Thermal treatment device for metal

A metal heat treatment and equipment technology, applied in the field of heat treatment, can solve the problems of reducing heat treatment quality and heat treatment efficiency, affecting the heat treatment effect of metal workpieces, affecting the process quality of metal workpieces, etc., to avoid heat transfer and heat loss, reduce heat loss, improve Effect of heat treatment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

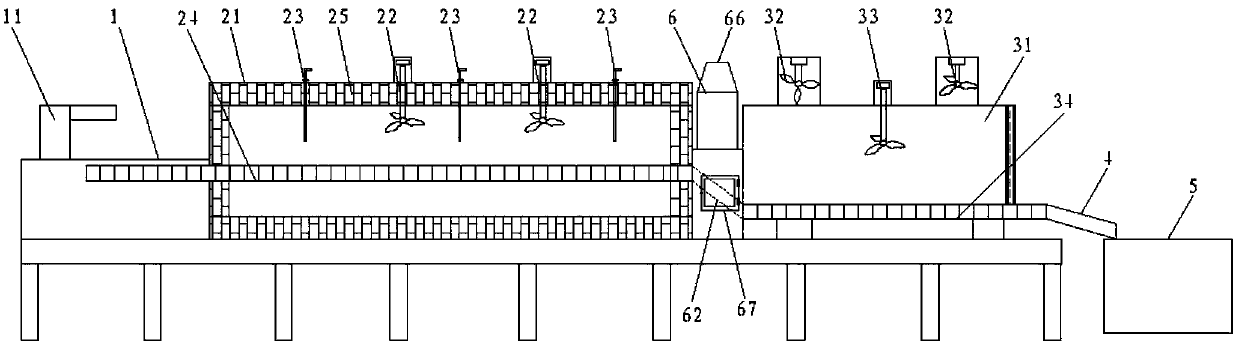

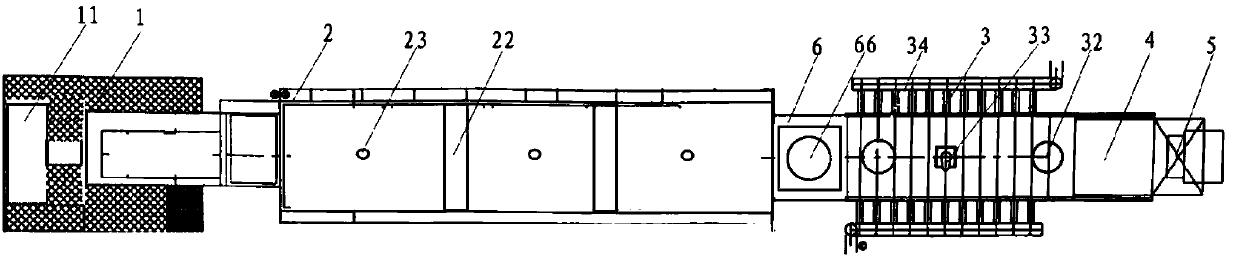

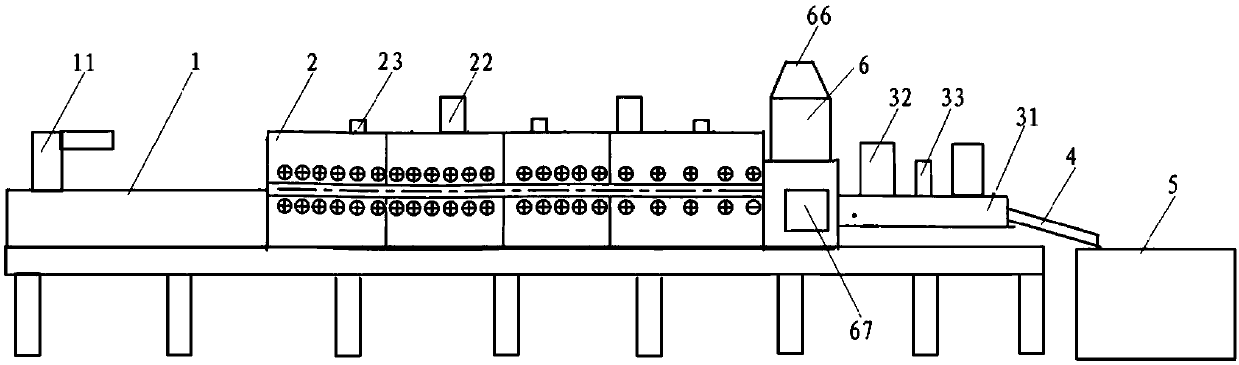

[0052] This embodiment provides a metal heat treatment equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a feeding area, a heating area and a cooling area arranged in sequence, and a discharge buffer zone is provided between the heating area and the cooling area.

[0053] The feeding area is connected to the feeding end of the heating area, and the feeding area includes a feeding platform 1, on which a feeding manipulator 11 is arranged, which reduces the labor intensity of workers and improves production efficiency.

[0054] The heating zone includes a heating furnace 2, and the heating furnace 2 includes an electric heating system or a fuel heating system. Preferably, in this embodiment, the heating furnace 2 adopts an electric heating system;

[0055] Specifically, the heating furnace 2 includes a furnace body 21, a first stirring fan 22, a temperature detection device 23 and a first conveying device 24 for transporting workpieces. The furnace bod...

Embodiment 2

[0070] The structure of the metal heat treatment equipment provided in this embodiment is basically the same as that in Embodiment 1, except that the structure of the first closing curtain 631 is different. A first closing curtain 631 is provided at the feeding port 63 of the buffer zone, and the first closing curtain 631 effectively blocks the outflow of internal air and the inflow of external air. Preferably, the first closed curtain 631 is a metal curtain, and the first closed curtain 631 includes a plurality of curtain panels 632 arranged side by side continuously, and the top of the curtain panels 632 is connected to the bottom of the buffer zone feeding port 64. The top edge is hinged, and the bottom end of the curtain plate 632 can be in contact with the surface of the inclined plate. Wherein, the curtain plate 632 includes a plurality of curtain plate monomers 633, and two adjacent curtain plate monomers 633 are hinged. The curtain plate 632 is divided into a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com