Preparation method of iron oxide nanowire

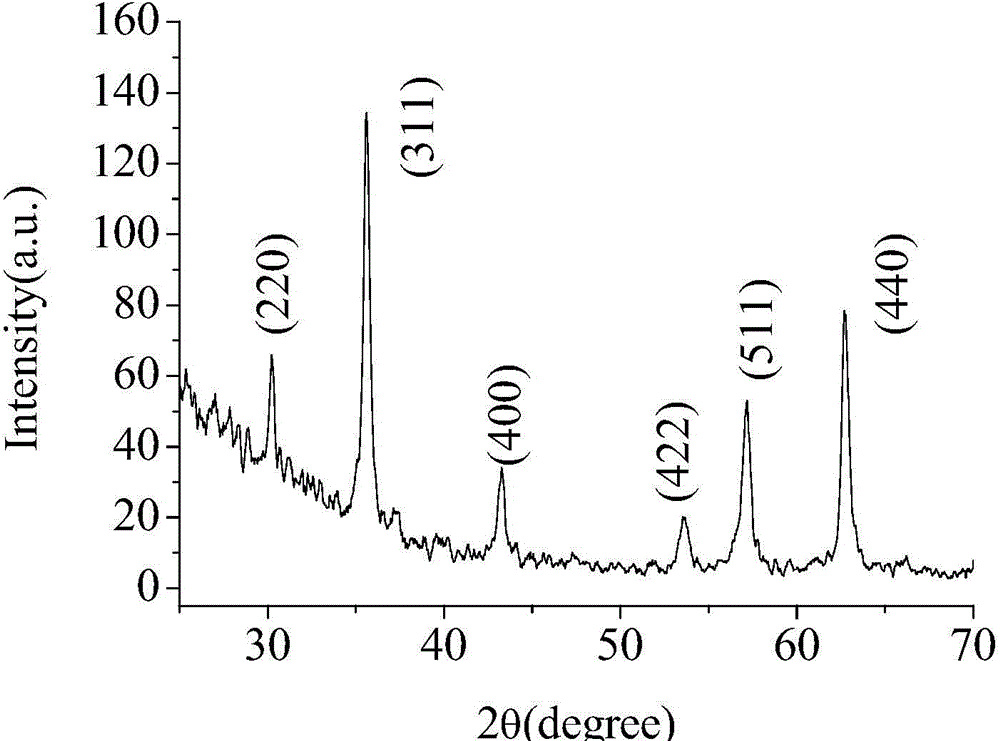

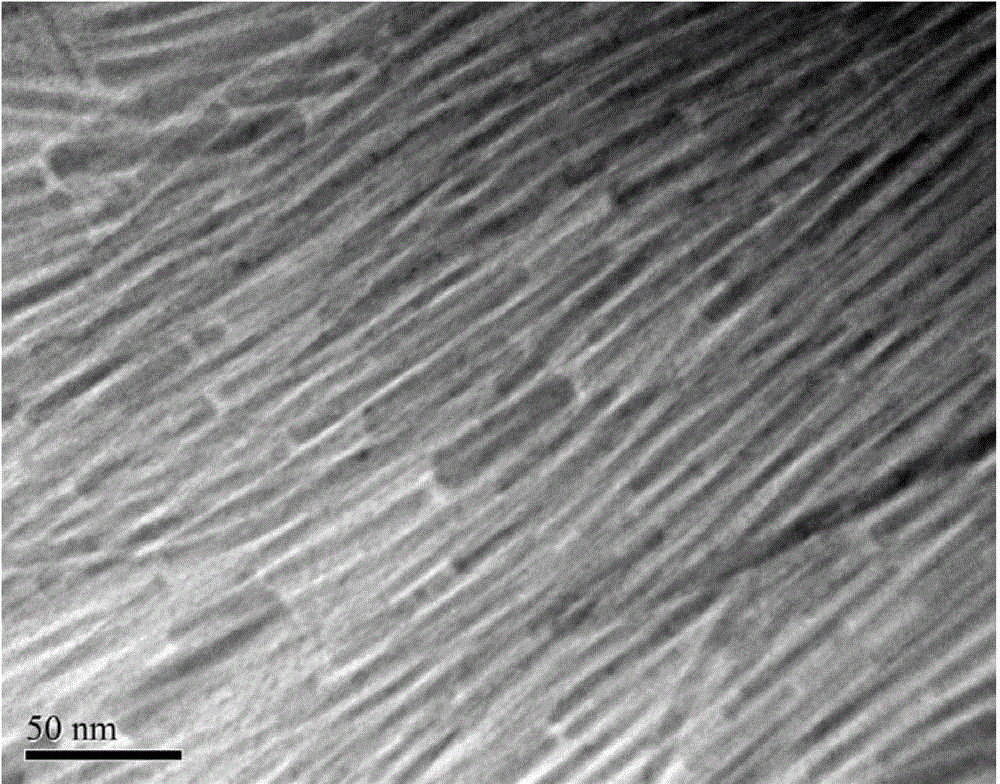

A technology of nano-iron oxide and iron carboxylate, which is applied in the field of nano-iron oxide, can solve the problems of difficulty in controlling the size of nano-materials and poor organic dispersion, and achieve the effects of good organic dispersion, low cost, and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the iron oxide nanowire of the present embodiment comprises the following steps:

[0025] 1) Mix 300ml oleylamine with 25g ferric oleate to obtain a mixture;

[0026] 2) Under stirring conditions, heat the mixed solution obtained in step 1) to 150°C, keep it warm for 1 hour, remove the moisture contained in the system, then rapidly heat it to 210°C, and react at constant temperature for 12 hours to obtain the reaction product;

[0027] 3) Cool the reaction product to room temperature, add an equal volume of acetone, and centrifuge to obtain a black precipitate;

[0028] 4) The obtained black precipitate was vacuum-dried at 60° C. for 12 hours, and the obtained black powder was the iron oxide nanowire.

Embodiment 2

[0030] The preparation method of the iron oxide nanowire of the present embodiment comprises the following steps:

[0031] 1) Mix 300ml oleylamine with 25g ferric oleate to obtain a mixture;

[0032] 2) Under stirring conditions, heat the mixed solution obtained in step 1) to 150°C, keep it warm for 1 hour, remove the water contained in the system, then rapidly heat it to 220°C, and react at constant temperature for 10 hours to obtain the reaction product;

[0033] 3) Cool the reaction product to room temperature, add an equal volume of acetone, and centrifuge to obtain a black precipitate;

[0034] 4) The obtained black precipitate was vacuum-dried at 60° C. for 12 hours, and the obtained black powder was the iron oxide nanowire.

Embodiment 3

[0036] The preparation method of the iron oxide nanowire of the present embodiment comprises the following steps:

[0037] 1) Mix 300ml oleylamine with 25g ferric oleate to obtain a mixture;

[0038] 2) Under stirring conditions, heat the mixed solution obtained in step 1) to 150°C, keep it warm for 1 hour, remove the water contained in the system, then rapidly heat it to 230°C, and react at constant temperature for 8 hours to obtain the reaction product;

[0039] 3) Cool the reaction product to room temperature, add an equal volume of acetone, and centrifuge to obtain a black precipitate;

[0040] 4) The obtained black precipitate was vacuum-dried at 60° C. for 12 hours, and the obtained black powder was the iron oxide nanowire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com