Method for preparing nano-copper

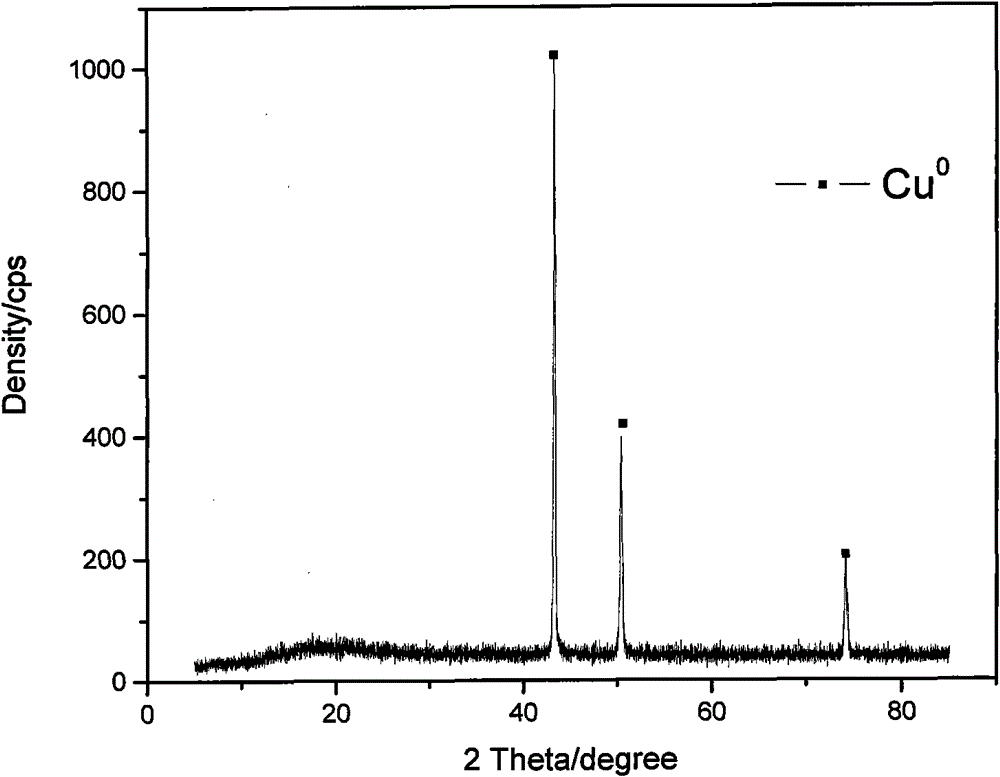

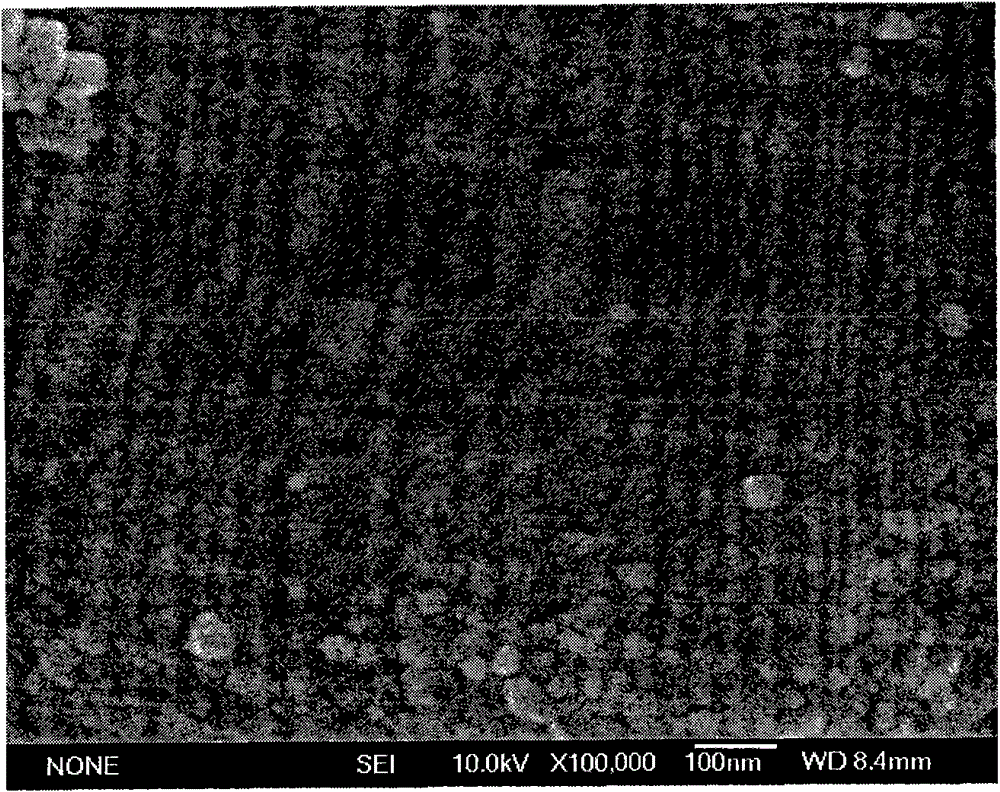

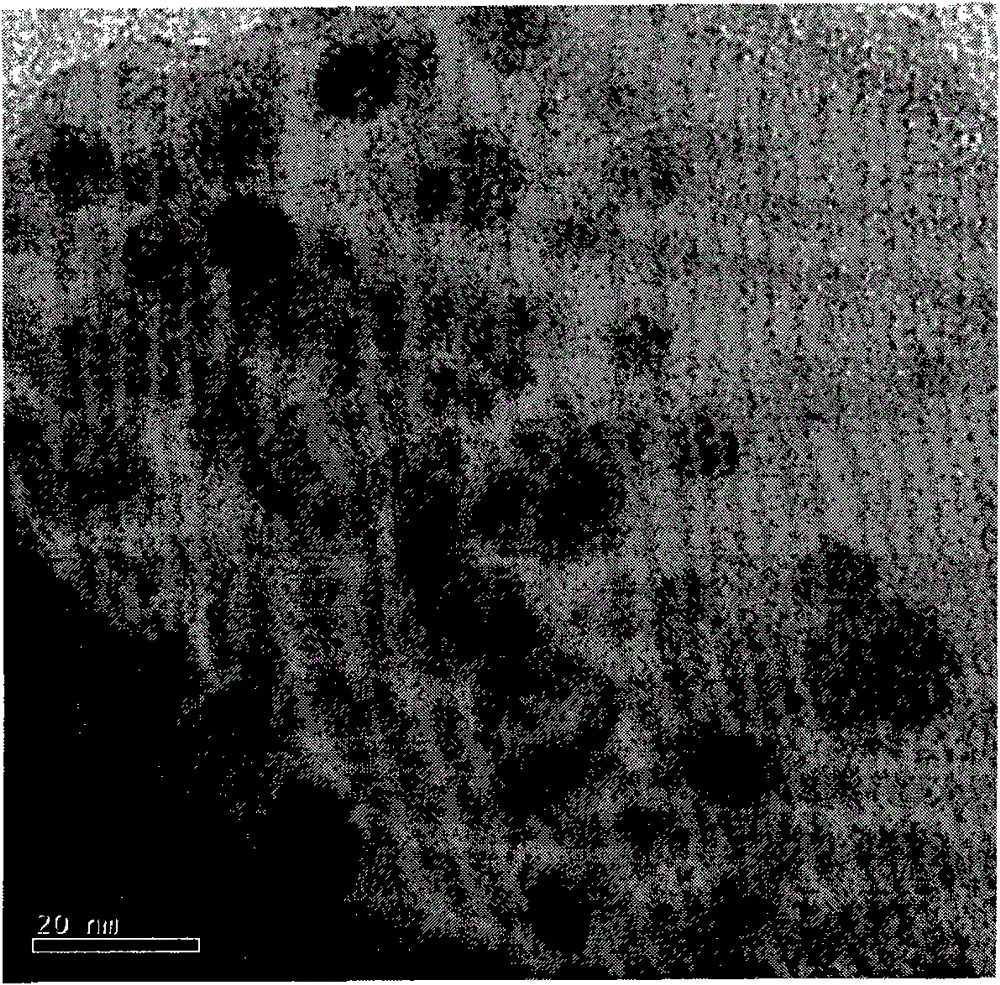

A technology of nano-copper and copper salt, which is applied in the field of preparation of copper powder with a particle size of less than 50 nm, can solve the problems of difficulty in large-scale production, high cost and toxicity of nano-copper, and achieves wide industrial use, high yield and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The precursor is copper salt to prepare nano-copper, proceed as follows:

[0022] (1) 0.01mol of copper nitrate (commercially available, analytically pure, molecular formula Cu(NO 3 ) 2 ·3H 2 0), grind to below 100 mesh, add in 150ml liquid paraffin while stirring, add 20ml span-80, stir 1h;

[0023] (2) After the copper nitrate is uniformly dispersed in the mixed solution and becomes a blue-green transparent emulsion, pour it into a 500ml three-necked flask, and pass N 2 , continue to stir, slowly raise the temperature to 300°C, and keep for 3h;

[0024] (3) centrifuging the product obtained in (2), discarding the upper layer oil, leaving the precipitate;

[0025] (4) Wash the precipitate obtained in (3) 4 times with petroleum ether, and centrifuge to leave the precipitate;

[0026] (5) The precipitate obtained in (4) was washed alternately with distilled water and absolute ethanol three times each, and centrifuged;

[0027] (6) naturally drying the precipitate o...

Embodiment 2

[0029] The preparation of nanometer copper is carried out according to the following steps:

[0030] (1) 0.01mol of copper hydroxide (commercially available, analytically pure, molecular formula Cu(OH) 2 ), grind to below 100 mesh, add 150ml liquid paraffin while stirring, add 20ml span-80, stir for 1h;

[0031] (2) After the copper nitrate is uniformly dispersed in the mixed solution and becomes a blue-green transparent emulsion, pour it into a 500ml three-necked flask, and pass N 2 , continue to stir, slowly raise the temperature to 300°C, and keep for 3h;

[0032] (3) centrifuging the product obtained in (2), discarding the upper layer oil, leaving the precipitate;

[0033] (4) Wash the precipitate obtained in (3) 4 times with petroleum ether, and centrifuge to leave the precipitate;

[0034] (5) The precipitate obtained in (4) was washed alternately with distilled water and absolute ethanol three times each, and centrifuged;

[0035] (6) naturally drying the precipitat...

Embodiment 3

[0037] The precursor is copper salt solution to prepare nano-copper, proceed as follows:

[0038] (1) 0.01mol of copper nitrate (commercially available, analytically pure, molecular formula Cu(NO 3 ) 2 ·3H 2 O), dissolved in 20ml of dehydrated ethanol containing 1.0g of PVA, added Tween 85 while stirring, added in 150ml of liquid paraffin, added 20mlspan-80, stirred for 1h;

[0039] (2) After the copper nitrate is uniformly dispersed in the mixed solution and becomes a blue-green transparent emulsion, pour it into a 500ml three-necked flask, and pass N 2 , continue to stir, slowly raise the temperature to 300°C, and keep for 3h;

[0040] (3) centrifuging the product obtained in (2), discarding the upper layer oil, leaving the precipitate;

[0041] (4) Wash the precipitate obtained in (3) 4 times with petroleum ether, and centrifuge to leave the precipitate;

[0042] (5) The precipitate obtained in (4) was washed alternately with distilled water and absolute ethanol three ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com