Gas type roller hearth furnace temperature control method and device

A temperature control method and technology of a temperature control device, which are applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of unsatisfactory temperature control effect of roller hearth furnace, low energy saving effect, poor temperature control accuracy, etc. The method is simple and dexterous, improves the heat treatment quality, and ensures the effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

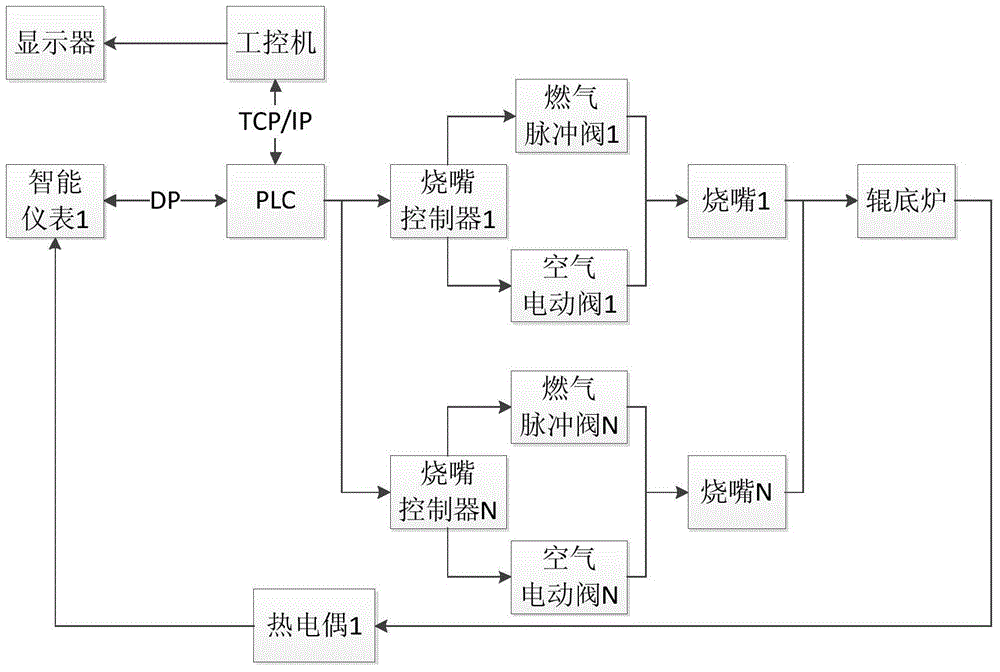

[0027] This preferred embodiment discloses a temperature control device for a gas-fired roller hearth furnace. Such as figure 1 As shown, the temperature control device includes a plurality of temperature sensors distributed in the gas-fired roller hearth furnace, intelligent temperature control instruments connected to the temperature sensors through compensation wires, PLC connected to the intelligent temperature control instruments through the network bus, and The industrial computer connected to the PLC, and the display connected to the industrial computer. When the heating process temperature of the roller hearth furnace is less than 900°C, the temperature sensor is preferably a K-type thermocouple with a stainless steel sleeve. N in the figure is the number of burners controlled by each area (each intelligent temperature control instrument).

[0028] The temperature control device also includes a burner control unit arranged between each burner and the PLC, and each gr...

Embodiment 2

[0043] This preferred embodiment discloses a temperature control method of a gas-fired roller hearth furnace, which is basically the same as the first preferred embodiment. In this temperature control method, a control unit is used to uniformly control the burning, extinguishing, and burning duration of all burners.

[0044] The difference is that the specific steps of the temperature control method are not limited, as long as the states of all burners can be uniformly controlled to achieve the purpose of precisely controlling the furnace temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com