MEMS bolometer sensor for measuring temperature in an exhaust pipe of an automotive vehicle

A technology of temperature sensor and exhaust manifold, applied in the direction of exhaust device, electrical control, fuel injection control, etc., can solve the problems of short signal response time, difficult engine control, harsh exhaust environment, etc., and achieve rapid temperature measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] To promote an understanding of the principles of the embodiments described herein, reference is now made to the drawings and descriptions in the following written specification. References are not intended to limit the scope of the subject matter. This disclosure also includes any alterations and modifications to the illustrated embodiments, and further applications of the principles of the described embodiments as would normally occur to one of ordinary skill in the art to which this document pertains.

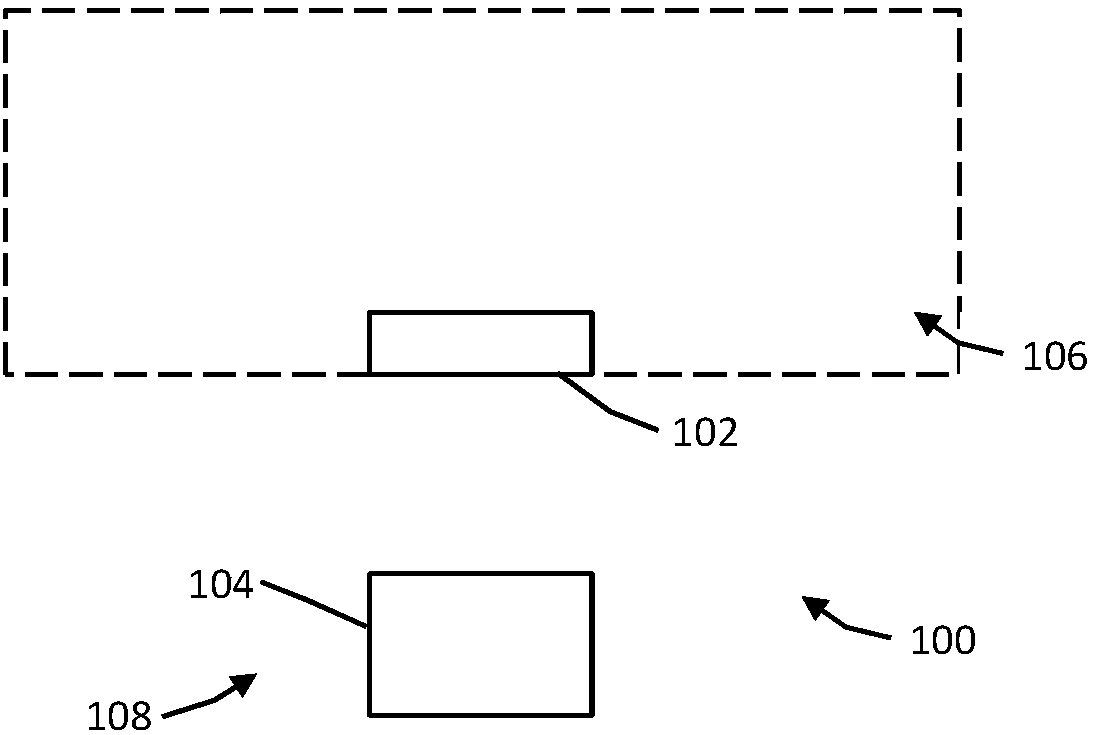

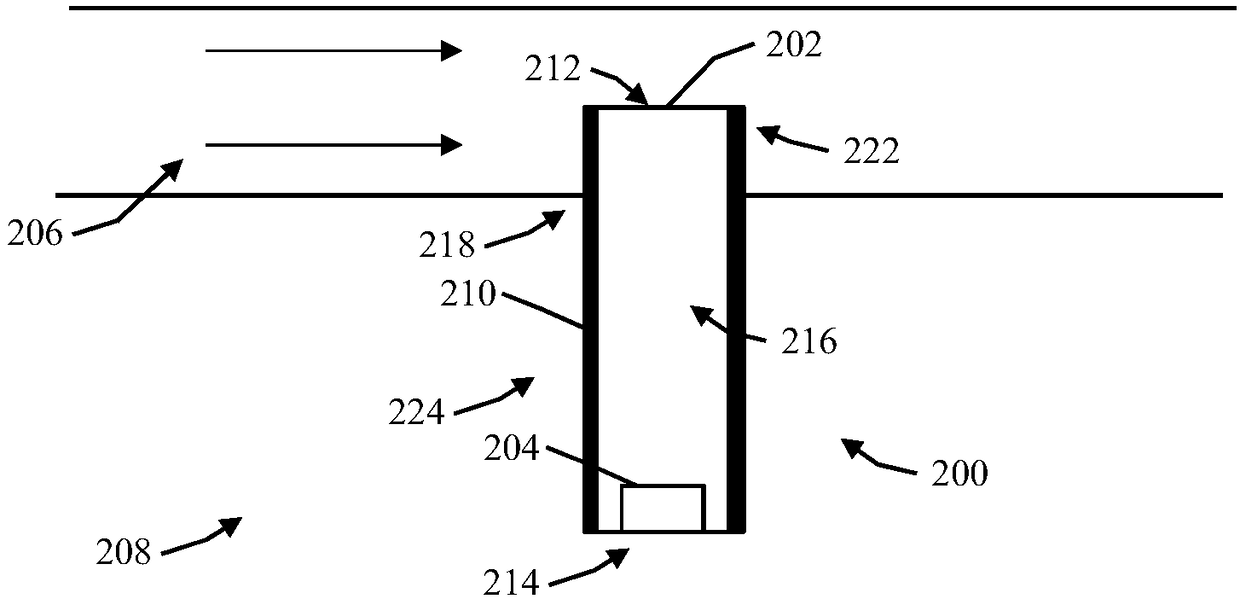

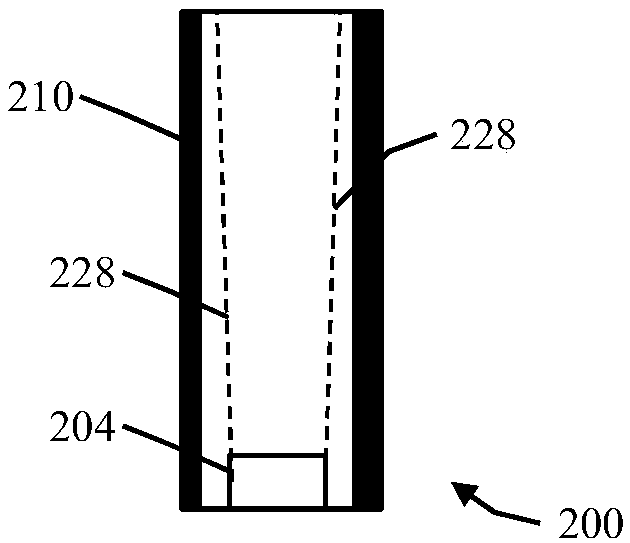

[0032] figure 1 is a schematic block diagram of a temperature sensing device 100 according to the present disclosure. The device 100 includes a probe unit 102 and a sensor unit 104 . The probe unit 102 is positioned such that it is substantially within the environment 106 to be measured. The probe unit 102 is exposed to the temperature of the environment 106 and is configured to reach a temperature corresponding to the temperature of the environment. The sensor uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com