Vacuum suction-casting forming process for temperature measuring layer of thermal-insulation container

A thermal insulation container and vacuum suction technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve problems such as inconvenience, damage to the thermal insulation structure of the thermal insulation container, and difficulty in fixing chips reliably, so as to reduce requirements and increase temperature measurement speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

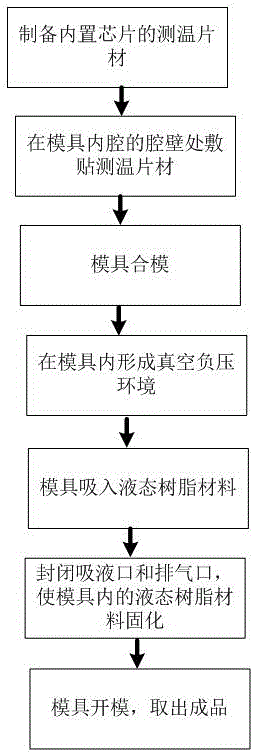

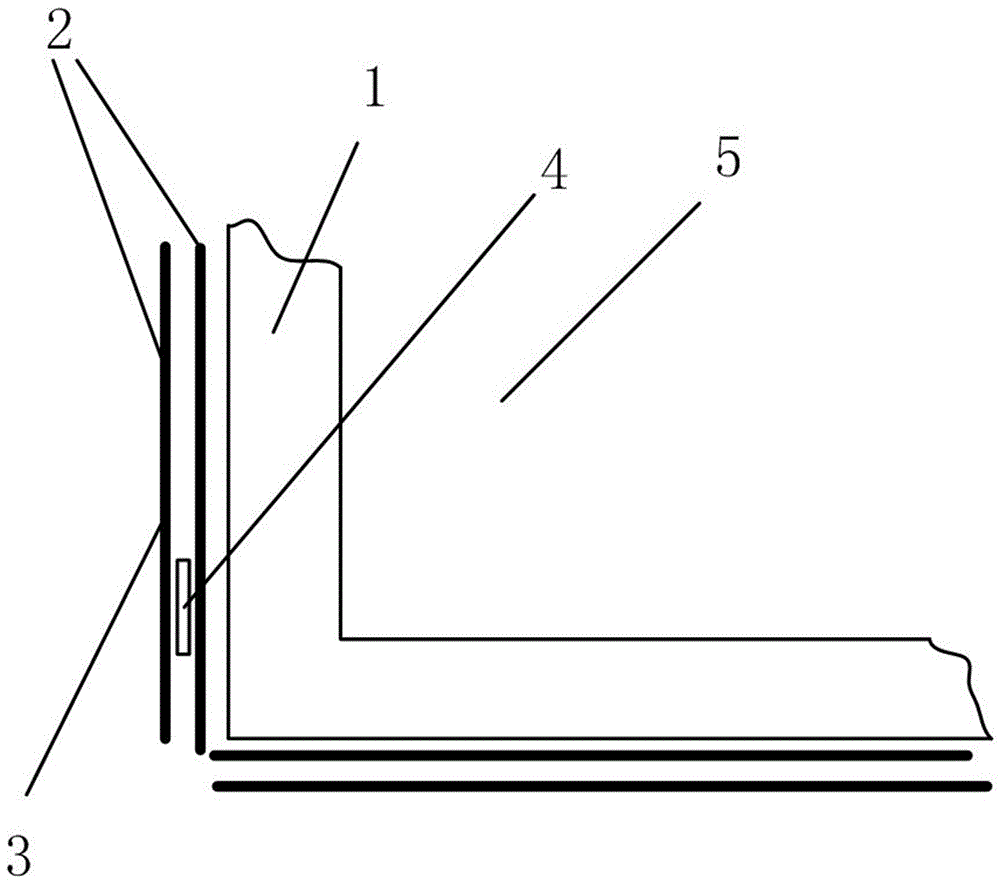

[0028] Such as figure 1 , 2 As shown, a temperature-measuring layer vacuum suction molding process of a thermal insulation container is used to form a surface layer with a temperature-measuring chip 4 at the thermal insulation container 1. The mold of the mouth comprises the following steps in turn.

[0029] A1. Cover the chip 4 with several raw material sheets 2 to make a temperature measuring sheet 3 .

[0030] A2. Apply the temperature measuring sheet 3 and the raw material sheet 2 on the cavity wall of the inner cavity of the mold.

[0031] A3. The mold is closed to form a vacuum negative pressure environment in the mold.

[0032] A4. Vacuum-introduce liquid epoxy resin and unsaturated resin into the mold where the sheet is applied.

[0033] A5. Close the liquid suction port and the exhaust port, and solidify the liquid resin material in the mold to form a thermal insulation container. The cured resin material of the temperature measuring sheet 3 and the raw material s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com