Method and apparatus for atomizing, freezing and drying for powder production by using low-temperature low-dew point gas

A technology of spray freeze drying and low dew point, which is applied in the direction of drying solid materials, heating to dry solid materials, and non-heating to dry solid materials, etc., to achieve the effect of shortening drying time and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

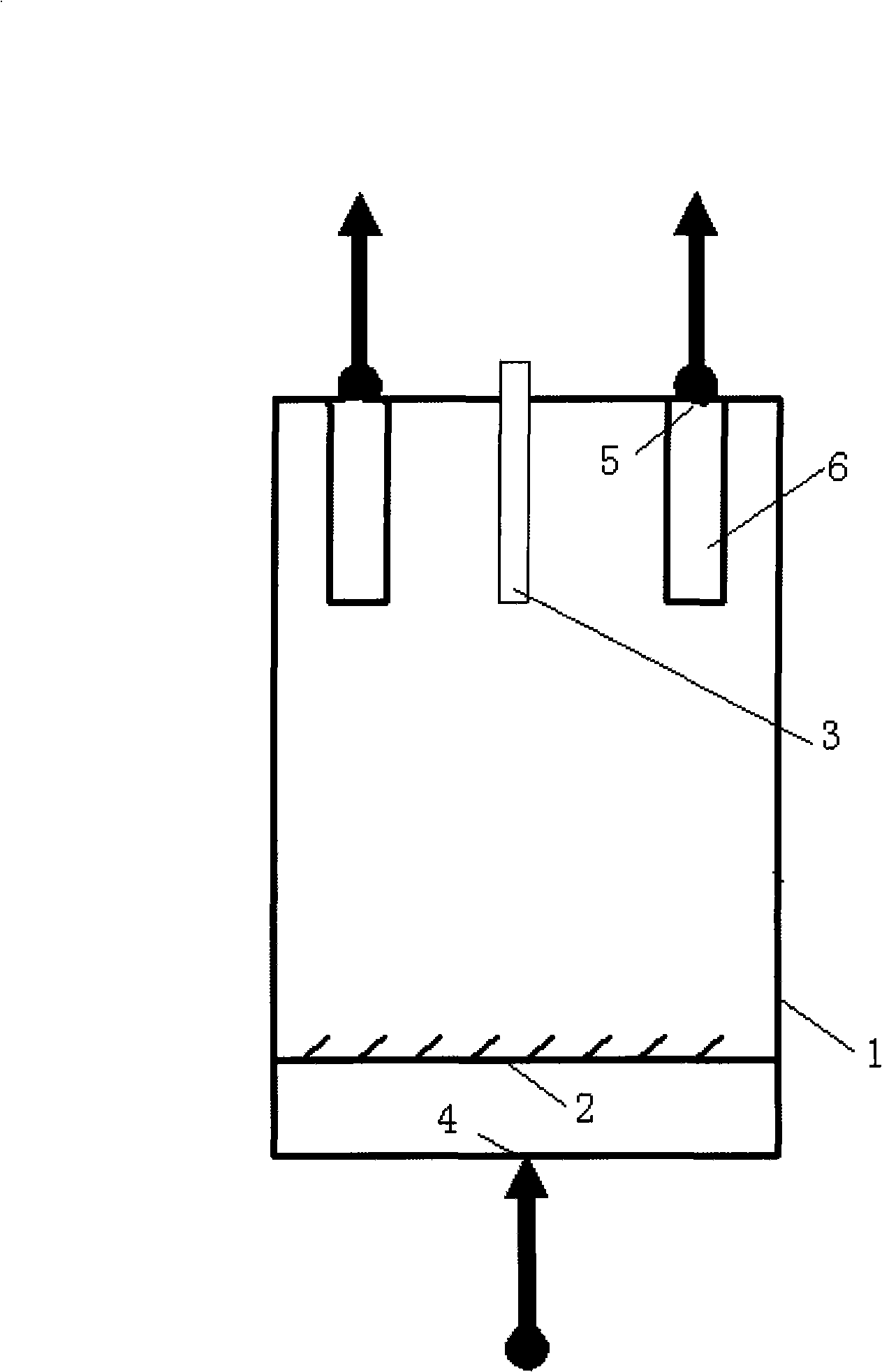

Image

Examples

Embodiment 1

[0027]A spray freezing powder making and combined drying device for milk powder drying, 750g of skimmed milk powder suspension with a solid content of 30%, is atomized to 1-120 microns in a container with a fluidized bed by a two-fluid atomizer At the same time, the mist droplets are in contact with the low-temperature and low-humidity gas with a temperature of -65°C and a dew point of -70°C, and are rapidly cooled into ice milk powder. After 30 minutes, the powder making process is completed and enters the sublimation drying stage. The dehumidified gas at -20°C is used Fluidize the ice milk powder for 480 minutes, start the gas temperature to 0°C, run for 30 minutes, then raise the temperature to 30°C, continue to patrol for 45 minutes, end the whole drying process, take out the dried milk powder, the particle size is 1-120 microns, the residual water content 5.2%, the protein content is basically the same as the original.

Embodiment 2

[0029] A method for preparing cherry powder with spray freeze combined drying, the solid content is 10% 800g cherry liquid is atomized into fine droplets with a two-fluid atomizer, and the pressure of the compressed air used for atomization is 0.35MPa. It is frozen into cherry ice powder in the low-temperature air at -70°C. After 50 minutes, the ice powder is completed. Then the drying temperature is -28°C, and it runs for 500 minutes. Then it starts to heat up and dry. Now it is dried at -10°C for 30 minutes, and then dried at 5°C. 60 minutes, and finally dried at 35° C. for 45 minutes to end the whole process. The moisture content of the obtained cherry powder is 6.5%, and the particle size is 2-220 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com