Preparation method of iron oxide nanowire

A technology of nano-iron oxide and iron carboxylate, which is applied in the field of nano-iron oxide, can solve the problems of poor organic dispersion and difficulty in controlling the size of nanomaterials, and achieve the effects of low cost, good organic dispersion, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

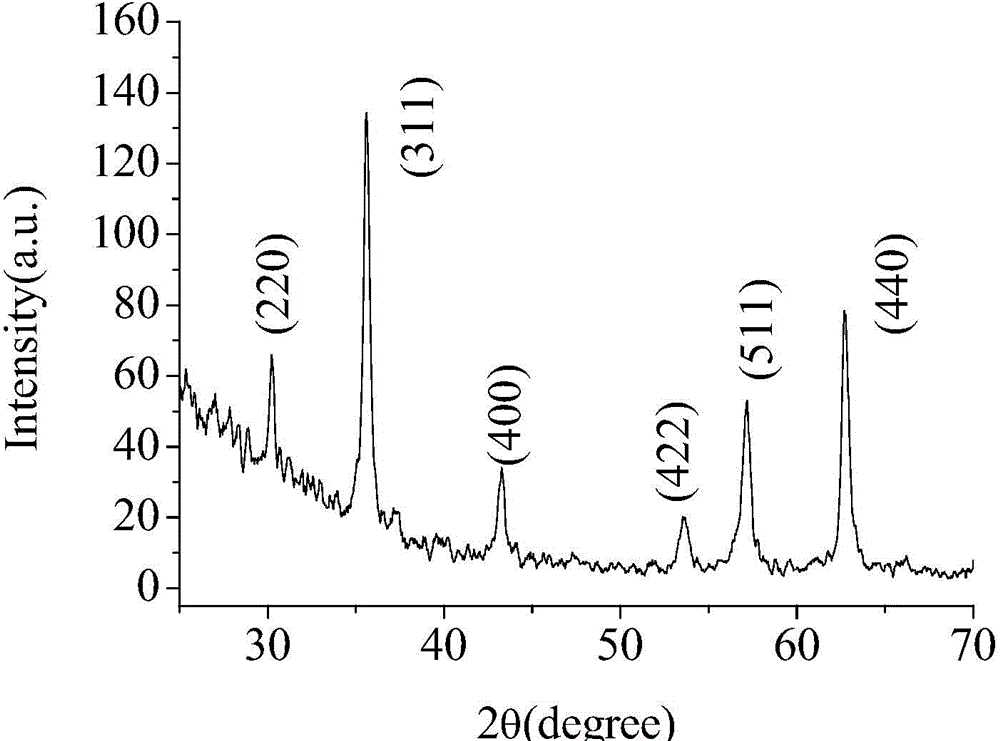

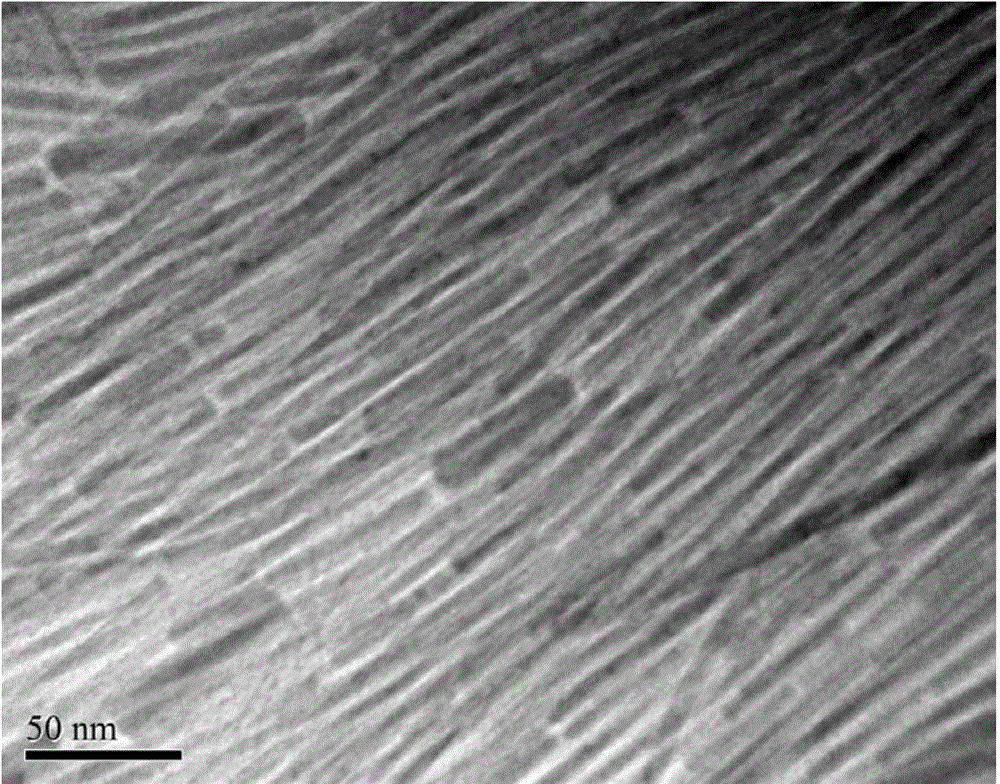

[0024] The preparation method of the iron oxide nanowire of the present embodiment comprises the following steps:

[0025] 1) Mix 300ml oleylamine with 25g ferric oleate to obtain a mixture;

[0026] 2) Under stirring conditions, heat the mixed solution obtained in step 1) to 150°C, keep it warm for 1 hour, remove the moisture contained in the system, then rapidly heat it to 210°C, and react at constant temperature for 12 hours to obtain the reaction product;

[0027] 3) Cool the reaction product to room temperature, add an equal volume of acetone, and centrifuge to obtain a black precipitate;

[0028] 4) The obtained black precipitate was vacuum-dried at 60° C. for 12 hours, and the obtained black powder was the iron oxide nanowire.

Embodiment 2

[0030] The preparation method of the iron oxide nanowire of the present embodiment comprises the following steps:

[0031] 1) Mix 300ml oleylamine with 25g ferric oleate to obtain a mixture;

[0032] 2) Under stirring conditions, heat the mixed solution obtained in step 1) to 150°C, keep it warm for 1 hour, remove the water contained in the system, then rapidly heat it to 220°C, and react at constant temperature for 10 hours to obtain the reaction product;

[0033] 3) Cool the reaction product to room temperature, add an equal volume of acetone, and centrifuge to obtain a black precipitate;

[0034] 4) The obtained black precipitate was vacuum-dried at 60° C. for 12 hours, and the obtained black powder was the iron oxide nanowire.

Embodiment 3

[0036] The preparation method of the iron oxide nanowire of the present embodiment comprises the following steps:

[0037] 1) Mix 300ml oleylamine with 25g ferric oleate to obtain a mixture;

[0038] 2) Under stirring conditions, heat the mixed solution obtained in step 1) to 150°C, keep it warm for 1 hour, remove the water contained in the system, then rapidly heat it to 230°C, and react at constant temperature for 8 hours to obtain the reaction product;

[0039] 3) Cool the reaction product to room temperature, add an equal volume of acetone, and centrifuge to obtain a black precipitate;

[0040] 4) The obtained black precipitate was vacuum-dried at 60° C. for 12 hours, and the obtained black powder was the iron oxide nanowire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com