Method for preparing surface modification oil solubility nanometer copper

A surface modification and oil-soluble technology, which is applied in the field of preparation of surface-modified oil-soluble nano-copper, can solve problems such as dispersion, production scale limitation, and complicated preparation process, and achieve low cost, long-term stable existence, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

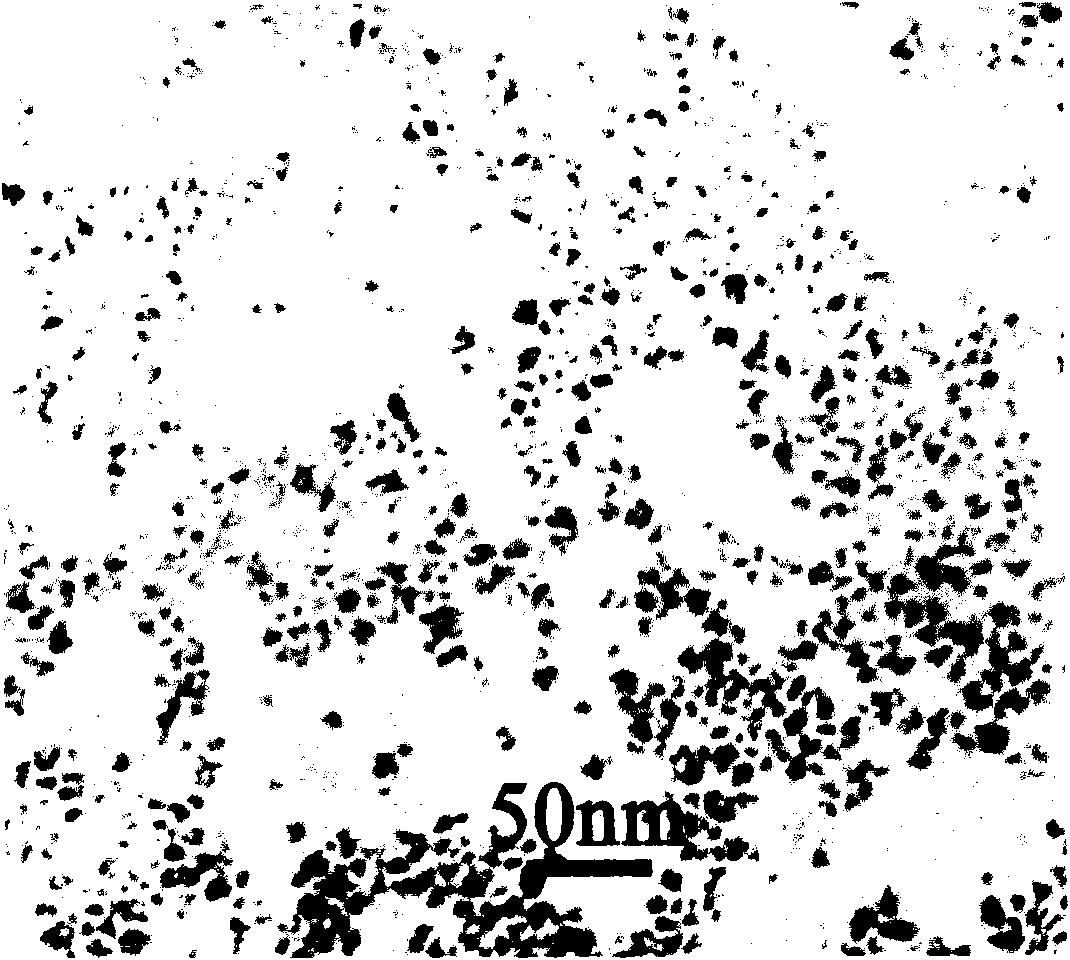

[0023] Add 0.91g of CuSn alloy (Sn content 10%, 300 mesh) in 500mL one-necked flask, add 2.73gO under magnetic stirring, the chloroform solution 80mL of O'-dioctyl dithiophosphoric acid, then add with 20mL37% (wt ) 80 mL of hydrochloric acid solution prepared by dissolving HCl in water, and magnetic stirring at room temperature for 24 h. Stop stirring, stand still, filter, the filtrate is divided into two layers, the water layer is clear and transparent, the chloroform layer is reddish brown, and CHCl is separated after reduced pressure filtration. 3 layer, and distilled under reduced pressure to obtain a brown-red viscous liquid, which is O, O'-dioctyl dithiophosphoric acid (C 8 DDP) modified copper nanoparticles, denoted as C 8 DDPCu; its transmission electron microscope image is shown in figure 1 , as can be seen, the obtained product has uniform particle size, and the average particle size is about 20nm. The optical photographs of it dissolved in various organic solvent...

Embodiment 2

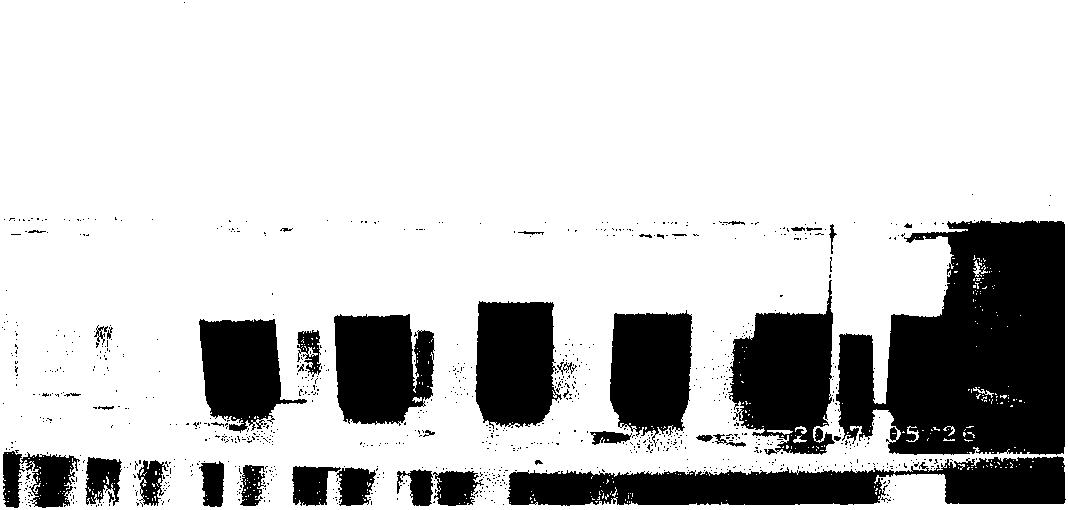

[0025] Add 0.91g of CuSn (Sn content 10%, 300 mesh) to a 500mL single-necked flask, add 2.73g of O, O'-dioctyl dithiophosphoric acid in chloroform under magnetic stirring 80mL, then add 1.25mol / L of NaOH 80 mL of the solution was stirred magnetically at 20°C for 24 hours. Stop stirring, filter under reduced pressure to separate CHCl 3 layer, and distilled under reduced pressure to obtain a brown-red viscous liquid, which is O, O'-dioctyl dithiophosphoric acid (C 8 DDP) modified copper nanoparticles, denoted as C 8 DDP-Cu. Its transmission electron microscope image is shown in figure 2 , it can be seen that the particle size of the obtained product is uniform, and the average particle size is about 10nm. The obtained copper nanoparticles were dissolved in liquid paraffin with a mass concentration of 1%, and there was no obvious precipitation after standing for 15 days, and the stability was good.

Embodiment 3

[0027] Add 0.91g of CuSn (Sn content 20%, 300 mesh) in 500mL one-necked flask, add 0.37g O under magnetic stirring, the toluene solution 80mL of O'-dioctylphosphonic acid, then add with 20mL 37% (wt) Dissolve 80 mL of hydrochloric acid solution prepared by dissolving HCl in water, and stir magnetically at 10°C for 6 h. The stirring was stopped, the organic layer was separated by filtration under reduced pressure, and the brown-red viscous liquid was obtained by distillation under reduced pressure, which was copper nanoparticles modified with O, O'-dioctylphosphonic acid. The obtained copper nanoparticles were dissolved in toluene at a concentration of 0.3%, and there was no obvious precipitation after standing for 15 days, and the stability was good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com