Method for preparing nano-nickel composite with protection of organic single molecular layer

A monomolecular layer, nano-nickel technology, applied in the direction of coating, etc., can solve the problems of harsh conditions, low yield, single variety, etc., and achieve the effect of low cost, high yield and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take 0.6M 95% ethanol NiCl 2 Add 15ml of 0.6M dodecylmercaptan 95% ethanol solution to 15ml of the solution, stir evenly, heat up to 60°C for use;

[0018] Take 20ml of 2.5mol / L hydrazine hydrate, add it to the above solution, keep stirring for 1-4 hours, filter the reacted product, rinse the obtained solid with a large amount of ethanol and acetone, and then dry it in vacuum at 80°C.

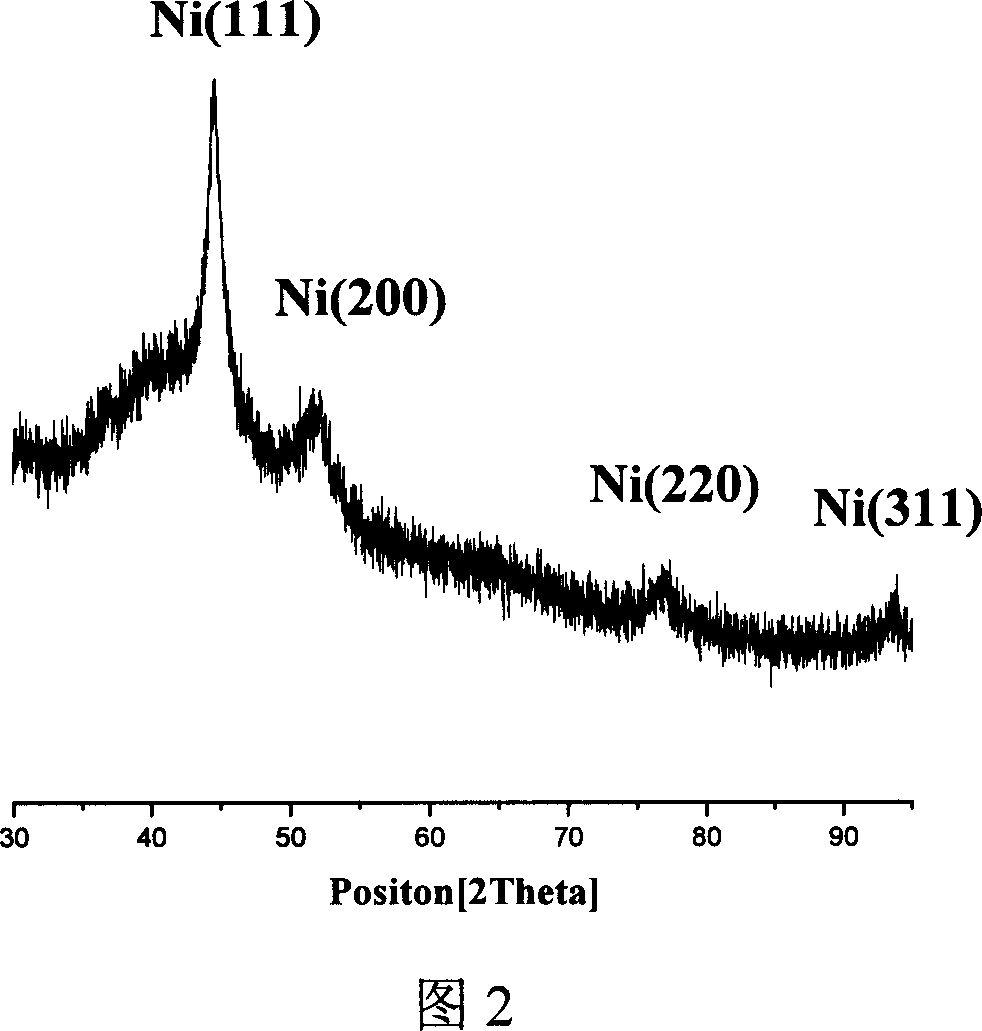

[0019] FIG. 1 is a transmission electron micrograph of the prepared organic monomolecular layer protected nano-copper composite. It can be seen that the prepared nanoparticles have a uniform particle size, no agglomeration, and a particle size of 4-7nm. Figure 2 is the XRD pattern of the prepared nanoparticles, from which it can be seen that the prepared organic monomolecular layer protective nanocomposite contains cubic nickel.

Embodiment 2

[0021] Take 0.6M 95% ethanol NiCl 2 Add 7ml of 0.6M 95% ethanol solution of hexanethiol to 15ml of the solution, stir evenly, heat up to 60°C for use;

[0022] Take 10ml of 2.5mol / L hydrazine hydrate, add it to the above solution, keep stirring and react for 1-4 hours, filter the reacted product, rinse the obtained solid with a large amount of ethanol and acetone, and then dry it in vacuum at 80°C.

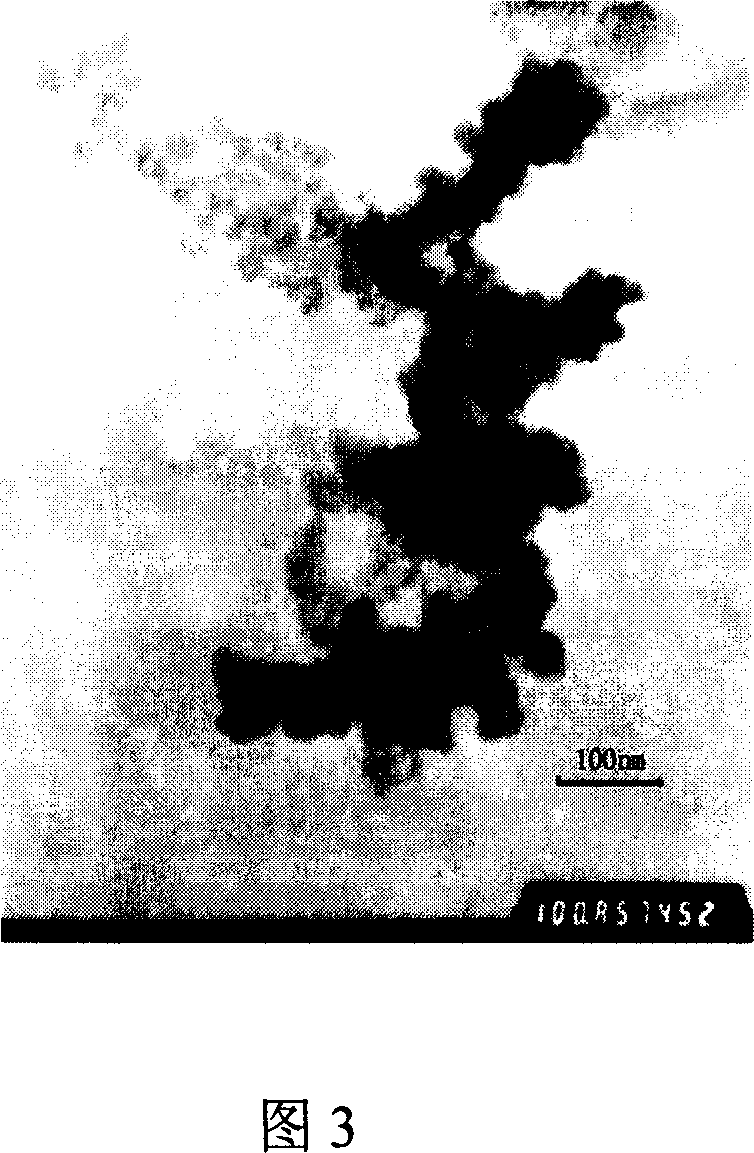

[0023] Fig. 3 is a transmission electron micrograph of the prepared organic monomolecular layer protected nano-nickel composite. It can be seen that the prepared nanoparticles have a uniform particle size, basically no agglomeration, and a particle size of 25nm.

Embodiment 3

[0025] Take 0.3M 95% ethanol NiCl 2 Add 30ml of 1M stearyl mercaptan solution in 95% ethanol to 30ml of the solution, stir evenly, heat up to 60°C for use;

[0026] Take 10ml of 2.5mol / L hydrazine hydrate, add it to the above solution, keep stirring and react for 1-4 hours, filter the reacted product, rinse the obtained solid with a large amount of ethanol and acetone, and then dry it in vacuum at 80°C.

[0027] Fig. 4 is an XRD pattern of the prepared organic monomolecular layer protected nano-nickel composite nano, which shows that the prepared organic monomolecular layer protected nano-composite contains cubic nickel.

[0028] Note: 95% ethanol in embodiment 1-3 refers to weight percent content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com