Bearing riveting and pressing tool

A riveting and tooling technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low unloading efficiency and short service life, achieve timely and accurate unloading, long service life, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Describe the present invention below in conjunction with specific embodiment:

[0015] The product to be processed in this embodiment requires the set pressure of the press to be 2KN, and the contact area of each riveting is about 3mm 2 , The radial indentation is about 3.5mm.

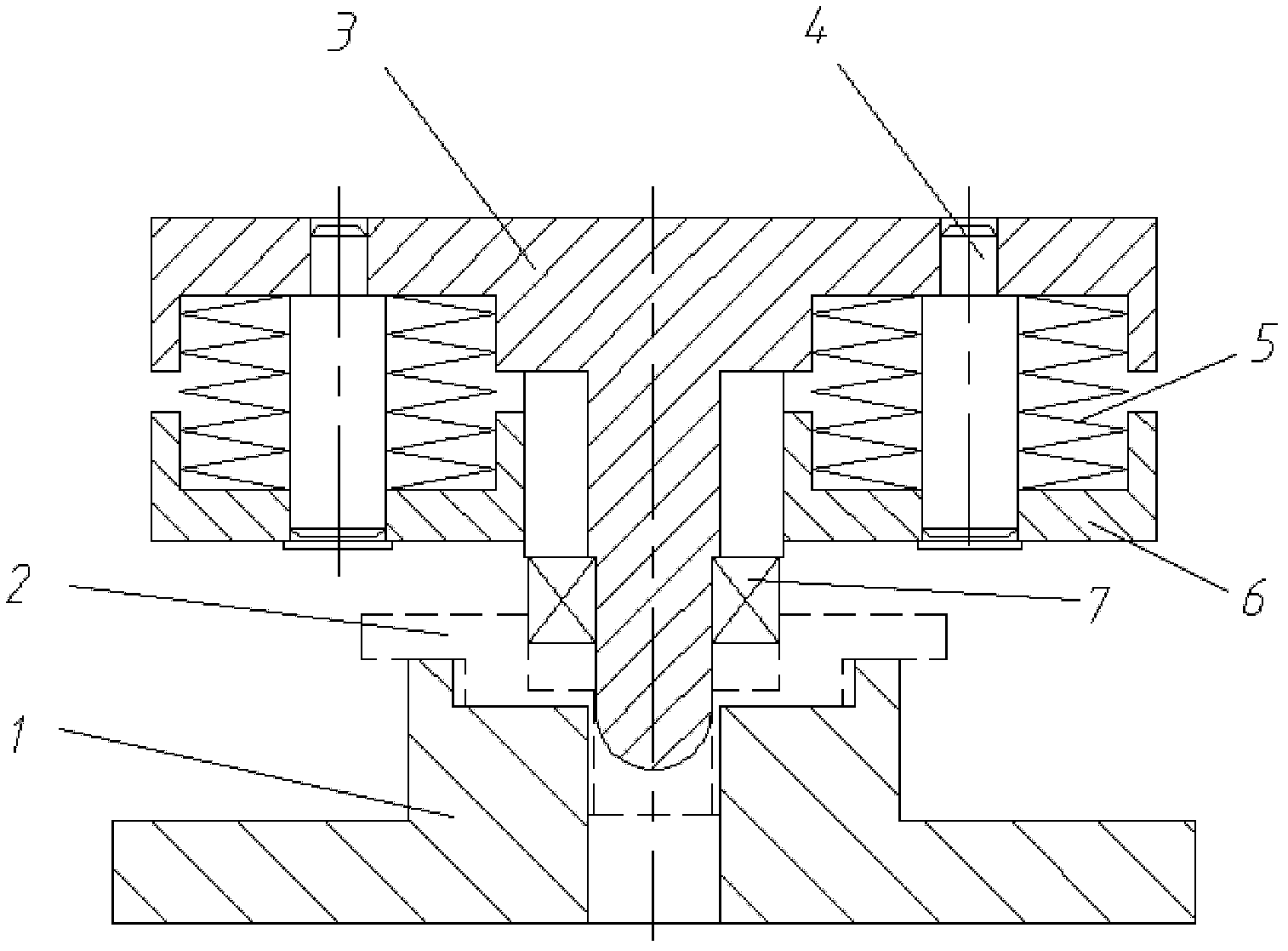

[0016] Refer to attached figure 1 , The bearing riveting tooling used in this embodiment includes a positioning sleeve 1, a die 3, a push rod 4, a disc spring 5 and a stripping plate 6.

[0017] The positioning sleeve is fixed on the processing base, and the middle part has a positioning through hole for placing the workpiece 2 to be processed and the bearing 7 to be riveted.

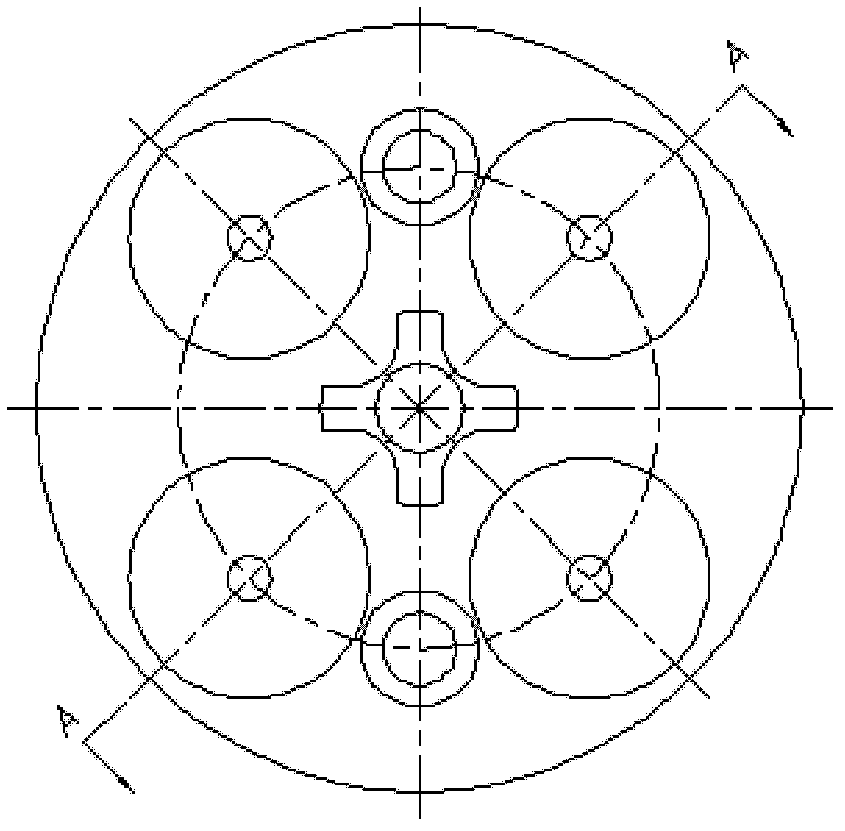

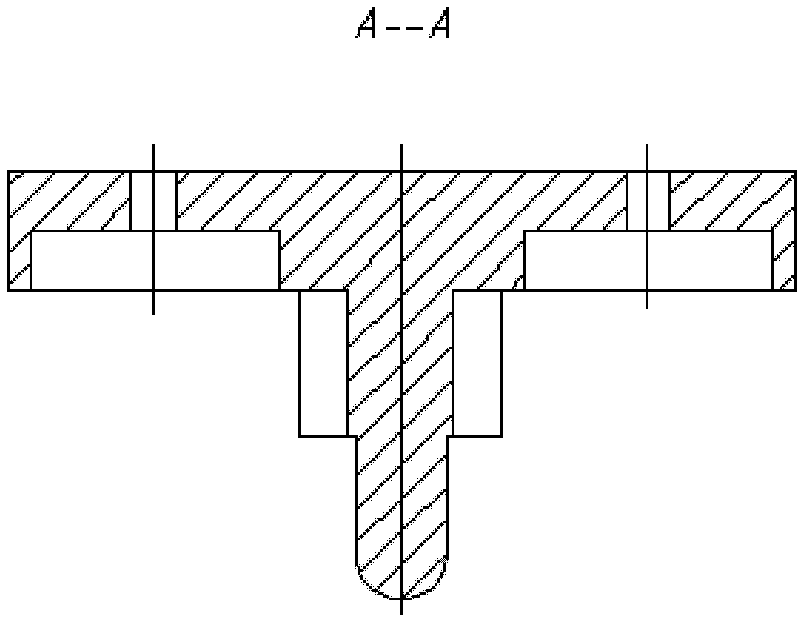

[0018] Refer to attached figure 2 And attached image 3 , the die is a circular plate structure with a guiding and positioning shaft head at the center, and the diameter of the guiding and positioning shaft head matches the inner diameter of the bearing 7 to be riveted. During processing, the guiding and positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com