Preparation method of organic phase change energy storage composite material

A composite material and organic phase technology, which is applied in the direction of microsphere preparation, heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor emulsification effect of core materials, affecting the efficiency of core material coating, etc., and achieves a wide range of industrial applications , low cost, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

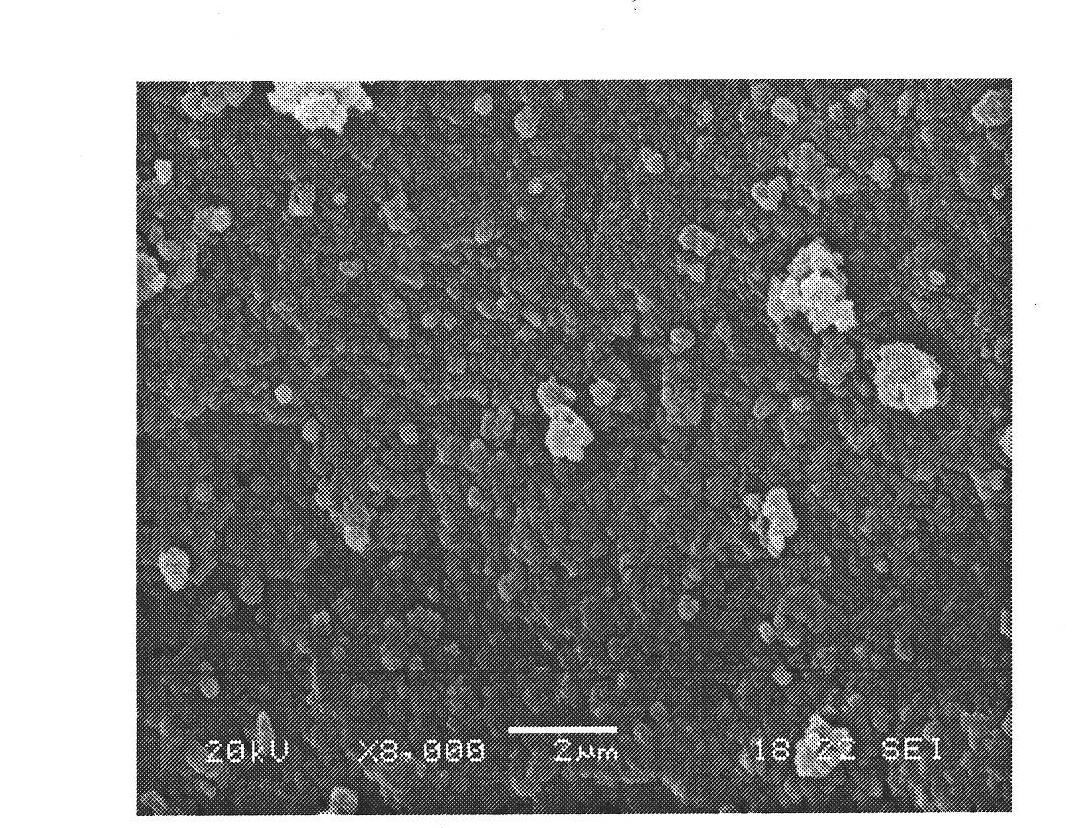

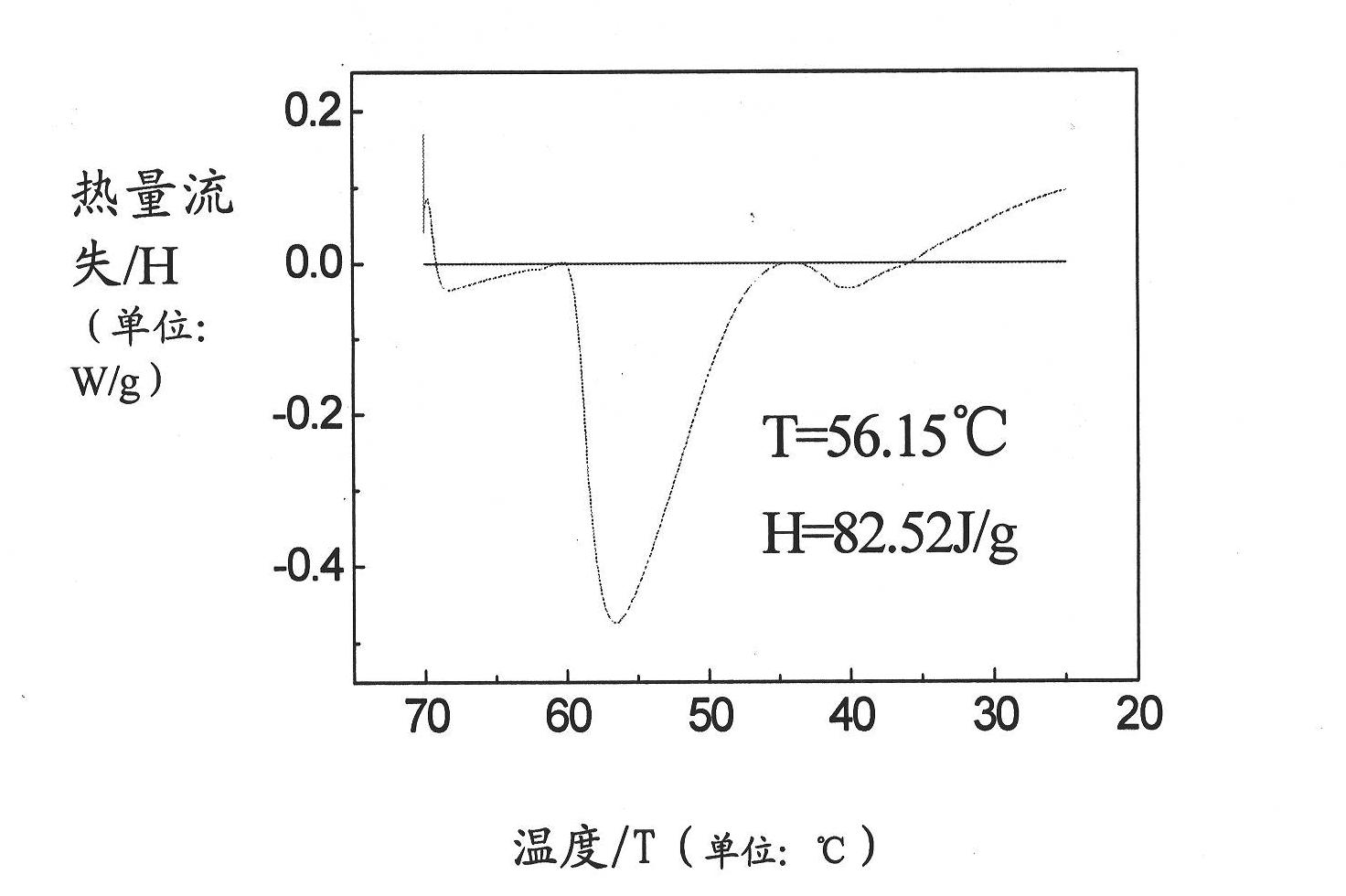

Embodiment 1

[0036] Take 24g of stearic acid and place it in a 1000mL three-necked flask. Heat to 70℃. After it is completely melted, add 240mL of aqueous solution containing 2.0g of OP-10 and 1.6g of sodium dodecylbenzene sulfonate, while vigorously mechanically stirring, fully After emulsifying for 60 minutes, the temperature is reduced to 50°C, and it is recorded as A emulsion. Take 24mL of styrene into a 500mL three-necked flask, heat to 50℃, add 200mL of an aqueous solution containing 2.0g OP-10 and 2.0g sodium dodecylbenzene sulfonate, emulsify for 180min under vigorous mechanical stirring, denoted as B Lotion. Add Emulsion B to Emulsion A. After mechanically stirring at 45°C for 60 minutes, add 80 mL of an aqueous solution containing 2.4 g of ammonium persulfate. After continuing the reaction for 4 hours, cool to room temperature. Transfer the resulting emulsion to a 1000 mL beaker. After 50mL of sodium hydroxide solution with a concentration of 1mol / mL was demulsified, filtered wit...

Embodiment 2

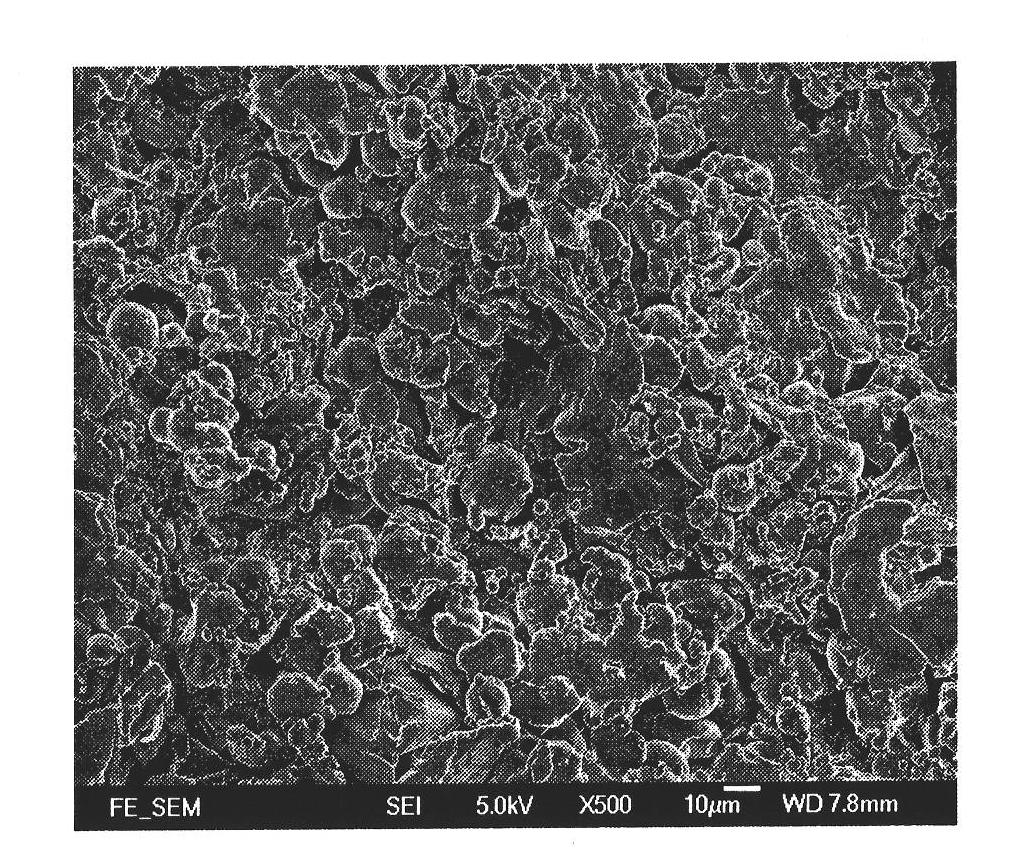

[0042] Take 24g of stearic acid and place it in a 1000mL three-necked flask. Heat to 70℃. After it is completely melted, add 240mL of aqueous solution containing 2.0g of OP-10 and 1.6g of sodium dodecylbenzene sulfonate, while vigorously mechanically stirring, fully After emulsifying for 60 minutes, the temperature is reduced to 60°C, and it is recorded as A emulsion. Take 12mL of styrene into a 500mL three-necked flask, heat it to 60℃, add 200mL of an aqueous solution containing 2.0g OP-10 and 2.0g sodium dodecylbenzene sulfonate, emulsify for 180min under vigorous mechanical stirring, denoted as B Emulsion: Add Emulsion B to Emulsion A. After mechanically stirring at 25°C for 120 minutes, add 80 mL of an aqueous solution containing 1.2 g of ammonium persulfate. After continuing the reaction for 4 hours, cool to room temperature, and transfer the resulting emulsion to a 1000 mL beaker After adding 25mL of sodium hydroxide solution with a concentration of 1mol / mL to demulsify, ...

Embodiment 3

[0048] Take 24g of stearic acid and place it in a 1000mL three-necked flask. Heat to 70℃. After it is completely melted, add 240mL of aqueous solution containing 2.0g of OP-10 and 1.6g of sodium dodecylbenzene sulfonate, while vigorously mechanically stirring, fully After emulsifying for 60 minutes, the temperature is lowered to 50°C, which is recorded as Emulsion A; 6mL of styrene is placed in a 500mL three-neck flask and heated to 50°C, and an aqueous solution containing 2.0g OP-10 and 2.0g sodium dodecylbenzene sulfonate is added 200mL, emulsify for 180min under vigorous mechanical stirring, and record it as B emulsion; add B emulsion to A emulsion, after mechanical stirring at 25℃ for 180min, add 80mL of aqueous solution containing 0.6g ammonium persulfate dropwise, continue to react for 4h, then cool To room temperature, transfer the emulsion obtained from the reaction to a 1000mL beaker, add 75mL of 1mol / mL sodium hydroxide solution to demulsify, filter with suction, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com