Packaging method for granular substance and device for packaging granular substance

A packaging method and technology for granular materials, which are applied in the types of packaging items, special packaging items, packaging and other directions to achieve the effect of preventing foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] Example 1 relates to the granular material packaging device of the present invention and the granular material packaging method of the present invention. In addition, Example 1 relates to the injection molding method of the thermoplastic resin, and also relates to the first mode of the injection molding machine. In addition, in the following description, the term "particulate" used for "raw material thermoplastic resin pellets" may be replaced and described.

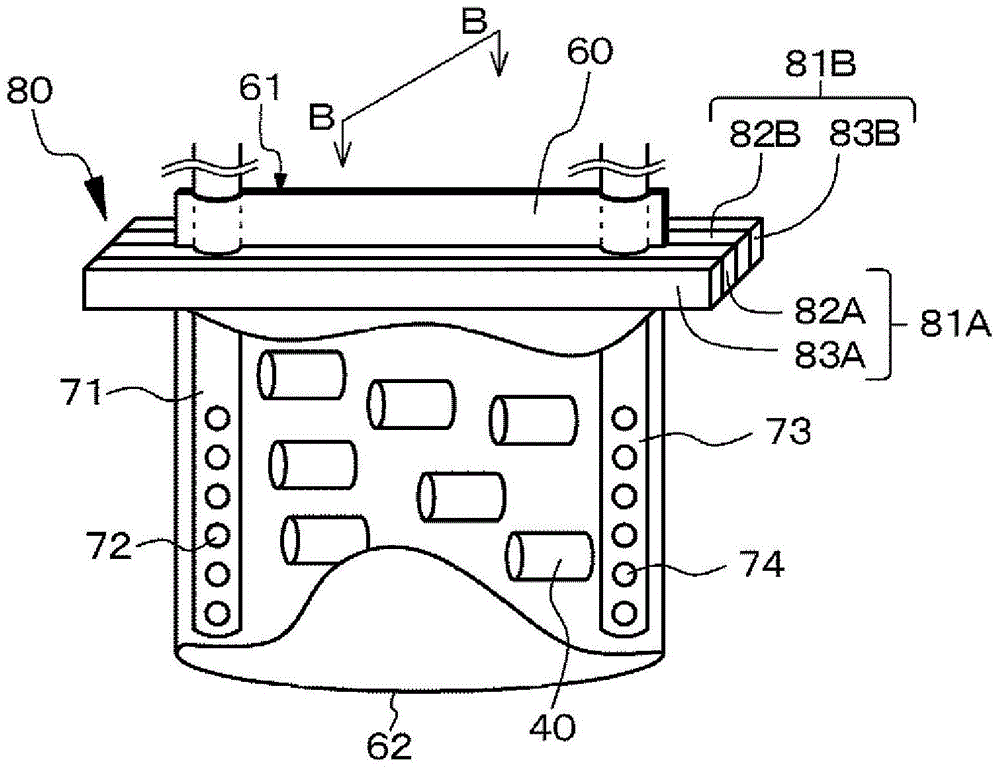

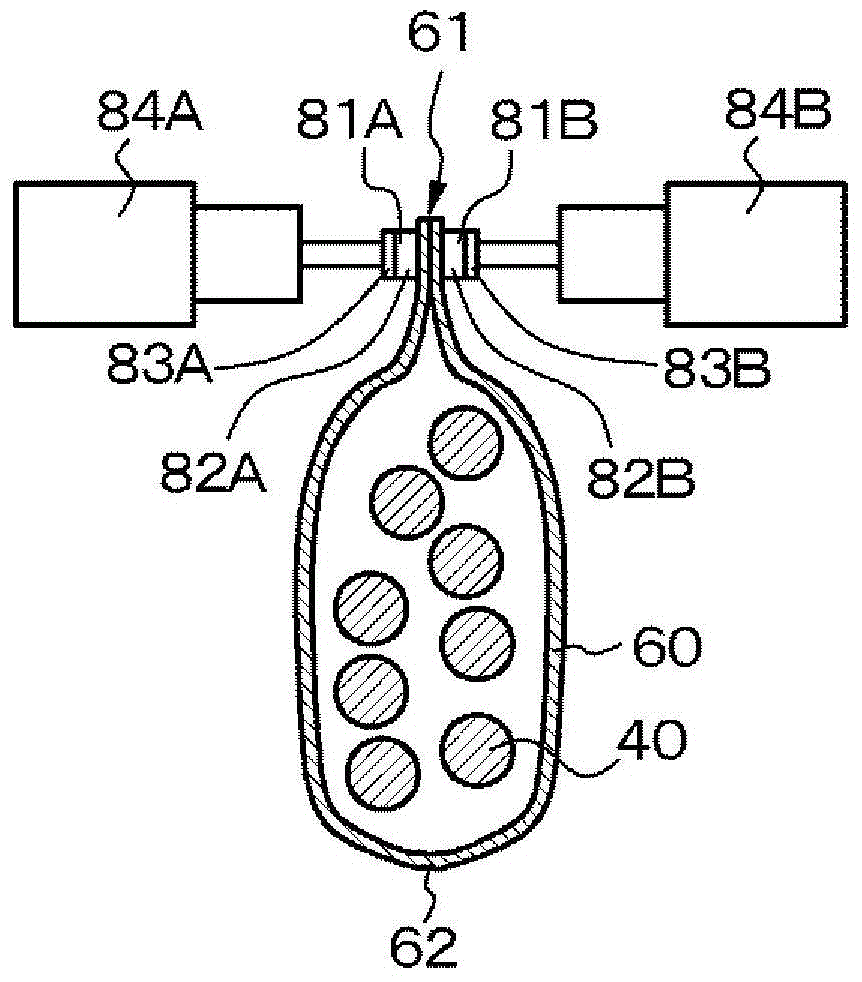

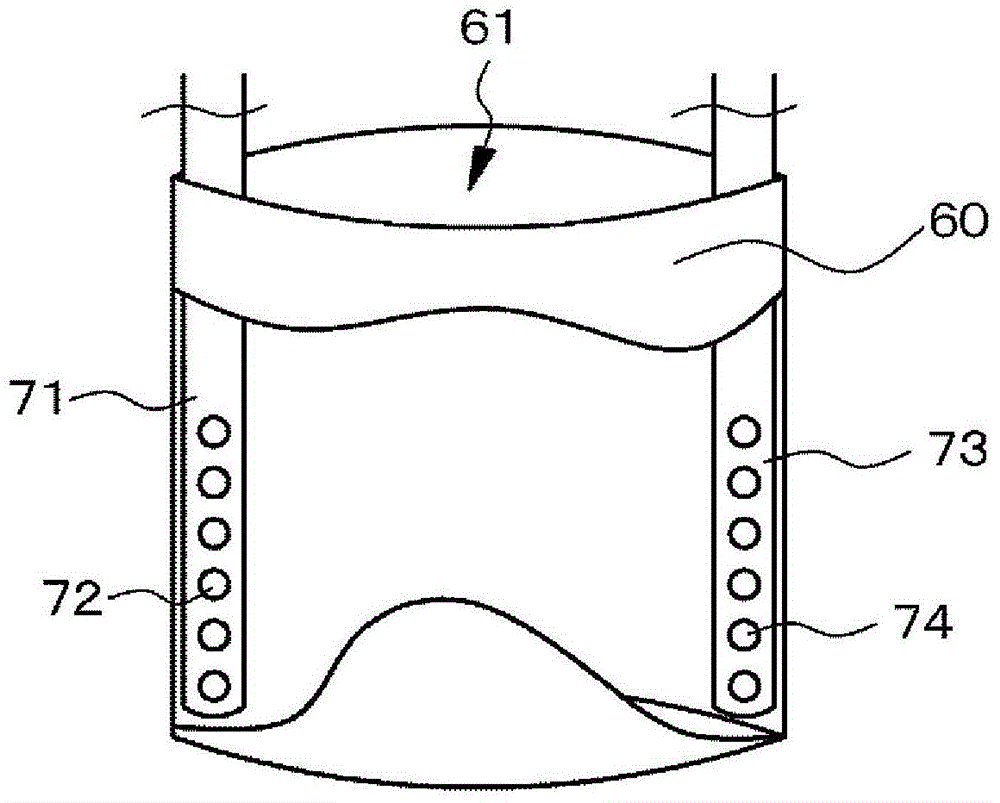

[0139] Respectively Figure 1A with Figure 1B A conceptual diagram and a schematic partial cross-sectional view of a closed container and the like for explaining the granular material packaging device of the present invention and the granular material packaging method of the present invention are shown in FIG. In addition, in Figure 2A , Figure 2B and image 3 Shown in is a conceptual diagram of a closed container and the like for explaining the granular material packaging method of the present invention. In these...

Embodiment 2

[0211] Embodiment 2 is a modification of Embodiment 1. In Example 2 or Examples 3 to 20 described later, the amount of dissolved oxygen per 1 gram of the raw material thermoplastic resin pellets was also 0.015 cm during packaging and storage. 3 Below, the moisture content of the raw material thermoplastic resin pellets is 2×10 2 Below ppm. In addition, the oxygen concentration inside the airtight container 60 is 2% by volume or less (specifically, 1×10 3 ppm or less), the total moisture content of the atmosphere in the airtight container 60 is 0.2 mg per 1 gram of the raw material thermoplastic resin pellets.

[0212] In addition, in Example 2 or Example 4 and Example 6 described later, the pressure inside the airtight container 60 was 1.3×10 4 Pa. In addition, in Examples 8 to 10, the pressure inside the airtight container 60 was 1.3×10. 4 Pa below. Immediately after the production of raw material thermoplastic resin pellets (raw material polycarbonate resin pellets), the raw m...

Embodiment 3

[0215] Embodiment 3 is a modification of Embodiment 1. In Example 3, the airtight container 60 was made of a nylon / gas barrier multilayer sheet package (packaging bag), more specifically, a nylon film / MXD nylon film / nylon film. In addition, the oxygen permeability of the airtight container 60 related to the oxygen and gas barrier properties is 50 [cm 3 / (m 2 ·24h·atm), 20~25℃]. In addition, as in Example 1, the oxygen concentration inside the airtight container 60 was 1×10 3 Below ppm.

[0216] The same raw material thermoplastic resin pellets as in Example 1 were packaged in a closed container 60 in the same manner as in Example 1, and were stored for the same time as in Example 1. After that, the airtight container 60 is unsealed, and the raw material thermoplastic resin pellets are directly put into the hopper provided in the injection molding machine. The amount of dissolved oxygen [C] is 0.015cm 3 / G or less. In addition, the molded product satisfies a parallel transmitta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com