Exchanging interface device of automatization tool

A technology of automated tools and interface devices, applied in workpiece clamping devices, positioning devices, manufacturing tools, etc., can solve problems such as increased cost and large system design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

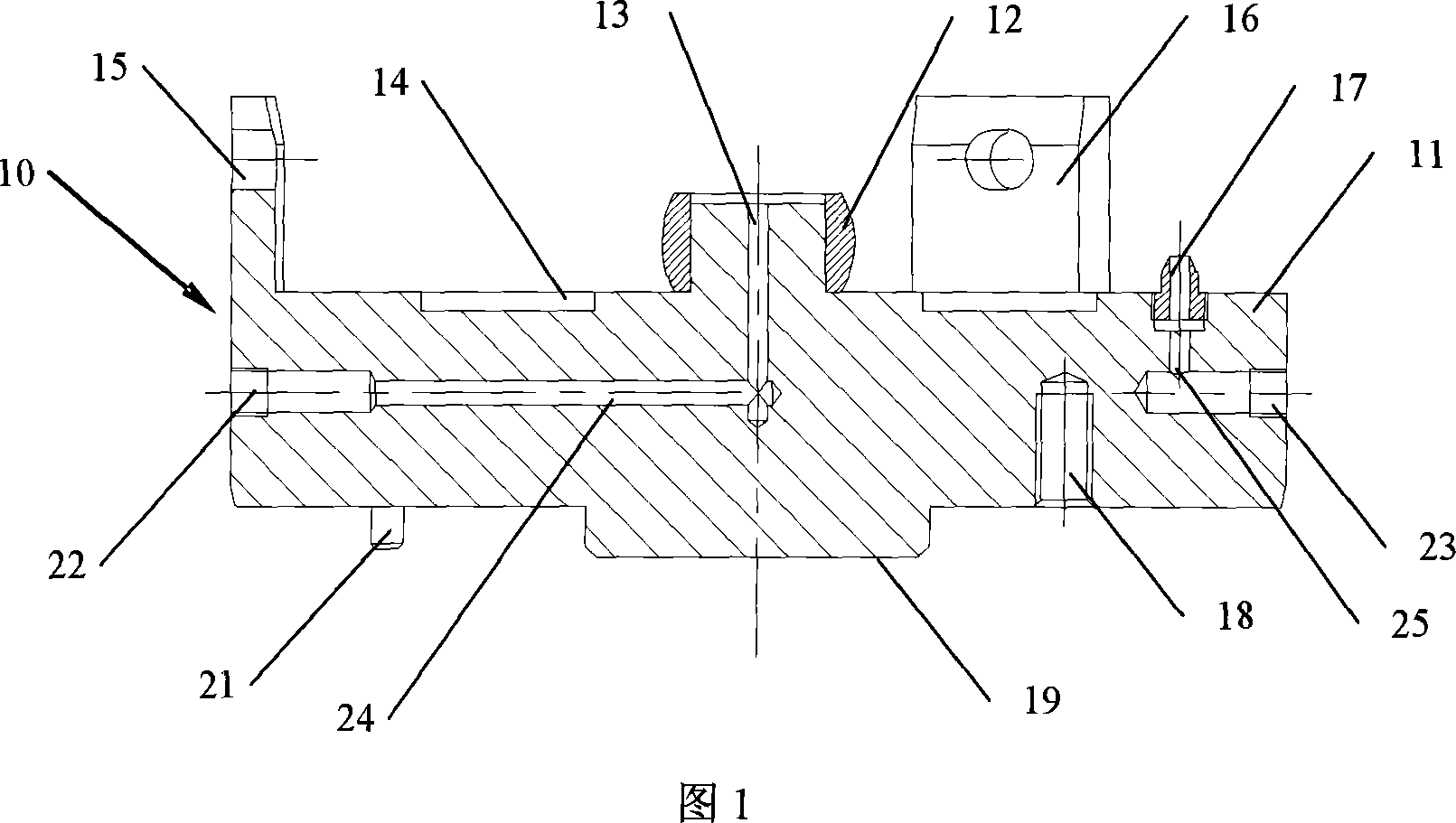

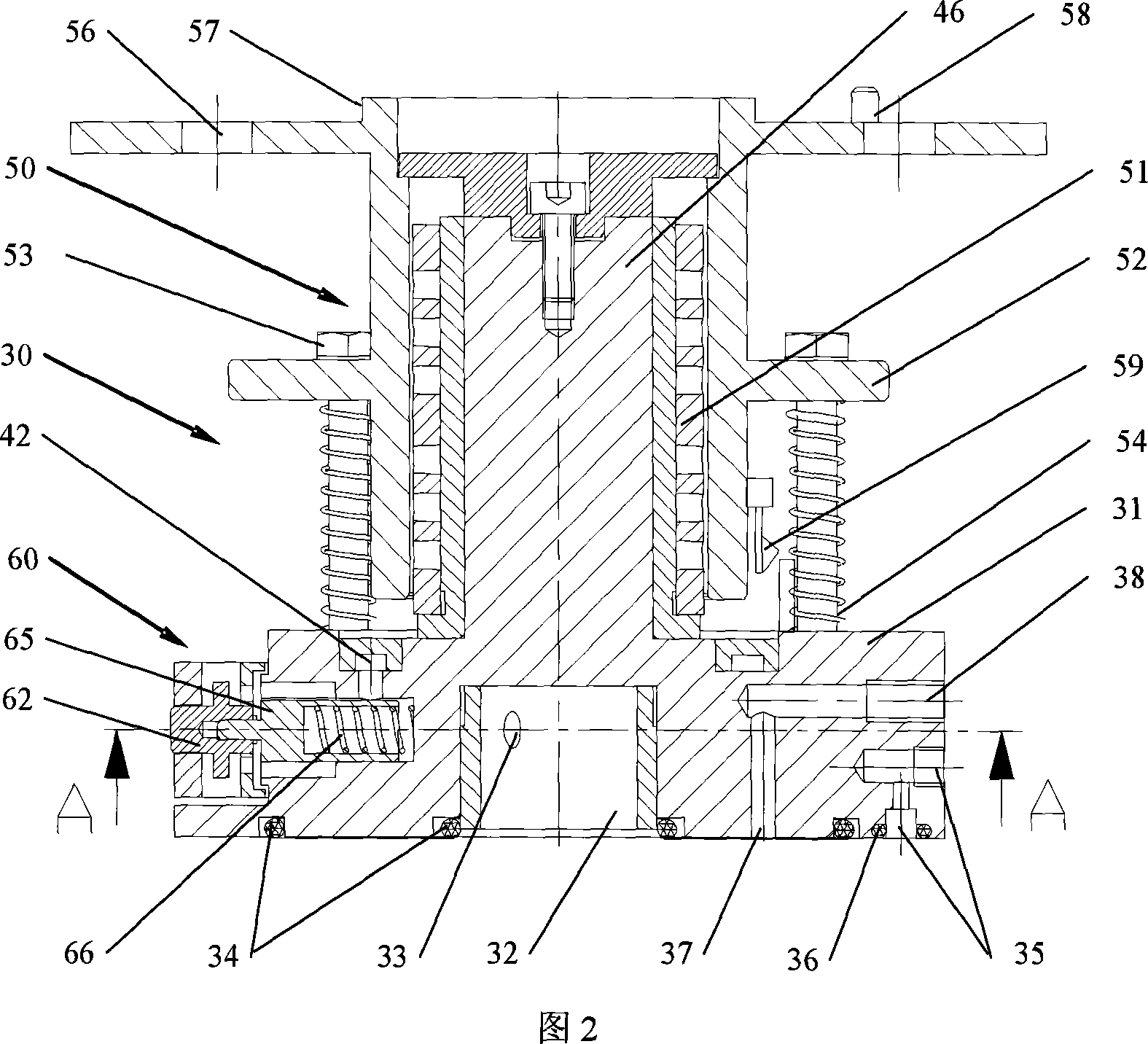

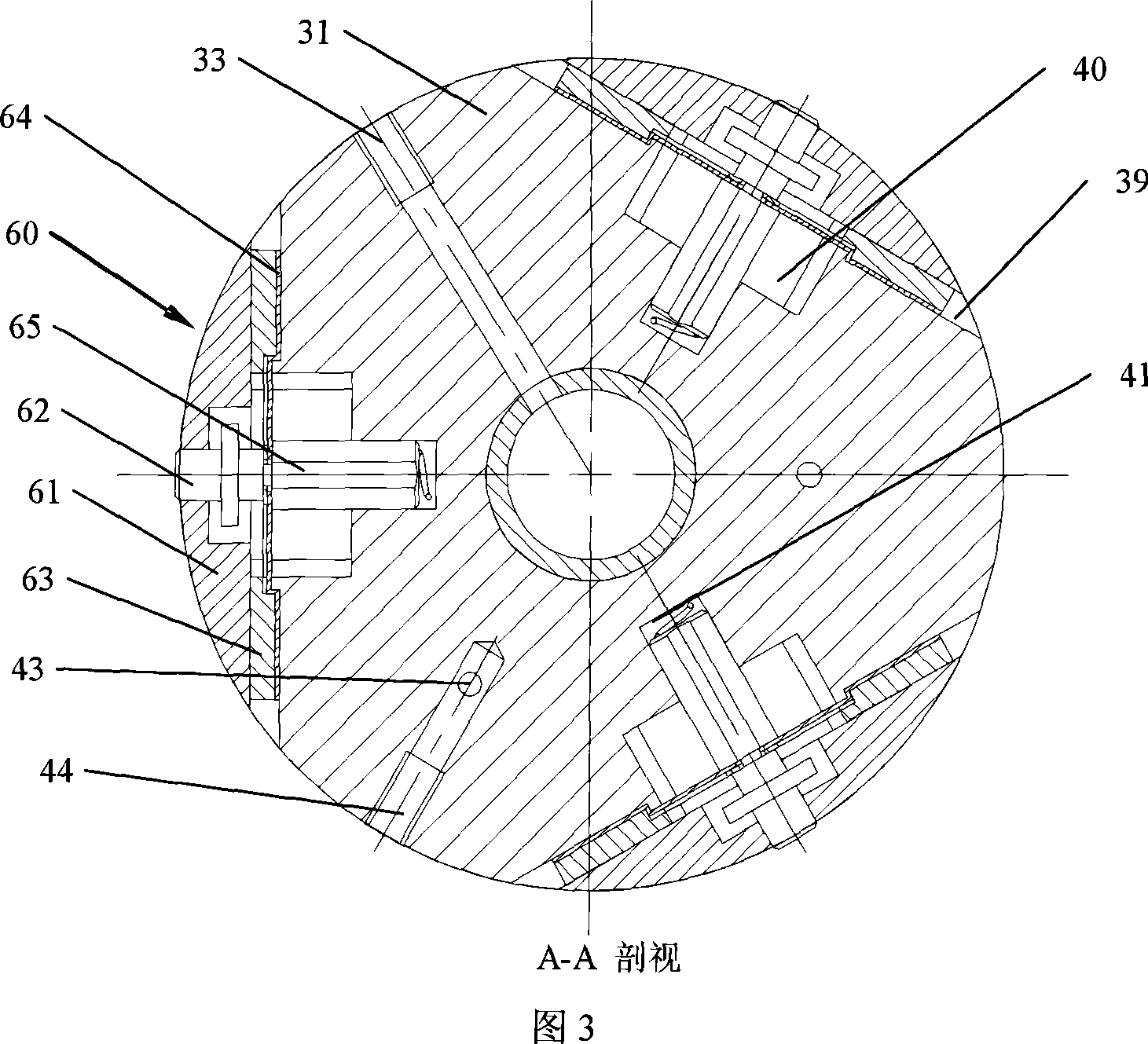

[0016] Referring to the accompanying drawings, an automatic tool exchange interface device includes a tool end device 10 and a fixed end device 30;

[0017] The tool end device 10 includes: a disc-shaped tool end body 11, a spherical centering pin 12 is arranged at the center of its upper end surface, and an air hole 13 is provided at the top of the spherical centering pin 12. The disc-shaped tool end body 11 There is an annular vacuum groove 14 on the top end surface, and there are three lugs 16 with pin holes 15 at intervals of 120° on the top edge, and a conical gas path interface pin 17 is installed at a fixed angle distance from the lug 16 in the circumferential direction. On the lower surface of the tool end body 11, there are tool mounting threaded holes 18, positioning cylindrical bosses 19 and directional pins 21 as interfaces for installation with the operating tool; Gas ports 22 and 23 communicate with the gas hole 13 and the conical gas path interface pin 17 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com