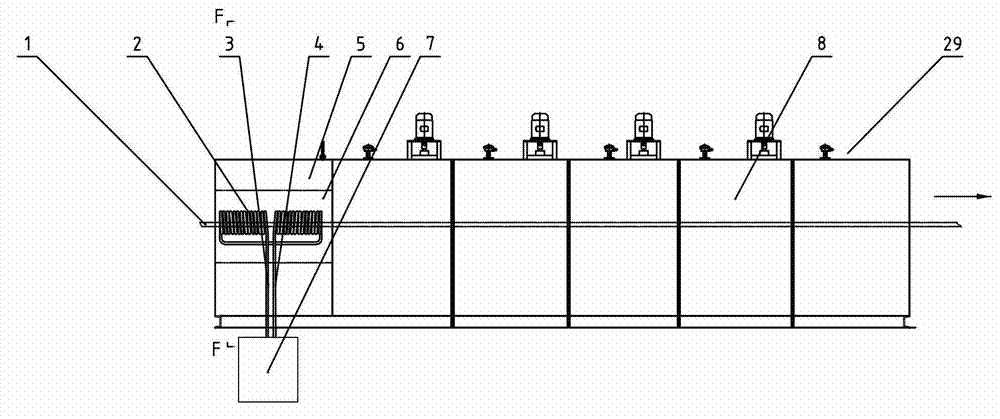

Quenching-tempering sensing rapid heating equipment and technology of heat treatment production line of bimetal strip sawblade

An induction heating and rapid heating technology, applied in heat treatment equipment, heat treatment furnace, quenching device, etc., can solve the problems of not being able to quickly and efficiently produce saw blade quality, long heating time, and difficulty in guaranteeing, and achieve shortened heating time, short heating time, The effect of heat treatment quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

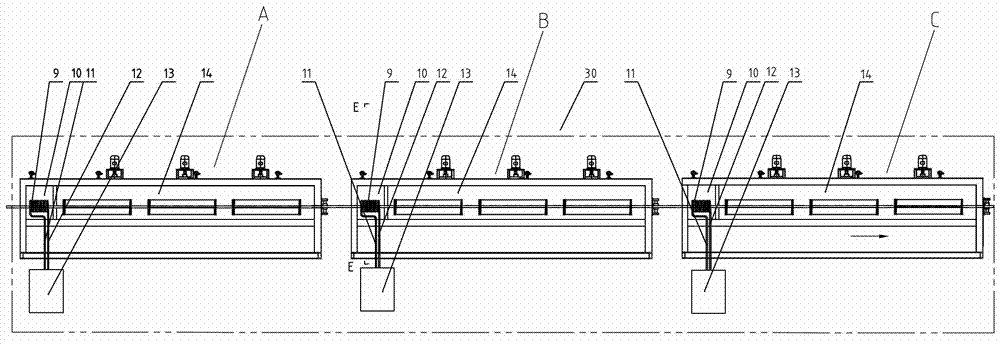

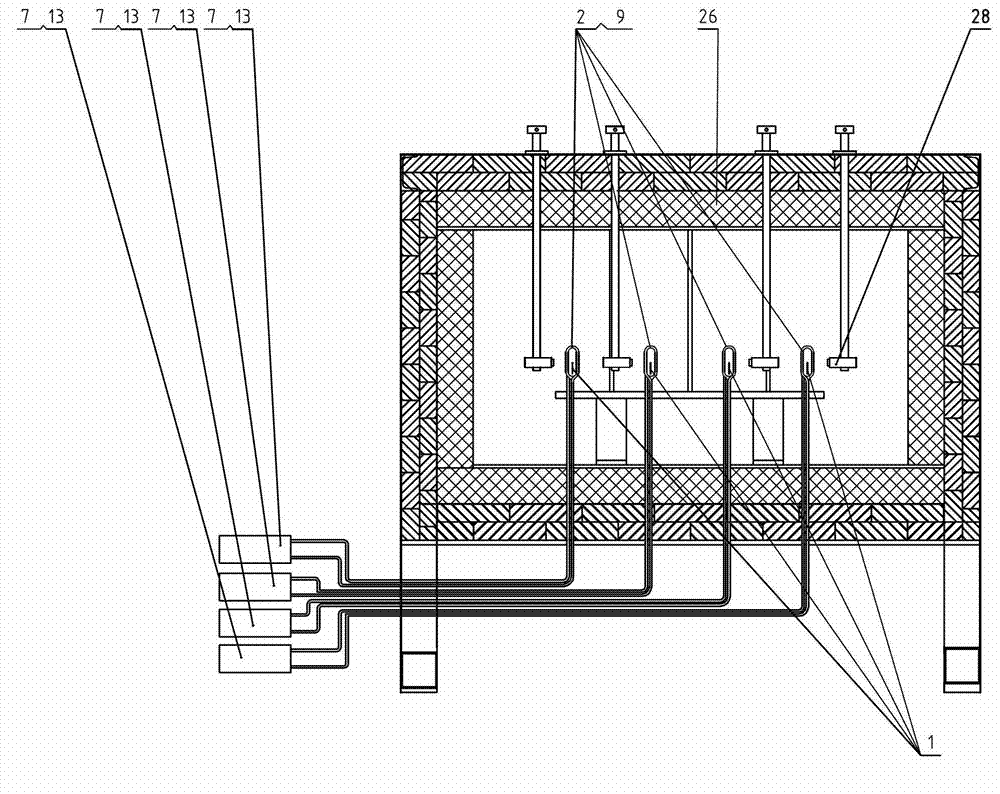

[0020] Specific implementation mode two: as image 3 and 5 As shown, the quenching induction heating furnace 5 and the tempering induction heating furnace 10 in this embodiment have the same phase structure, and a layer of insulation layer 26 is provided on the outer surface of both furnaces. Other components and connections are the same as those in the first embodiment.

[0021] Specific implementation mode three: as image 3 and 5 As shown, there are four quenching induction heaters 2 and quenching induction heating generators 7 in this embodiment, and four tempering induction heaters 9 and four tempering induction heating generators 13 . Other compositions and connections are the same as those in Embodiment 1 or 2.

[0022] Specific implementation mode four: as Figure 3-6 As shown, the quenching induction heating furnace 5 in this embodiment is provided with temperature measuring elements 18 consistent with the number of quenching induction heaters 2, and the temperin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com