All fins heat-exchanger combined lithium bromide absorption refrigerator

A heat and mass exchanger, absorption refrigeration technology, applied in heat exchange equipment, refrigerators, adsorption machines, etc., can solve the problem of no lithium bromide and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

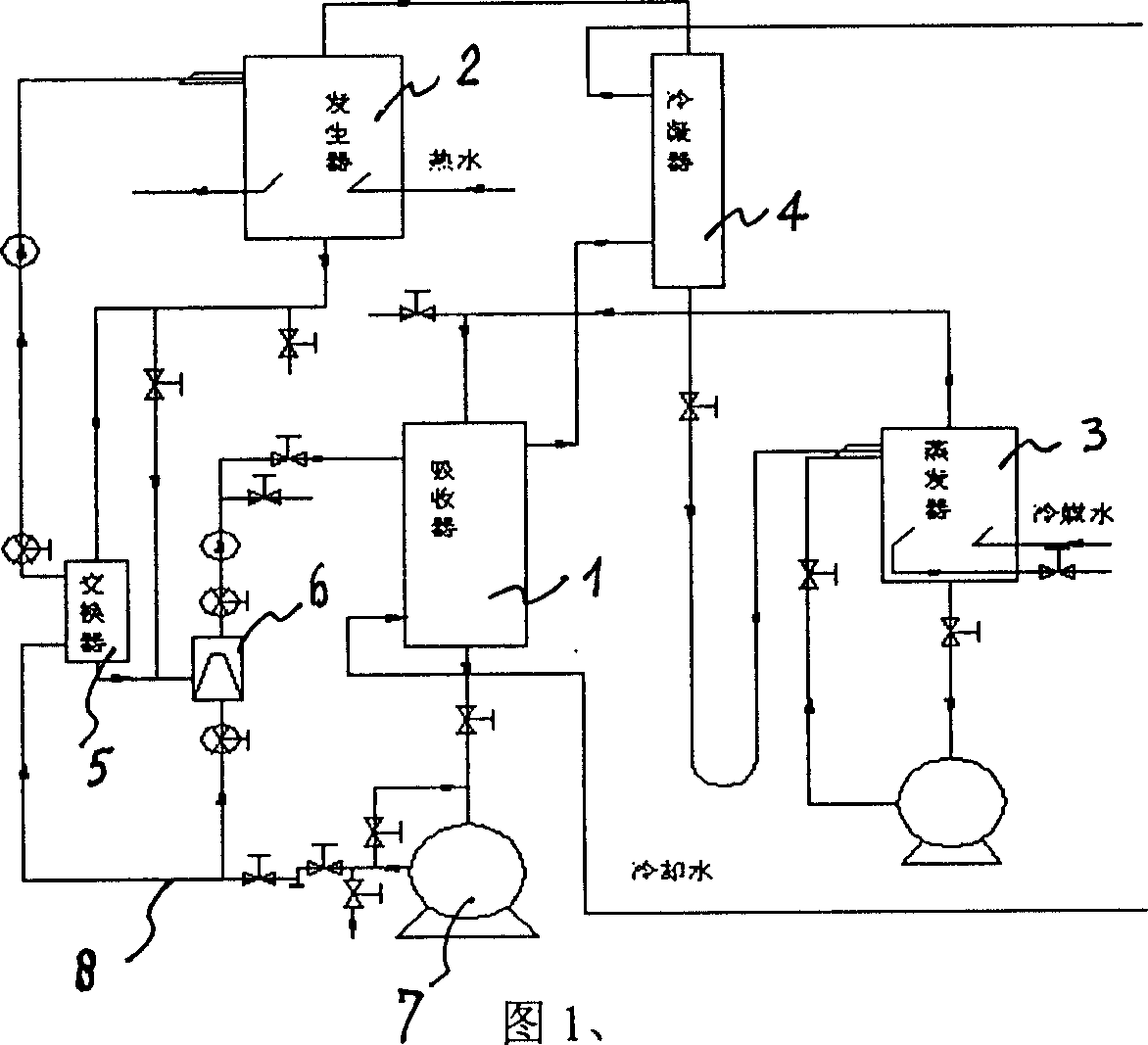

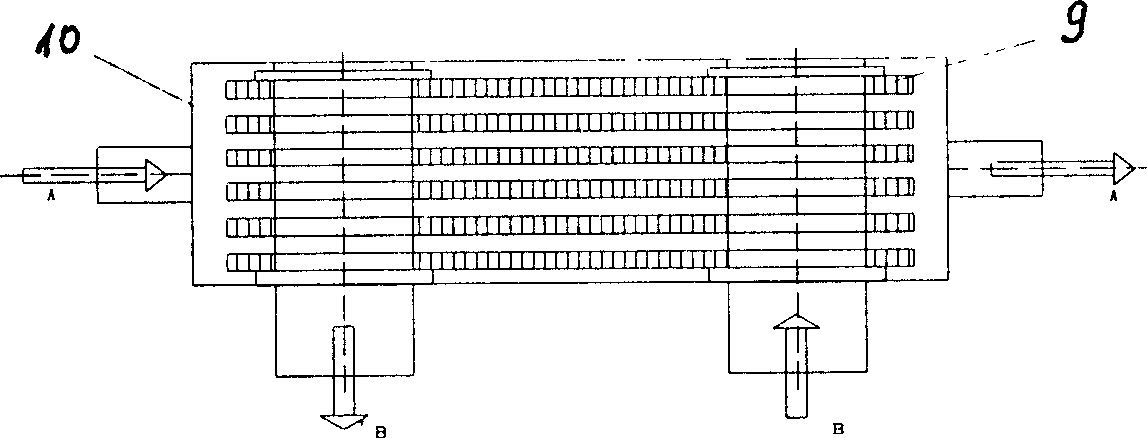

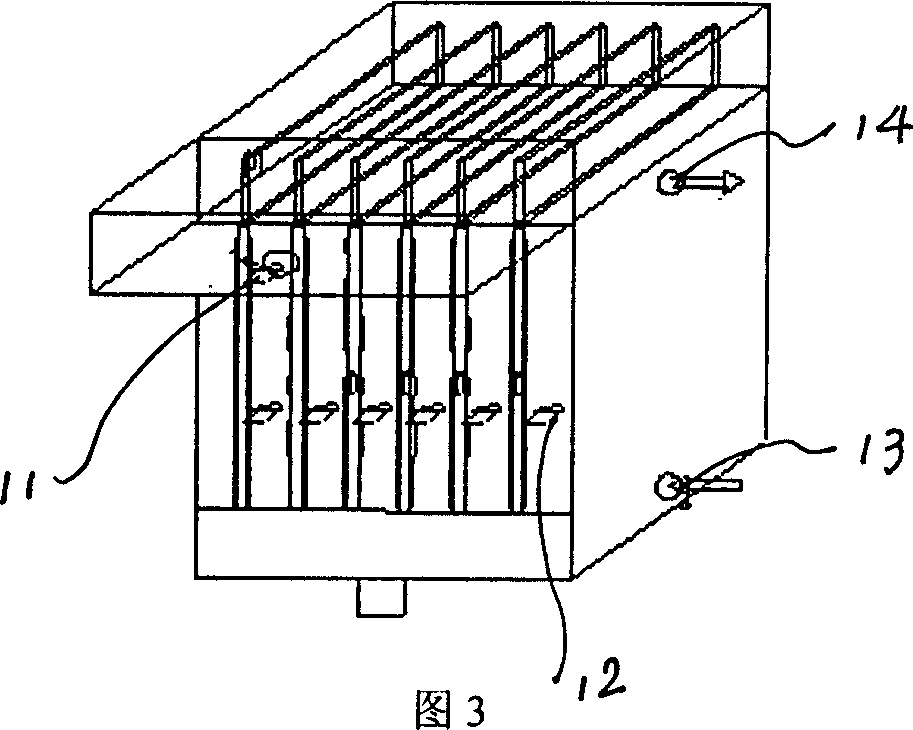

[0013] As shown in Figure 1, the lithium bromide absorption refrigeration device composed of a full-plate-fin heat and mass exchanger consists of absorber 1, generator 2, evaporator 3, condenser 4, solution exchanger 5, ejector 6, pump 7 , Pipeline 8 and other components, figure 2 In order to be used as the basic structure diagram of the plate-fin heat exchanger of absorber, generator, evaporator and condenser, the solution heat exchanger can adopt this structure, or it can be an ordinary plate and plate-fin heat exchanger. After the fluid B enters the heat exchanger, it is distributed into the flow passages on the side of each fin 9 and then collected to another outlet pipe to flow out. The fluid A flows on the housing 10 side. The plate-fin heat exchanger is modified and applied to the components of the system according to the working characteristics of different components, see the description of each component below.

[0014] (1) Absorber: The solution side is a falling film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com