A preparation method of composite hydrophobic nano-powder coated liquid marbles

A hydrophobic nano, liquid marble technology, applied in the field of coating materials, can solve the problems of unfavorable collection and transfer of liquid marbles, low success rate, polluted air, etc., and achieves wide industrial use, smooth inner wall and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

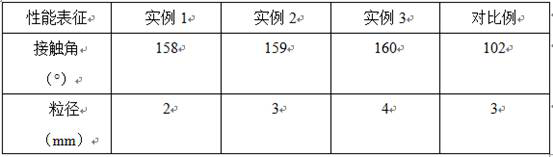

Examples

example 1

[0042] In parts by weight, weigh 15 parts of nano-zinc oxide powder with a particle size of 10nm, 8 parts of stearic acid, and 180 parts of absolute ethanol, dissolve the stearic acid and add it to absolute ethanol. Stir at a speed of 150r / min for 20~30min to obtain a stearic acid ethanol solution, add nano-zinc oxide powder to the stearic acid ethanol solution, and stir at a speed of 600r / min for 6 hours at room temperature to obtain a zinc oxide mixture, mix the zinc oxide The solution was placed in a centrifuge at a speed of 4500r / min for centrifugation, the lower layer of solid was removed, washed three times with deionized water, and dried at 60°C for 2 hours to obtain hydrophobic nano-zinc oxide powder, which were weighed in parts by weight. Measure 15 parts of nano-titanium dioxide powder with a particle size of 10nm, 8 parts of stearic acid, and 180 parts of absolute ethanol, dissolve the stearic acid and add it to the absolute ethanol, and stir for 20 minutes at a spee...

example 2

[0044]In parts by weight, weigh 17 parts of nano-zinc oxide powder with a particle size of 15nm, 9 parts of stearic acid, and 190 parts of absolute ethanol, dissolve the stearic acid and add it to absolute ethanol. Stir at a speed of 200r / min for 25min to obtain a stearic acid ethanol solution, add the nano-zinc oxide powder into the stearic acid ethanol solution, and stir at a speed of 700r / min for 7 hours at room temperature to obtain a zinc oxide mixed solution, place the zinc oxide mixed solution in Centrifuge and separate in a centrifuge at a speed of 4750r / min, remove the solid in the lower layer, wash with deionized water for 4 times, and dry at 70°C for 3 hours to obtain hydrophobic nano-zinc oxide powder, and then weigh 17 Particle diameter 15nm nano-titanium dioxide powder, 9 parts of stearic acid, 190 parts of dehydrated alcohol, stearic acid is dissolved and added in dehydrated alcohol, under normal temperature with 200r / min rotating speed stirring 25min, obtain ste...

example 3

[0046] In terms of parts by weight, weigh 20 parts of nano-zinc oxide powder with a particle size of 20nm, 10 parts of stearic acid, and 200 parts of absolute ethanol, dissolve stearic acid and add it to absolute ethanol. Stir at a speed of 250r / min for 30min to obtain a stearic acid ethanol solution, add the nanometer zinc oxide powder into the stearic acid ethanol solution, and stir at a speed of 800r / min for 8 hours at room temperature to obtain a zinc oxide mixture, place the zinc oxide mixture in Centrifuge and separate in a centrifuge at a speed of 5000r / min, remove the lower layer of solids, wash with deionized water for 5 times, and dry at 80°C for 4 hours to obtain hydrophobic nano-zinc oxide powder, and weigh 20 Particle diameter 20nm nano-titanium dioxide powder, 10 parts of stearic acid, 200 parts of dehydrated alcohol, stearic acid is dissolved and added in dehydrated alcohol, under normal temperature with 250r / min rotating speed stirring 30min, obtain stearic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com