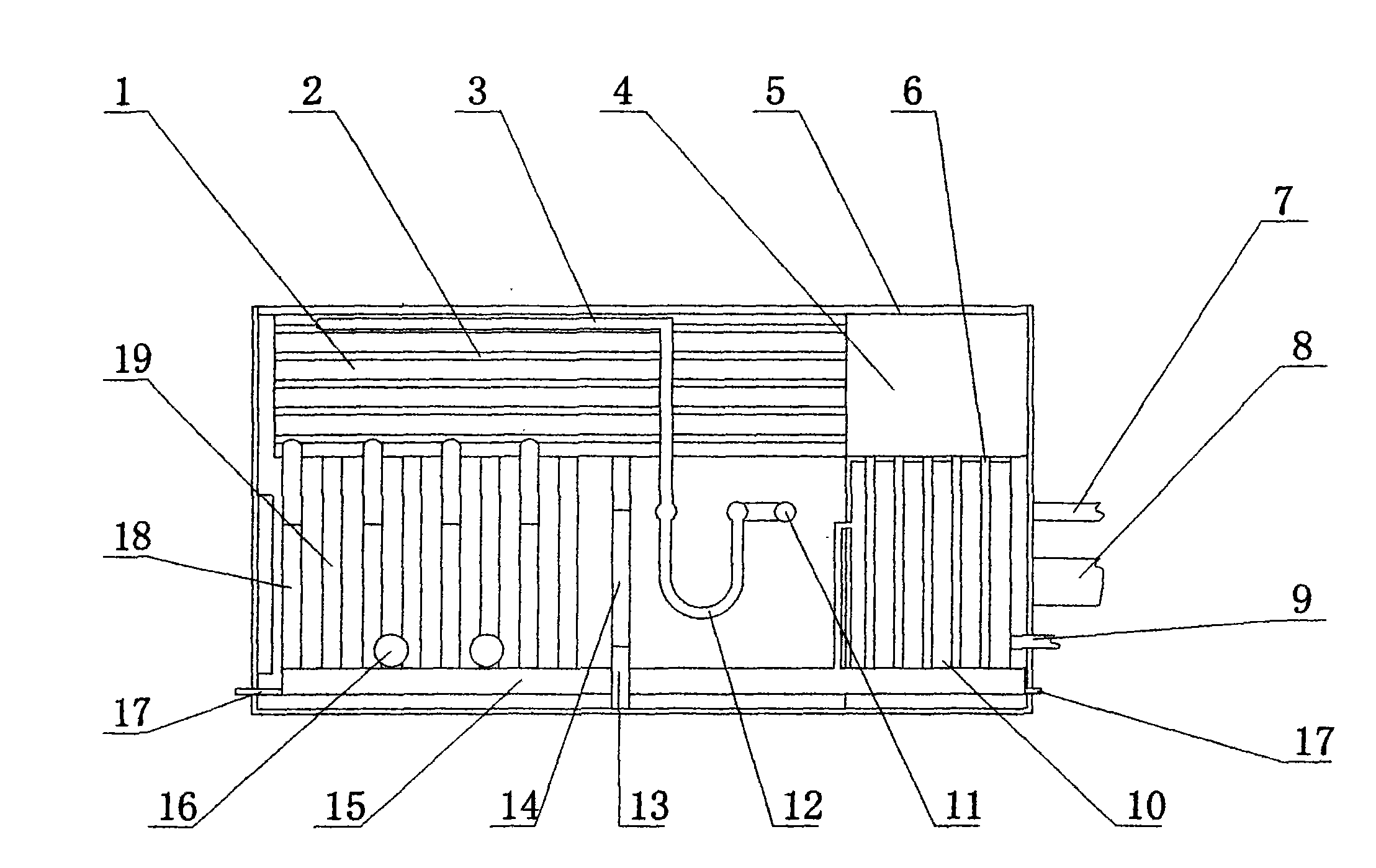

[0026] as attached figure 1 As shown, a boiler includes a casing 5, the front end of the casing 5 is provided with a combustion inlet, and the rear end is provided with a smoke outlet 8 and a water outlet 7. Usually, a fan is connected to the smoke outlet 8 to increase the speed of the smoke flow. In the present invention, a vertical partition wall 13 is provided in the middle of the housing 5, and a combustion chamber is formed between the partition wall 13 and the combustion inlet. The combustion chamber is where fuel such as coal is burned. Several openings 14 are provided in the middle of the partition wall 13 . In the present invention, the number of openings is three, and three openings are the best solution obtained through actual tests. Simultaneously, outside some through holes are reserved between the partition wall 13 and the shell 5, the remaining parts are completely closed.

[0027] In this embodiment, a waste heat recovery box 10 is provided at the rear of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com