Preparation method of ionic conductive polyurethane

A polyurethane, ionic technology, applied in the field of preparation of conductive polyurethane, can solve the problems of complicated preparation process, poor solubility, poor film-forming performance, etc., and achieve the effects of simple equipment process, good conductivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

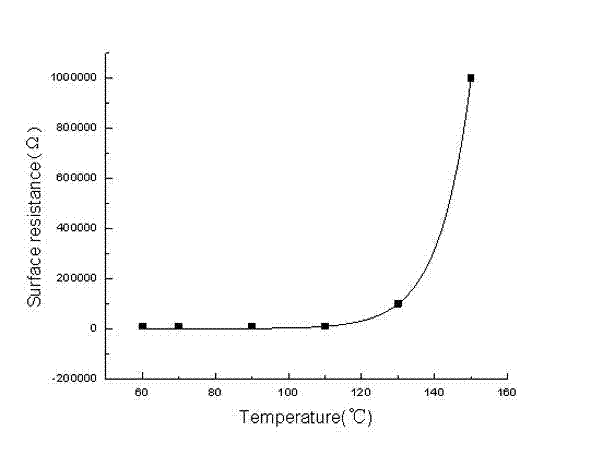

Examples

Embodiment 1

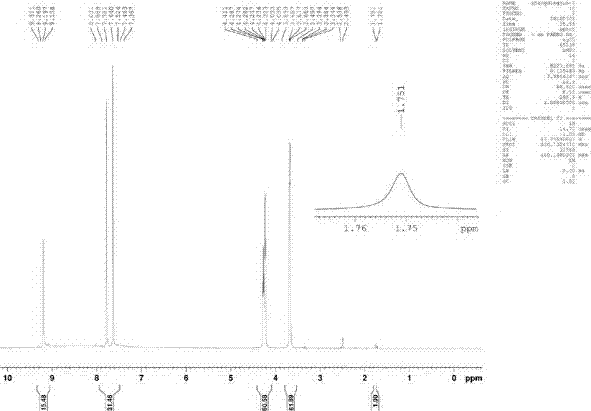

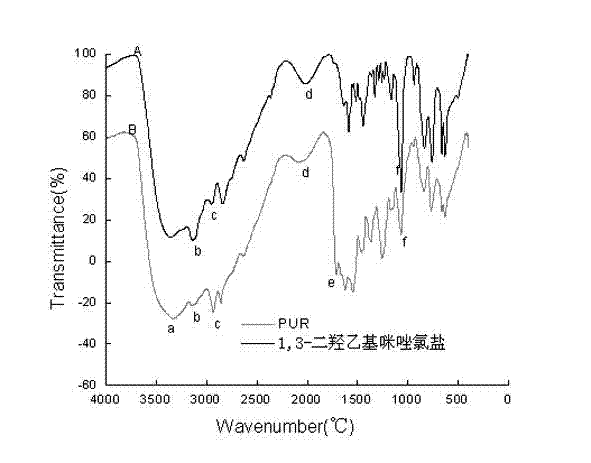

[0013] (1) Dissolve 0.05 mol of imidazole in 50 ml of acetonitrile, stir until it is completely dissolved and then heat up to 50°C, then add 50 ml of acetonitrile solution containing 0.11 mol of chloroethanol with a dropping funnel, and heat up to 80°C after the addition is complete. Reflux at ~81°C for 24 hours;

[0014] When the reaction is over, cool to room temperature, use a rotary evaporator to distill off acetonitrile under reduced pressure, wash with ethyl acetate three times to remove unreacted chloroethanol, and then dry in vacuum at 80°C for 5 hours to obtain yellow 1,3 -Dihydroxyethylimidazolium chloride salt ionic liquid, standby.

[0015] (2) After dissolving 0.02 mol of toluene diisocyanate (TDI) in 100 ml of N,N-dimethylformamide (DMFA), add a slight excess of 0.021 mol of 1,3-dihydroxyethylimidazolium chloride, and heat up Reaction at a constant temperature of 90~95°C for 12 hours;

[0016] After the reaction, cool to room temperature, pour the reaction mixt...

Embodiment 2

[0018] (1) Dissolve 0.05 mol of imidazole in 50 ml of acetonitrile, stir until it is completely dissolved and then heat up to 50°C, add 50 ml of acetonitrile solution containing 0.13 mol of chloroethanol with a dropping funnel, and heat up to 80°C after the dropwise addition Reflux at ~81°C for 24 hours;

[0019] When the reaction is over, cool to room temperature, use a rotary evaporator to distill off acetonitrile under reduced pressure, wash with ethyl acetate three times to remove unreacted chloroethanol, and then dry in vacuum at 80°C for 5 hours to obtain yellow 1,3 -Dihydroxyethylimidazolium chloride salt ionic liquid, standby.

[0020] (2) After dissolving 0.02 mol of toluene diisocyanate (TDI) in 100 ml of N,N-dimethylformamide (DMFA), add a slight excess of 0.025 mol of 1,3-dihydroxyethylimidazolium chloride, and heat up Reaction at a constant temperature of 90~95°C for 12 hours;

[0021] After the reaction, cool to room temperature, pour the reaction mixture solut...

Embodiment 3

[0023] (1) Take 0.05 mol of imidazole and dissolve it in 50 ml of acetonitrile, stir until it is completely dissolved and heat up to 50°C, add 50 ml of acetonitrile solution containing 0.15 mol of chloroethanol with a dropping funnel, and heat up to 80°C after the dropwise addition Reflux at ~81°C for 24 hours;

[0024] When the reaction is over, cool to room temperature, distill off the solvent acetonitrile with a rotary evaporator under reduced pressure, wash with ethyl acetate three times to remove unreacted chloroethanol, and then vacuum dry at 80°C for 5 hours to obtain yellow 1,3 -Dihydroxyethylimidazolium chloride salt ionic liquid, for subsequent use.

[0025] (2) After dissolving 0.02 mol of toluene diisocyanate (TDI) in 100 ml of N,N-dimethylformamide (DMFA), add a slight excess of 0.03 mol of 1,3-dihydroxyethylimidazolium chloride, and heat up Reaction at a constant temperature of 90~95°C for 12 hours;

[0026] After the reaction, cool down to room temperature, po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com