Patents

Literature

41results about How to "Wide range of industrial uses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing SOx in gas by using ethylene glycol complex solution

ActiveCN103611391ADecreased sulfur absorption capacityBroad marketGas treatmentDispersed particle separationMicrowave methodPolyethylene glycol

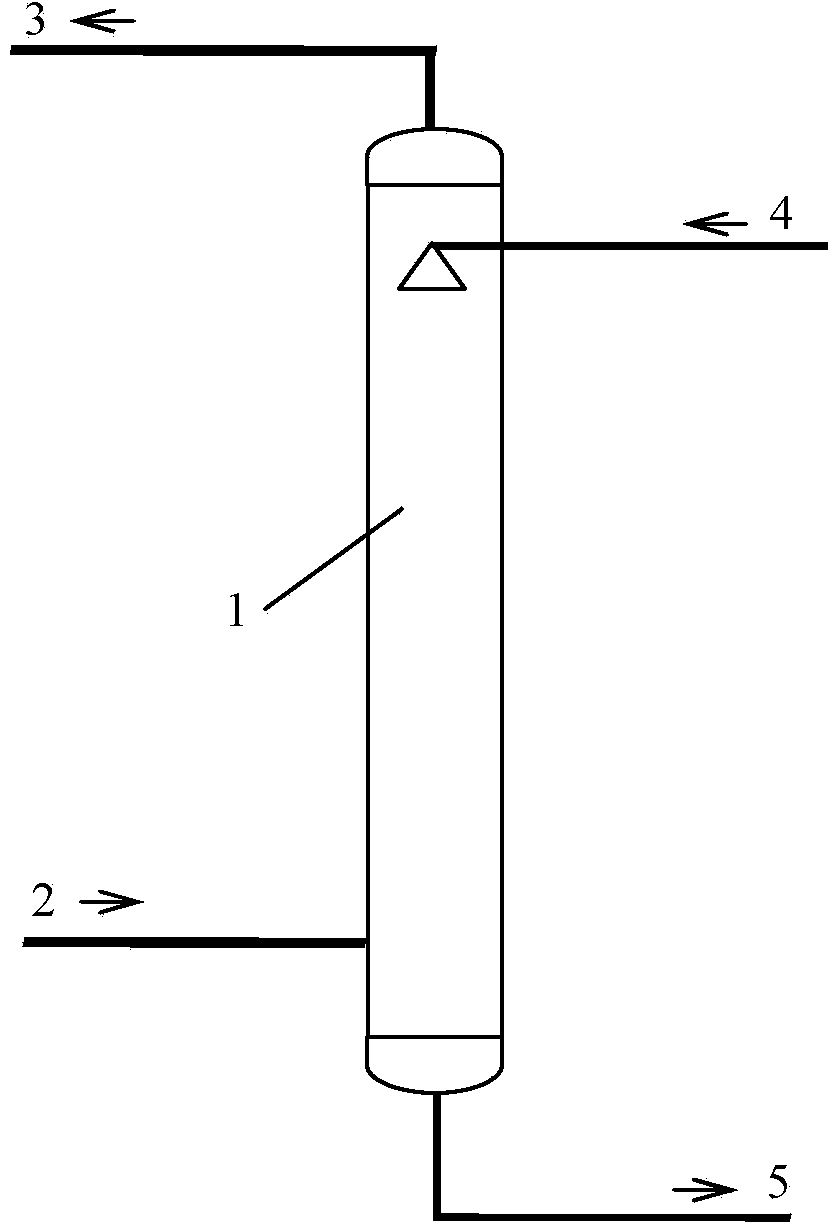

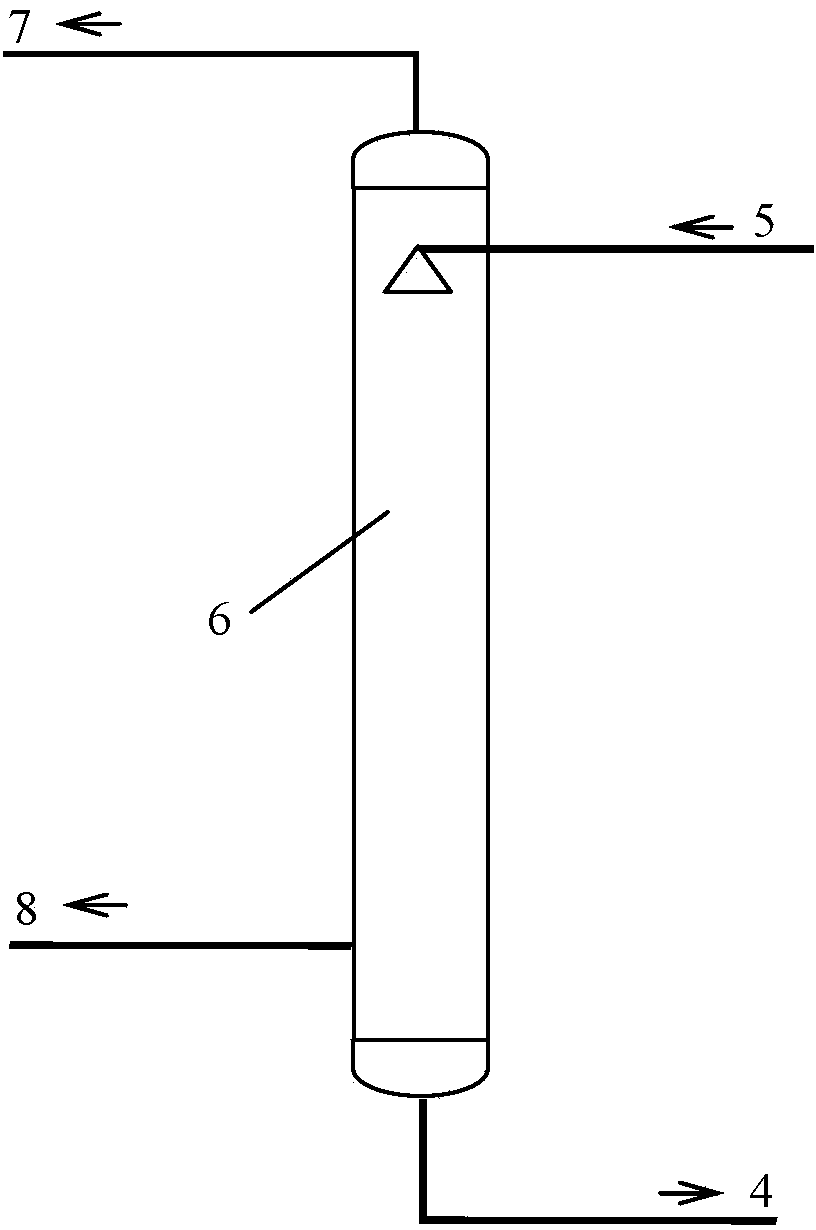

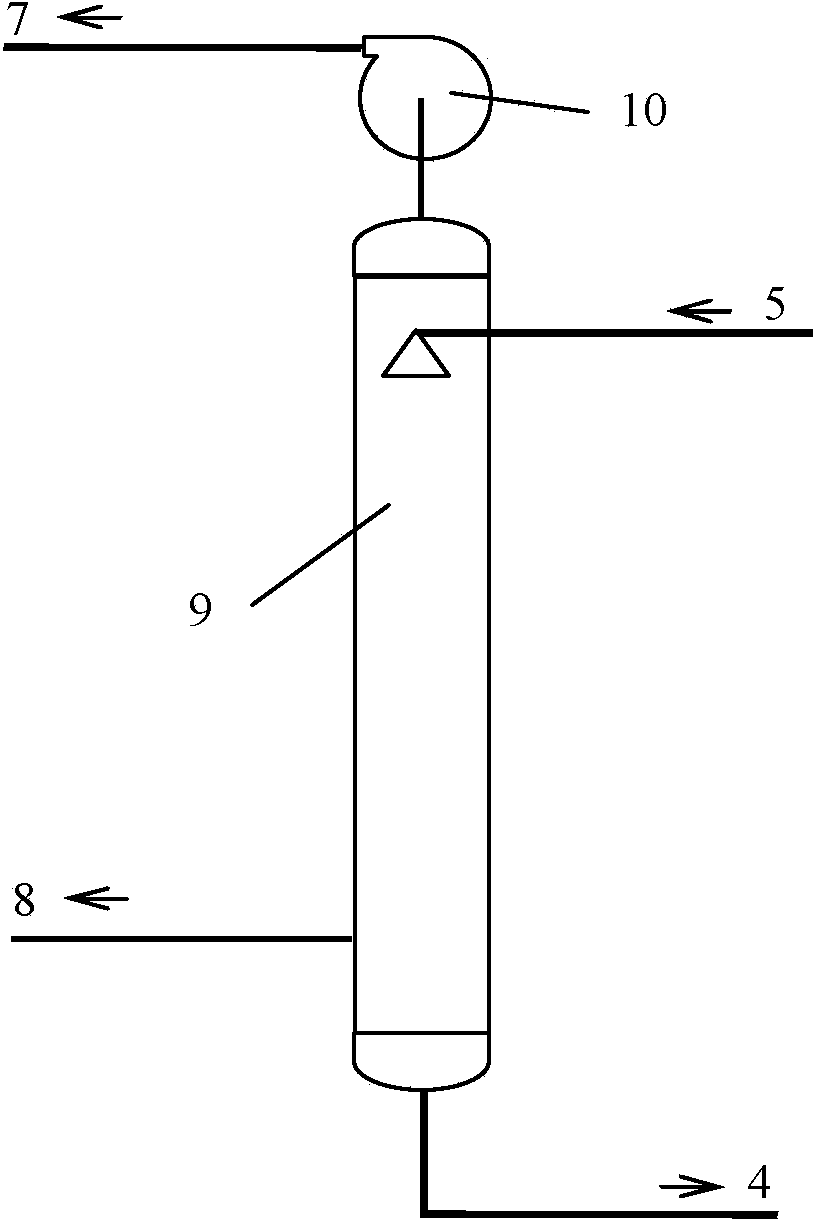

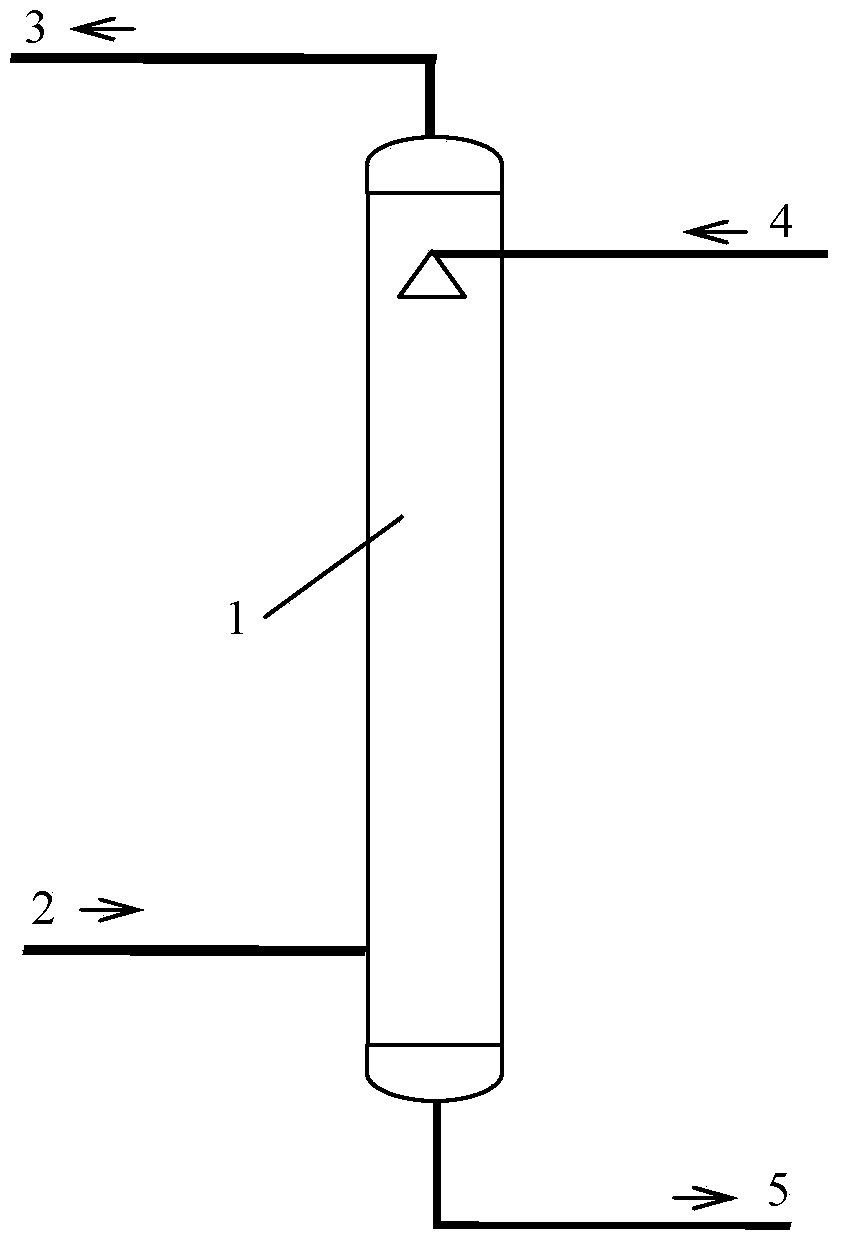

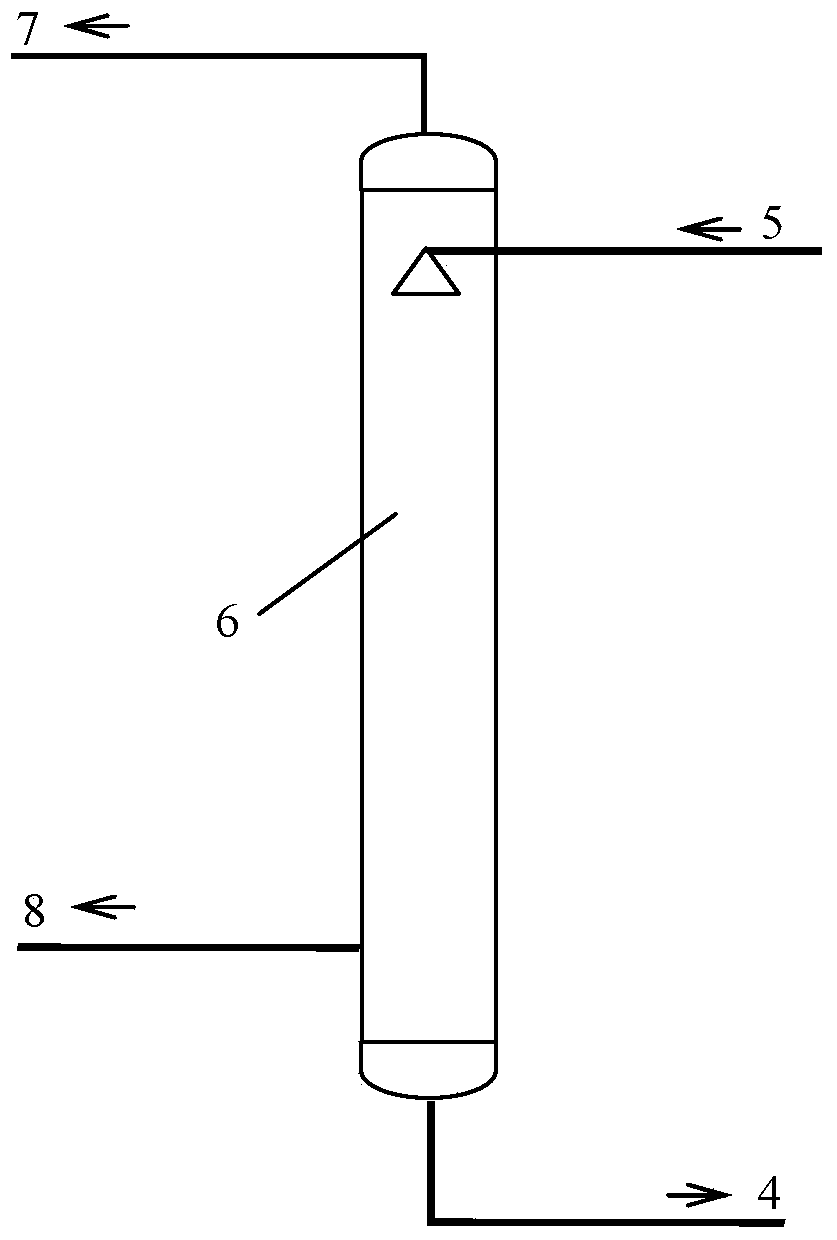

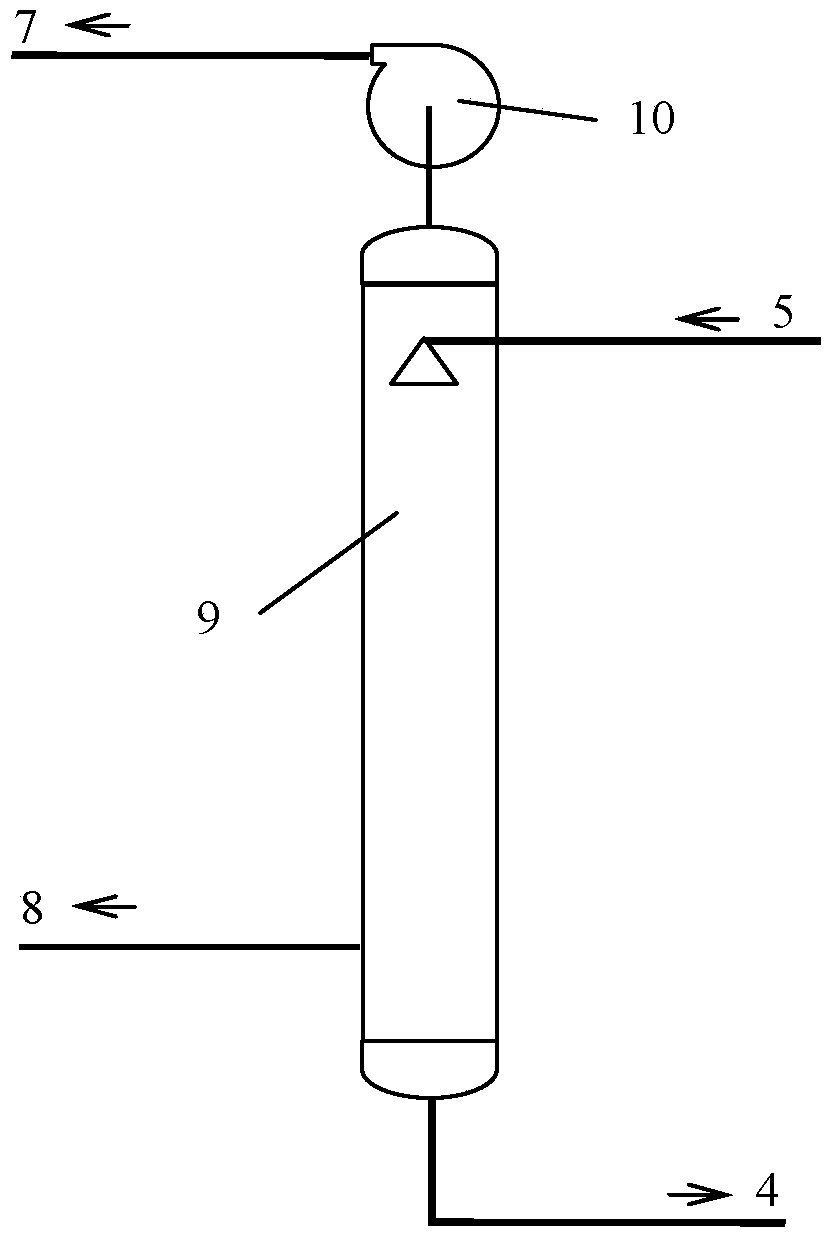

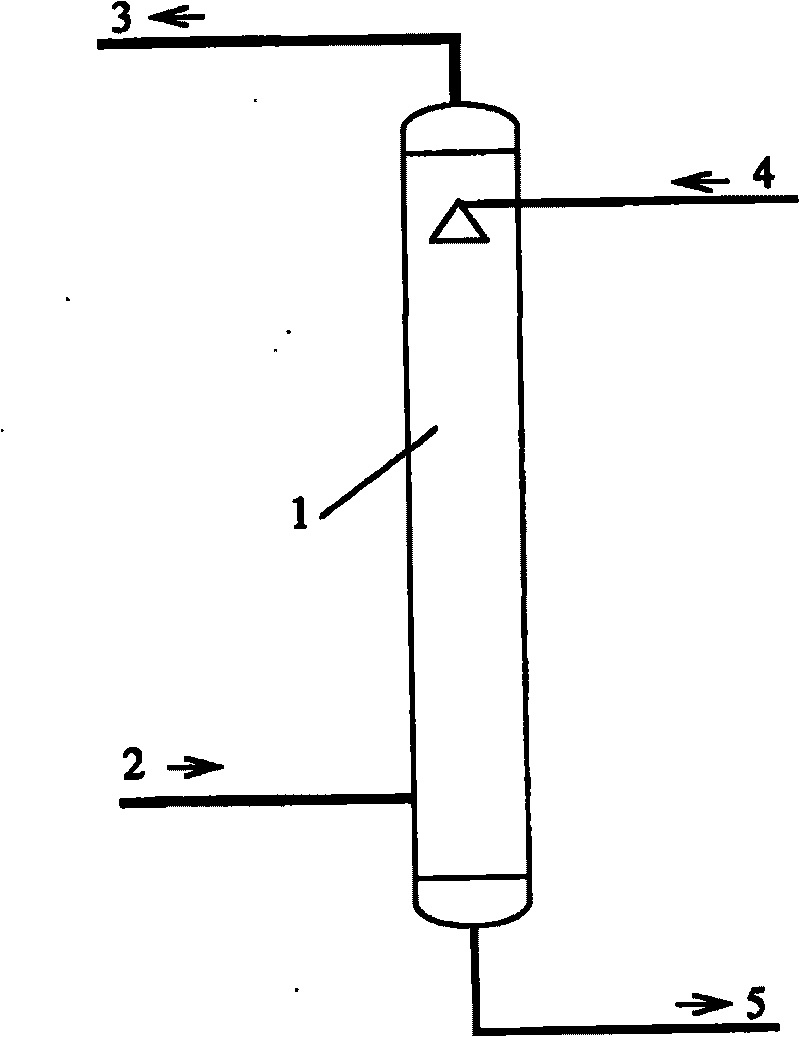

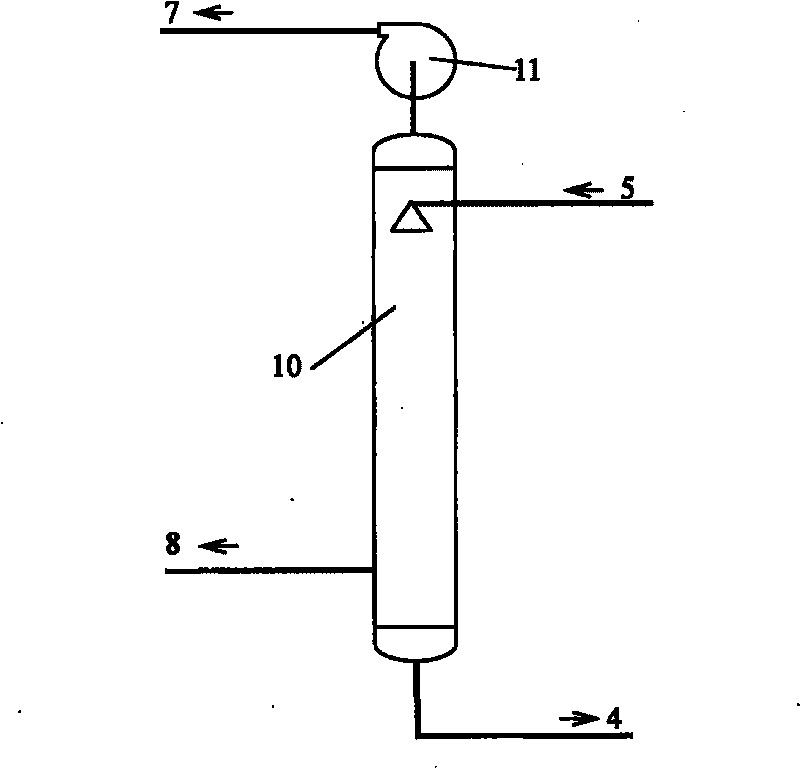

The invention discloses a method for SOx in a gas by using ethylene glycol complex solution. Ethylene glycol and / or polyethylene glycol is mixed with organic acid or organic acid salt without containing nitrogen atoms in molecules to form the ethylene glycol complex solution, and the ethylene glycol complex solution is in contact with the gas containing Sox to absorb SOx in the gas, wherein x is equal to 2 and / or 3; the ethylene glycol complex solution in which SOx is absorbed is regenerated by using one or more ways of a heating method, a vacuum method, a gas stripping method, an ultrasonic method, a microwave method and a radiation method, sulfur dioxide and sulfur trioxide byproducts are released, and the regenerated ethylene glycol complex solution is recycled. The method can be applied to desulfurization of flue gases, incineration gases, coke furnace gases, synthetic waste gases in a dyestuff plant and sewage disposal gases in a chemical fibre factory, and other industrial raw material gases or waste gases containing SOx.

Owner:BEIJING BOYUAN HENGSHENG HIGH TECH +2

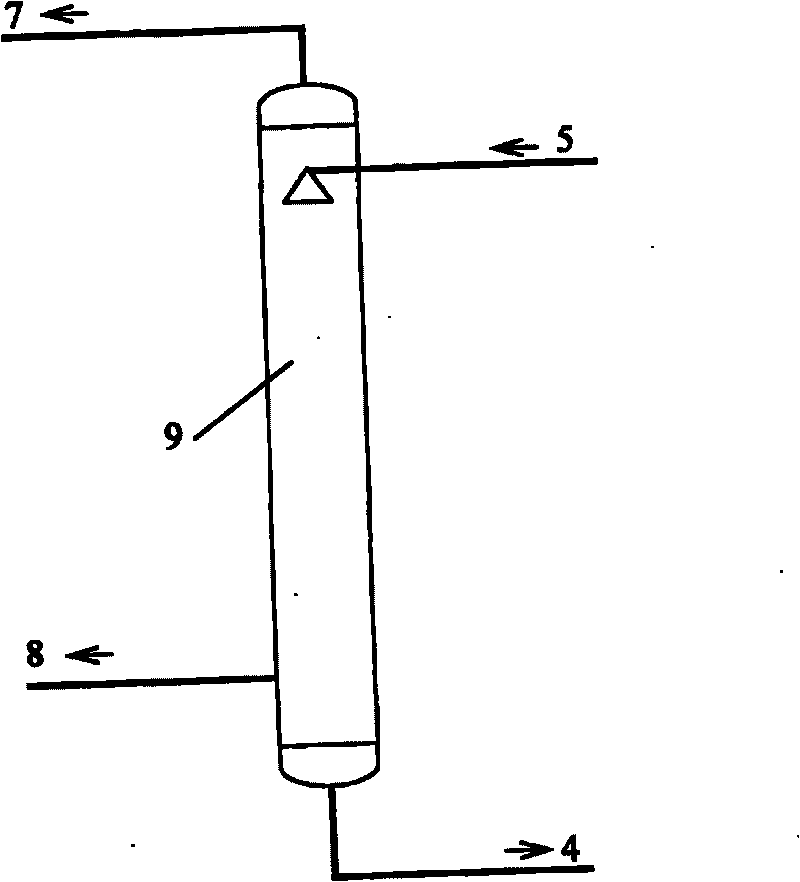

Method for removing SOx in gases with polyol complex solution

ActiveCN103623689ADecreased sulfur absorption capacityWon't spoilDispersed particle separationAir quality improvementFiberMicrowave method

The invention discloses a method for removing SOx in gases with a polyol complex solution. The method is characterized by mixing polyols with organic acids and / or organic acid salts to prepare the polyol complex solution, and contacting the polyol complex solution with gases containing SOx to absorb SOx in gases, wherein x is equal to 2 and / or 3; the polyols refer to organic compounds simultaneously containing two or more hydroxy groups in the same organic molecule except glycol and polyethylene glycol. The polyol complex solution absorbing SOx is regenerated by one or more of a heating method, a vacuum method, a gas stripping method, an ultrasonic wave method, a microwave method and a radiation method and releases sulfur dioxide and sulfur trioxide byproducts, and the regenerated polyol complex solution is recycled. The method can be used for desulfurizing flue gases, incineration gases, coke oven gases, synthetic waste gases in dye houses, blow-down gases in chemical fiber factories and other industrial raw gases or waste gases containing SOx.

Owner:BEIJING BOYUAN HENGSHENG HIGH TECH +2

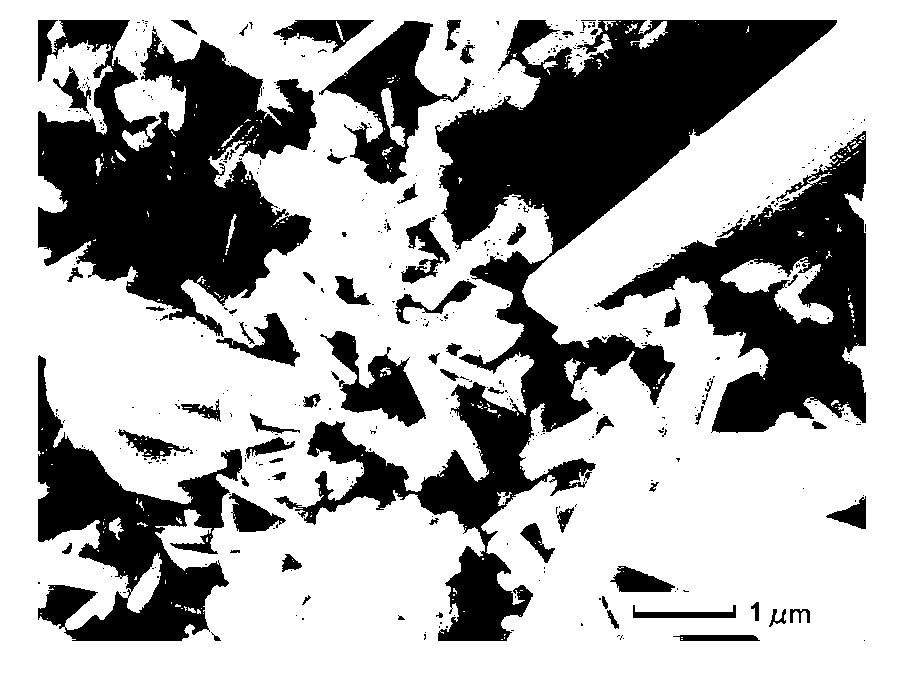

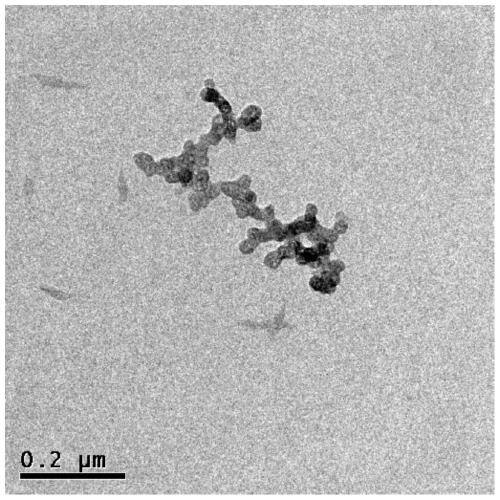

Method for preparing surface modification oil solubility nanometer copper

The invention belongs to the technical field of nanometer materials preparation with a novel function, and especially relates to a method for preparing surface modification oil solubility nanometer copper. The method comprises the following steps: taking copper alloy as raw material; adding organic solvent with modifier, adding acid or alkaline solution which can react with the alloy metal, fully reacting for 6-24h under the temperature of 0-100 DEG C, separating and purifying to obtain the surface modification oil solubility nanometer copper. The preparation method in the invention has simple process and equipment, easily obtained raw materials in cheap price, low cost, high yield and the like, which is applicable to large-scale industrial production.

Owner:浙江可沛尔新材料有限公司

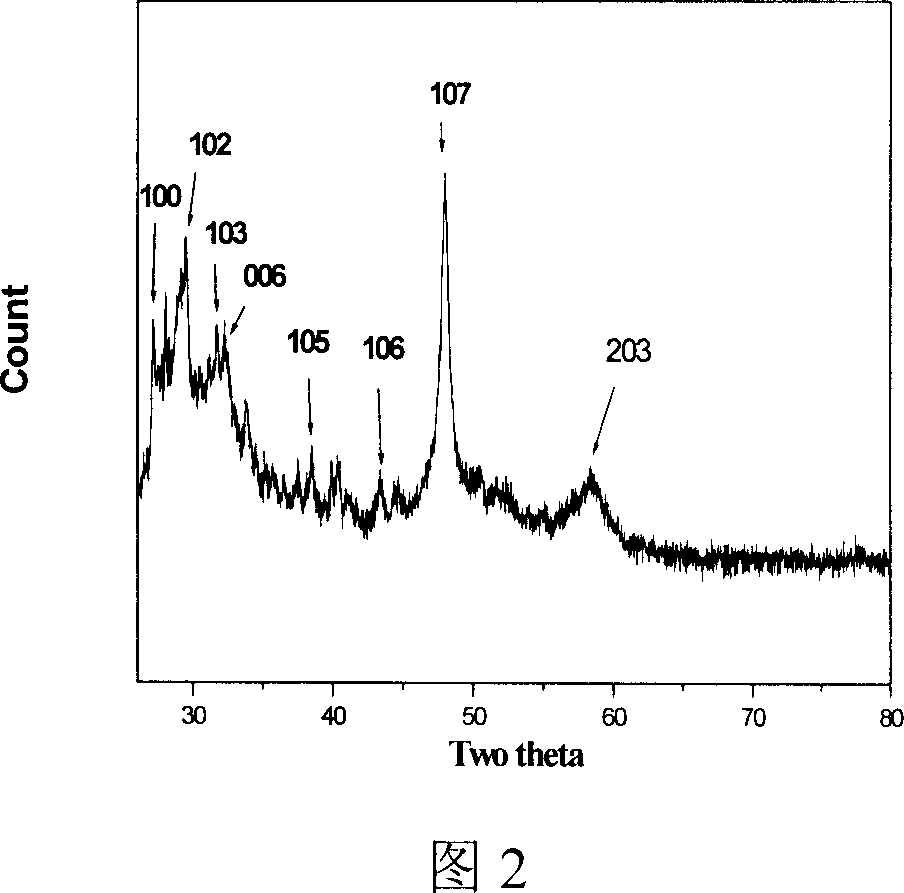

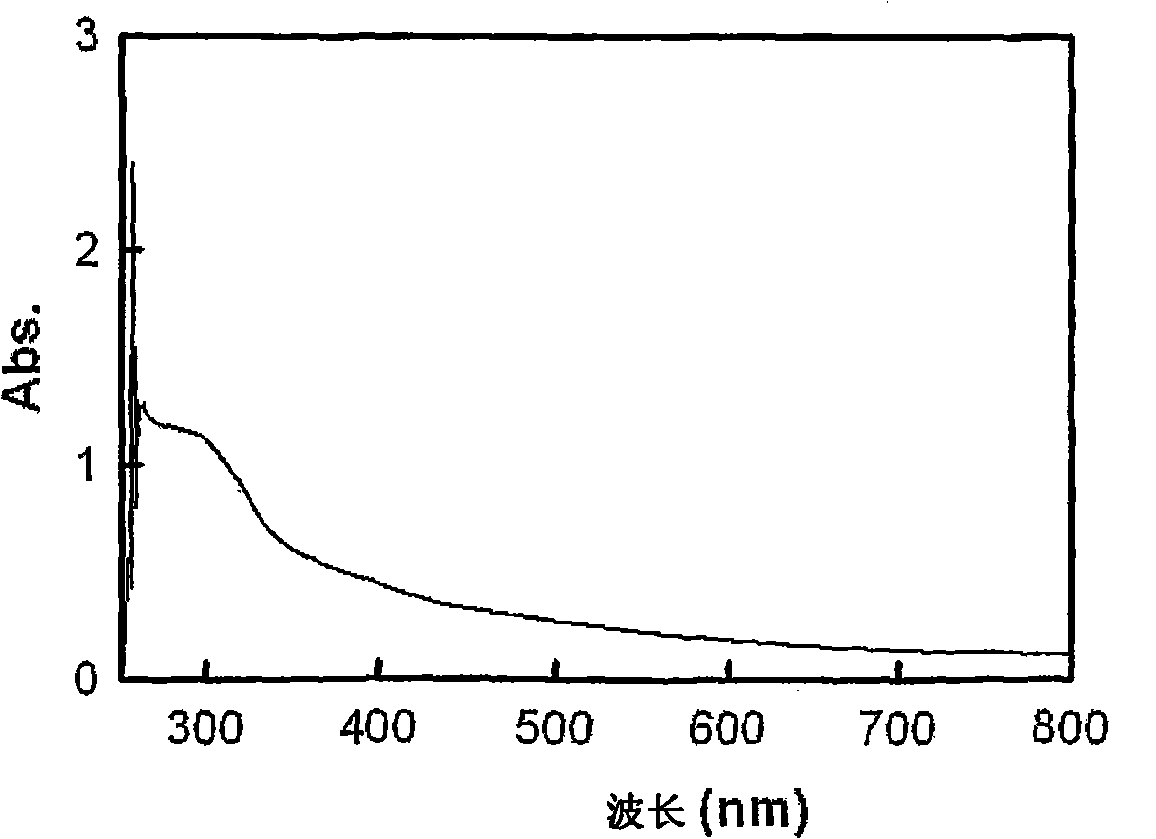

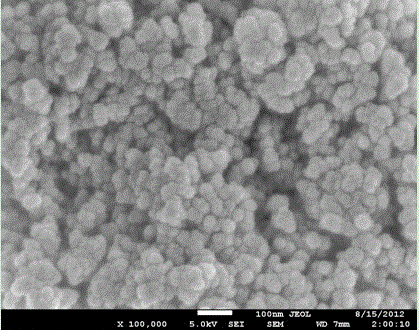

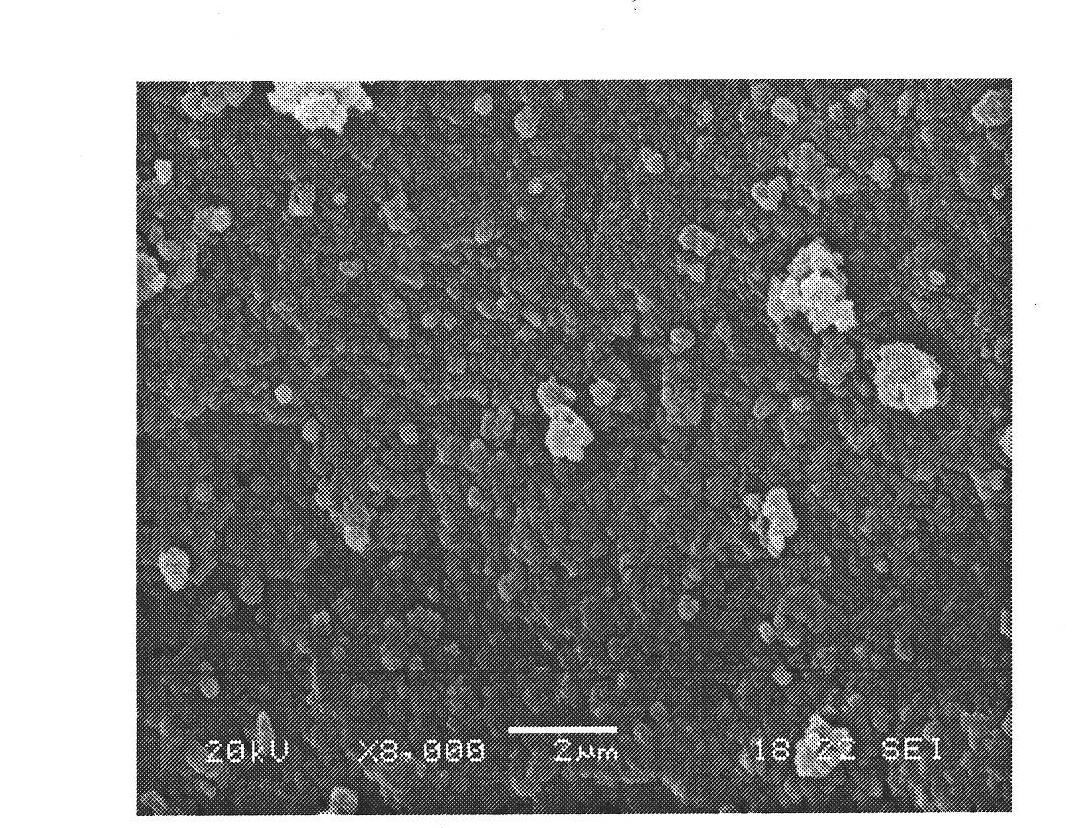

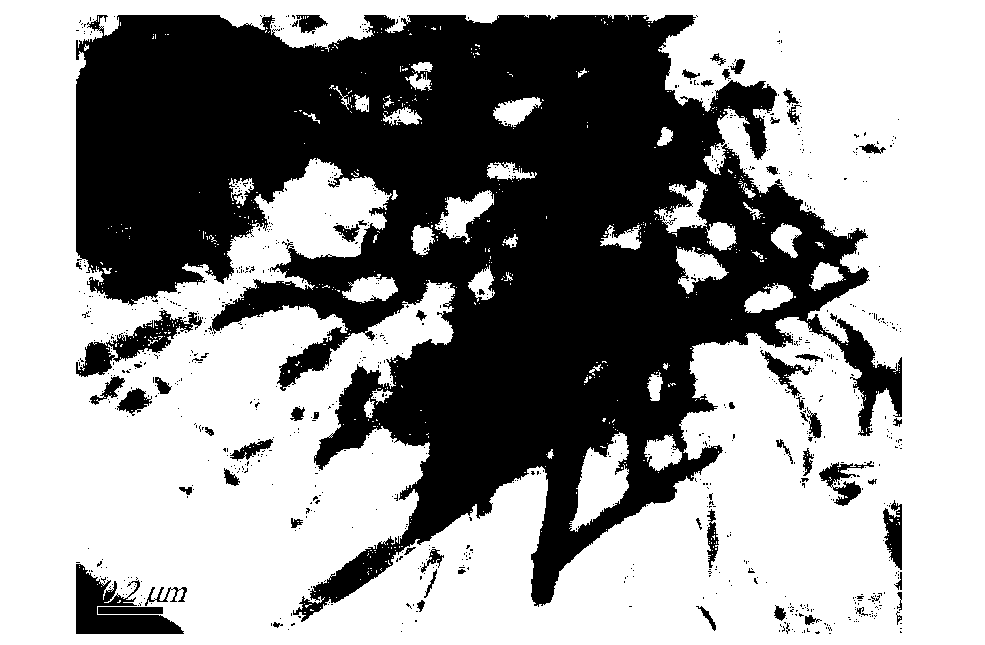

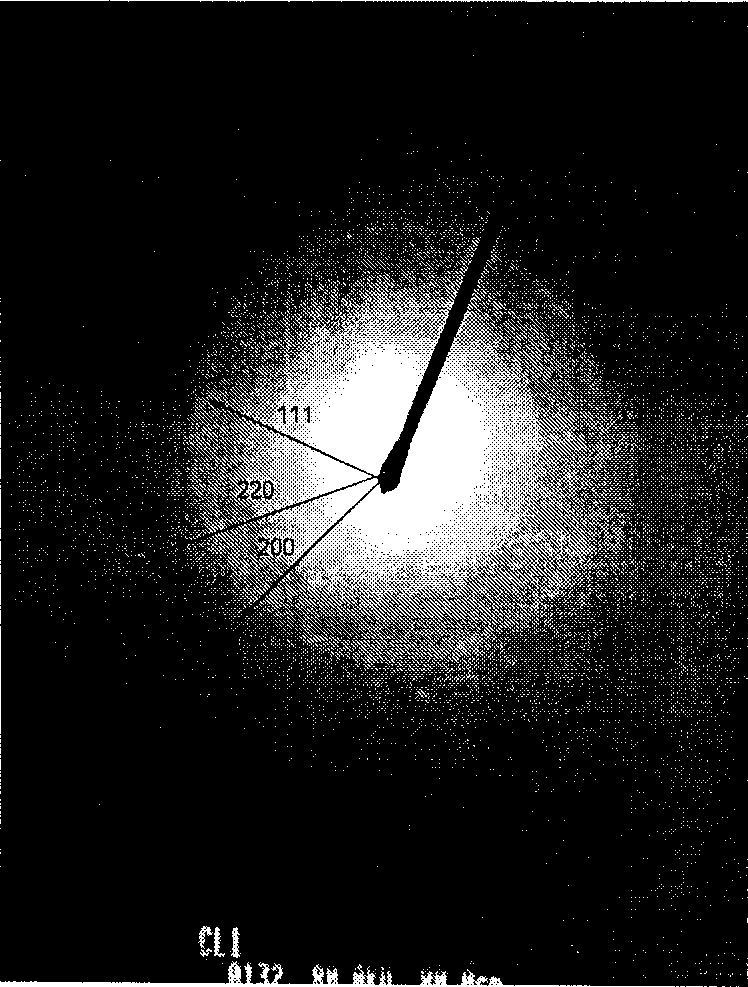

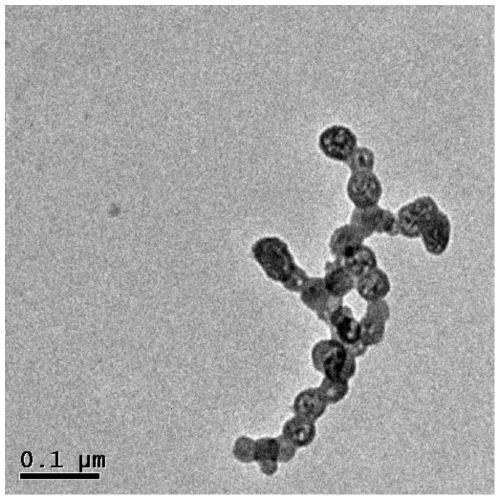

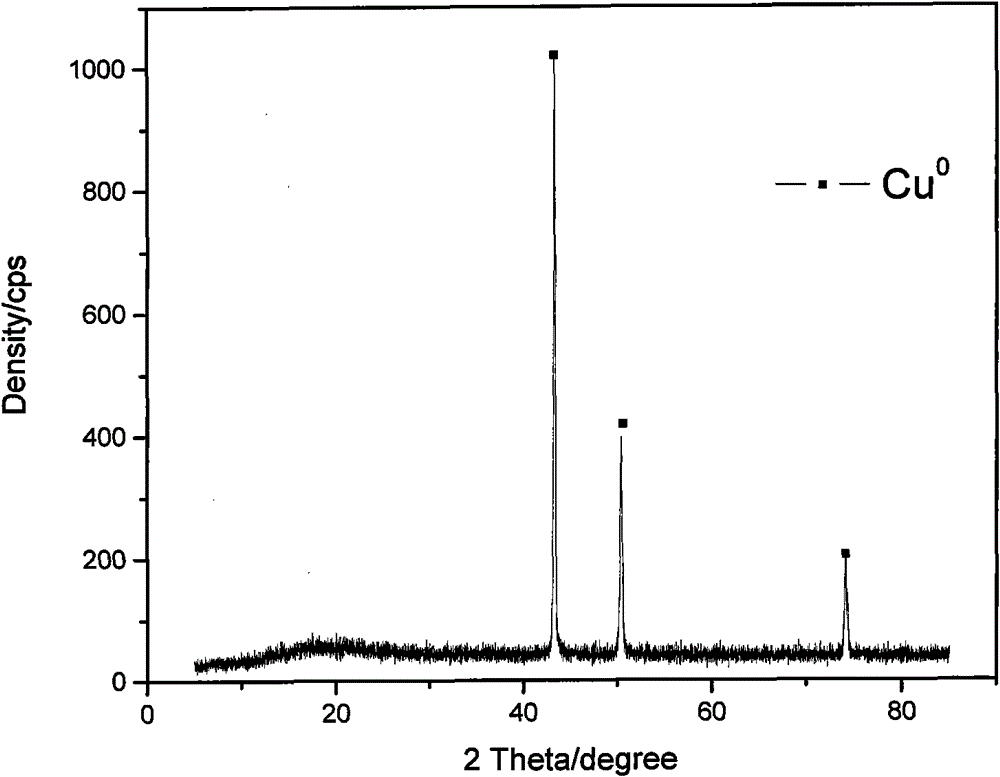

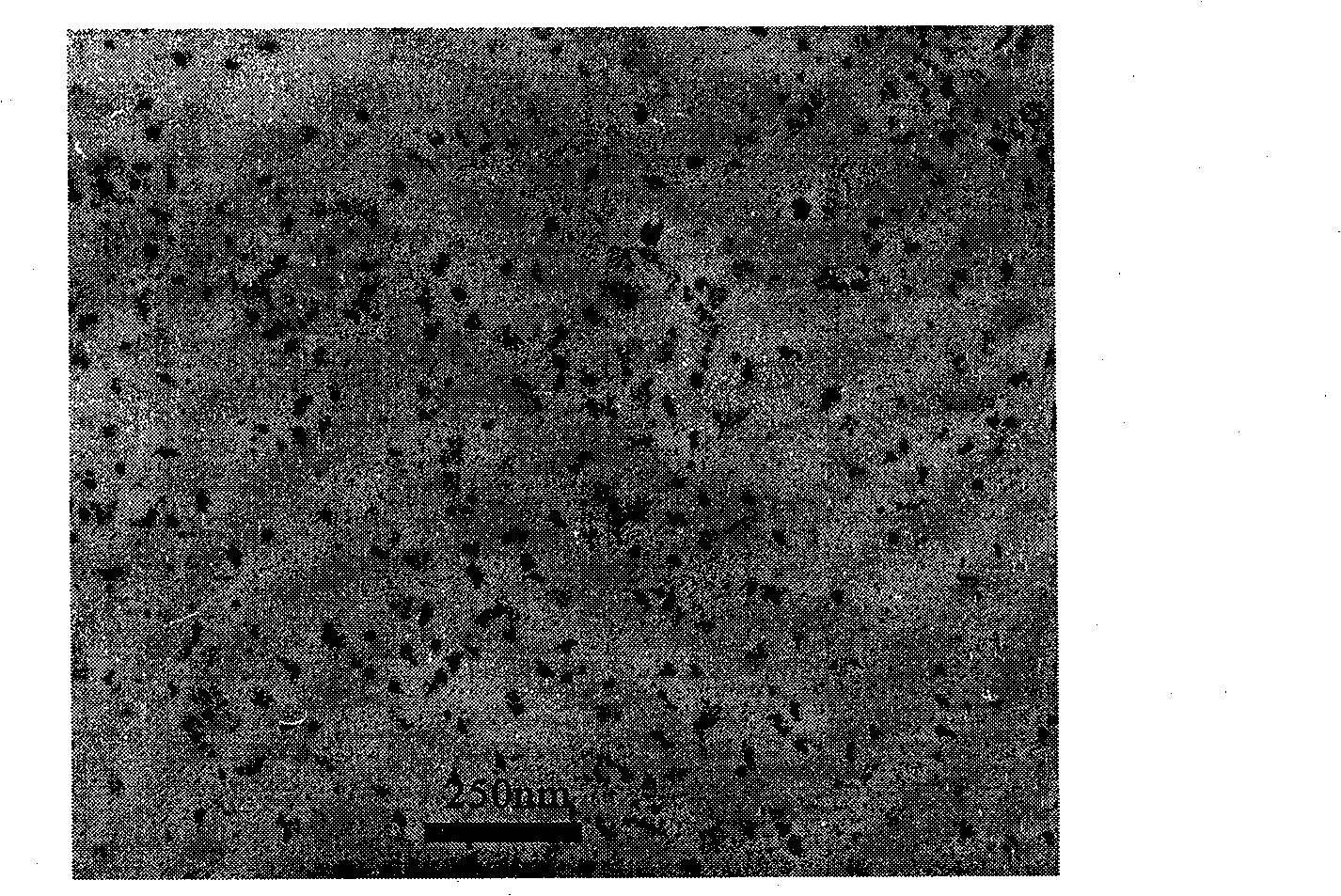

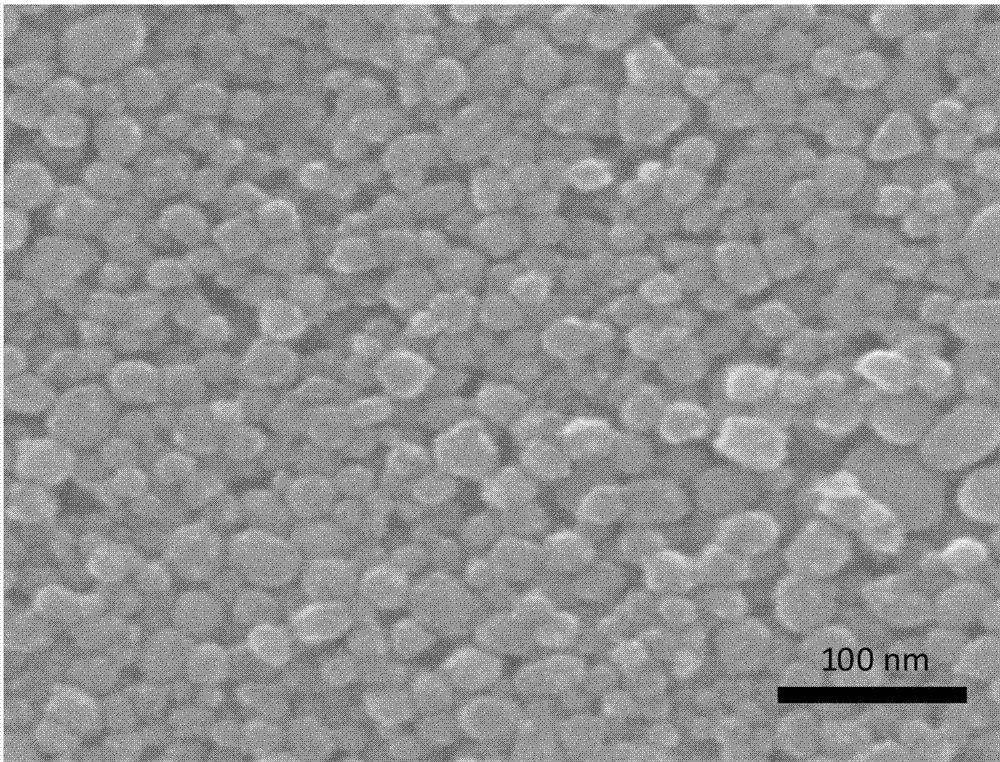

Method for synthesizing copper nanoparticles

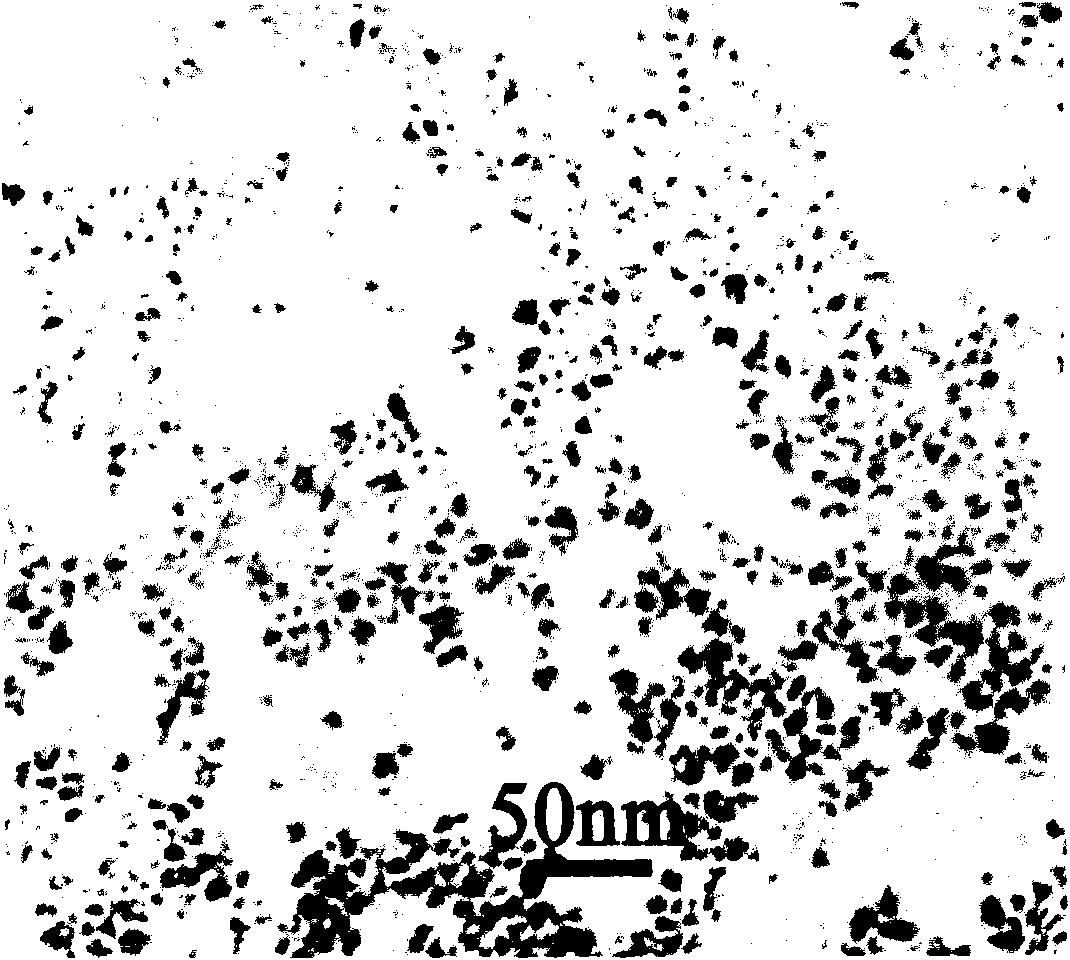

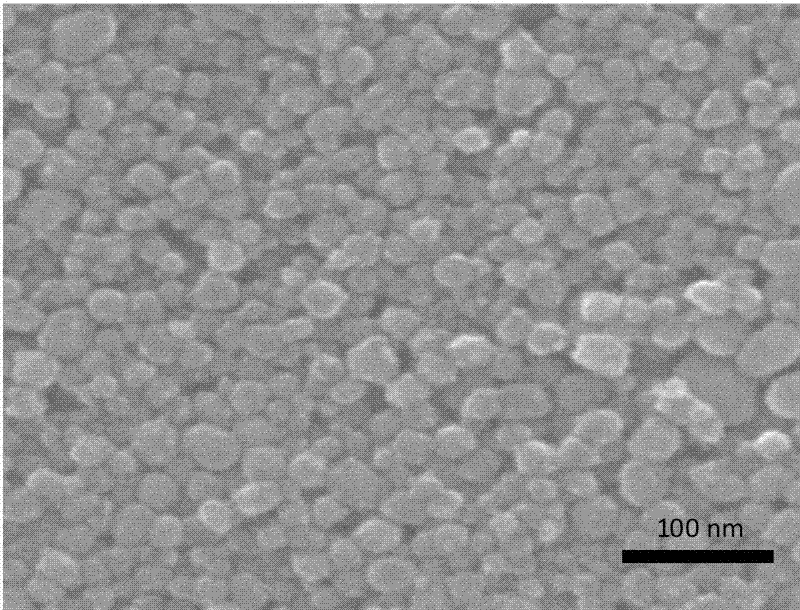

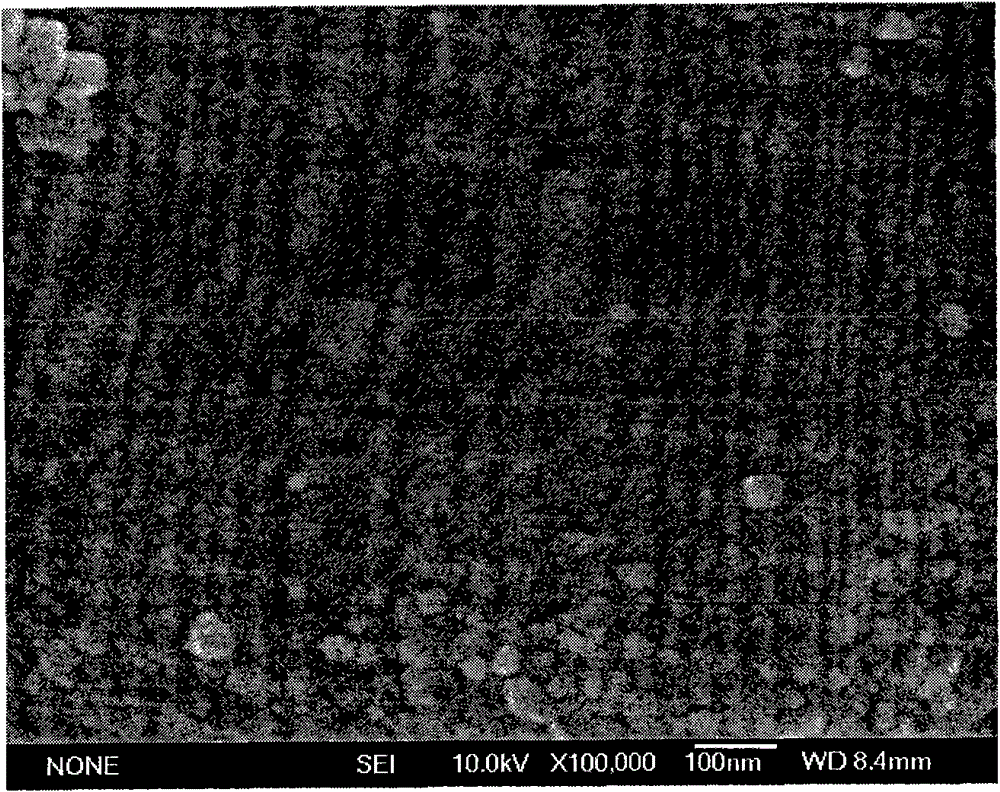

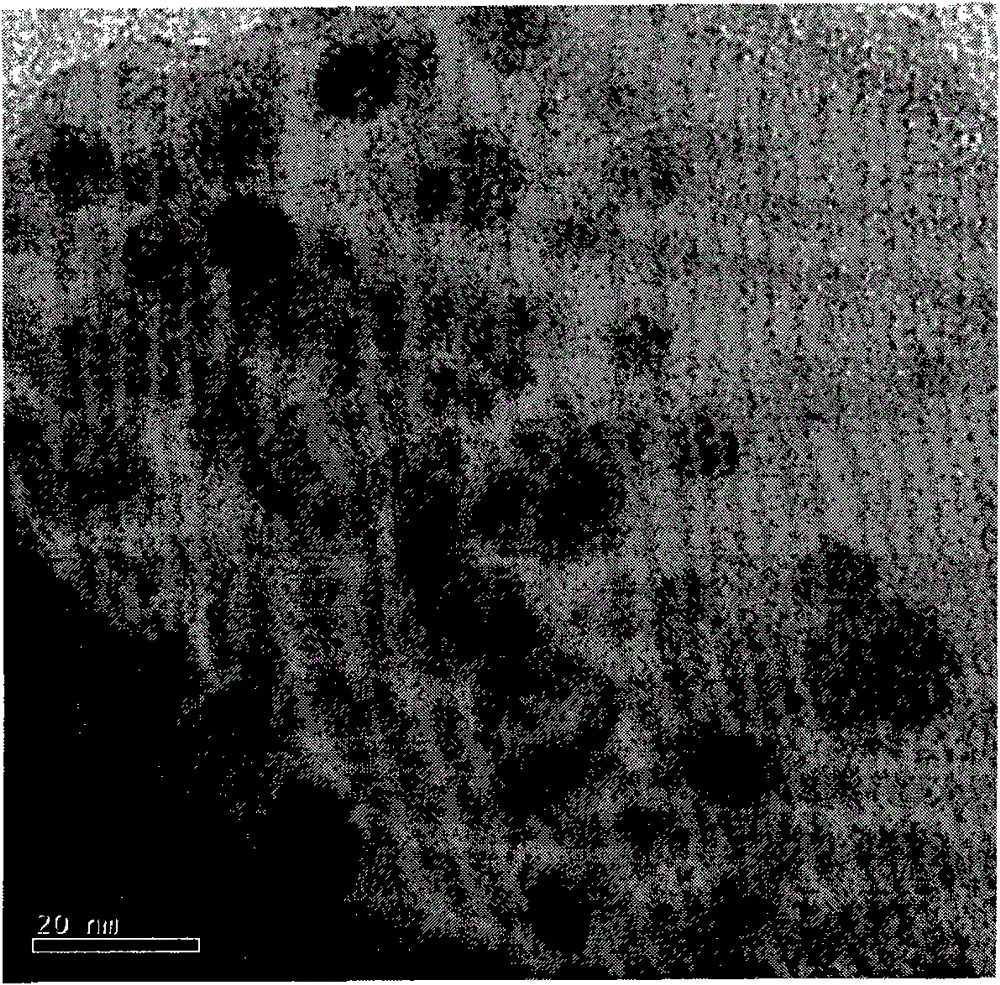

InactiveCN102407343AEasy to controlIncrease temperatureMaterial nanotechnologySynthesis methodsSolvent

The invention discloses a method for synthesizing copper nanoparticles, which comprises the following steps of: using a half solid phase synthesis method to mix a cupric salt, a reducing agent, a stabilizing agent and water to obtain a uniform mixture; and using a microwave heating method to quickly synthesize the copper nanoparticles. The water or other polar organic molecules can quickly absorbmicrowaves to quickly increase the temperature of a reaction system so as to promote reduction of copper ions, and due to half solid phase and large viscosity and poor flowability of the reaction system, the high molecular polymer stabilizing agent can effectively contact and cover the copper nanoparticles to control growth of the nanoparticles so as to obtain smaller copper nanoparticles. The method has the characteristics of low cost, quickness, simpleness, convenience, no large amounts of solvents, and the like, and is suitable for large scale industrial production; and the prepared coppernanoparticles are 1-100nm in particle size and can be used for preparing a conductive paste along with wide industrial application.

Owner:EAST CHINA NORMAL UNIV

Method for preparing monodisperse copper sulfide semiconductor nano particles

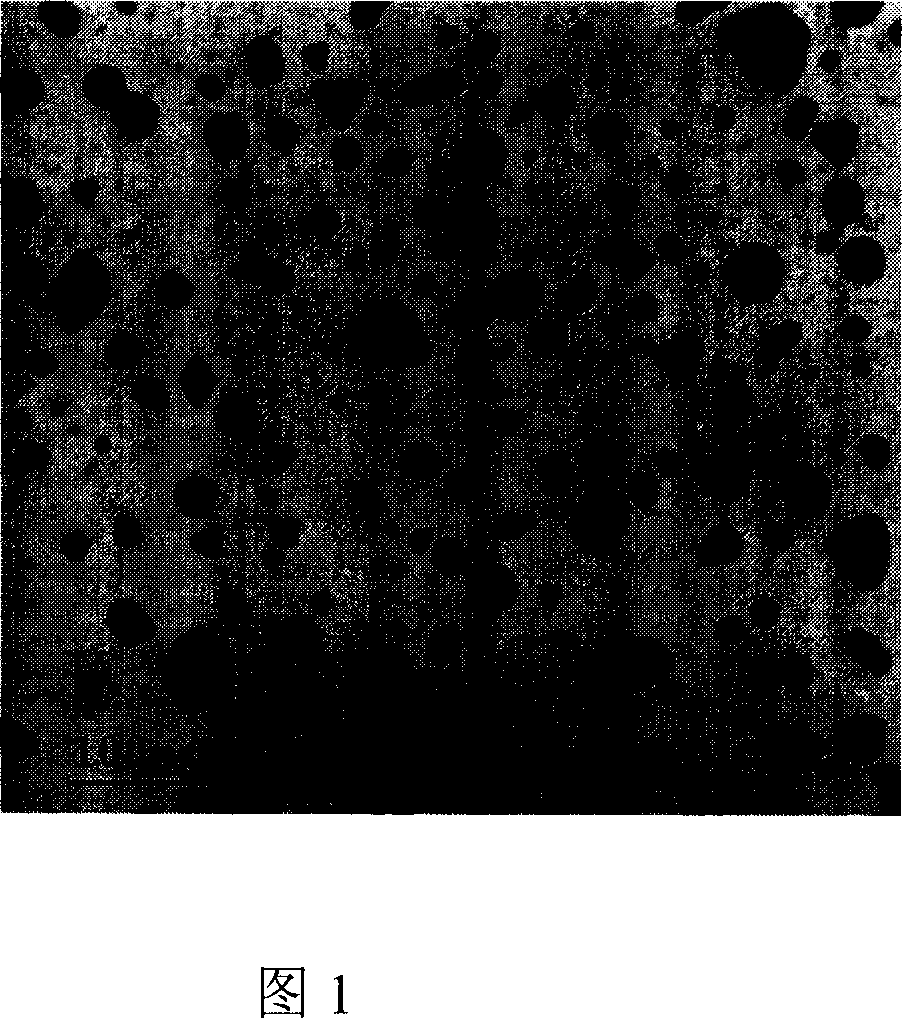

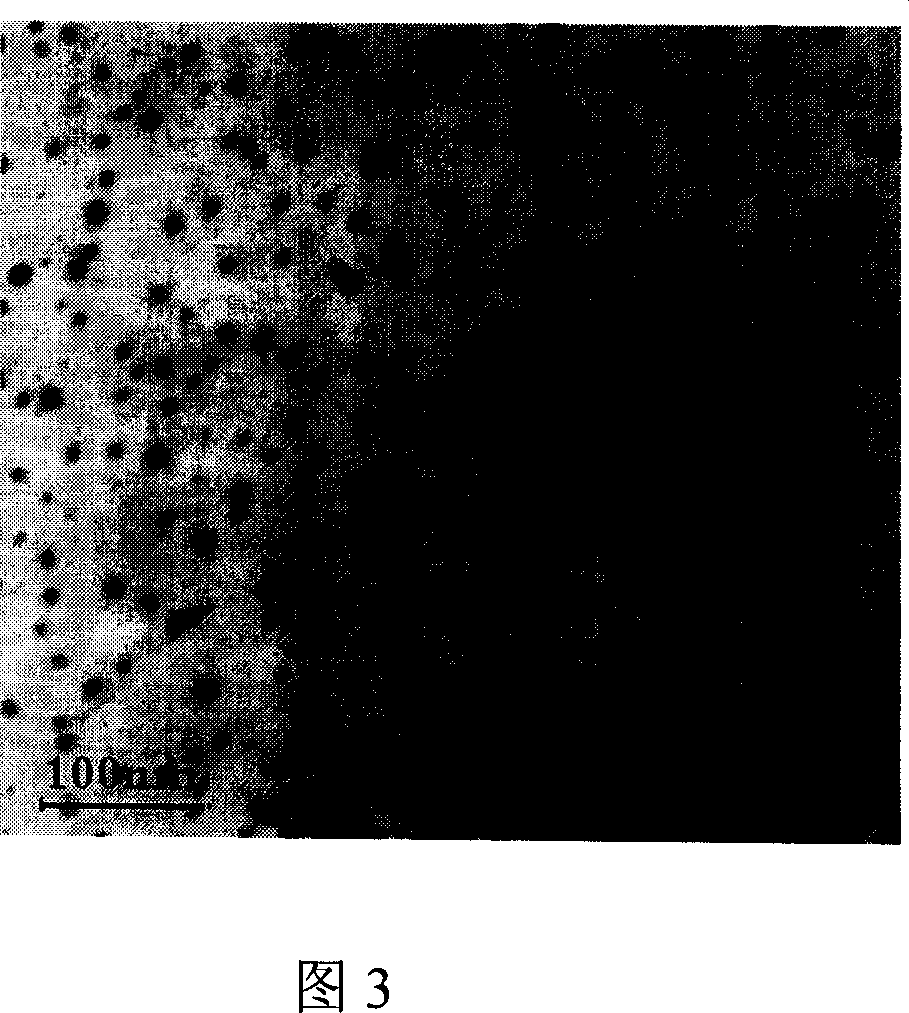

InactiveCN101077791AUniform particle sizeRaw materials are cheap and easy to getCopper sulfidesChemical reactionSemiconductor

The present invention discloses process of preparing monodispersive nanometer granular copper sulfide semiconductor. The preparation process with common copper salt, sodium sulfide and N, N-dialkyl dithio formate as material is one simple chemical reaction process. The present invention has the features of facile material, simple process, high efficiency, high yield, high stability, etc, and is suitable for industrial production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

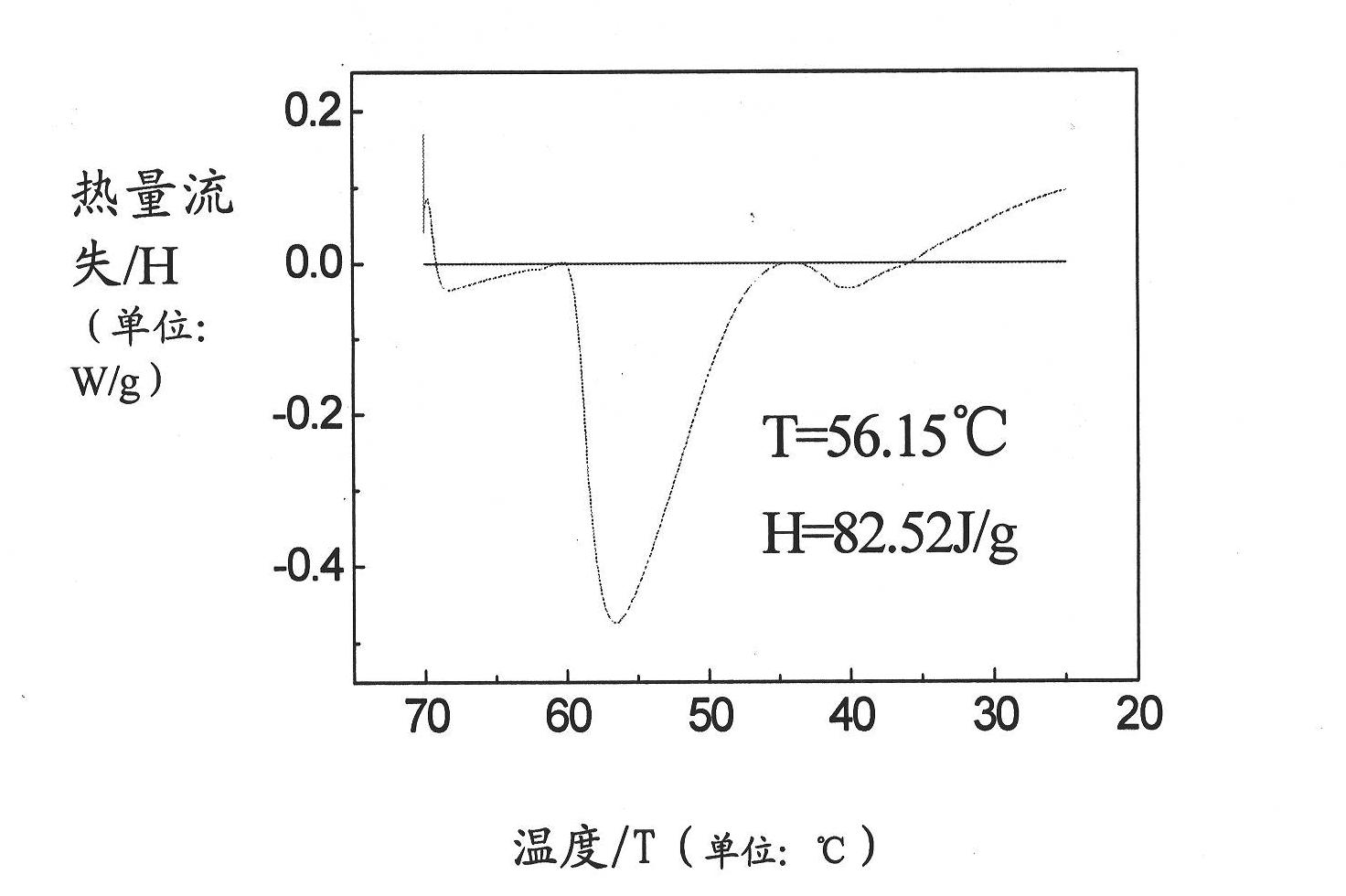

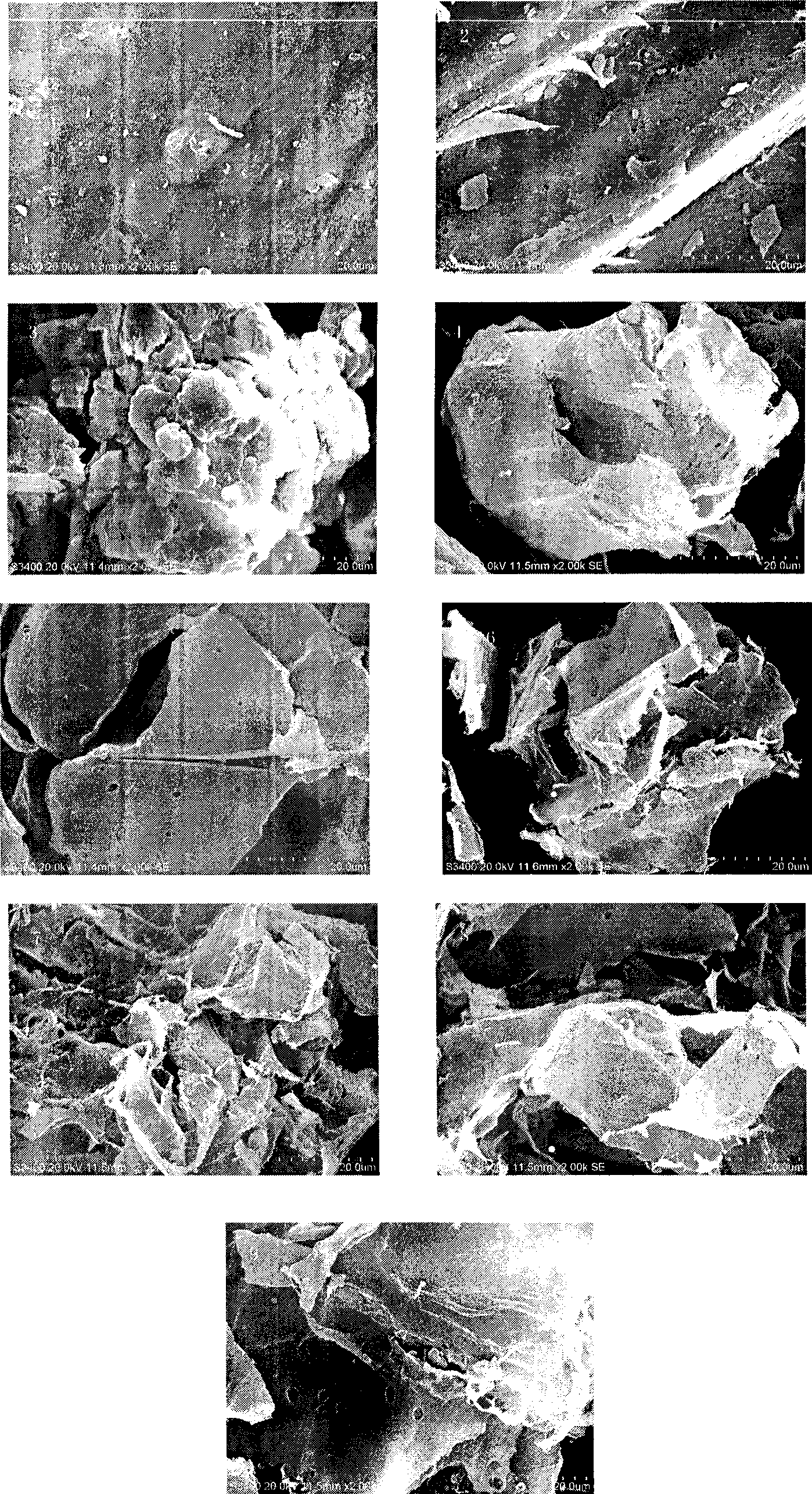

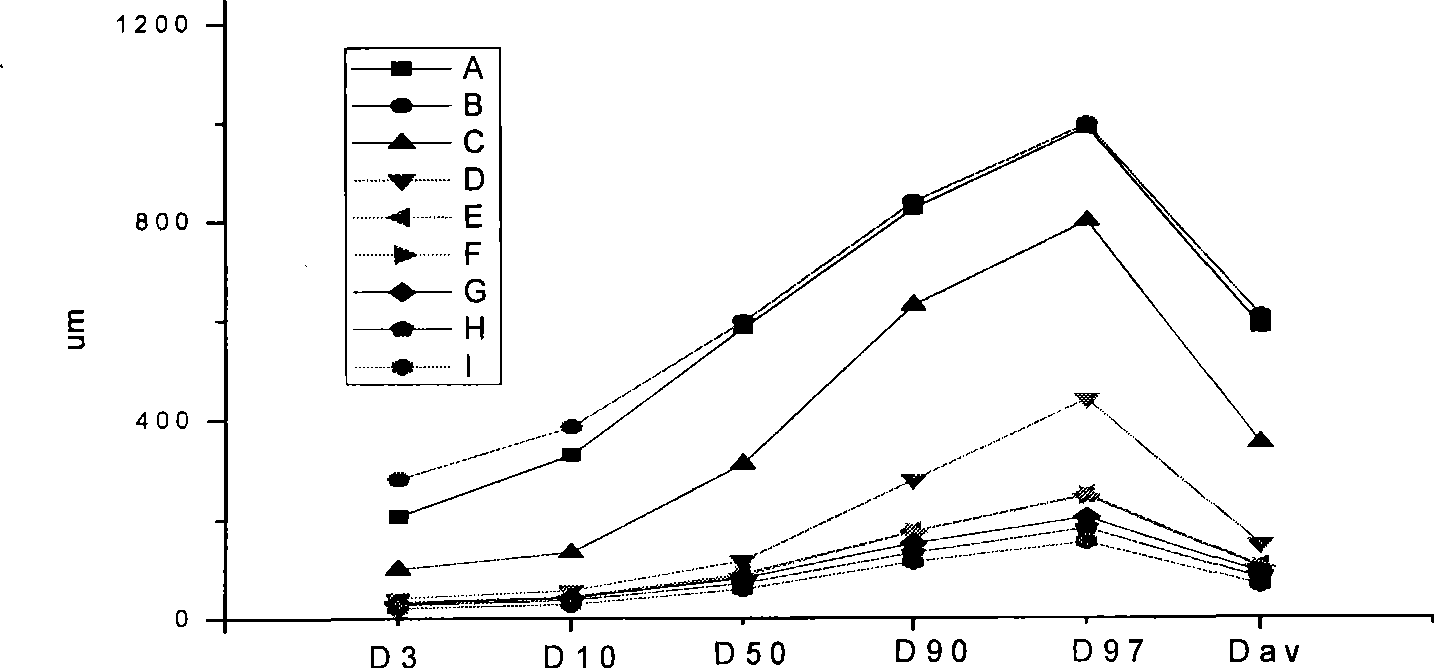

Preparation method of nano-capsule composite phase change material

ActiveCN104592946AAvoid reunionImprove dispersion uniformityHeat-exchange elementsMicroballoon preparationFiltrationThermal insulation

The invention discloses a preparation method of a nano-capsule composite phase change material. According to the invention, a composite emulsifier, a co-emulsifier and distilled water are added into a reaction kettle, such that a clarified solution is formed; an organic phase change material is added into the clarified solution, and stirring is carried out under a temperature higher by 5-10 DEG C than the phase change temperature, such that an emulsion is obtained; an inorganic silicon source and a stabilizing and dispersing agent are added into the emulsion, and the mixture is stirred, such that a uniformly dispersed stable emulsion is obtained; an acid solution catalyst is slowly dropped into the emulsion, such that silicon source hydrolysis and polymerization reactions are initiated; stirring is stopped when a white precipitate is completely precipitated; the reaction solution is naturally cooled to room temperature, and a precipitation solution is obtained; the precipitate is repeatedly washed by using a mixture of water and petroleum ether; and suction filtration and drying are carried out, such that the material is obtained. According to the nano-capsule composite phase change material provided by the invention, the particle size of capsule particles is smaller than 1mum. The material has relatively high chemical stability, thermal stability, heat transfer and thermal conduction performance, and phase change latent heat. The material can be widely applied in the fields of heat transfer and energy storage thermal insulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

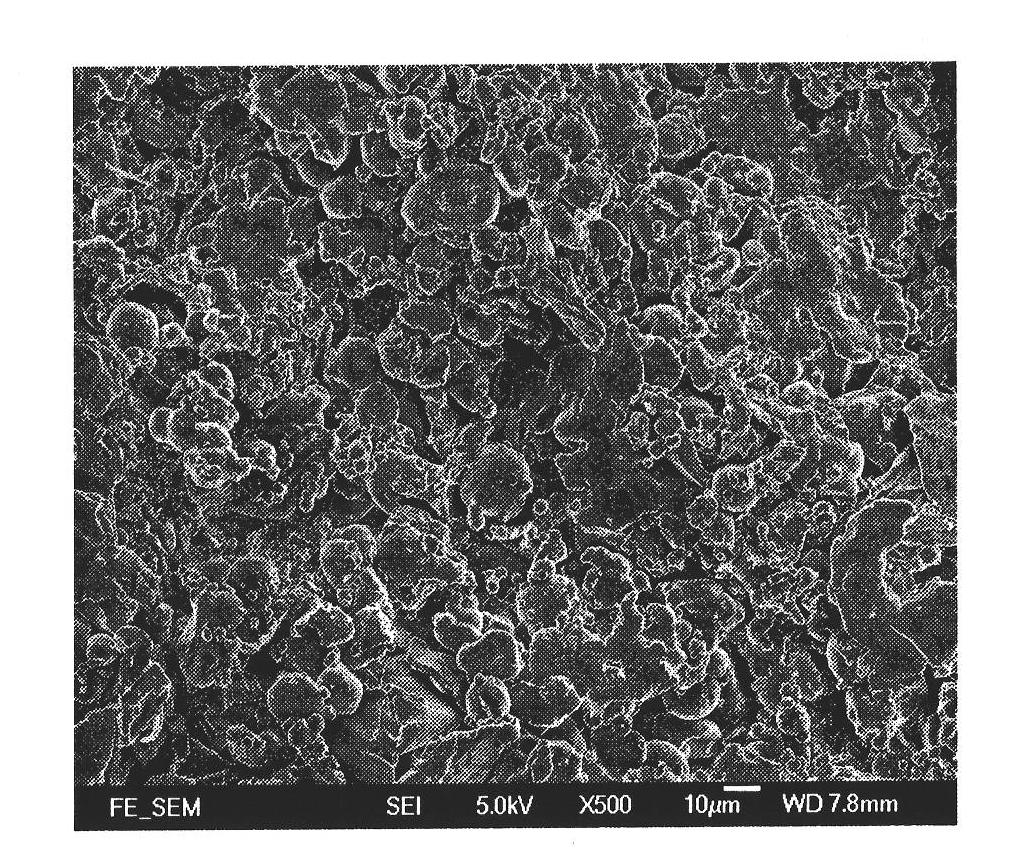

Preparation method of organic phase change energy storage composite material

ActiveCN101982475AGood physical and chemical stabilityHigh adsorption rateHeat-exchange elementsMicroballoon preparationSmall dropletSolid particle

The invention relates to a preparation method of an organic phase change energy storage composite material, which is mainly based on a two-phase interfacial polymerization method and comprises the following steps: at a certain temperature, when an oil-soluble core material is molten, emulsifying the oil-soluble core material and water by utilizing a surfactant to form small droplets; then, cooling to solidify the small droplets into small solid particles; and then, polymerizing a shell material on the surfaces of the particles to form the organic phase change energy storage composite material with a core-shell structure. Because the core material and the shell material are respectively emulsified and then mixed for reacting, thus the emulsifying effect is good; and the core material is changed into small solid particles after being cooled, thus the adsorption rate of the shell material can be improved, the coating efficiency is improved, and the physicochemical stability of the composite material is enhanced.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

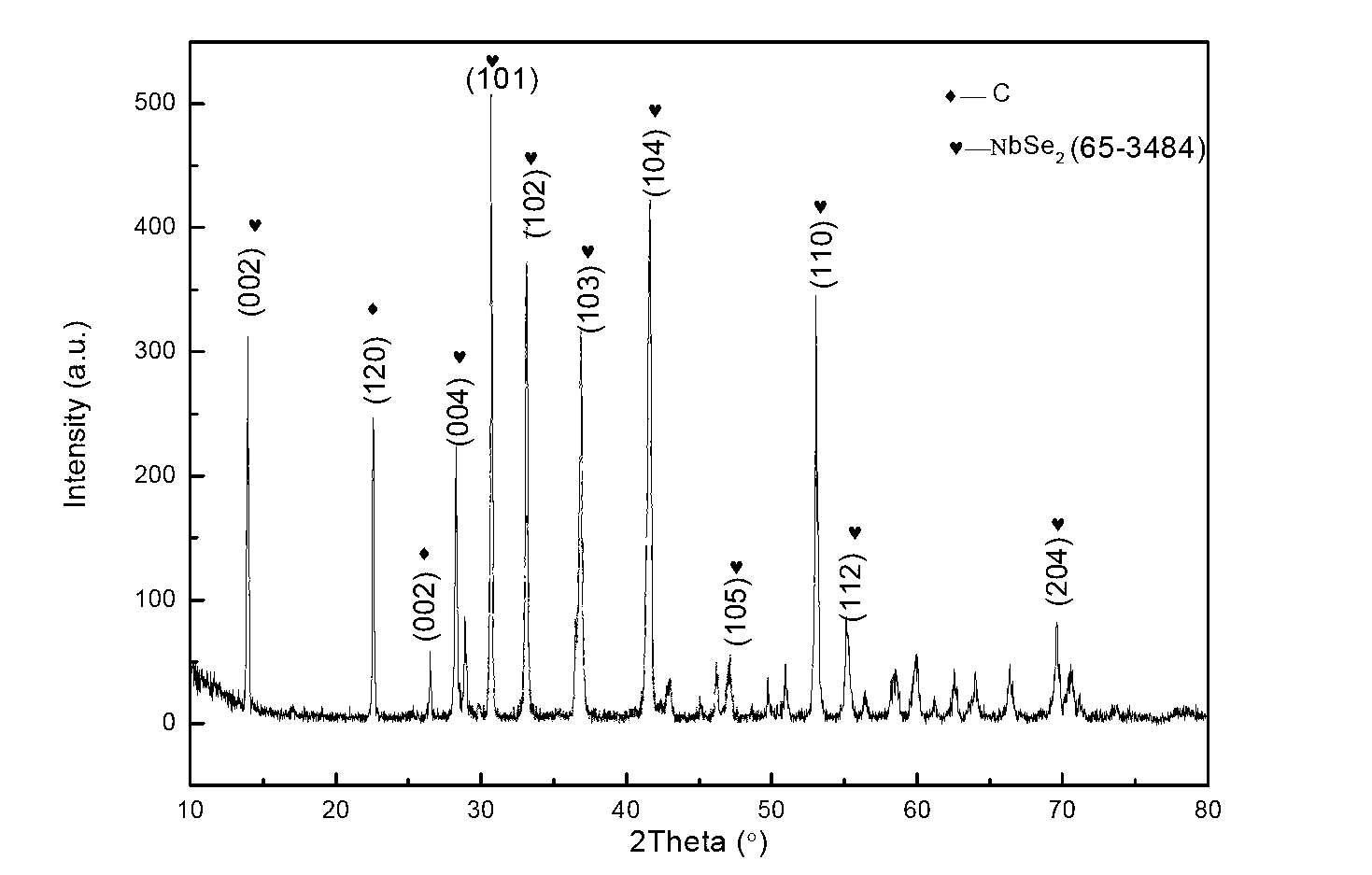

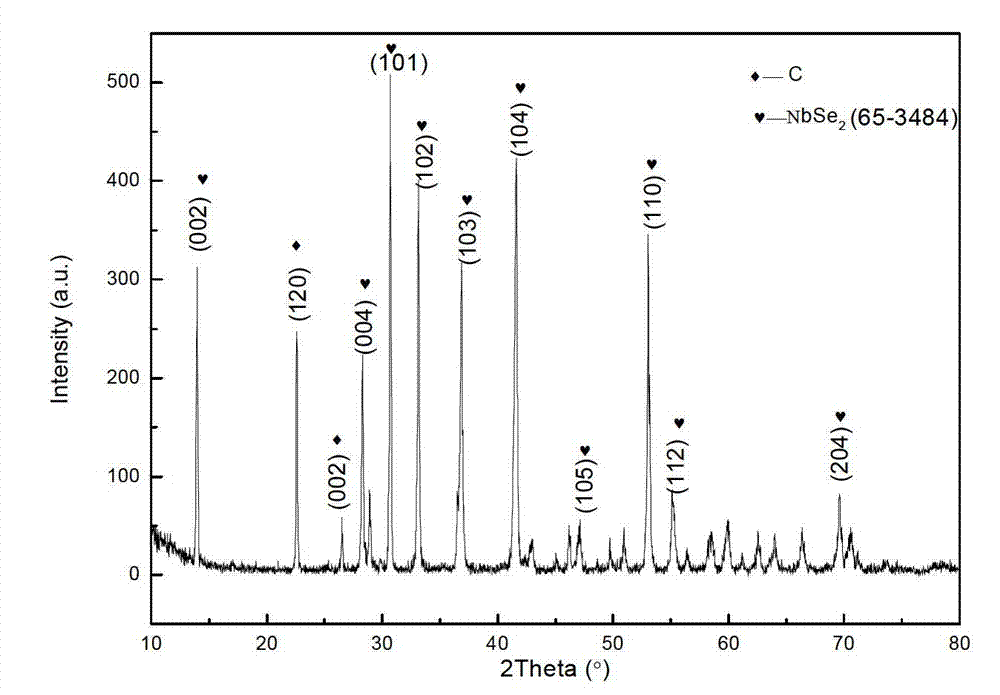

Preparation method of graphite-bi-selenylation niobium nanocomposite

InactiveCN102703160AImprove tribological propertiesImprove conductivityConductive materialBase-materialsNiobiumGraphite

The invention relates to a preparation method of a graphite-bi-selenylation niobium nanocomposite. The preparation method enables niobium powder, selenium powder and graphite powder to serve as raw materials, conducts solid-phase reaction at certain temperature conditions and synthetizes sheet-shaped particles formed by a graphite-selenylation niobium nanocomposite. The preparation method is simple in process, high in productivity, environmental friendly, free of pollution and capable of achieving large-scale industrial preparation. Simultaneously, nano materials are small in size and have good physical chemistry effects so that the nano materials can serve as an excellent annexing agent of an electric contact material.

Owner:无锡润鹏复合新材料有限公司

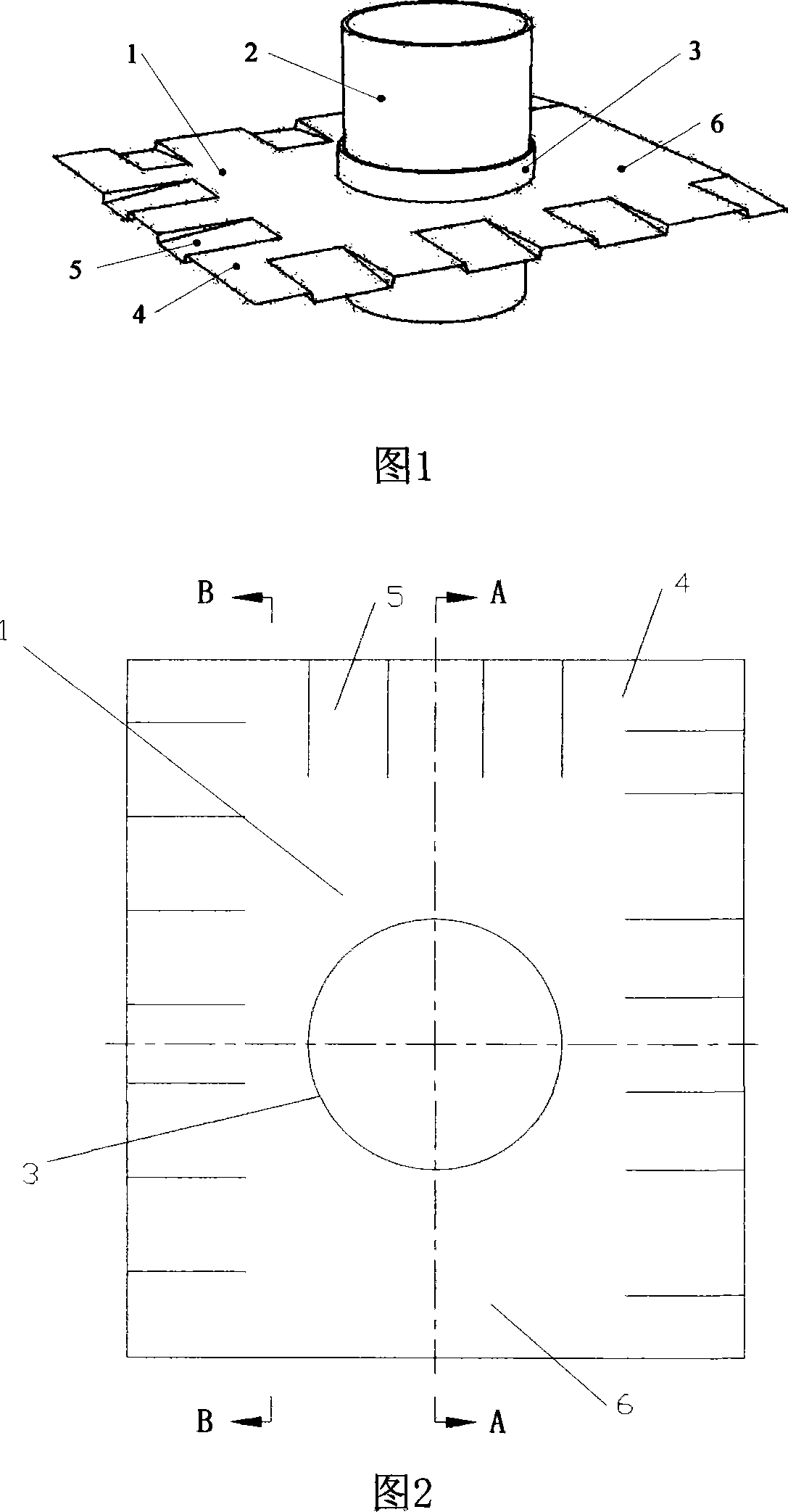

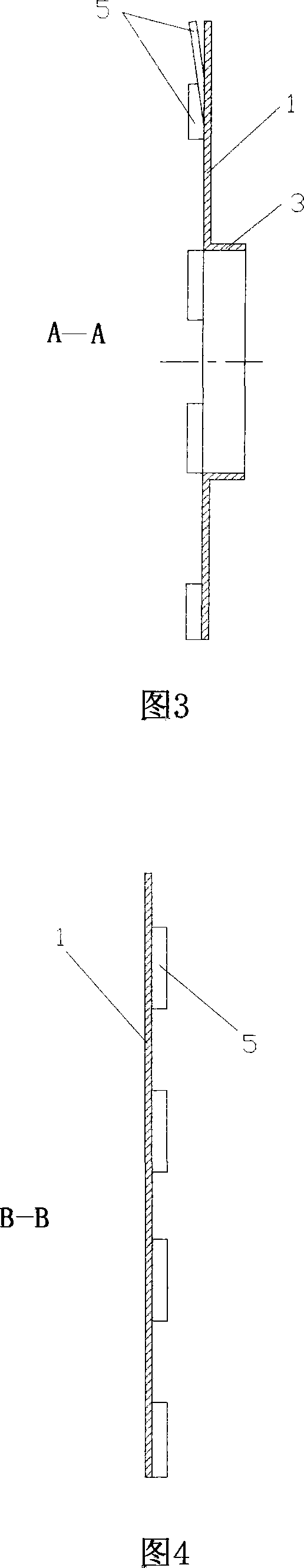

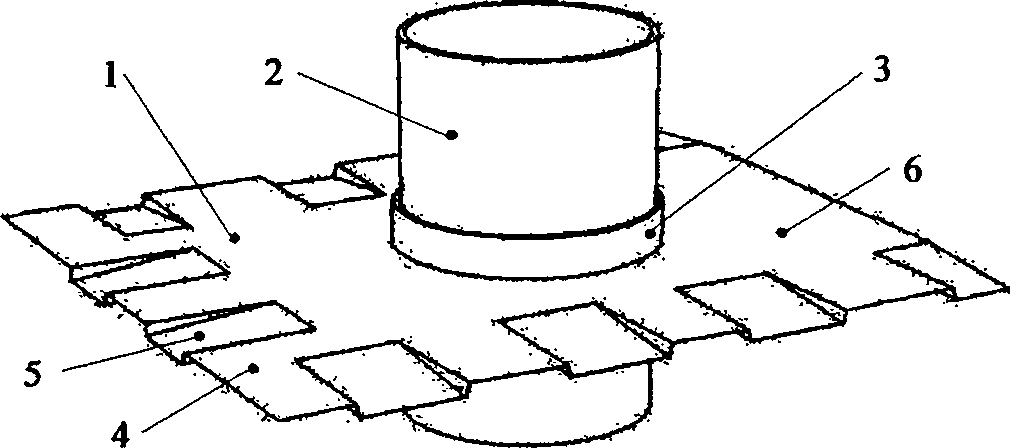

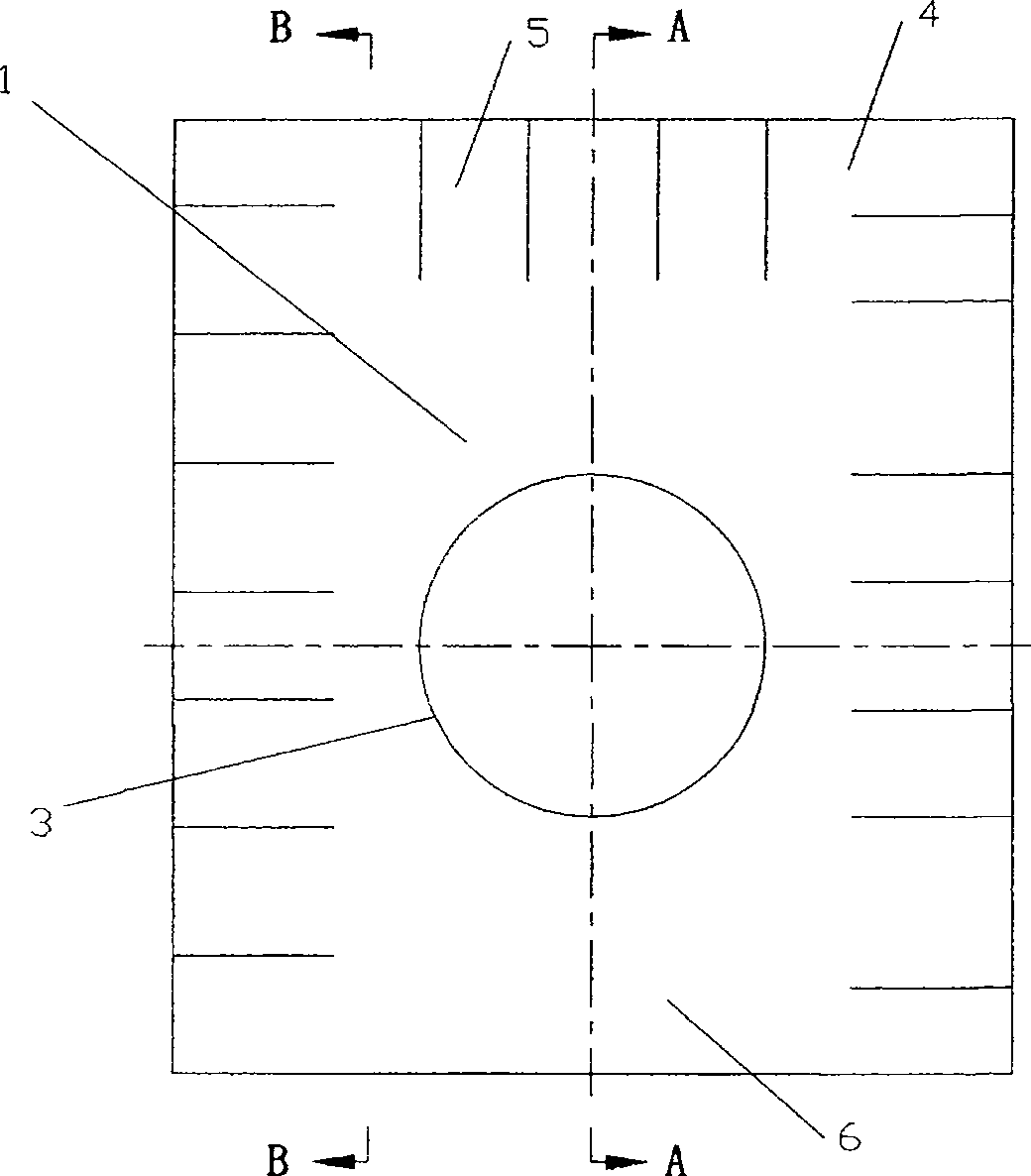

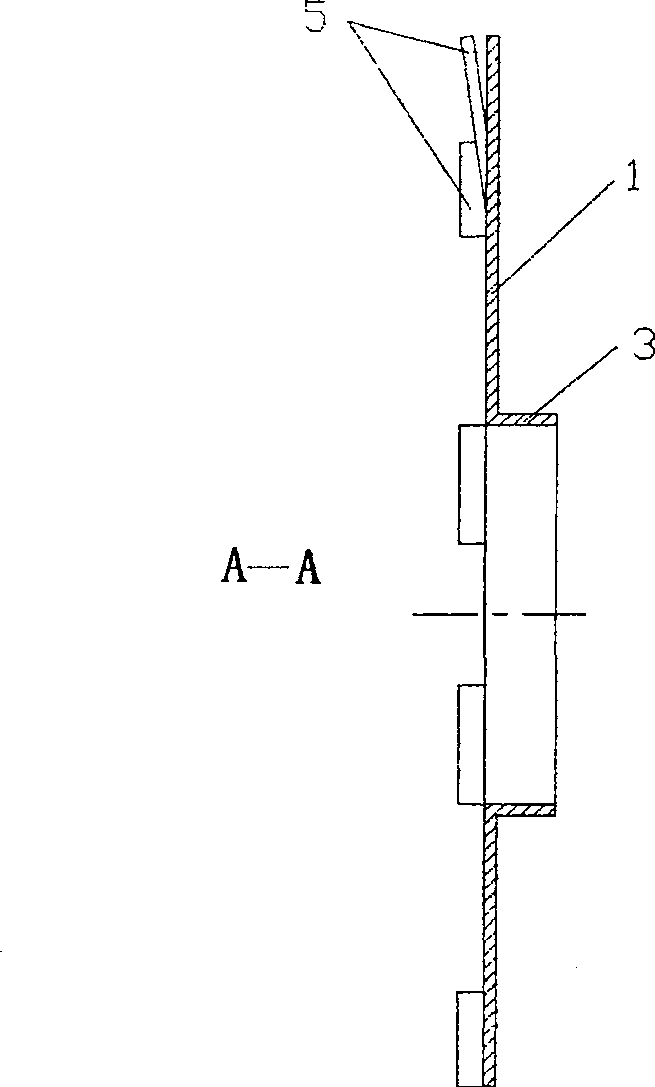

Rectangular offset strip fin heat transfer pipe and uses thereof

InactiveCN101216269AHigh heat and mass transferImprove heat transfer coefficientTubular elementsCondensation processEngineering

The invention provides a heat transfer tube with rectangular staggered fins and application thereof. The inventive heat transfer tube comprises a tube body and a plurality of rectangular staggered fins fixed on the tube body. The outer edge of the lee side of rectangular staggered fin is flat, and the other three outer edges are staggered in cross section along thickness direction and respectively provided with 5-8 sphenoid narrow grooves. The inventive heat transfer tube with the rectangular staggered fins can be used for heat and mass exchange equipment in gas-solid sublimation process and gas-liquid condensation process. The invention has simple structure and low manufacturing cost, can improve local turbulence, and can remarkably reinforce gas lateral heat exchange and phase-change heat transfer and mass transfer processes.

Owner:DONGGUAN UNIV OF TECH

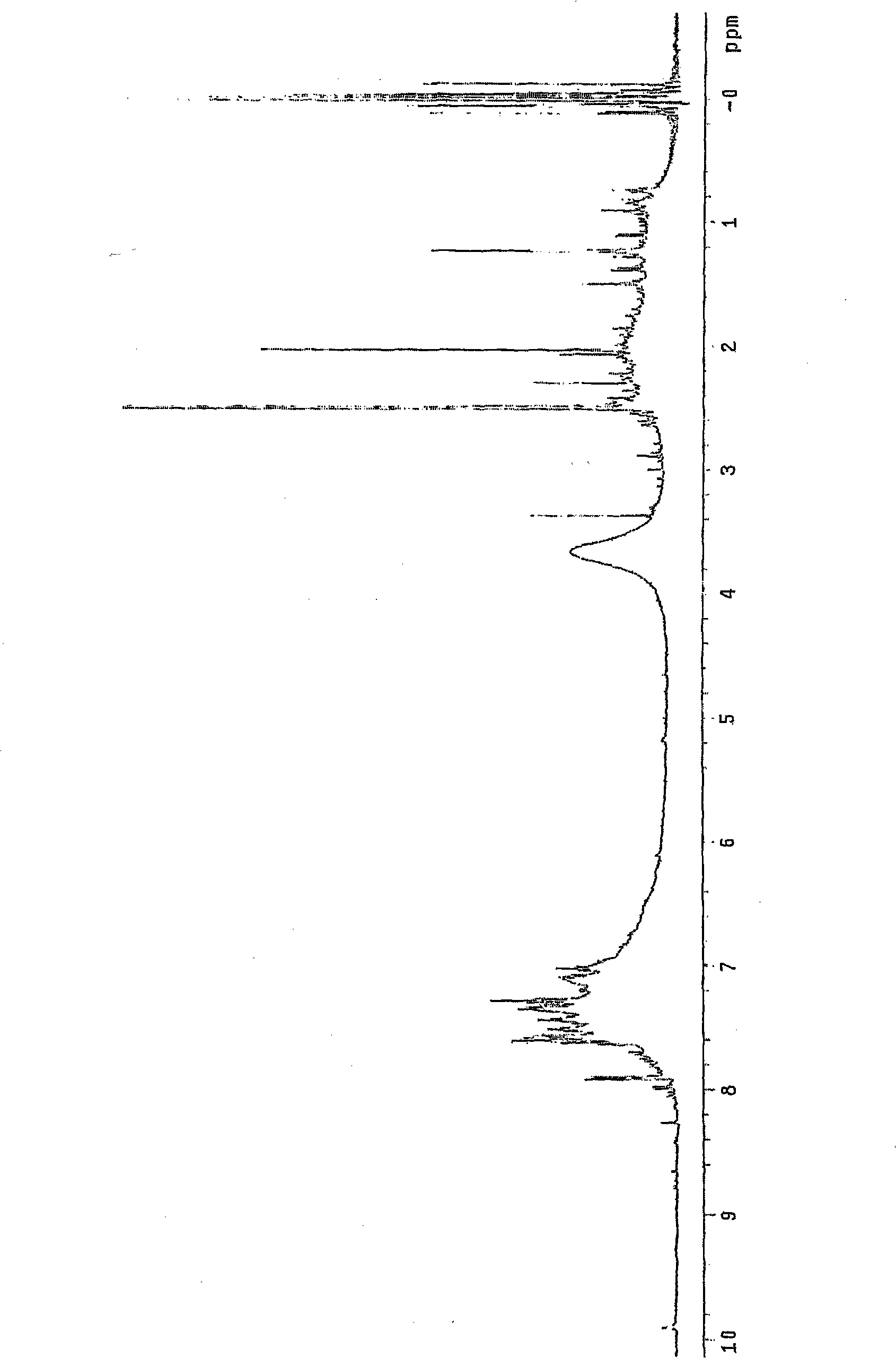

Preparation method of nano copper composition protected by organic monomolecular layer

InactiveCN1766008AUniform particle sizeRaw materials are cheap and easy to getPigment treatment with non-polymer organic compoundsNanoparticleNano copper

The invention discloses a preparation method for organic monomolecular layer to protect nano copper compound, which comprises: mixing water solution of surface activator of common nantokite and cationicy ammonium salt with sulfide-containing benzene liquid, reducing with NaBH4 solution to form by one step the object product with 2-10nm size and even distribution and well dispersibility in nonpolar solvent. This method is simple, and has high yield with high efficiency.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

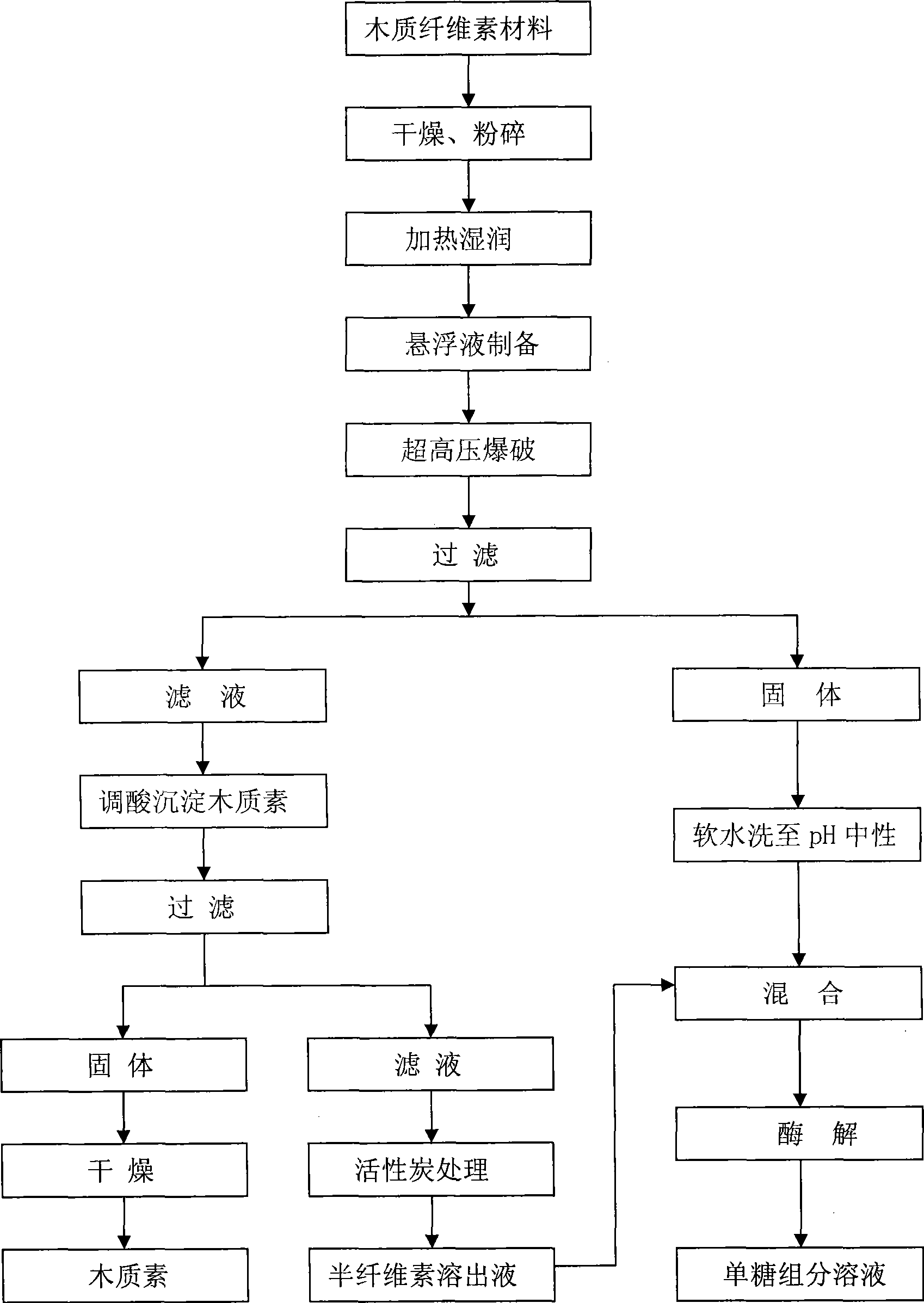

Pretreatment method for ultra-high pressure blasting wood fiber material

InactiveCN101463571AImprove enzymatic hydrolysis rateReduce processing intensityPulping with inorganic basesRaw material divisionCelluloseFiber

The invention discloses a pretreatment method for lignocellulosic materials. The method is as follows: a high-pressure homogenizer which is conventional but is currently only used for processing liquid state materials is taken as the treatment equipment, a stirring device is installed at the feed funnel of the homogenizer, the materials are exploded under ultrahigh pressure by means of transient pressure and pressure elimination in the homogenizing process. The method comprises the steps as follows: the pre-processes like drying, smashing and sieving, etc. of the lignocellulosic materials, the heating and moistening of the materials, the preparation of the suspending liquid, the ultrahigh pressure explosion and the material process after explosion, etc. Compared with various currently disclosed pretreatment methods for lignocellulosic materials, the method not only has the advantages of low requirement for equipment, mild process condition, no harmful substances which inhibit microorganism fermentation and low energy consumption, etc. but also can process the ultramicrostructure which totally changes the lignocellulosic materials and creatively realize the full hydrolyzation of the lignocellulosic materials by making use of the cellulolytic enzyme system of low beta-glucosidase activity.

Owner:GUANGXI ACAD OF SCI

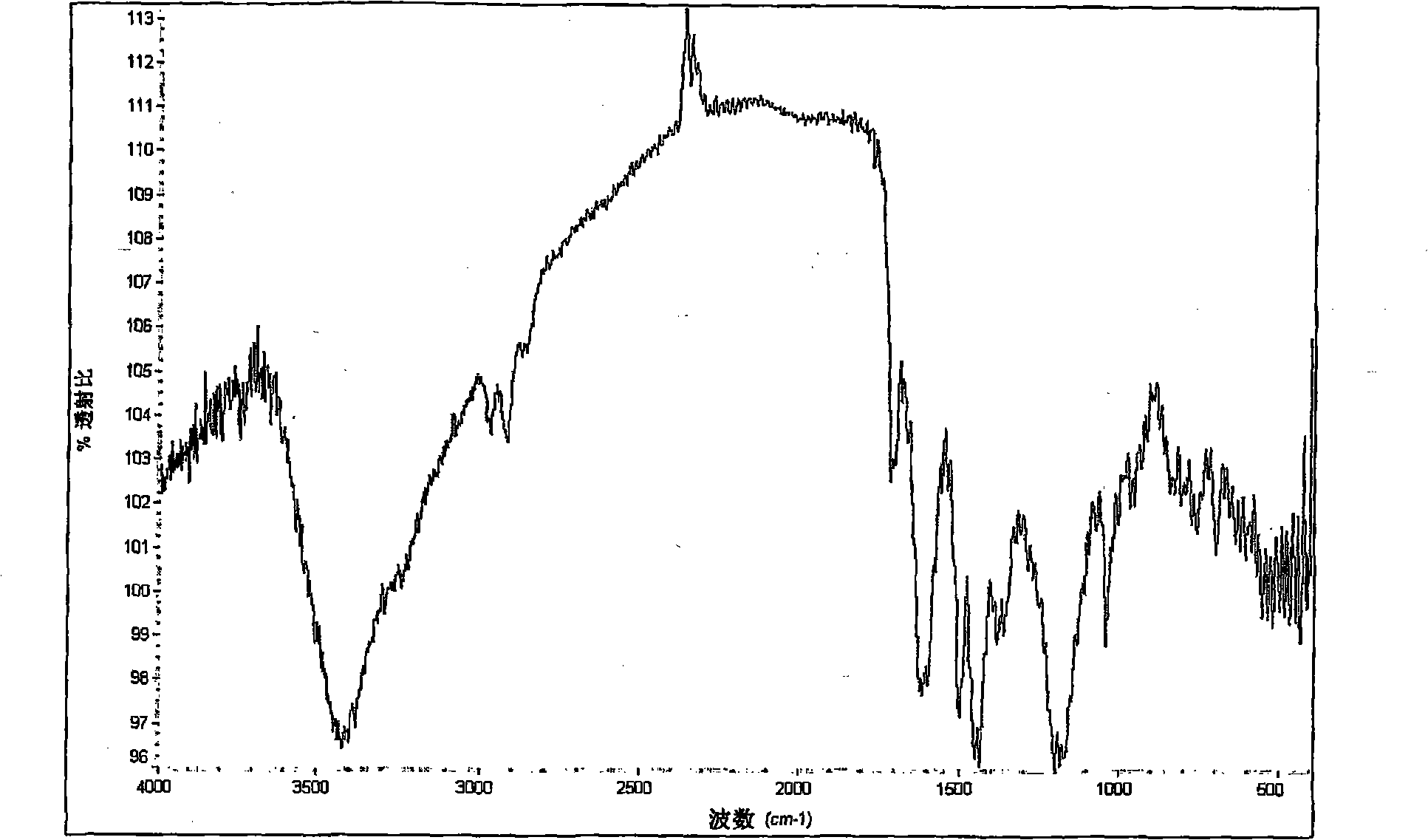

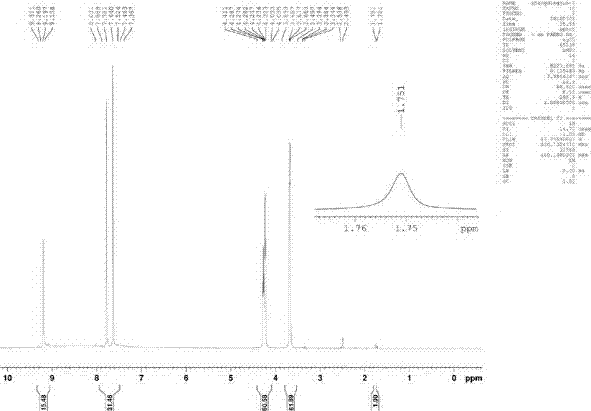

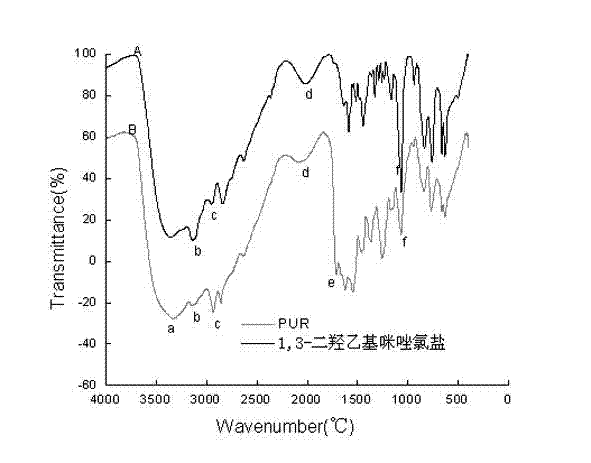

Preparation method of ionic conductive polyurethane

The invention relates to a preparation method of ionic conductive polyurethane, which comprises: dissolving imidazole in acetonitrile, heating to 50 DEG C, adding chloroethanol, wherein the molar ratio of the imidazole to the chloroethanol is 1: (2.1-3), heating to 80-81 DEG C, and carrying out constant-temperature backflow for 24 hours; carrying out vacuum distillation to remove the solvent acetonitrile, washing for three times with ethyl acetate, placing the mixture into a vacuum drying oven, and keeping the temperature of 80 DEG C for 5 hours to prepare 1, 3-dihydroxyethyl imidazolium chloride ionic liquid; adding N, N-dimethylformamide into another container, adding the 1, 3-dihydroxyethyl imidazolium chloride ionic liquid and toluene diisocynate, wherein the molar ratio of the toluene diisocynate to the 1, 3-dihydroxyethyl imidazolium chloride ionic liquid is 1: (1.1-1.5), heating to 90-95 DEG C, and keeping the temperature 12 hours for reaction; and pouring reaction mixture solution into acetone with the amount being twice the amount of the N, N-dimethylformamide in the previous step, keeping the mixture overnight, collecting yellow viscous substances, drying in vacuum, and thus obtaining the ionic conductive polyurethane.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

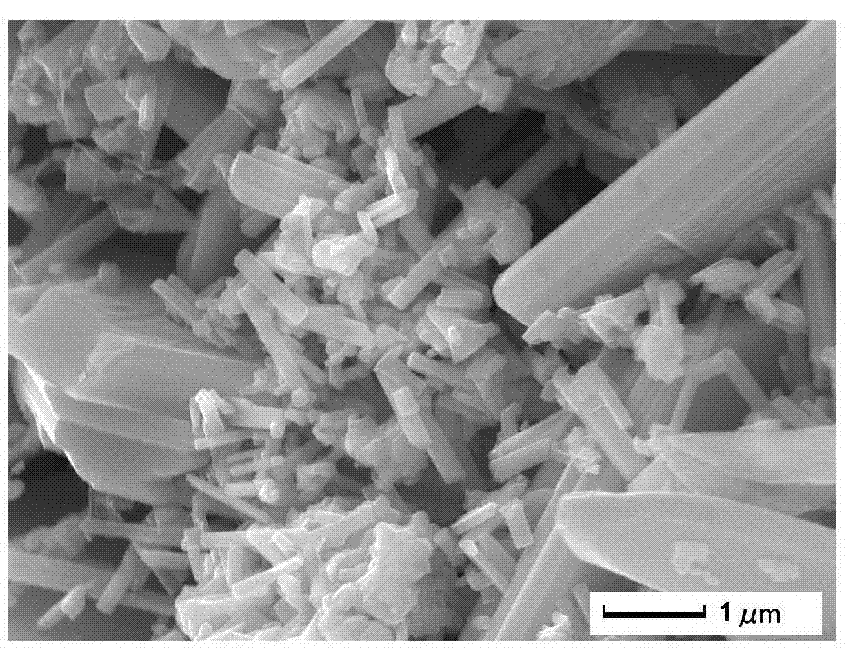

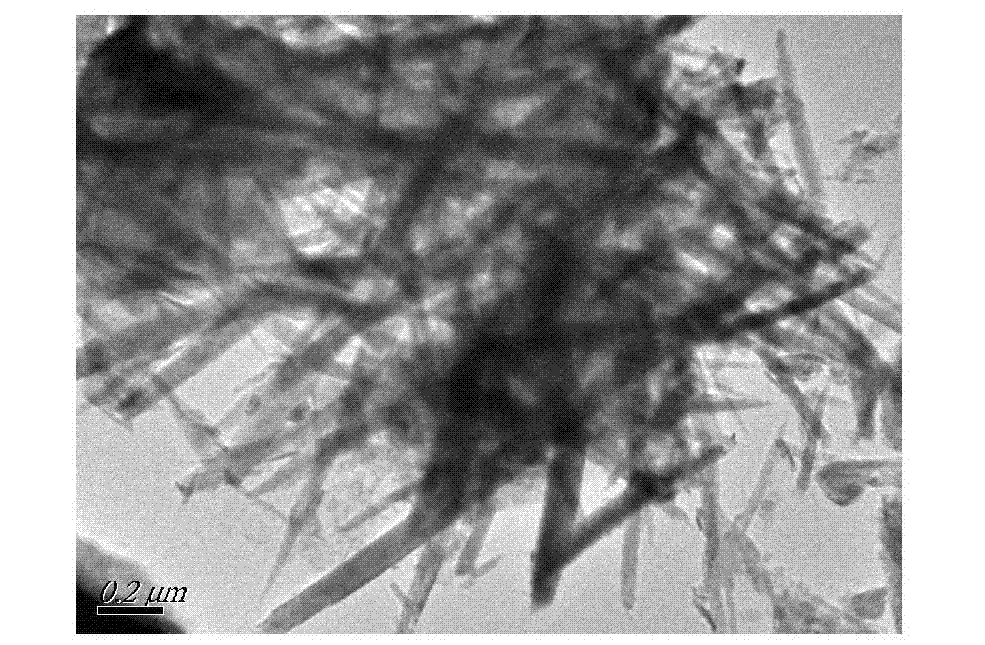

Preparation method and use of nano-SiC whisker

InactiveCN103382030AImprove productivityReduce process costSolid waste disposalSilicon carbideSmooth surfaceCarbon source

The invention discloses a preparation method of a nano-SiC whisker. The preparation method has a whisker yield of 100%. The preparation method adopts a uniform mixture of a commercial carbon source and rice husk lime as raw materials. The preparation method comprises the following steps of heating the uniform mixture to a high temperature of 1500 DEG C in an inert atmosphere, carrying out heat preservation at the temperature for a certain time, after the reaction, heating the reaction products mainly comprising nano beta-SiC whiskers which have smooth surfaces or are provided with granules on the surface thereby forming beading structures to a temperature of 700 DEG C in air, and carrying out heat preservation for 120min to remove residual carbon so that a high-purity SiC whisker product is obtained, wherein the high-purity SiC whisker product has the diameter of 200-400nm and the length of dozens of microns. SiC has a series of excellent properties and thus SiC can be widely used, for example, SiC can be used for a reinforcing phase of a composite material and for increasing a heat transfer coefficient of a hot fluid. The SiC whisker having a beading structure can be used for reinforcement of a composite material. Compared with the traditional smooth fibers, the SiC whisker has better effects. The SiC whisker can greatly improve a heat transfer coefficient of a hot fluid.

Owner:JIANGSU RUILI NEW MATERIAL SCI & TECH CO LTD

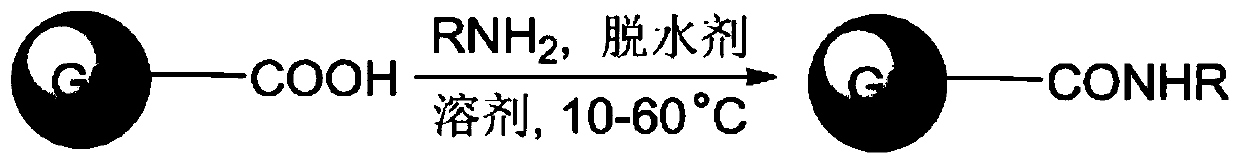

Preparation method of surface-modified oil-soluble graphene oxide

ActiveCN110028062AGood organic dispersionSmall dispersionGrapheneAdditivesOrganic solventOil soluble

The invention belongs to the technical field of preparation of novel nanometer functional materials, and particularly relates to a preparation method of surface-modified oil-soluble graphene oxide. The preparation method comprises the following steps: uniformly mixing graphene oxide, a modifier and at least two dehydrating agents in an organic solvent, and preforming a reaction on an obtained mixed solution at 10-60 DEG C for 12-48 hours to obtain the oil-soluble graphene oxide, wherein the modifier is an organic amine compound, and the organic amine compound comprises C6-C20 alkyl. Accordingto the preparation method, a technology and equipment are simple, a raw material is easy to obtain, a reaction condition is mild, operation and posttreatment processes are simple, and the yield is high; the preparation method is suitable for large-scale industrial production.

Owner:SUZHOU UNIV +1

Method for preparing nano-copper

Owner:TAIYUAN UNIV OF TECH

Method for breeding special industrial high-resistance rape variety

InactiveCN106577258AHigh erucic acid contentReduce usagePlant genotype modificationHigh resistancePlant disease

The invention belongs to the technical field of special rape disease resistance breeding and discloses a method for breeding a special industrial high-resistance rape variety. The method includes that a high-erucic-acid rape variety, a glyphosate herbicide resistant rape variety, a sclerotinia sclerotiorum resistant variety, a rape virus disease resistant variety and a rape white rust resistant variety are taken as parents and subjected to hybridization, multi-cross polymerization and multi-generation resistance identification, erucic acid content measurement, agricultural and yield trait screening to obtain a special industrial high-resistance rape variety which is highly resistant to three diseases, resistant to glyphosate herbicide and high in erucic acid content. The special industrial high-resistance rape variety is resistant to diseases, planting the variety can reduce weeding labor cost and farm chemical consumption and increase yield, rape oil is high in erucic acid content, and erucic acid produced by taking rape oil as a raw material is quite extensive in industrial application.

Owner:FUJIAN AGRI & FORESTRY UNIV

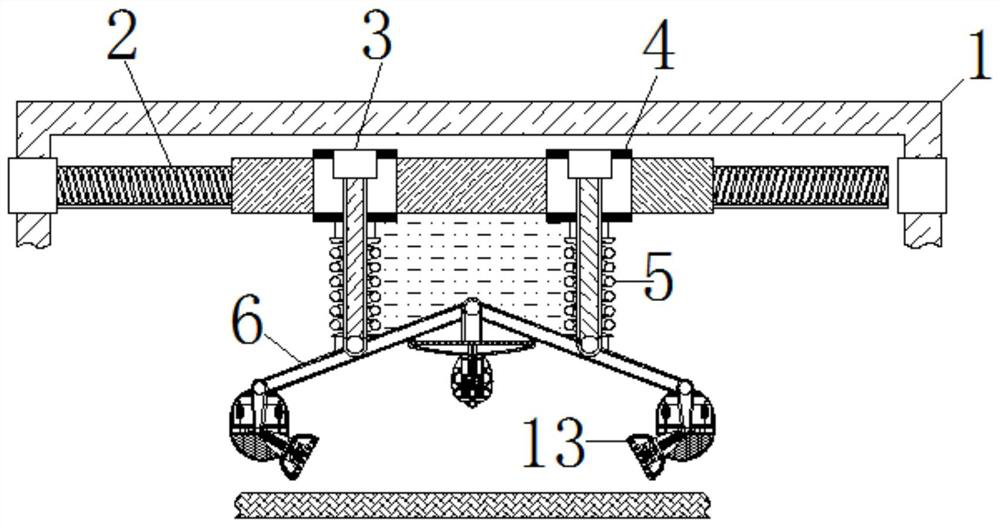

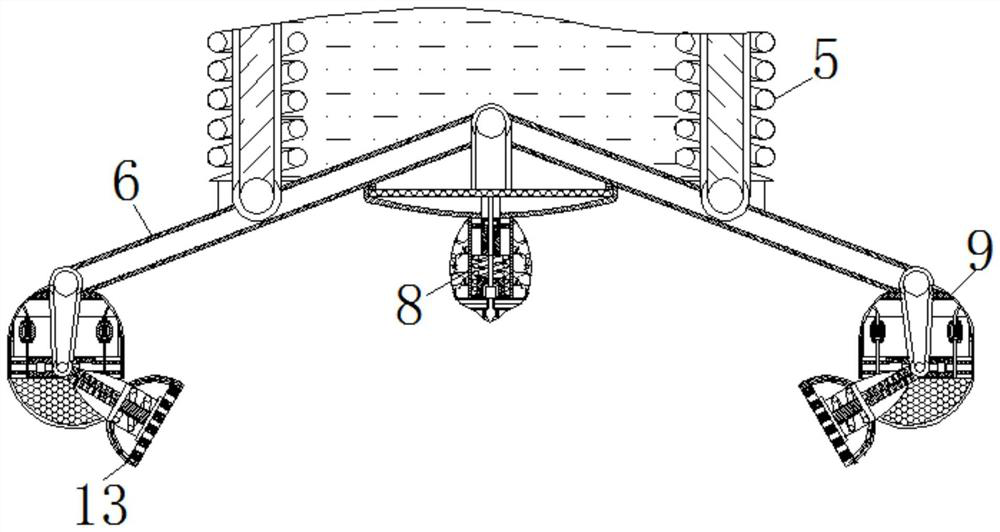

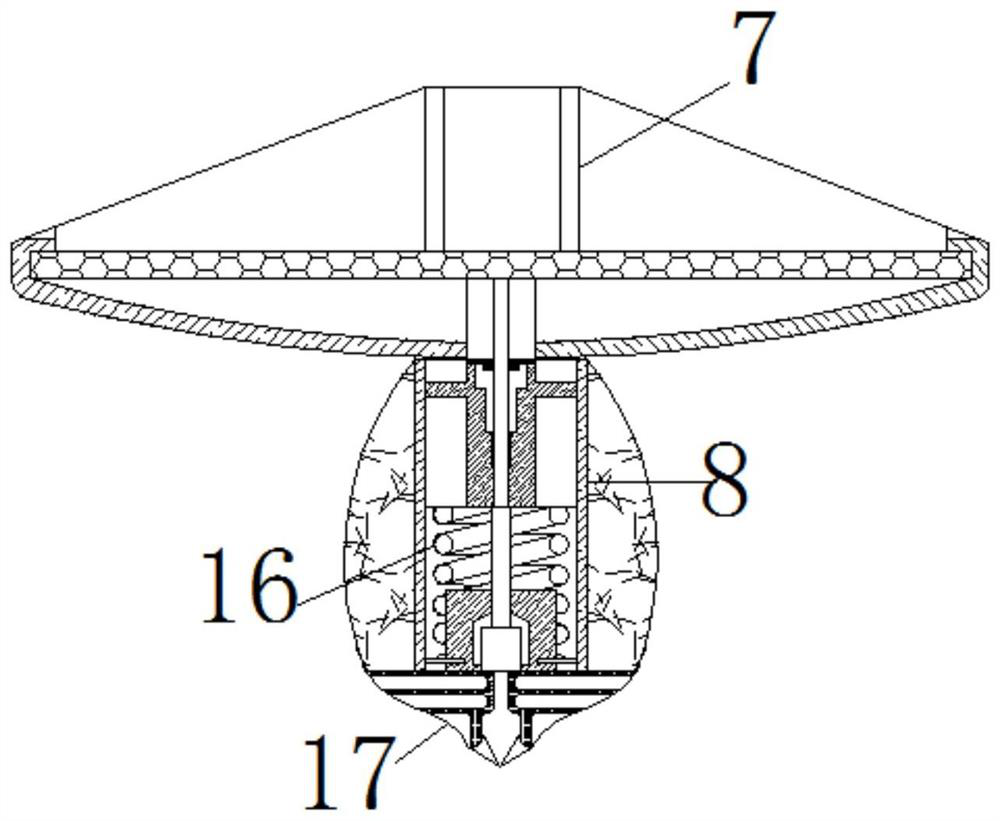

Wet etching equipment of antenna baseband for interphone

The invention relates to the technical field of interphones as digital products, and discloses wet etching equipment of an antenna baseband for an interphone. The wet etching equipment comprises a shell, wherein a rotating shaft is movably connected to the interior of the shell, a movable plate is movably connected to the surface of the rotating shaft, a sliding rail is formed in the movable plate, a compression spring is connected to the surface of the sliding rail in a sliding mode, a hollow rod is movably connected to the lower end of the compression spring, a feed pipe is movably connectedto the right end of the hollow rod, a spoiler is movably connected to one end, which is far from the hollow rod, of the feed pipe, an adjusting tank is movably connected to one end, which is far fromthe feed pipe, of the hollow rod, spring rods are movably connected to the interior of the adjusting tank and are located on both sides of a guide rod respectively, and a clamping plate is movably connected to one end, which is far from the guide rod, of an airflow pipe. An internal flowing space is narrowed, and therefore, chemical agents in a liquid storage bag can stop flowing out by utilizingsuction airflow when the flow direction of the chemical agents on the surface of a paster is changed, so that the effect of controlling the flow direction of corrosive liquid is achieved.

Owner:杭州殿训科技有限公司

Method for preparing carbon fiber containing polybenzimidazole compound material

The invention discloses a method for preparing a carbon fiber containing polybenzimidazole compound material. The method comprises the following steps that: polybenzimidazole is polymerized in situ onthe surface of the carbon oxide fiber to form carbon fiber containing polybenzimidazole; and the carbon fiber containing polybenzimidazole undergoes hot pressed sintering in a vacuum hot pressed sintering furnace for one-time formation to form the carbon fiber containing polybenzimidazole compound material. The method has the advantages of overcoming defects of uneven distribution of carbon fiberfilling materials and poor shearing stress between the polybenzimidazole and the carbon fiber filling materials, along with simple and convenient operation, simple equipment and process and the suitability for mass production. The compound material prepared by the method has good mechanical property and wide industrial values and application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

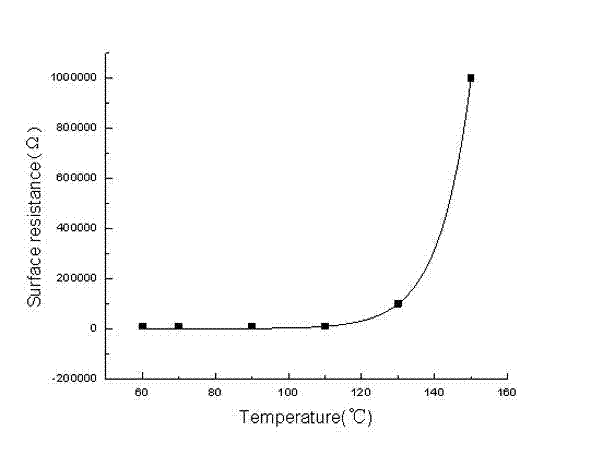

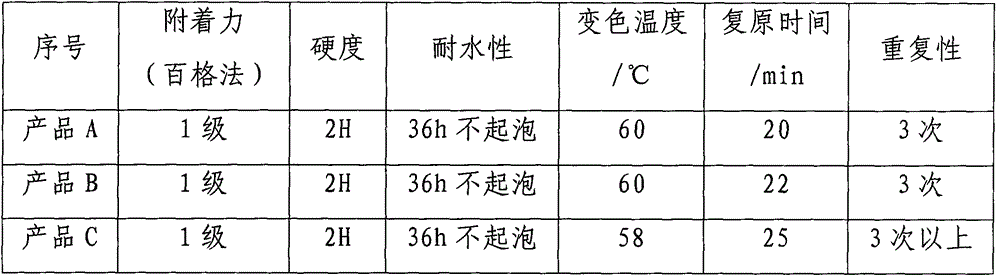

A kind of color-changing environmental protection coating and preparation method thereof

ActiveCN104830228BExtended reaction timeLow discoloration temperatureCoatingsEnvironmental resistanceBismuth vanadate

Disclosed is color-variable environment-friendly paint. The color-variable environment-friendly paint is prepared by, by weight, 30-40 parts of organic silicon resin, 40-50 parts of bismuth vanadate, 10-15 parts of hybi, 20-30 parts of poval, 10-20 parts of Sl203, 20-30 parts of talcum powder, 8-15 parts of mica powder, 6-10 parts of organic silicon coupling agent, 20-30 parts of xylene, 2-4 parts of dispersant, 1-3 parts of anti-settling agent and 3-5 parts of defoamer. The color-variable environment-friendly paint is excellent in reaction time within a range of 50-70 DEG C, low in color changing temperature, short in restoring time and reversible in color changing effect. The color-variable environment-friendly paint is smooth in coating, high in hardness, large in adhesive force, excellent in water resistance, less prone to aging, convenient in operation and simple in process, and has relatively-wide industrial application range.

Owner:安华新材科技(北京)有限公司

Method for ethylene glycol removing SOx (X=2 or 3) in flue gas

ActiveCN101053746BImprove the degree of purificationBroad marketDispersed particle separationMicrowave methodFlue gas

Owner:PEKING UNIV +2

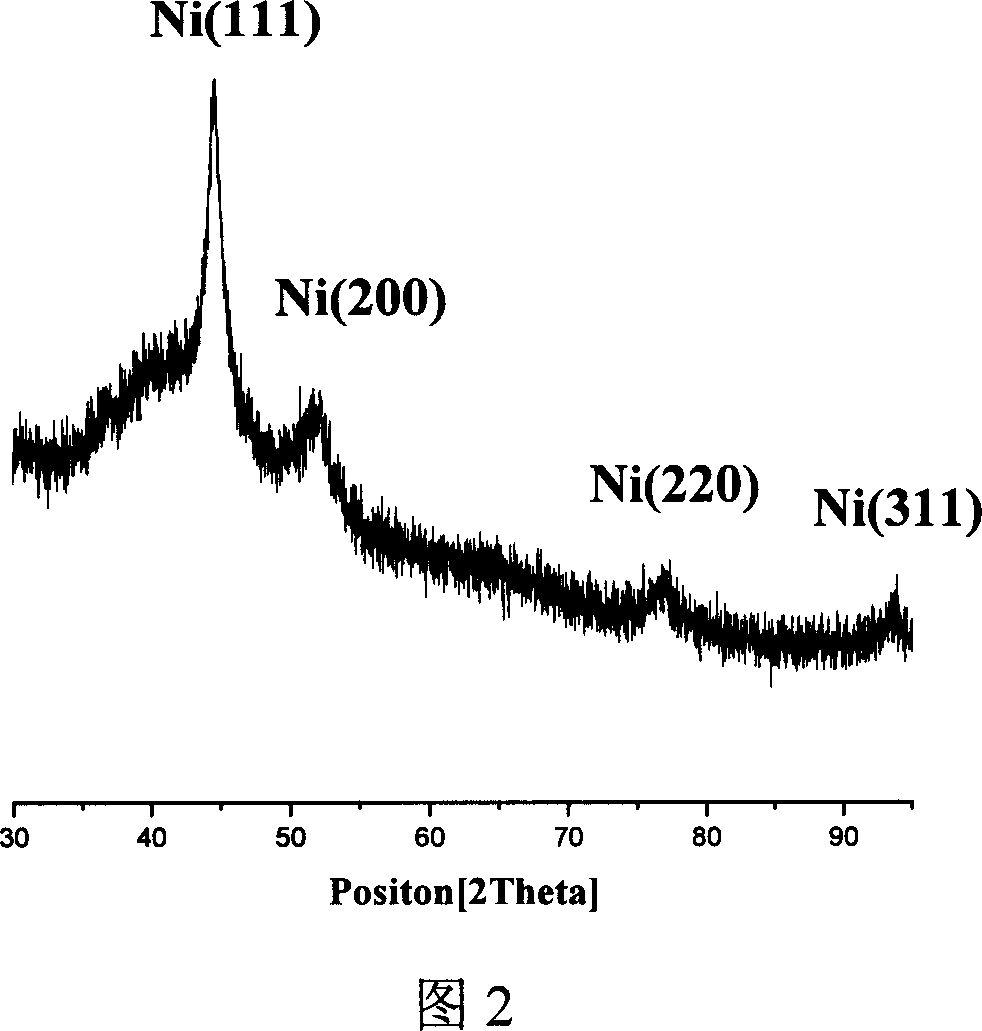

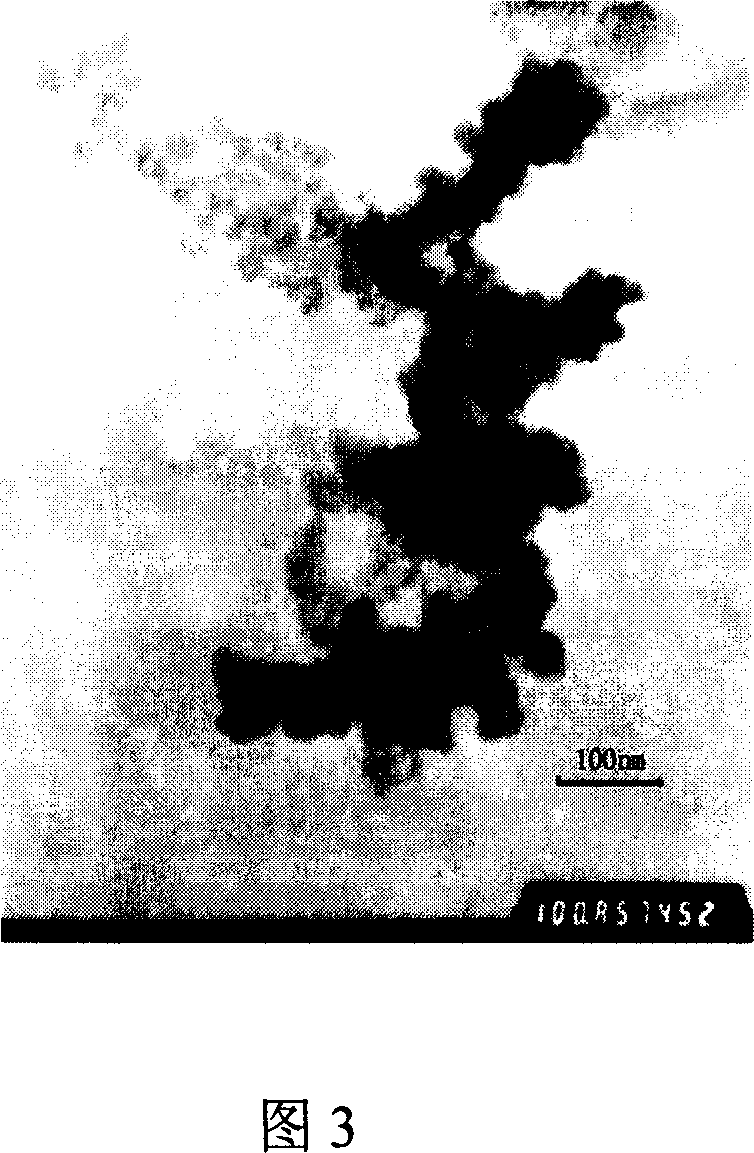

Method for preparing nano-nickel composite with protection of organic single molecular layer

A process for preparing the organic single molecular layer protected Ni nanoparticle includes such steps as mixing the alcohol solution of Ni salt with the alcohol solution of S-contained compound and chemical reducing by hydrazine hydrate.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

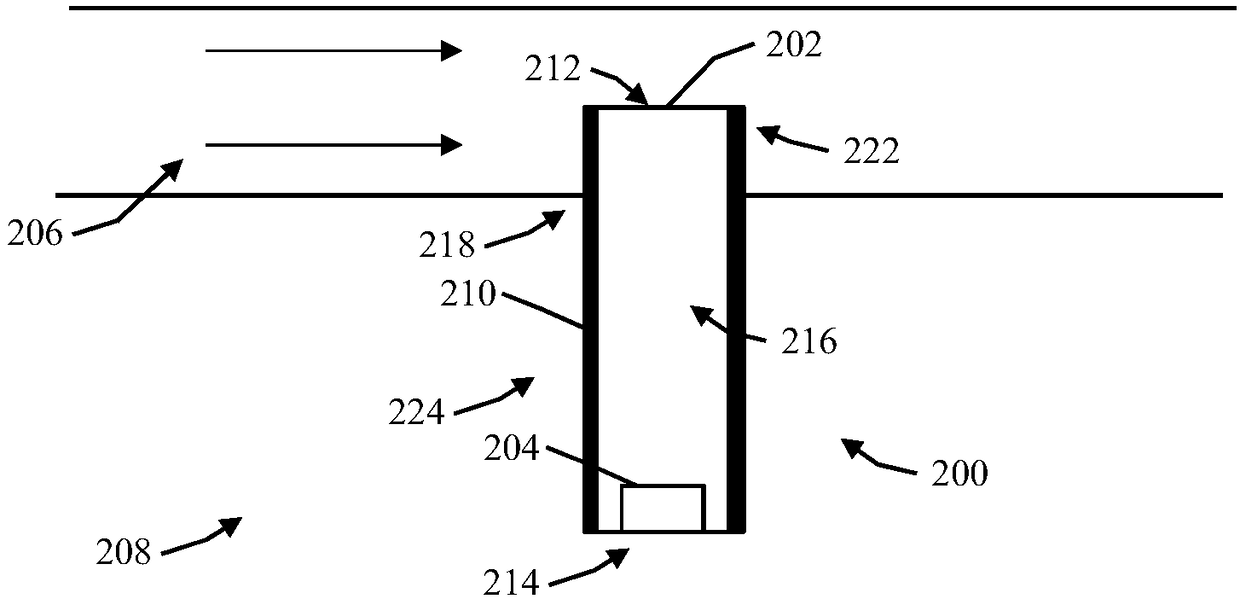

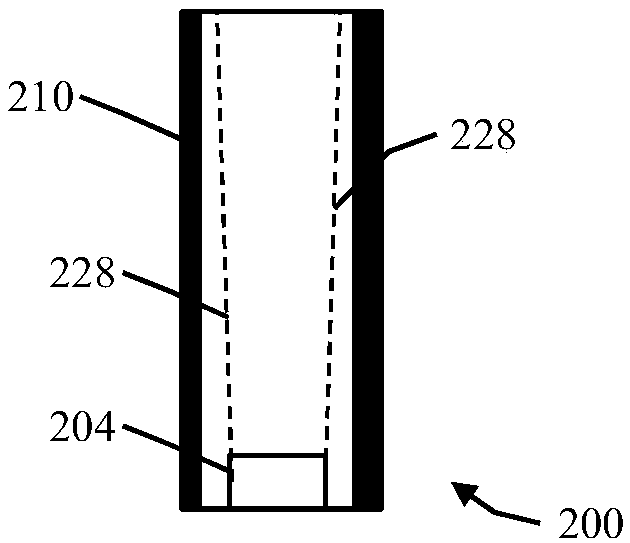

MEMS bolometer sensor for measuring temperature in an exhaust pipe of an automotive vehicle

InactiveCN108368790AFast temperature measurementWide range of industrial usesElectrical controlInternal combustion piston enginesControl systemBolometer

A control system for an internal combustion engine includes a temperature sensor and an engine controller. The sensor measures the temperature of exhaust gas passing through an exhaust manifold of theengine during each cycle. The controller selectively operates the engine in a first state and a second state. In the first, normal state, a quantity of fuel based on an open loop fuel mass command value is injected into the engine each cycle. In the second state, the controller determines a temperature of the exhaust gas during a normal cycle, injects the quantity and additional fuel into the engine during a second cycle, determines the temperature of the exhaust gas during the second cycle, compares the temperatures, and adjusts the command value for fuel to be injected each cycle when operating the engine in the first state.

Owner:ROBERT BOSCH GMBH

Method for preparing carbon fiber containing polybenzimidazole compound material

The invention discloses a method for preparing a carbon fiber containing polybenzimidazole compound material. The method comprises the following steps that: polybenzimidazole is polymerized in situ on the surface of the carbon oxide fiber to form carbon fiber containing polybenzimidazole; and the carbon fiber containing polybenzimidazole undergoes hot pressed sintering in a vacuum hot pressed sintering furnace for one-time formation to form the carbon fiber containing polybenzimidazole compound material. The method has the advantages of overcoming defects of uneven distribution of carbon fiber filling materials and poor shearing stress between the polybenzimidazole and the carbon fiber filling materials, along with simple and convenient operation, simple equipment and process and the suitability for mass production. The compound material prepared by the method has good mechanical property and wide industrial values and application prospect.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Rectangular offset strip fin heat transfer pipe and uses thereof

InactiveCN100520270CHigh heat and mass transferImprove heat transfer coefficientTubular elementsCondensation processEngineering

The invention provides a heat transfer tube with rectangular staggered fins and application thereof. The inventive heat transfer tube comprises a tube body and a plurality of rectangular staggered fins fixed on the tube body. The outer edge of the lee side of rectangular staggered fin is flat, and the other three outer edges are staggered in cross section along thickness direction and respectively provided with 5-8 sphenoid narrow grooves. The inventive heat transfer tube with the rectangular staggered fins can be used for heat and mass exchange equipment in gas-solid sublimation process and gas-liquid condensation process. The invention has simple structure and low manufacturing cost, can improve local turbulence, and can remarkably reinforce gas lateral heat exchange and phase-change heat transfer and mass transfer processes.

Owner:DONGGUAN UNIV OF TECH

A kind of preparation method of graphite-niobium diselenide nanocomposite material

InactiveCN102703160BImprove tribological propertiesImprove conductivityConductive materialBase-materialsNiobiumSolid reaction

The invention relates to a preparation method of a graphite-bi-selenylation niobium nanocomposite. The preparation method enables niobium powder, selenium powder and graphite powder to serve as raw materials, conducts solid-phase reaction at certain temperature conditions and synthetizes sheet-shaped particles formed by a graphite-selenylation niobium nanocomposite. The preparation method is simple in process, high in productivity, environmental friendly, free of pollution and capable of achieving large-scale industrial preparation. Simultaneously, nano materials are small in size and have good physical chemistry effects so that the nano materials can serve as an excellent annexing agent of an electric contact material.

Owner:无锡润鹏复合新材料有限公司

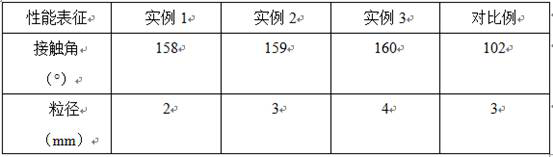

A preparation method of composite hydrophobic nano-powder coated liquid marbles

InactiveCN109806819BImprove wear resistanceSmall roughnessMicroballoon preparationMicrocapsule preparationNano al2o3Materials science

The invention relates to a method for preparing composite hydrophobic nano powder-coated liquid marbles, which belongs to the technical field of coating materials. The invention uses nano-zinc oxide powder, nano-titanium dioxide powder and nano-alumina powder as raw materials to prepare a composite hydrophobic nano-powder that wraps liquid, and can effectively reduce the liquid in the marble by wrapping the hydrophobic nano-zinc oxide powder. The risk of harmful bacterial contamination, thereby improving the safety of liquid marbles, nano-titanium dioxide has a strong UV shielding effect, and is effective against Bacillus subtilis var. niger, Pseudomonas aeruginosa, E. The extinction rate reaches 98~99%, which can effectively improve the medical use and safety of liquid marbles. Nano-alumina is in the state of white fluffy powder, which has the advantages of large specific surface area, high porosity, strong adsorption and good formability. It can effectively adsorb on the surface of the liquid, and effectively adsorb and bond other particles on the surface of the liquid, thus forming a stable liquid marble.

Owner:JILIN UNIV

Method for synthesizing copper nanoparticles

InactiveCN102407343BEasy to controlIncrease temperatureMaterial nanotechnologySynthesis methodsSolvent

The invention discloses a method for synthesizing copper nanoparticles, which comprises the following steps of: using a half solid phase synthesis method to mix a cupric salt, a reducing agent, a stabilizing agent and water to obtain a uniform mixture; and using a microwave heating method to quickly synthesize the copper nanoparticles. The water or other polar organic molecules can quickly absorbmicrowaves to quickly increase the temperature of a reaction system so as to promote reduction of copper ions, and due to half solid phase and large viscosity and poor flowability of the reaction system, the high molecular polymer stabilizing agent can effectively contact and cover the copper nanoparticles to control growth of the nanoparticles so as to obtain smaller copper nanoparticles. The method has the characteristics of low cost, quickness, simpleness, convenience, no large amounts of solvents, and the like, and is suitable for large scale industrial production; and the prepared coppernanoparticles are 1-100nm in particle size and can be used for preparing a conductive paste along with wide industrial application.

Owner:EAST CHINA NORMAL UNIV

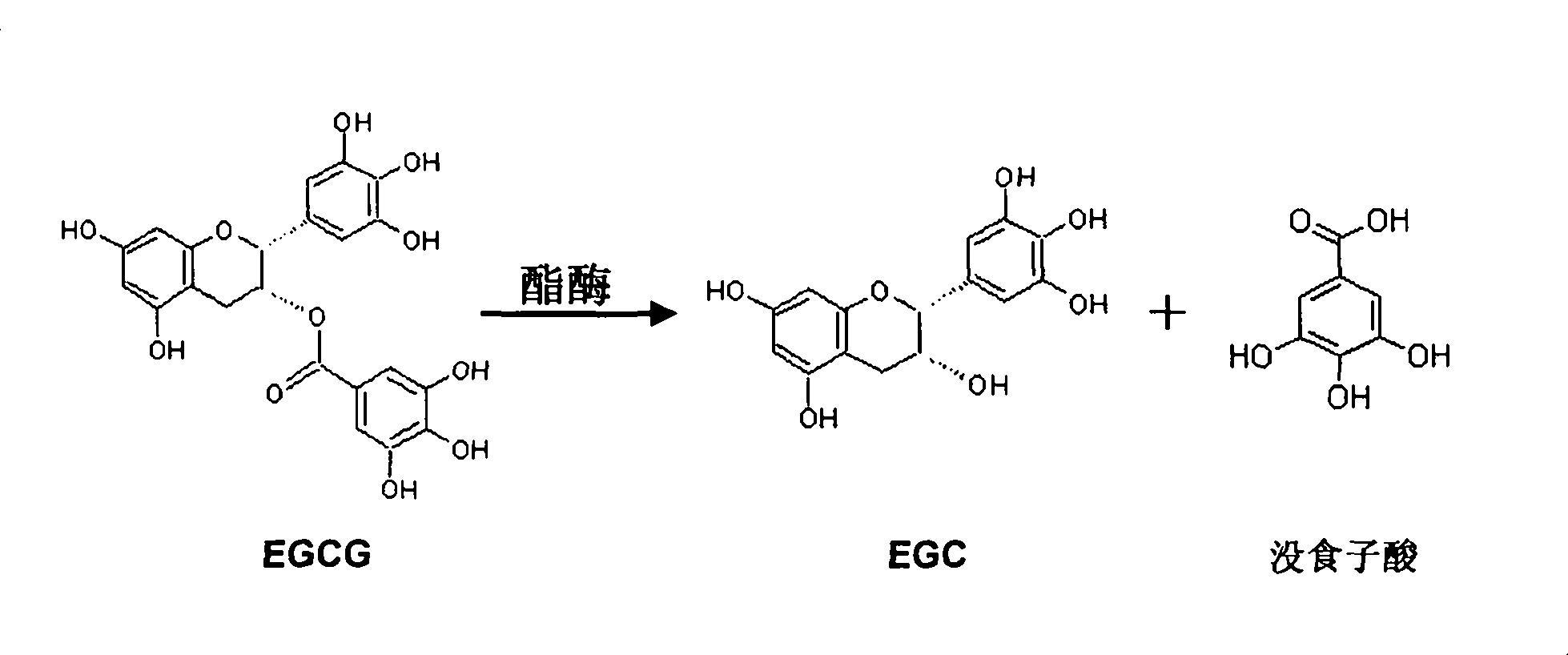

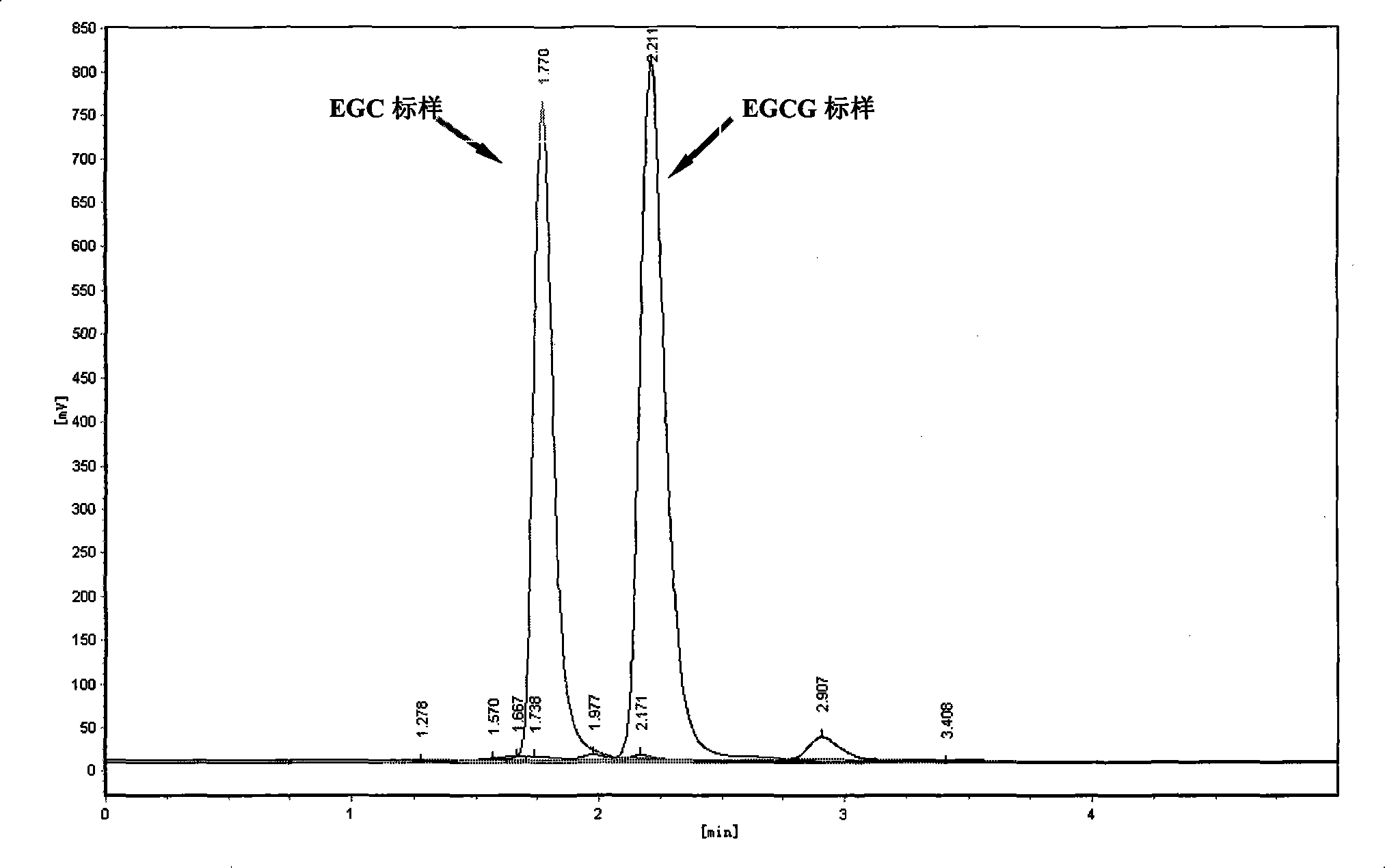

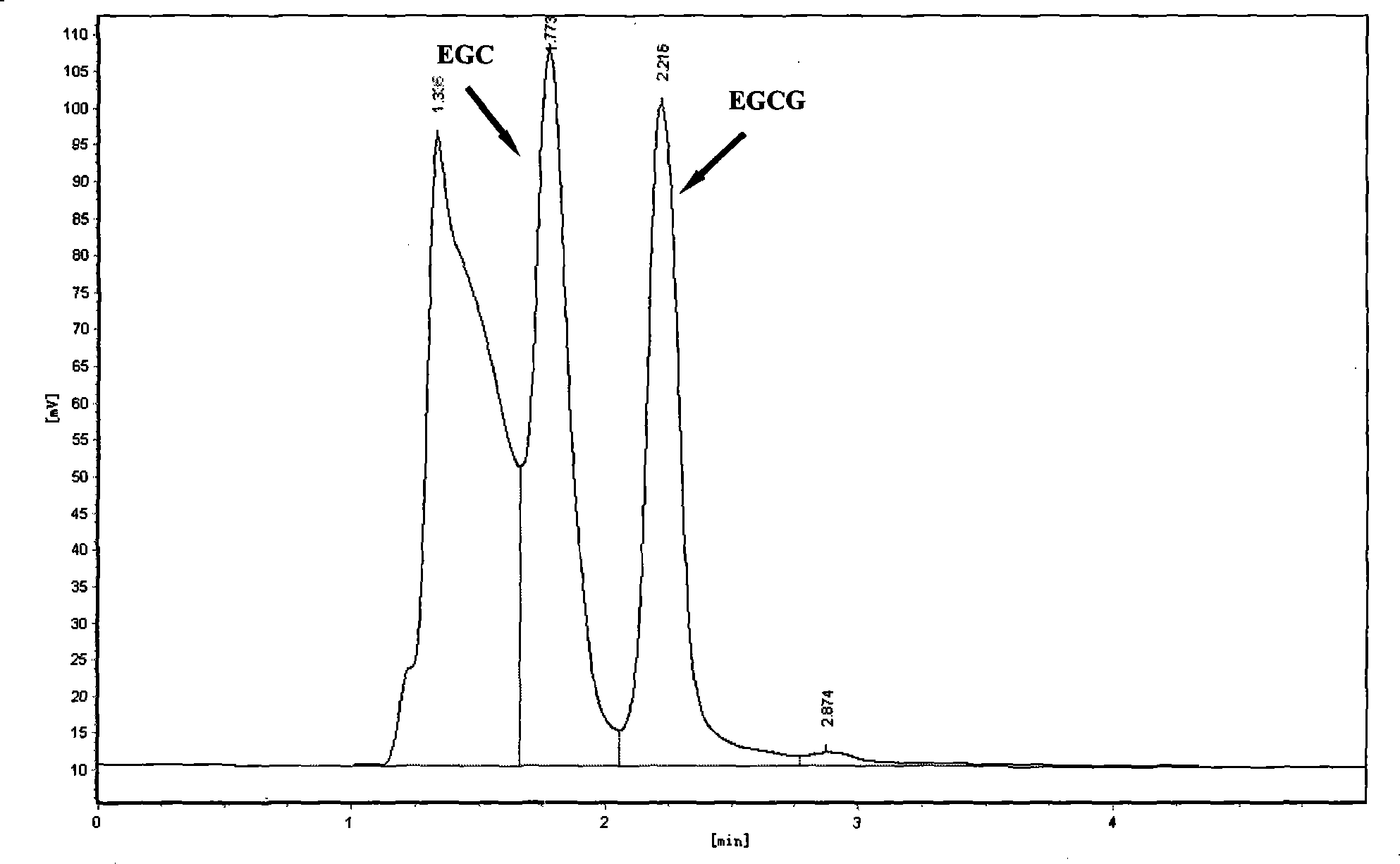

Induction preparation of EGCG esterase and method for producing EGC and gallic acid by using the enzyme

InactiveCN101113411BSafety and environmental protectionEasy to operateFungiHydrolasesGallic acid esterHydrolysis

The invention relates to a method for inducing aspergillus niger to generate EGCG (epigallocatechin-3-gallate) esterase with EGCG, comprising the steps that: (1) an aspergillus niger seed culture medium is cultivated for 36 hours at 25-30 DEG C and 100-250r / min; (2) the aspergillus niger seed culture medium with a inoculated dose of 4-10 percent is transferred to a fermented culture medium that contains the EGCG and cultivated for 72 hours at 25-30 DEG C and 100-250r / min, and filtered and centrifugated to get enzyme liquid; then the enzyme is used for hydrolyzing the EGCG so as to transfer the EGCG into EGC (epigallocatechin) and ellagic acid, comprising: (1) an EGCG enzyme hydrolysis reaction system, an enzyme liquid blank system and a substrate blank system are constructed; (2) the reaction system and the blank systems are reacted for 0-48 hours at 25-60 DEG C or until the hydrolysis reaction is almost over; (3) high performance liquid and thin layer chromatography are used for analyzing the substrate and the products. The invention has high EGC transfer ratio and yield and the products are stable and easy to be separated, besides, the invention has the advantages of safety, environment protective, simple operation and strong controllability, thereby being applicable to mass scale production.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com