Alkali-metal-based nano fluid CO2 absorption solution

A nanofluid and absorption liquid technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of low reactivity of alkali metal-based solid absorbents, difficulty in cyclic transport of solid absorbents, heat and mass transfer Poor performance and other problems, to achieve the effect of convenient circulation transportation, enhanced gas-liquid heat and mass transfer effect, and not easy to degrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

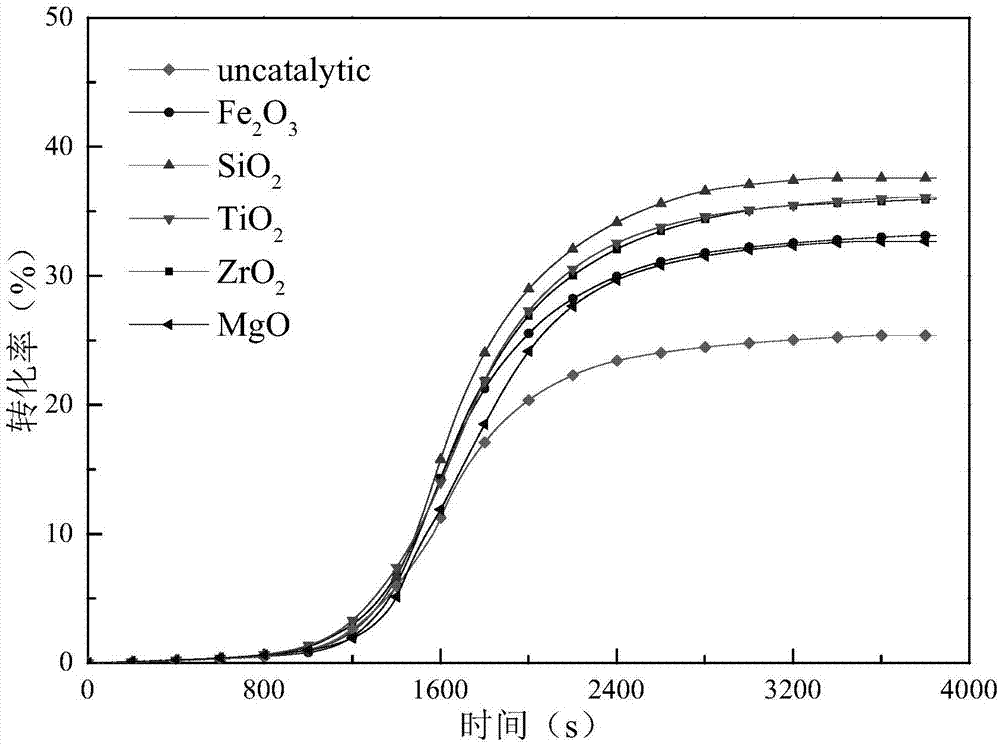

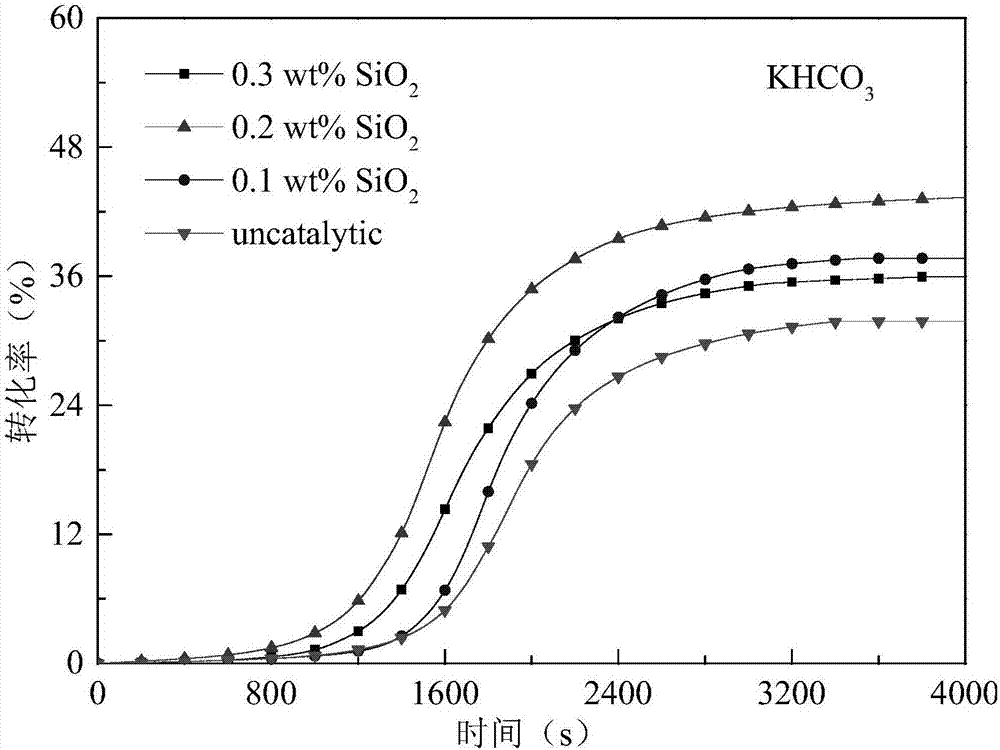

[0026] Weigh 200g of potassium carbonate and dissolve it in 798.5ml of deionized water, stir for 1h at room temperature with a magnetic stirrer; measure 1g of nano-SiO 2 Powder and 0.5g hydroxyethyl cellulose are poured into the prepared solution and stirred evenly with a magnetic stirrer; the prepared solution is put into an ultrasonic breaker with 10 seconds as an oscillation cycle (5 seconds to run, 5 seconds to cool) Ultrasonic oscillation for 30 minutes to obtain the alkali metal-based nanofluid CO 2 Absorb fluid.

[0027] The decarburization-regeneration capability test was carried out on the above-mentioned prepared absorption liquid, the prepared absorption liquid was injected into the pressure vessel, and CO 2 Gas, raise the temperature of the reactor from room temperature to the decarburization temperature of 40°C, then keep it constant, and use a flue gas analyzer to detect CO in the outlet gas 2 Change the concentration until its concentration is basically consta...

Embodiment 2

[0029] Weigh 200g of potassium carbonate and dissolve it in 798.5ml of deionized water. Stir for 1 hour at room temperature using a magnetic stirrer; measure 1g of nano-Fe 2 o 3 Pour the granules and 0.5g hydroxyethyl cellulose into the prepared solution and stir evenly with a magnetic stirrer; put the prepared solution into an ultrasonic breaker with 10 seconds as an oscillation cycle (5 seconds to run, 5 seconds to cool) Ultrasonic oscillation for 30 minutes to obtain the alkali metal-based nanofluid CO 2 Absorb fluid.

[0030] Inject the prepared absorption solution into the pressure vessel and pass through CO 2 Gas, raise the temperature of the reactor from room temperature to the decarburization temperature of 40°C, then keep it constant, and use a flue gas analyzer to detect CO in the outlet gas 2Change the concentration until its concentration is basically constant; switch the gas to Ar gas, raise the temperature of the reactor to the set final decomposition temperat...

Embodiment 3

[0032] Weigh 200g of potassium carbonate and dissolve it in 798.5ml of deionized water. Stir with a magnetic stirrer for 1h at room temperature; measure 1g of nano-TiO 2 Granules and 0.5g sodium lauryl sulfate are poured into the prepared solution and stirred evenly using a magnetic stirrer; ) ultrasonic oscillation for 30 minutes to obtain the alkali metal-based nanofluid CO used 2 Absorb fluid.

[0033] Inject the prepared absorption solution into the pressure vessel and pass through CO 2 Gas, raise the temperature of the reactor from room temperature to the decarburization temperature of 40°C, then keep it constant, and use a flue gas analyzer to detect CO in the outlet gas 2 Change the concentration until its concentration is basically constant; switch the gas to Ar gas, raise the temperature of the reactor to the set final decomposition temperature of 85°C, then keep it constant, and use a flue gas analyzer to detect CO in the outlet gas 2 Change the concentration unti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com