Combined treatment method of polycyclic aromatic hydrocarbon wastewater

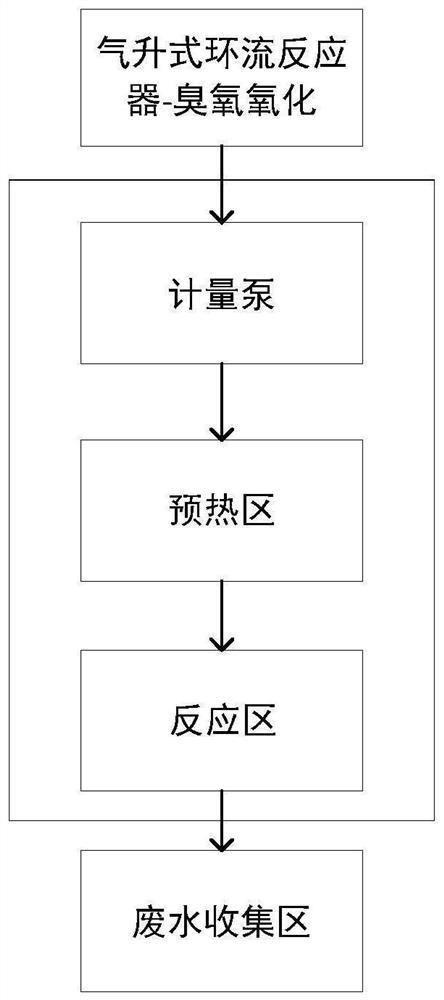

A technology of polycyclic aromatic hydrocarbons and treatment methods, applied in the field of wastewater treatment, can solve problems such as complex wastewater components, achieve the effects of increasing mass transfer and heat transfer, good sealing, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

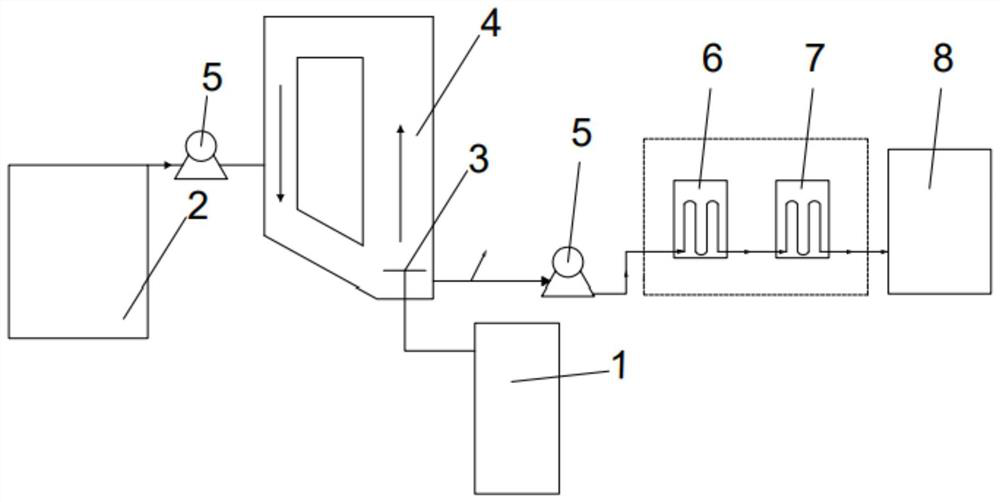

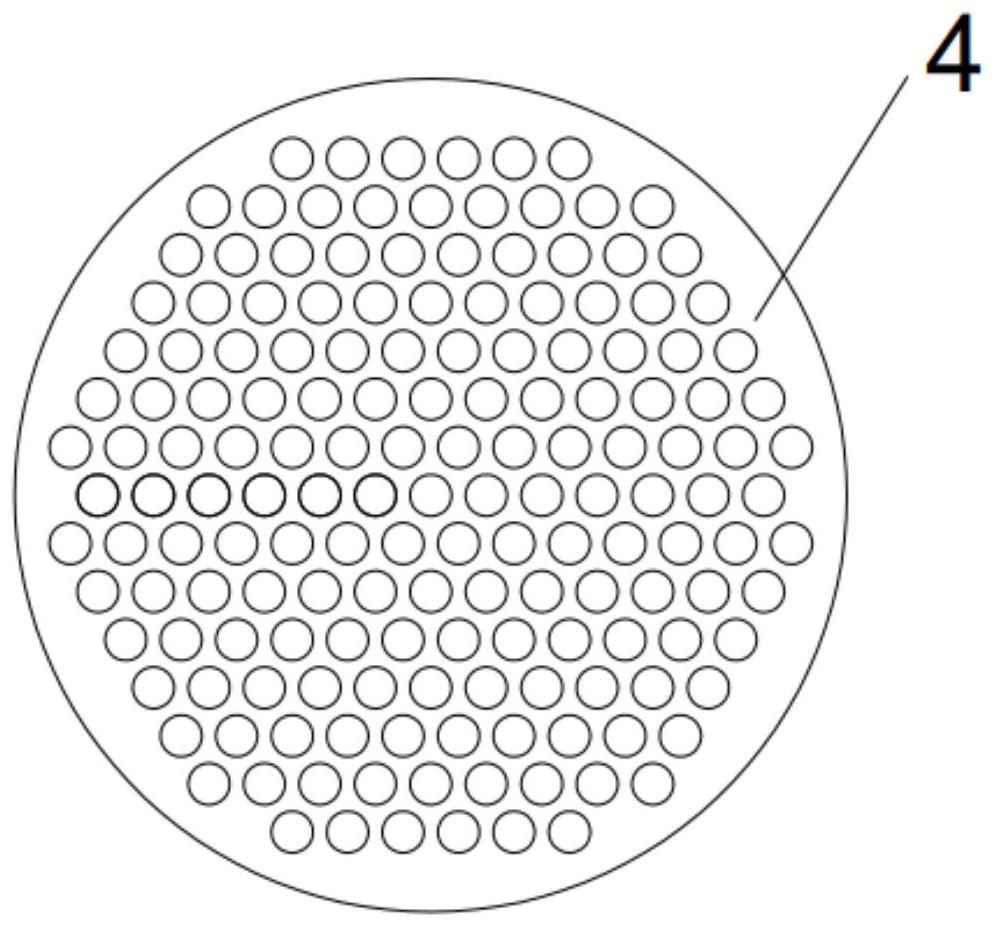

[0034] (1) Get polycyclic aromatic hydrocarbon wastewater (COD: 23476mg / L, BOD: 2817mg / L, B / C=0.12, content of polycyclic aromatic hydrocarbons=1265mg / L) add in the waste water storage tank and adjust pH to be 1, through The metering pump enters the air-lift loop reactor, in which ozone enters from the air inlet at the bottom of the tower, and a gas splitter is installed at the bottom of the tower, and the wastewater enters the reactor from the downflow area of the reactor. The COD mass ratio is 1:1. The reaction time is 1h.

[0035] (2) The waste water after the reaction flows out from the water outlet at the bottom of the tower, and it is detected by sampling. At this time, the effluent COD=6703mg / L, BOD=1609mg / L, B / C=0.24, and the content of polycyclic aromatic hydrocarbons=690mg / L.

[0036] (3) The wastewater oxidized by ozone enters the microchannel reactor through the metering pump (wherein the structural combination is a-straight channel, b-circular cake type pulse v...

Embodiment 2

[0039] (1) Get polycyclic aromatic hydrocarbon wastewater (COD: 22954mg / L, BOD: 2525mg / L, B / C=0.11, polycyclic aromatic hydrocarbon substance content is 1480mg / L) and add in the waste water storage tank and adjust pH to be 2, through The metering pump enters the air-lift loop reactor, in which ozone enters from the air inlet at the bottom of the tower, and a gas splitter is installed at the bottom of the tower, and the wastewater enters the reactor from the downflow area of the reactor. The COD mass ratio is 1:2. The reaction time is 1.5h.

[0040](2) The waste water after the reaction flows out from the water outlet at the bottom of the tower, and it is detected by sampling. At this time, the effluent COD=6003mg / L, BOD=2041mg / L, B / C=0.34, and the content of polycyclic aromatic hydrocarbons=101mg / L.

[0041] (3) The wastewater oxidized by ozonation enters the microchannel reactor through the metering pump (wherein the structural combination is a-straight channel, c-orthorho...

Embodiment 3

[0044] (1) Get polycyclic aromatic hydrocarbon wastewater (COD: 30279mg / L, BOD: 4239mg / L, B / C=0.14, polycyclic aromatic hydrocarbon substance content is 1585mg / L) and add in the waste water storage tank and adjust pH to be 3, through The metering pump enters the air-lift loop reactor, in which ozone enters from the air inlet at the bottom of the tower, and a gas splitter is installed at the bottom of the tower, and the wastewater enters the reactor from the downflow area of the reactor. The COD mass ratio is 1:3. The reaction time is 2h.

[0045] (2) The waste water after the reaction flows out from the water outlet at the bottom of the tower, and it is detected by sampling. At this time, the effluent COD=6075mg / L, BOD=2005mg / L, B / C=0.33, and the content of polycyclic aromatic hydrocarbons=121mg / L.

[0046] (3) The wastewater after ozone oxidation enters the microchannel reactor through the metering pump (wherein the structural combination is b-round cake type pulse variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com