Rectangular offset strip fin heat transfer pipe and uses thereof

A technology of heat transfer tubes and staggered teeth, which is applied in the field of heat and mass exchange, can solve the problems of not fully exerting the effect of heat transfer enhancement, expanding the limitation of effective heat transfer area, and poor heat transfer enhancement, so as to achieve a wide range of industrial applications and raw materials High utilization rate, increase the effect of heat and mass transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

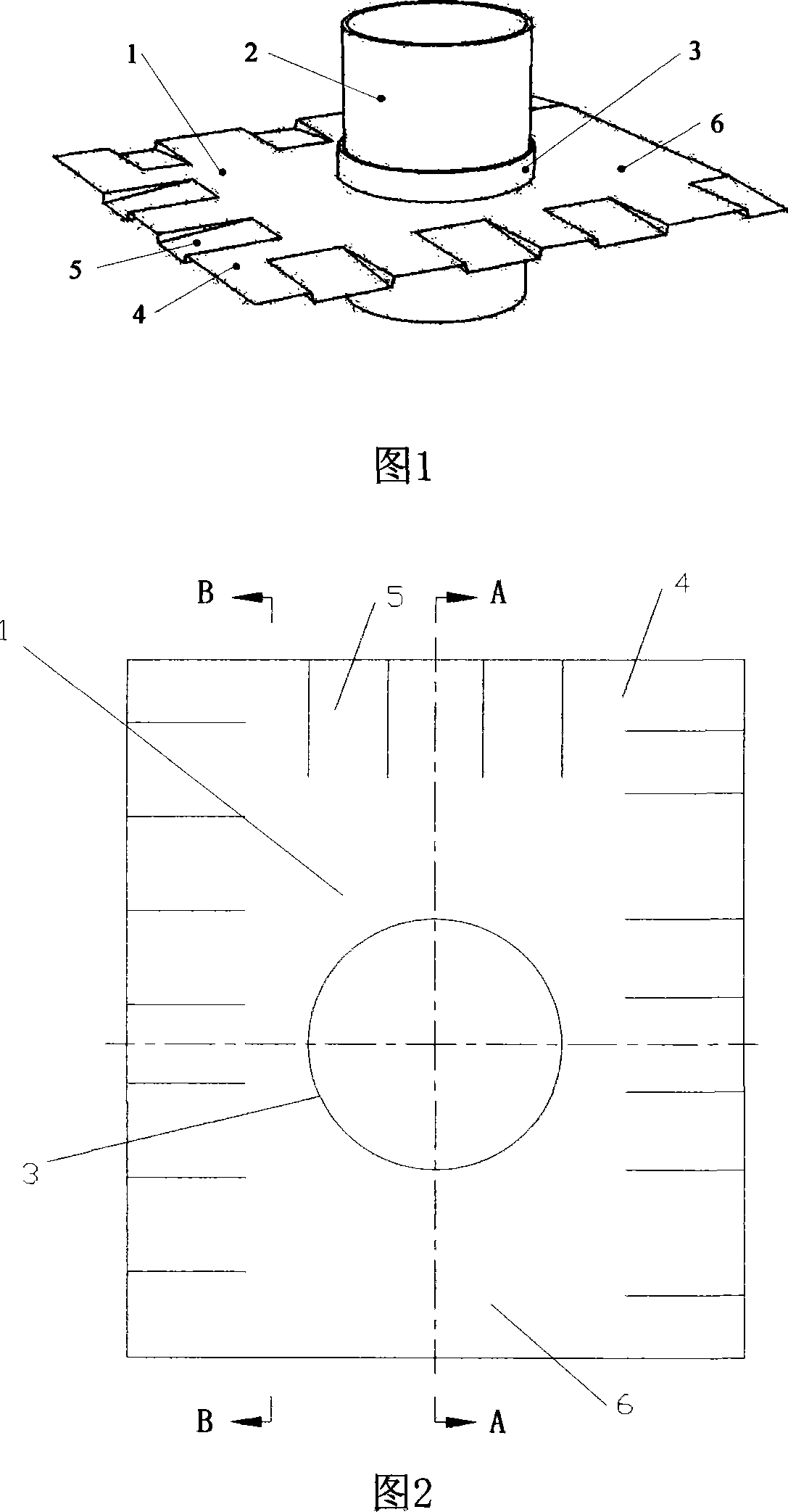

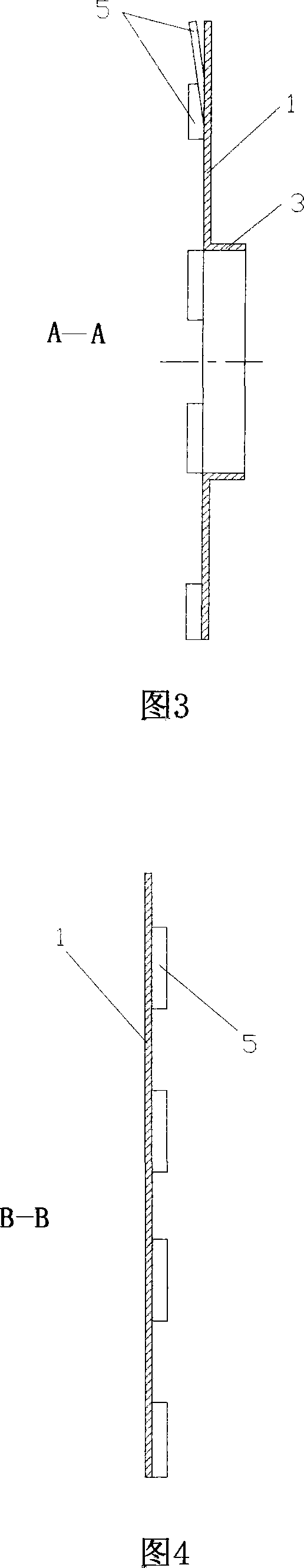

[0027] As shown in Figure 1, the rectangular staggered fin heat transfer tube includes a tube body 2 and a plurality of rectangular staggered fins 1 sleeved on the tube body 2; as shown in Figures 2, 3 and 4, the rectangular staggered The outer edge of the leeward side of the tooth fin 1 is a flat outer edge 6, and the other three outer edges are staggered outer edges 4, which are respectively provided with 5 to 8 wedge-shaped narrow grooves 5, and the three staggered outer edges 4 are along the thickness direction The cross-section is staggered.

[0028] The rectangular staggered fin 1 adopts a rectangular thin steel plate with a length of 90mm, a width of 80mm, and a thickness of 0.5-1mm; the width of the wedge-shaped narrow groove 5 is 8-12mm, and the width of each wedge-shaped narrow groove can be the same or different; The mutual spacing of the narrow slots can be the same or different; the outer end of the wedge-shaped narrow slot protrudes from the plane of the rectangu...

Embodiment 2

[0031] The above-mentioned rectangular staggered fin heat transfer tube can be applied to the heat and mass exchange equipment of vapor-solid, vapor-liquid phase change desublimation process, sublimation process and condensation process. When using the hot-melt condensation box in the process, the vapor-phase working medium can be sublimated into a solid and attached to the surface of the finned tube, increasing the yield of desublimation and reducing the energy consumption of the system. The tube body 2 of the rectangular staggered fin heat transfer tube in the hot-melt condenser box is a U-shaped tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com