A solar cell panel electrode welding temperature measurement positioning device and using method

A technology of solar panels and positioning devices, applied in measuring devices, radiation pyrometry, auxiliary devices, etc., can solve problems such as difficult removal of oxide layer, incorrect welding position, unstable product quality, etc., and achieve fast temperature measurement , Guaranteed quality, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

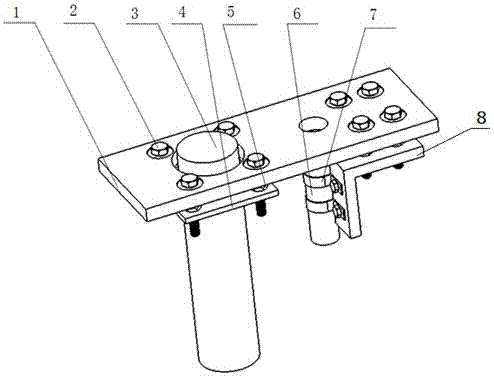

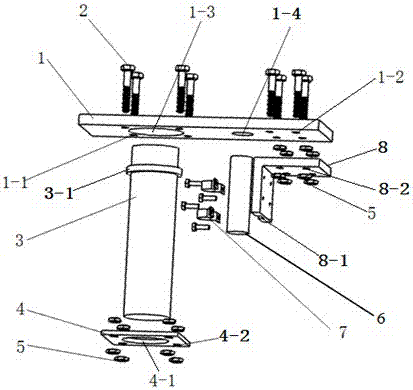

[0021] Such as figure 1 , 2 , 3, a solar panel electrode welding temperature measurement positioning device, including infrared sensor 3, laser sensor 6, also includes platform 1, bolt 2, adjustment platform I4, nut 5, throat clamp 7, adjustment platform II8.

[0022] The platform 1 is a rectangular plate, and four screw holes I1-1, four screw holes II1-2, one large hole 1-3, and one small wire hole 1-4 are respectively arranged on the surface of the platform 1.

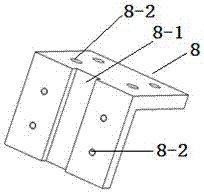

[0023] The adjustment platform II8 is L-shaped, and there is a vertical groove 8-1 on the vertical plate of the adjustment platform II8, and four grooves are respectively arranged on the vertical surface of the groove 8-1 and the horizontal surface of the adjustment platform II8. Via II8-2.

[0024] Place one side of the laser sensor 6 in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com