Reforming hydrogen production reactor of micro-bump structure with annular array

An annular array, reforming hydrogen production technology, applied in the fields of hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low uniformity of flow velocity distribution, high distribution non-uniformity, etc., to improve heat and mass transfer performance , compact structure, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

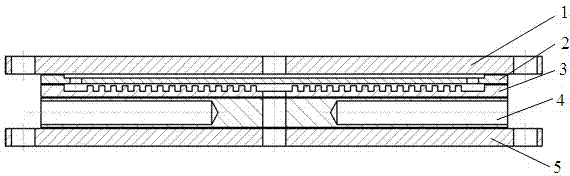

[0029] Such as figure 1 As shown, the present invention consists of an inlet cover 1 , an evaporation unit 2 , a reaction carrier unit 3 , a heating unit 4 and an outlet cover 5 coaxially superimposed sequentially from top to bottom.

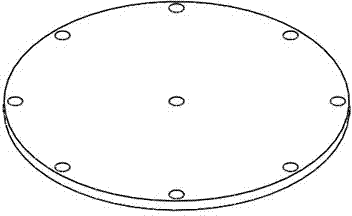

[0030] Such as figure 2 As shown, the inlet cover plate 1 is a circular plate, the inlet cover plate 1 is equidistantly distributed with through bolt positioning holes on the same circumference, and the center of the inlet cover plate 1 has a through fluid inlet hole.

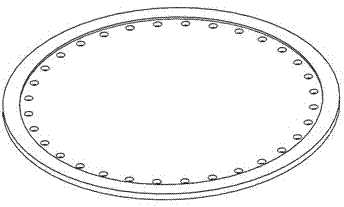

[0031] Such as Figure 6 As shown, the outlet cover plate 5 is a circular plate, and the outlet cover plate 5 is equidistantly distributed with through bolt positioning holes on the same circumference, and the center of the outlet cover plate 5 has a through fluid outlet hole, the inlet cover plate 1 and the outlet cover plate ( 5) The positions of all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com