Reactor and method for preparing epoxypropane by reactor

A propylene oxide and reactor technology, which is applied in the field of reactors and the preparation of propylene oxide by using the reactor, can solve the problems of increasing separation difficulty, transportation, storage and use danger, etc., and achieves reduction of side reactions, improvement of utilization rate, reduction of Effect of feed amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

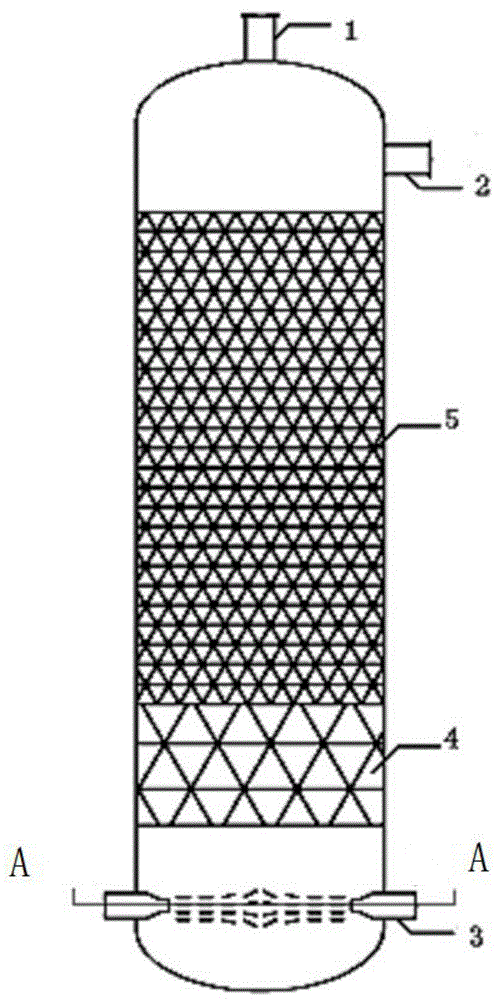

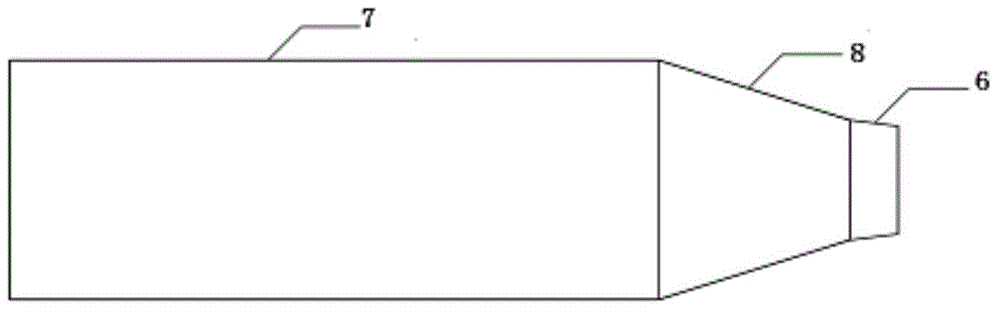

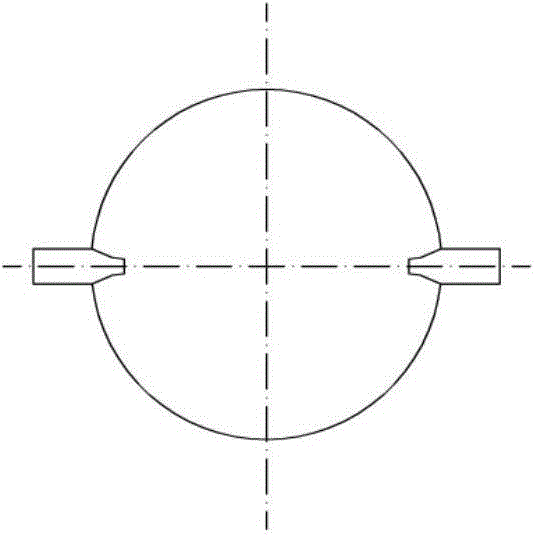

[0036] Such as figure 1 shown and image 3 As shown, a reactor, the reactor is a fixed bed reactor, the middle part of the reactor is filled with an epoxidation catalyst, the top wall is provided with a gas outlet 1, the upper side wall is provided with a liquid outlet 2, and the lower side wall is provided with a 1 A group of injectors, each group of injectors includes 2 injectors 3, distributed on the same plane and symmetrical to each other; as figure 2 As shown, the injector 3 is composed of a nozzle 6 connected to the nozzle and the nozzle, the nozzle 6 is frusto-conical, and the diameter of the end of the nozzle connected to the nozzle is greater than the diameter of the end away from the nozzle. The nozzle 6 extends into the fixed bed reactor, and the nozzle is divided into two sections. The section 7 of the nozzle away from the nozzle is cylindrical, and the other section 8 is truncated conical. The diameter of the end of the nozzle away from the nozzle is larger tha...

Embodiment 2

[0038] Identical to the structure of Example 1, the difference is that the molecular formula of catalyst I is (TiO2) 0.08 (SiO2) 0.02 , the molecular formula of catalyst II is (TiO2) 0.04 (SiO2) 0.06 .

Embodiment 3

[0040] Identical to the structure of Example 1, the difference is that the lower side wall of the reactor is provided with 2 groups of injectors, such as Figure 4 As shown, each injector in the 2 sets of injectors is 90 degrees to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com