Preparation method of nano-capsule composite phase change material

An energy storage material and composite phase change technology, applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of poor thermal stability, existing environment, low heat transfer efficiency, etc., and achieve improved compactness and Mechanical strength, improve dispersion uniformity, and overcome the effect of low heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

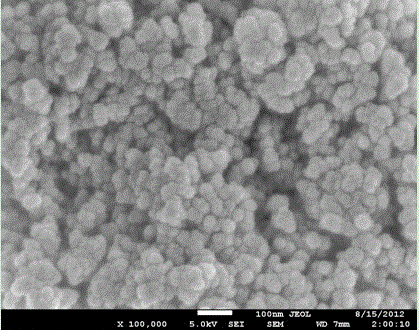

Image

Examples

Embodiment 1

[0027] First, add 0.1kg of compound emulsifier (mass ratio of sodium dodecylbenzenesulfonate to OP-10 is 0.4:0.7), 0.05kg of co-emulsifier diethylene glycol monobutyl ether into 2.5kg of distilled water, at 2000rpm Stirring at rotational speed for 10 minutes resulted in a clear aqueous solution. Then, 1 kg of n-heptadecane was added to the above clear solution, and stirred at 2000 rpm for 30 minutes in a water bath at 30° C. to form a uniform emulsion. 0.5 kg of tetraethyl orthosilicate and 0.02 kg of methylcellulose were sequentially added to the obtained emulsion, and stirred at 10000 rpm for 30 minutes. Add 0.5 kg of hydrochloric acid solution with a pH of about 2 slowly into the emulsion drop by drop to initiate hydrolysis polymerization reaction, react for 12 hours, stop stirring, cool the reaction product solution to room temperature, wash it several times with petroleum ether solution and distilled water, and filter it with suction , and dried to obtain a paraffin nano...

Embodiment 2

[0029] First, add 0.15kg of compound emulsifier (the mass ratio of sodium dodecylbenzenesulfonate to span-40 is 0.5:0.7), 0.03kg of co-emulsifier propylene glycol monobutyl ether into 2.5kg of distilled water, and stir at 2000rpm for 10 minutes , forming a clear aqueous solution. Then, 1.2 kg of n-octadecane was added to the above clear solution, and stirred at 2000 rpm for 30 minutes in a water bath at 40° C. to form a uniform emulsion. Add 1.0 kg of tetraethyl orthosilicate and 0.015 kg of hydrocarbon propyl-grade methyl cellulose in turn to the emulsion, and stir for 30 minutes at 10,000 rpm. Slowly drop 0.8kg of hydrochloric acid solution with a pH of about 2 into the emulsion drop by drop to initiate a hydrolysis polymerization reaction, react for 12 hours, stop stirring, cool the reaction product solution to room temperature, wash it several times with petroleum ether solution and distilled water, and filter it with suction , and dried to obtain the paraffin nanocapsule...

Embodiment 3

[0031]First, add 0.2kg of compound emulsifier (the mass ratio of sodium lauryl sulfate to OP-10 is 0.45:0.65), 0.05kg of co-emulsifier diethylene glycol monobutyl ether into 2.8kg of distilled water, and stir at 2000rpm for 10 minutes to form a clear aqueous solution. Then, 1 kg of n-nonadecane was added to the above clear solution, and stirred at 2000 rpm for 30 minutes in a 40° C. water bath to form a uniform emulsion. 0.5 kg of tetraethyl orthosilicate and 0.01 kg of ethyl cellulose were sequentially added to the obtained emulsion, and stirred at 10000 rpm for 30 minutes. Slowly drip 0.5kg of acetic acid solution with a pH of about 2 into the emulsion drop by drop to initiate a hydrolysis polymerization reaction. The reaction time is 12 hours, stop stirring, cool the reaction product solution to room temperature, and wash it several times with petroleum ether solution and distilled water repeatedly. After suction filtration and drying, the paraffin nanocapsule composite ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com