Resistance pit annealing furnace

An annealing furnace and resistance technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of large one-time investment and complex design, and achieve the effect of reducing investment, saving costs, and simple overall structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

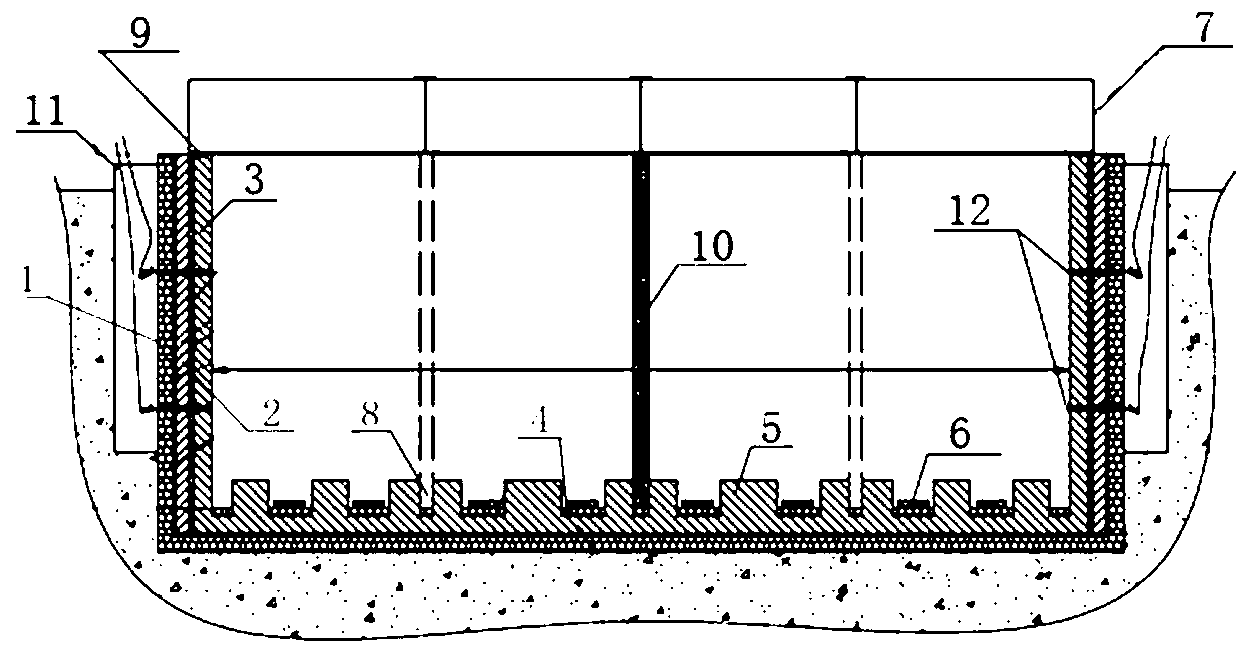

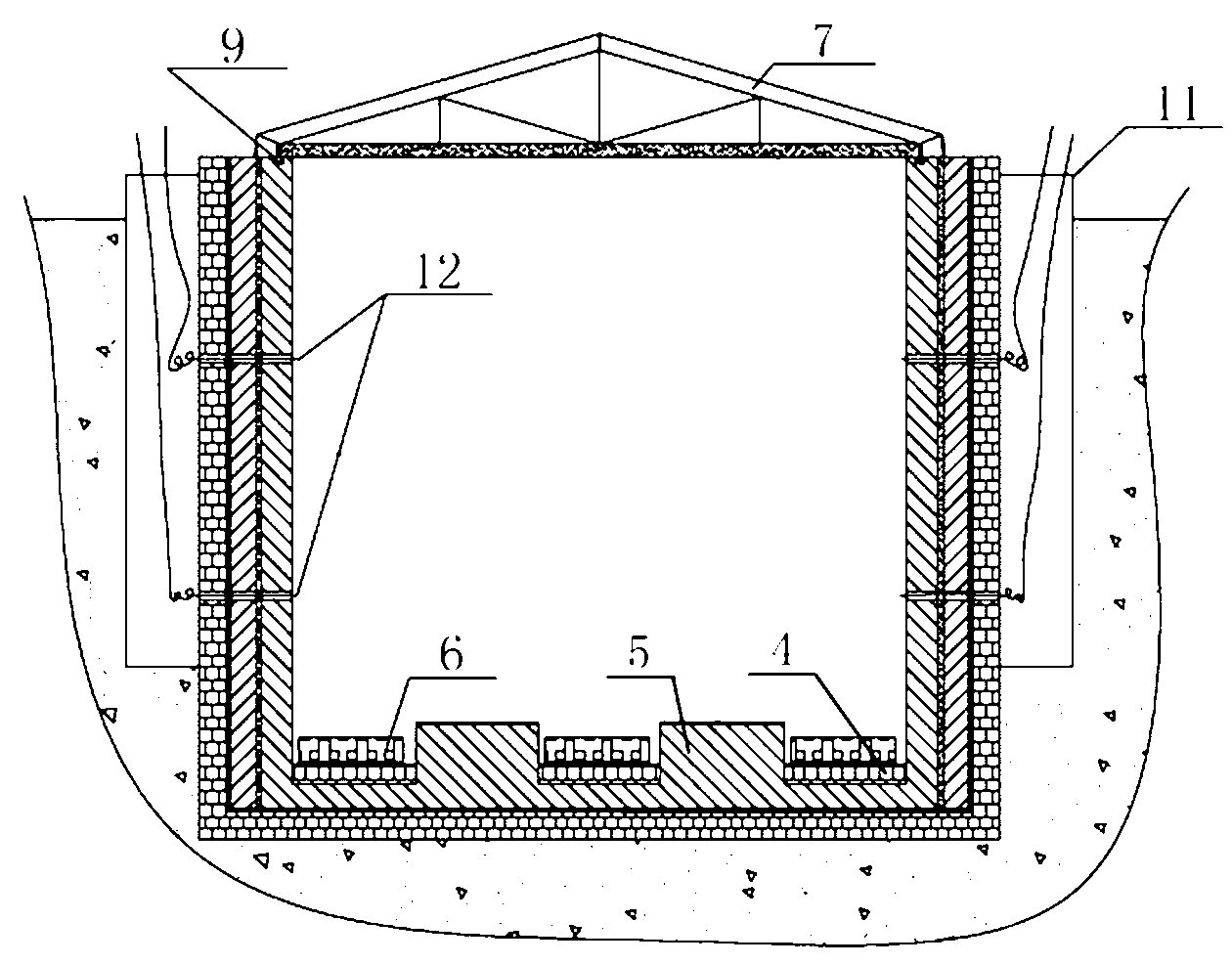

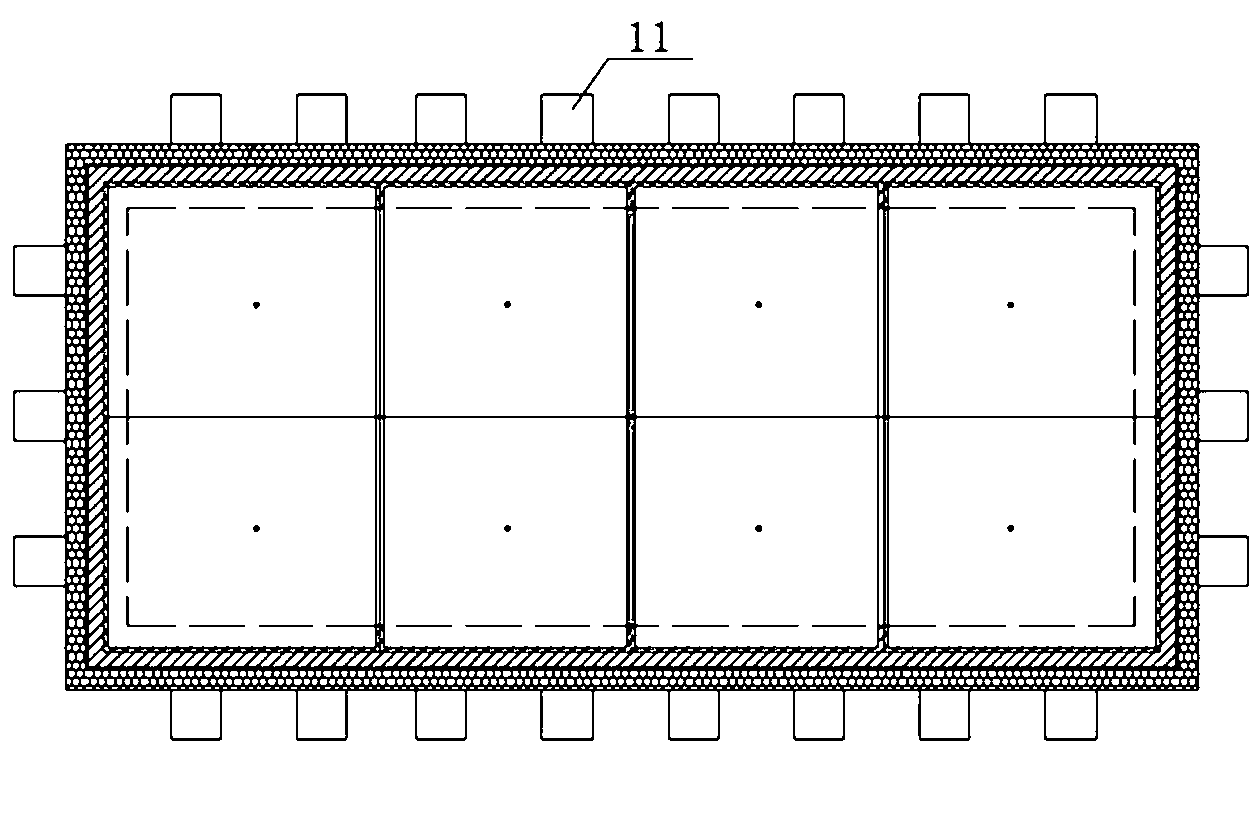

[0021] Such as Figure 1~Figure 4 As shown, the furnace body shown in the figure is in the shape of a cuboid, of course, it can also be in the shape of a cube. The furnace body is mainly buried in the pit under the ground. The furnace wall and furnace bottom adopt integral pouring design. The furnace wall includes: brick wall 1→cement mortar plastering layer (or plastering layer)→waterproof layer from outside to inside →Reinforced concrete furnace wall 2→Refractory fiberboard insulation layer→Heat-resistant reinforced concrete furnace wall 3. The upper edge of the furnace wall may be properly higher than the upper edge of the pit by 500-600mm. The outermost brick wall 1 of the furnace wall is designed to be 240mm thick. The inner wall of the brick wall 1 is plastered with cement mortar and then covered with 4mm thick SBS polyester tire waterproof membrane for two layers; the thickness of the reinforced concrete furnace wall 2 is 200mm. Two layers of 20mm thick refractory fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com