A preparation method of surface-modified core-shell structure cusio2 nanoparticles

A core-shell structure and nanoparticle technology is applied in the field of preparation of nanocomposite materials, which can solve the problems of nanoscale copper powder being easily oxidized and disperse, restricting applications, etc., and achieve good organic dispersibility, prevent oxidation, and expand application fields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

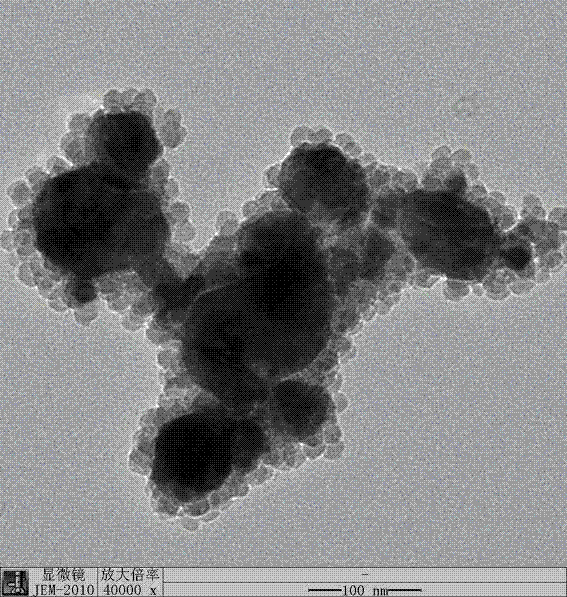

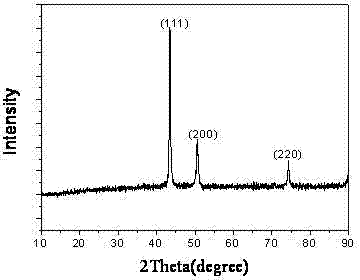

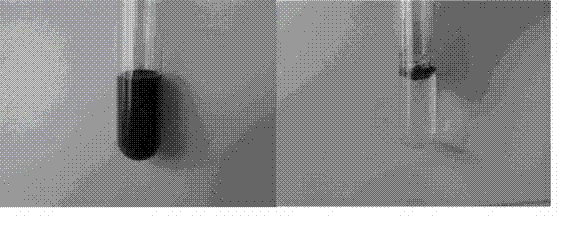

[0024] Weigh 12.5g of copper sulfate pentahydrate in 60mL of deionized water, add concentrated ammonia water to make the pH of the solution about 7 after the dissolution is complete, transfer the resulting solution to a 250mL three-neck flask, stir and heat with magnetic force, take 4.8g of sodium borohydride and add Dilute with 44mL deionized water, when the temperature of the system is constant at 40°C, add sodium borohydride solution dropwise, stir for 30 minutes, then add 2.08g of tetraethyl orthosilicate (TEOS) to it, continue to stir and react at 40°C for 2h; 1h, remove 100mL of supernatant, then add modifier KH570 (γ-(methacryloyloxy)propyltrimethoxysilane) in molar ratio, modifier: ethyl orthosilicate = 1:3, stir at 60°C After reacting for 10 hours, the surface-modified CuSiO with core-shell structure was obtained. 2 Nanoparticle emulsion; the obtained emulsion is suction-filtered, washed with water to remove by-products, and then dried to obtain surface-modified c...

Embodiment 2

[0027] Weigh 12.4g of copper nitrate trihydrate in 60mL of deionized water, and dissolve sodium hydroxide to make the pH of the solution about 9. Transfer the resulting solution to a 250mL three-neck flask, stir and heat with magnetic force, and add 8mL of hydrazine hydrate to 44mL Dilute with deionized water; when the temperature of the system is constant at 50°C, add hydrazine hydrate solution dropwise, stir for 10 minutes, then add 2.4g of silica sol, continue stirring and reacting at 50°C for 2h; let stand for 1h, remove 100mL of the supernatant, Then add the modifier (hexamethyldisilazane) according to the molar ratio, modifier: silica sol = 1:6, and stir and react at 30°C for 24 hours to obtain the surface-modified core-shell structure CuSiO 2 Nanoparticle emulsion; the above obtained emulsion is suction filtered, washed with water to remove by-products, and then dried to obtain surface-modified core-shell structure CuSiO 2 Nanoparticles, the mass is 3.6g.

Embodiment 3

[0029] Weigh 4.9g of copper hydroxide in 60mL of deionized water, add potassium hydroxide to make the pH of the solution about 10, transfer the resulting solution to a 250mL three-neck flask, stir and heat with magnetic force, take 4mL of hydrazine hydrate and add 44mL of deionized water to dilute , when the temperature of the system is constant at 25°C, add hydrazine hydrate solution and stir for 10 hours; remove 100mL of the supernatant after standing and layering, add 3.04g of orthosilicate methyl ester (TMOS) to it, and continue stirring at 30°C for reaction 1h; then add the modifier KH151 (vinyltriethoxysilane) according to the molar ratio, modifying agent: methyl orthosilicate = 1:3, stir and react at 60°C for 1h, then raise the temperature to 80°C and continue the reaction for 2h to obtain the surface Modified core-shell CuSiO 2 Nanoparticle emulsion; the above obtained emulsion is suction filtered, washed with water to remove by-products, and then dried to obtain surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com